Last Updated on 2025-03-18 by Anze

In the ever-evolving world of manufacturing, innovation is the key to staying ahead of the competition. This is especially true in the leather industry, where the demand for high-quality, customized leather products is constantly growing. To meet this demand, our factory has dedicated itself to developing and manufacturing the most advanced máquina perforadora de cuero on the market. These machines have revolutionized the leather processing industry, enabling manufacturers to achieve precision, efficiency, and versatility in their production processes.

The Evolution of Leather Processing

Leather processing has come a long way since its inception. Traditional methods involved manual labor and rudimentary tools, resulting in inconsistent quality and limited production capacity. As technology advanced, so did the tools and machines used in leather processing. However, it wasn’t until the advent of modern perforating leather machines that the industry saw a true revolution.

Our factory has been at the forefront of this revolution, continuously pushing the boundaries of what’s possible with leather perforating technology. Our machines are designed to meet the evolving needs of the leather industry, offering unparalleled precision, efficiency, and customization options.

The Benefits of Perforating Leather Machines

There are numerous benefits to using perforating leather machines, both for manufacturers and end-users. Here are just a few:

Precision and Consistency:

Our perforating leather machines are equipped with state-of-the-art technology that ensures precise and consistent perforations. This means that every leather product produced using our machines will have uniform hole patterns, sizes, and shapes. This consistency is crucial for maintaining brand integrity and meeting consumer expectations.Efficiency and Productivity:

Traditional leather processing methods were time-consuming and labor-intensive. With our perforating leather machines, manufacturers can significantly increase their production capacity while reducing labor costs. Our machines are designed for high-speed operation, allowing for the rapid processing of large quantities of leather. This increased efficiency not only boosts productivity but also enables manufacturers to keep up with the demands of a fast-paced market.Customization and Versatility:

One of the most significant advantages of our perforating leather machines is their ability to offer customization. Our machines can be programmed to create a wide variety of hole patterns, sizes, and shapes, allowing manufacturers to create unique and eye-catching designs. This versatility is essential for staying ahead of the competition and catering to the diverse needs of consumers.Durability and Reliability:

Our perforating leather machines are built to last. We use only the highest quality materials and components in our manufacturing process, ensuring that our machines are durable and reliable. This means that manufacturers can trust our machines to perform consistently over time, even under the most demanding conditions.Environmentally Friendly:

In today’s world, sustainability is a top priority. Our perforating leather machines are designed to minimize waste and reduce environmental impact. By using precision technology, we can ensure that only the necessary amount of leather is perforated, reducing the amount of scrap material generated. Additionally, our machines are energy-efficient, consuming less power than traditional methods.

Our Range of Perforating Leather Machines

At our factory, we offer a wide range of perforating leather machines to cater to the diverse needs of manufacturers. Our machines come in various sizes, configurations, and specifications, ensuring that there’s a perfect fit for every production process.

Manual Perforating Leather Machines:

For smaller-scale production or custom projects, our manual perforating leather machines are an excellent choice. These machines offer precision and control, allowing manufacturers to create intricate designs and patterns. They are also easy to operate and maintain, making them a cost-effective solution for many manufacturers.Semi-Automatic Perforating Leather Machines:

