Última actualización el 2025-02-20 por Anze

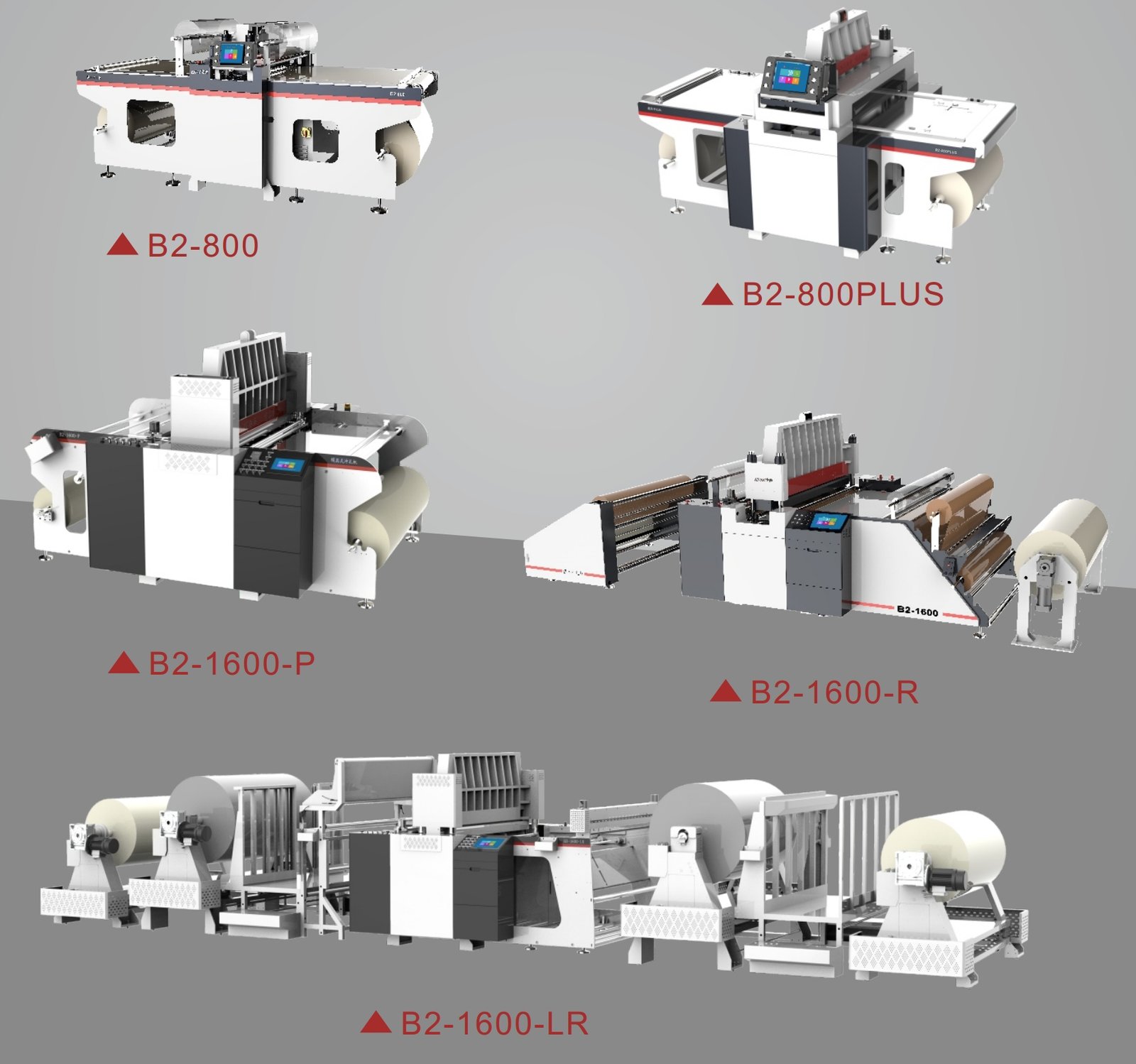

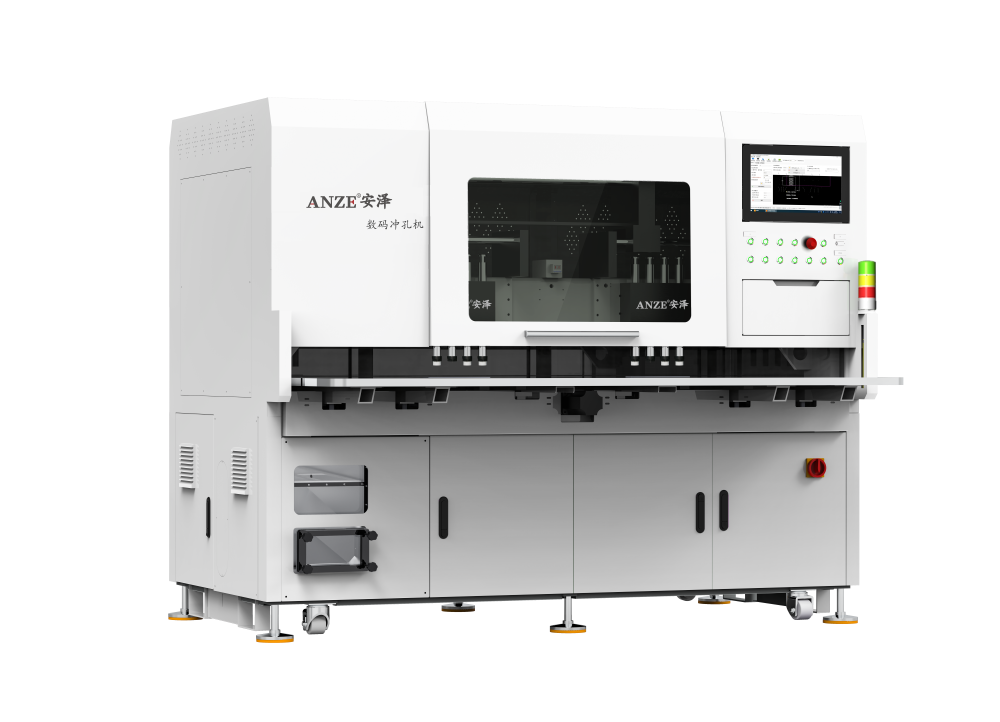

In the leather processing industry, mould punzonadora de cuero, as an efficient and precise processing equipment, is gradually becoming the preferred tool for many leather product manufacturers. It can not only complete leather punching operations quickly and accurately, but also customize various complex patterns and hole types according to customer needs, adding unique visual effects and functionality to leather products. This article will deeply explore the working principle, characteristics, advantages, application fields and future