Last Updated on 2025-02-20 by Anze

In modern car design, details often determine the overall quality and user experience of the product. As an important part of the interior space of the car, the choice and design of the material of the car seat is directly related to the comfort and driving experience of the passengers. Among them, the design of the seat leather with holes is a clever arrangement that can improve both comfort and aesthetics. This article will explore in depth the reasons for the car seat leather with holes, design considerations and its impact on the design of modern car seats.

1. Reasons for the car seat leather with holes

The design of the car seat leather with holes is mainly based on the following reasons:

1. Improve breathability

As a natural or synthetic material, leather has an elegant appearance and a comfortable touch, but in the case of long-term riding, it is easy to cause the seat surface to be damp and stuffy due to lack of breathability, affecting the riding comfort. By punching holes in the leather, the air circulation on the seat surface can be effectively increased, sweat accumulation can be reduced, and the breathability of the seat can be improved, so that passengers can stay dry and comfortable when riding for a long time.

2. Enhance comfort

The design of the seat leather with holes can also enhance the comfort of the seat to a certain extent. The perforated leather is softer and can better fit the curve of the human body and reduce the pressure points. At the same time, the presence of holes can also disperse the pressure on the seat surface to a certain extent, making passengers feel more relaxed and comfortable when riding.

3. Improve aesthetics

In addition to practical functions, the design of seat leather with holes can also improve the aesthetics of the seat. Different hole patterns and arrangements can add unique visual effects to the seat, making it more in line with modern aesthetic trends. In addition, the perforated leather can also produce rich light and shadow effects under light, adding a sense of dynamism and vitality to the interior space.

2. Design considerations

When designing car seat leather with holes, multiple factors need to be considered to ensure the quality and performance of the final product.

1. Hole size and shape

The size and shape of the hole are important factors affecting the breathability and aesthetics of the seat. Generally speaking, the hole should not be too large to avoid affecting the structural strength and durability of the seat; at the same time, it should not be too small to avoid affecting the breathability. In terms of shape, it can be designed according to the overall style and brand characteristics of the seat, such as round, square, diamond, etc.

2. Hole arrangement

The arrangement of holes is also one of the factors that need to be considered during design. Different arrangements can produce different visual effects and breathability. For example, a regular arrangement can make the seat look neater and more orderly; while an irregular arrangement can add a sense of casualness and naturalness. When designing, it is necessary to choose according to the overall style of the seat and user needs.

3. Leather material and craftsmanship

The choice of leather material and craftsmanship is crucial to the quality and performance of perforated seats. High-quality leather materials have better wear resistance, tear resistance and feel; while exquisite craftsmanship can ensure the uniformity and beauty of the holes. When choosing leather materials and craftsmanship, factors such as cost, performance and beauty need to be considered comprehensively.

3. Impact on modern car seat design

The design of seat leather with holes has a profound impact on modern car seat design.

1. Promote innovation in seat design

The design of perforated seats brings more possibilities and innovation space to car seat design. Designers can create a variety of seat styles and styles by changing the size, shape and arrangement of holes to meet the needs and preferences of different users. At the same time, the design of the perforated seat can also be combined with other design elements, such as stitching, embroidery, etc., to further enhance the beauty and quality of the seat.

2. Improve user experience

The design of the perforated seat not only improves the breathability and comfort of the seat, but also brings a better riding experience to users through unique visual effects. In the hot summer or long driving, the perforated seat can keep the seat surface dry and comfortable, reducing the fatigue and discomfort of passengers. At the same time, the unique hole pattern and arrangement can also add a sense of fashion and personalization to the interior space, improving the overall satisfaction of users.

3. Leading the development trend of the industry

As consumers’ requirements for car quality and comfort continue to increase, the design of perforated seats has gradually become one of the mainstream trends in car seat design. More and more automakers have begun to adopt the design of perforated seats to meet market demand and enhance product competitiveness. At the same time, the design of perforated seats has also promoted the continuous innovation and development of car seat materials, processes and technologies.

How to make car seat more comfortable

The design of perforated leather seats is an important innovation in car seat design. It not only improves the breathability and comfort of the seat, but also adds a sense of fashion and personalization to the interior space through a unique visual effect. When designing a perforated seat, it is necessary to comprehensively consider factors such as the size, shape, arrangement of the holes, as well as the leather material and craftsmanship to ensure the quality and performance of the final product. As consumers’ requirements for car quality and comfort continue to increase, the design of perforated seats will continue to lead the development trend of car seat design and bring passengers a better riding experience.

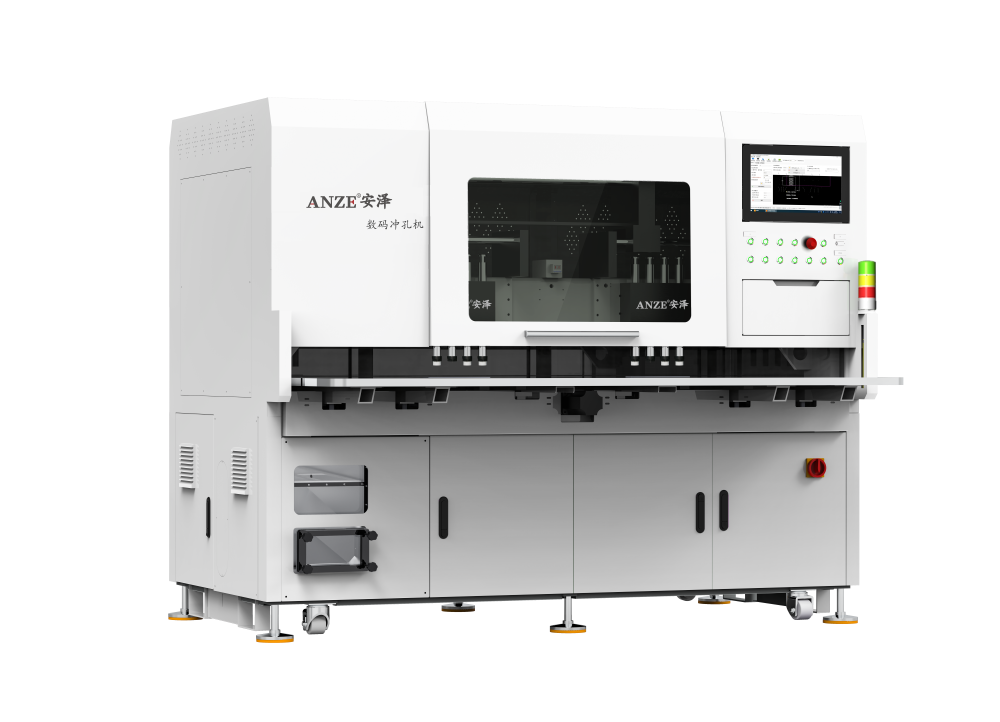

If you want to watch video of leather punching machine,please visit our YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.