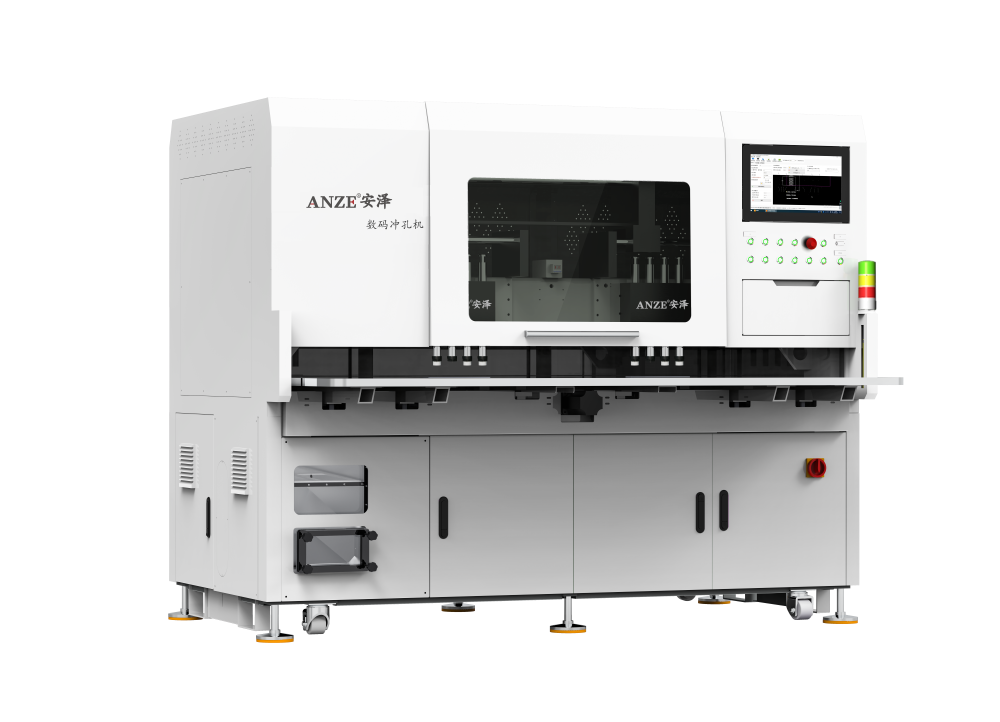

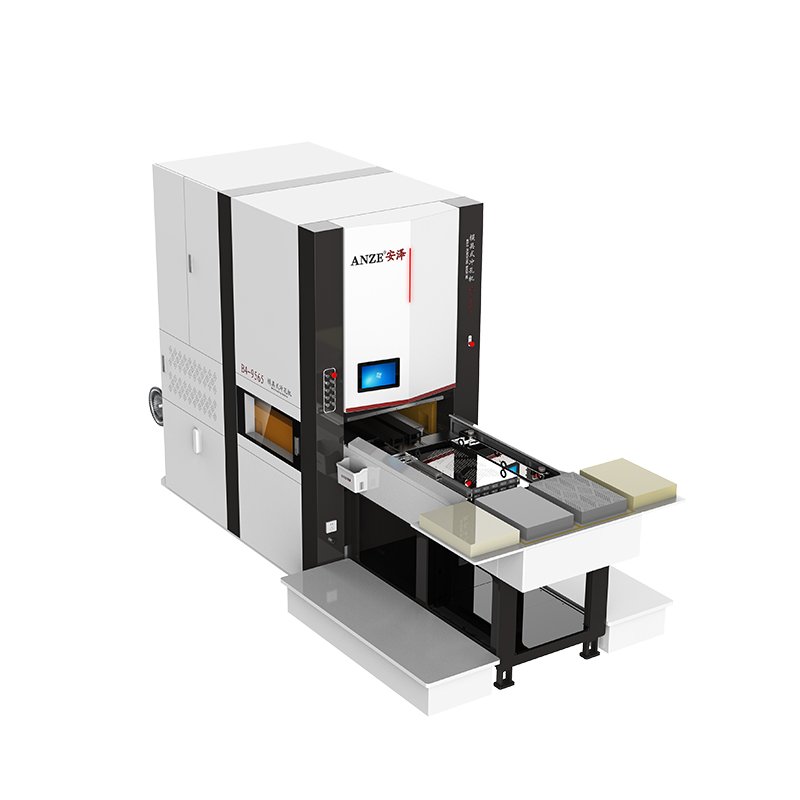

For medium-scale production, our semi-automatic perforating leather machines offer a balance of precision, efficiency, and cost. These machines are equipped with automated features that streamline the production process, reducing labor costs and increasing productivity.Fully Automatic Perforating Leather Machines:

For large-scale production, our fully automatic perforating leather machines are the ultimate solution. These machines are designed for high-speed operation, enabling manufacturers to process large quantities of leather quickly and efficiently. They are also equipped with advanced features such as sensors and automated control systems, ensuring consistent and reliable performance.

Customizing Your Perforating Leather Machine

At our factory, we understand that every manufacturer has unique needs and requirements. That’s why we offer customization options for our perforating leather machines. Our experienced team of engineers can work with you to design a machine that meets your specific production needs, whether it’s a custom hole pattern, size, or shape.

We also offer a range of accessories and attachments for our machines, allowing you to further customize your production process. From die sets and punches to feeders and conveyors, we have everything you need to create a fully integrated production line.

Our Commitment to Quality and Service

At our factory, quality and service are our top priorities. We are committed to providing our customers with the highest quality perforating leather machines and unparalleled service.

Our machines are manufactured using the latest technology and the highest quality materials, ensuring that they are durable, reliable, and precise. We also offer comprehensive training and support for our customers, ensuring that they can operate and maintain their machines effectively.

In addition to our quality machines and services, we also offer competitive pricing and flexible financing options. We understand that investing in new equipment can be a significant expense, so we work with our customers to create a financing plan that fits their budget and needs.

The Future of Leather Processing

As the leather industry continues to evolve, so will the technology used in leather processing. At our factory, we are committed to staying ahead of the curve, continuously innovating and improving our perforating leather machines.

We are currently working on new technologies and features that will further enhance the precision, efficiency, and customization options of our machines. From advanced sensors and control systems to new materials and manufacturing processes, we are always looking for ways to improve our products and services.

We also believe in the power of collaboration. By working with manufacturers, designers, and industry experts, we can develop new solutions that address the unique challenges and opportunities facing the leather industry. Together, we can push the boundaries of what’s possible and create a brighter future for the leather processing industry.

Perforating leather machines have revolutionized the leather processing industry

Perforating leather machines have revolutionized the leather processing industry, offering manufacturers precision, efficiency, and customization options that were previously unimaginable. At our factory, we are proud to be at the forefront of this revolution, offering a wide range of state-of-the-art perforating leather machines that cater to the diverse needs of manufacturers.

With our commitment to quality, service, and innovation, we are confident that our machines will continue to lead the industry for many years to come. We invite you to explore our range of machines and discover how they can transform your leather processing production process. Contact us today to learn more about our perforating leather machines and how they can benefit your business.

Algunos modelos se envían montados de fábrica. Los equipos grandes se embalan en varias piezas y se suministra un manual de instalación. Todos los equipos están equipados con manuales de usuario en chino e inglés.

Los clientes pueden enviar a alguien a la fábrica de anze para que aprenda o nosotros enviamos a expertos técnicos para que impartan formación in situ.

La máquina debe fijarse en una mesa estable y el entorno debe mantenerse limpio y ordenado para evitar que el contacto con el polvo, la electricidad estática, la humedad y las virutas provoquen fallos en las piezas.

Contamos con un experimentado equipo de postventa, servicio en línea 24 horas y un completo sistema de postventa. Soporte de formación en fábrica, video técnico disponible para dar servicio a la maquinaria en el extranjero. soporte, soporte en línea, Ingenieros.

Por supuesto, le invitamos a visitar nuestra empresa y tener una comunicación cara a cara para avanzar en los negocios mutuos.

El plazo de entrega varía en función de la cantidad del pedido y de la personalización, normalmente oscila entre 7 y 10 días laborables.Si se trata de un pedido de punzonadoras de cuero personalizadas, tarda entre 1 y 2 meses.