development trends of mould leather punching machine, and comprehensively analyze this innovative tool in the field of leather processing for you.

1. Working principle of mould leather punching machine

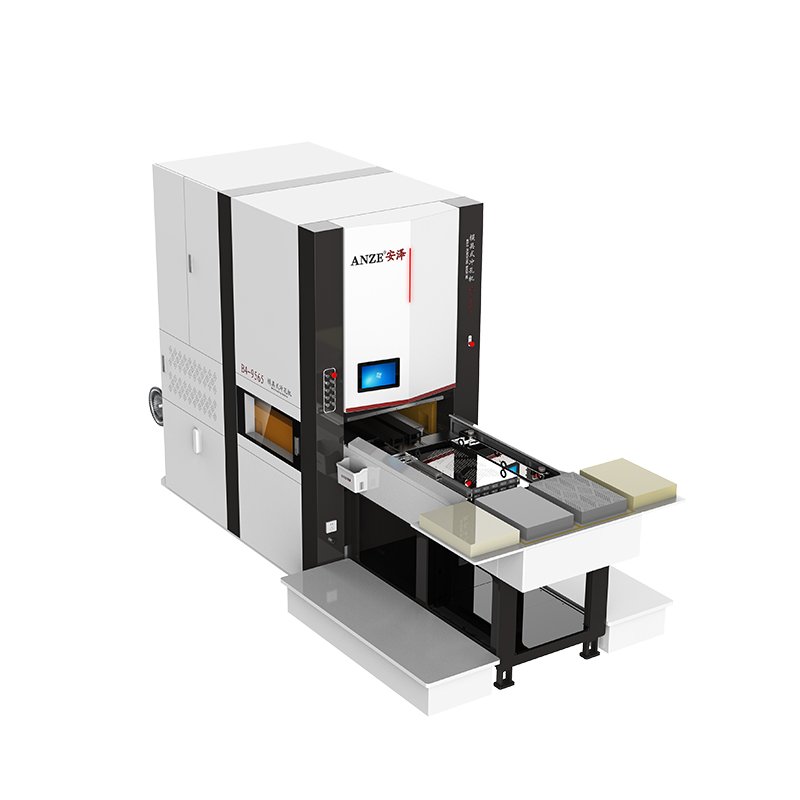

Punzonadora para cuero moldeado, as the name implies, forms holes of specific shapes and sizes on leather through the cooperation of mold and punch. Its working principle is roughly as follows:

Mold design: First, design the corresponding punching mold according to customer needs and the design requirements of leather products. The shape, size and arrangement of the mold will directly affect the final punching effect.

