Última actualización el 2025-02-20 por Anze

In the leather processing industry, máquina perforadora de cuero, as an indispensable and important equipment, provide strong support for the production of leather products with its efficient, precise and flexible processing capabilities. This article will explore in depth the definition, types, working principles, application fields and important position of leather perforation machines in the modern leather processing industry, and give you a comprehensive understanding of this “secret weapon” in the field of leather processing.

1. Definition and basic principles of leather perforation machine

Leather perforation machines, as the name suggests, are a type of equipment specifically used for punching holes on leather materials. It forms regular holes or patterns on the surface of leather through a specific mechanical structure or laser technology to meet the processing needs of different leather products. The basic principles of leather punching machines mainly include mechanical punching and laser cutting.

Mechanical stamping leather perforation machine:

This type of equipment usually uses a crank slider mechanism or a hydraulic transmission system to punch the leather through a mold to form the required holes. Mechanical stamping punching machines have the advantages of simple structure, easy operation and low cost, and are suitable for large-scale, standardized punching operations.

Laser cutting leather perforation machine:

Uses high-energy laser beam to instantly heat and vaporize leather to form holes. Laser cutting punching machine has the advantages of high processing precision, fast speed, strong adaptability, etc., especially suitable for complex patterns and small batch customization production needs.

2. Types and characteristics of leather perforation machine

According to different processing requirements and material properties, leather punching machines can be divided into many types, each with its own unique characteristics and scope of application.

Manual perforation machine:

suitable for small batch, low-precision punching operations. It is easy to operate, but the efficiency is low, and the operator’s skills are required to be high.

Semi-automatic perforation machine:

combines the advantages of manual and automatic operation, suitable for medium batch punching operations. The operation is relatively simple and the efficiency is high, but the accuracy and flexibility are limited.

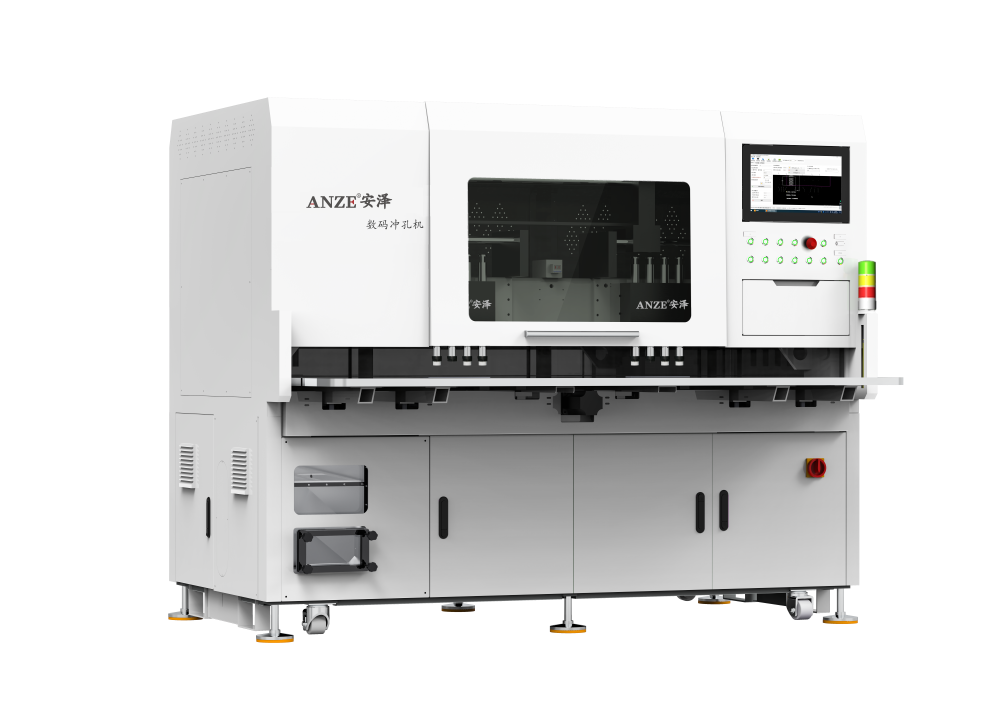

Fully automatic perforation machine

using advanced CNC technology, it can achieve high-precision and high-efficiency punching operations. It is suitable for large-scale, customized production needs, and can automatically complete punching, nesting and other processes, greatly improving production efficiency.

Laser perforation machine:

uses laser technology to achieve high-precision, contactless punching operations. It is suitable for complex patterns, small batch customization, and has less damage to leather materials.

3. Uses and application fields of leather perforation machines

Leather punching machines have a wide range of applications in the leather processing industry, and their main uses include the following aspects:

Shoe manufacturing

Shoe manufacturing: In the process of shoe manufacturing, leather punching machines are used to punch ventilation holes, decorative holes, etc. on parts such as uppers and insoles to improve the comfort and aesthetics of shoes.

Luggage manufacturing

In luggage manufacturing, leather punching machines are used to punch handle holes, decorative holes, etc. on parts such as bag bodies and straps to enhance the practicality and fashion sense of luggage.

Furniture manufacturing

In the field of furniture manufacturing, leather punching machines are used to punch ventilation holes, massage holes, etc. on the leather covering surface of furniture such as sofas and chairs to improve the comfort and service life of furniture.

Automotive interior

In the manufacture of automotive interior, leather perforation machines are used to punch ventilation holes, decorative holes, etc. on parts such as seats and steering wheel covers, which enhances the luxury and comfort of automotive interiors.