Positioning and fixing: Place the leather to be processed on the workbench of the punching machine and fix it with devices such as clamps or suction cups to ensure that it will not move or deform during the punching process.

Punching operation: After starting the punching machine, the punch rotates at high speed and moves downward under the drive of the motor. When the punch contacts the mold, the shape of the mold will determine the shape and size of the punch. As the punch continues to press down and rotate, the leather will be gradually penetrated and holes will be formed.

Collection and sorting: After the punching is completed, the leather is removed from the workbench and the holes are sorted and inspected as necessary. Subsequent processing and decoration can also be carried out as needed.

2. Features of mould leather punching machine

En punzonadora de moldes para cuero stands out in the leather processing industry for its high efficiency, precision and flexibility. Its main features include:

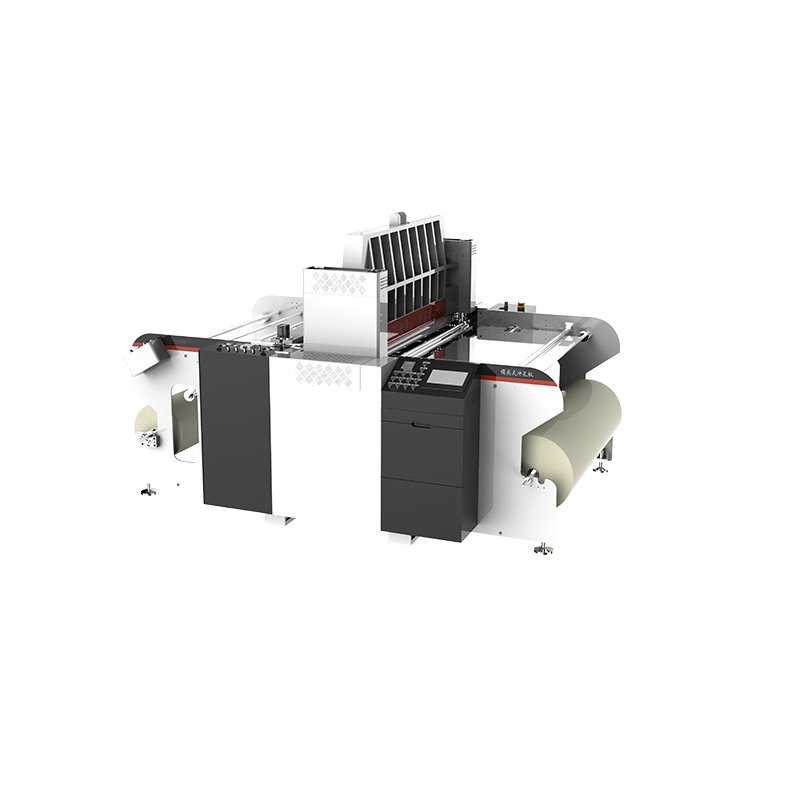

Efficiency: The mould leather punching machine adopts an automated production method, which can significantly improve production efficiency. Compared with the traditional manual punching method, the mold-type punching machine can complete a large number of leather punching operations in a short time.

Accuracy: Through precise mold design and advanced punching technology, the mold leather punching machine can ensure that the shape, size and position of each hole meet the design requirements. This accuracy is essential to ensure the quality and beauty of leather products.

Flexibilidad: The mould leather punching machine can customize various shapes of molds according to customer needs, so as to realize the punching of holes of different shapes and sizes. This flexibility enables the die-type punching machine to adapt to the production needs of various leather products.

Easy to operate: The mould leather punching machine usually adopts a touch screen or a computer control system, making the operation easier and more intuitive. At the same time, the equipment is also equipped with a safety protection device and a fault alarm system to ensure the safety and stability of the production process.

3. Advantages of the mould leather punching machine

The mould punzonadora de cuero has significant advantages in the leather processing industry, which are mainly reflected in the following aspects:

Mejorar la eficacia de la producción: Through automated production methods, the mould leather punching machine can significantly improve production efficiency and reduce production costs.

Ensure product quality: Precise mold design and advanced punching technology can ensure that the shape, size and position of each hole meet the design requirements, thereby ensuring the quality and beauty of leather products.

Strong adaptability: The mould leather punching machine can customize various shapes of molds according to customer needs, so as to realize the punching of holes of different shapes and sizes. This adaptability enables the die-type punching machine to adapt to the production needs of various leather products.

Reduce labor intensity: Compared with the traditional manual punching method, the mould leather punching machine can significantly reduce labor intensity, improve production efficiency and employee satisfaction.

4. Application fields of mould leather punching machine

The mould punzonadora de cuero has a wide range of applications in the leather processing industry, mainly including the following aspects:

Shoe manufacturing: In the process of shoe manufacturing, the mould leather punching machine is widely used in the punching of parts such as uppers and insoles. Through precise mold design and advanced punching technology, footwear products with unique visual effects and breathability can be produced.

Luggage manufacturing: Luggage manufacturing is another important application field of die-type leather punching machines. By customizing molds of various shapes, pattern decoration and functional hole design on the surface of luggage can be realized.

Automotive interior: In the manufacture of automotive interiors, mould leather punching machines are used for punching of parts such as seats and steering wheels. Through precise punching and pattern design, the beauty and comfort of automotive interiors can be improved.

Home decoration: In the field of home decoration, die-type leather punching machines are also widely used in the processing of leather coverings for furniture such as sofas and chairs. By customizing various patterns and hole types, a unique artistic atmosphere can be added to the home environment.

5. Future development trends of mould leather punching machines

With the continuous advancement of science and technology and the changing needs of consumers, mould leather punching machines are also constantly innovating and developing. In the future, mould leather punching machines will show the following development trends:

Intelligence: With the continuous development of intelligent manufacturing technology, mould leather punching machines will gradually realize intelligent production. By integrating intelligent components such as sensors and control systems, functions such as automatic monitoring, fault warning and remote maintenance of equipment can be realized.

Alta precisión: As consumers’ requirements for the quality and aesthetics of leather products continue to increase, mould leather punching machines will pay more attention to the processing of precision and details. By adopting more advanced die design and punching technology, higher precision punching processing can be achieved.

Environmental protection: With the continuous improvement of environmental awareness, mould leather punching machines will pay more attention to environmental protection and sustainable development. By adopting environmentally friendly materials, reducing energy consumption and reducing waste emissions, we will promote green production in the leather processing industry.

Customized service: With the increasing demand for personalization by consumers, the mould leather punching machine will pay more attention to customized services. By providing a variety of die designs and punching solutions, the personalized needs of different customers can be met.

Mould leather punching machine is important

As one of the important equipment in the leather processing industry, the mould punzonadora de cuero has been widely used in the fields of footwear manufacturing, luggage manufacturing, automotive interiors and home decoration with its high efficiency, precision, flexibility and significant advantages. In the future, with the continuous advancement of science and technology and the continuous changes in consumer demand, the die-type leather punching machine will continue to innovate and develop, bringing more opportunities and challenges to the leather processing industry. We believe that with the joint efforts of all employees, the die-type leather punching machine will continue to maintain its leading position and make greater contributions to the prosperity and development of the leather processing industry.

Si desea ver el vídeo de la punzonadora de cuero, por favor visite nuestro YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Algunos modelos se envían montados de fábrica. Los equipos grandes se embalan en varias piezas y se suministra un manual de instalación. Todos los equipos están equipados con manuales de usuario en chino e inglés.

Los clientes pueden enviar a alguien a la fábrica de anze para que aprenda o nosotros enviamos a expertos técnicos para que impartan formación in situ.

La máquina debe fijarse en una mesa estable y el entorno debe mantenerse limpio y ordenado para evitar que el contacto con el polvo, la electricidad estática, la humedad y las virutas provoquen fallos en las piezas.

Contamos con un experimentado equipo de postventa, servicio en línea 24 horas y un completo sistema de postventa. Soporte de formación en fábrica, video técnico disponible para dar servicio a la maquinaria en el extranjero. soporte, soporte en línea, Ingenieros.

Por supuesto, le invitamos a visitar nuestra empresa y tener una comunicación cara a cara para avanzar en los negocios mutuos.

El plazo de entrega varía en función de la cantidad del pedido y de la personalización, normalmente oscila entre 7 y 10 días laborables.Si se trata de un pedido de punzonadoras de cuero personalizadas, tarda entre 1 y 2 meses.