Clothing accessories

In the field of clothing accessories, leather perforation machines are used to punch decorative holes, breathable holes, etc. on accessories such as belts, hats, gloves, etc., to increase the fashion elements and practicality of products.

4.The important position of leather perforation machines in the modern leather processing industry

With the continuous development and technological progress of the leather processing industry, the position of leather punching machines has become increasingly prominent. It not only improves the efficiency and quality of leather processing, but also promotes the diversification and personalization of leather products.

Improve production efficiency

Leather perforation machines can realize automated and continuous punching operations, greatly shorten the production cycle, and improve production efficiency. At the same time, its high-precision and low-loss processing characteristics also reduce production costs and improve the competitiveness of enterprises.

Enrich product variety

Leather perforation machine can punch out holes and patterns of various shapes and sizes according to different needs, providing more possibilities for the design of leather products. This not only enriches the types and styles of products, but also meets the growing personalized needs of consumers.

Promote technological innovation

With the continuous advancement of science and technology and the continuous changes in the market, leather punching machines are also constantly innovating and upgrading. For example, the use of more advanced CNC technology, laser technology, etc. has improved the accuracy and efficiency of punching; combined with intelligent, automated and other technical means, the intelligent management and control of the production process has been realized. These technological innovations have not only promoted the development of the leather processing industry, but also provided useful reference and inspiration for the development of other related fields.

Importance of perforation machine

As one of the important equipment in the leather processing industry, the leather perforation machine provides strong support for the production of leather products with its efficient, precise and flexible processing capabilities. With the continuous advancement of technology and the continuous development of the market, the leather perforation machine will continue to play an important role in the future and promote the continuous innovation and upgrading of the leather processing industry. At the same time, we also look forward to more advanced technologies and concepts being integrated into the research and development and production of leather punching machines, bringing more surprises and possibilities to the leather processing industry.

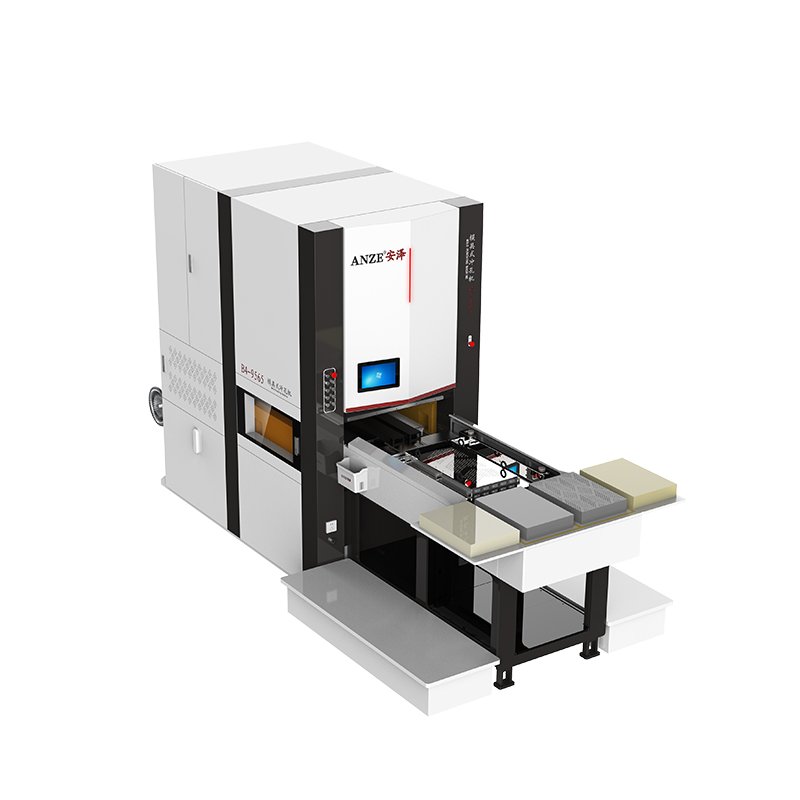

Anze Perforation machine

Dongguan Anze Automation Equipment Co., Ltd. se encuentra en la ciudad de Dongguan, provincia de Guangdong. Fundada en 2005, la compañía se ha centrado en la industria de punzonado durante casi 20 años y actualmente cubre un área completa de 5000 metros cuadrados. La empresa está especializada en CNC leather perforation machines, mould leather perforation machines,leather bag perforation machine,luggage leather perforation machine,shoes leather perforation machine,furniture leather perforation machine y otros equipos.

Si desea ver el vídeo de la punzonadora de cuero, por favor visite nuestro YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Algunos modelos se envían montados de fábrica. Los equipos grandes se embalan en varias piezas y se suministra un manual de instalación. Todos los equipos están equipados con manuales de usuario en chino e inglés.

Los clientes pueden enviar a alguien a la fábrica de anze para que aprenda o nosotros enviamos a expertos técnicos para que impartan formación in situ.

La máquina debe fijarse en una mesa estable y el entorno debe mantenerse limpio y ordenado para evitar que el contacto con el polvo, la electricidad estática, la humedad y las virutas provoquen fallos en las piezas.

Contamos con un experimentado equipo de postventa, servicio en línea 24 horas y un completo sistema de postventa. Soporte de formación en fábrica, video técnico disponible para dar servicio a la maquinaria en el extranjero. soporte, soporte en línea, Ingenieros.

Por supuesto, le invitamos a visitar nuestra empresa y tener una comunicación cara a cara para avanzar en los negocios mutuos.

El plazo de entrega varía en función de la cantidad del pedido y de la personalización, normalmente oscila entre 7 y 10 días laborables.Si se trata de un pedido de punzonadoras de cuero personalizadas, tarda entre 1 y 2 meses.