Last Updated on 2025-02-21 by Anze

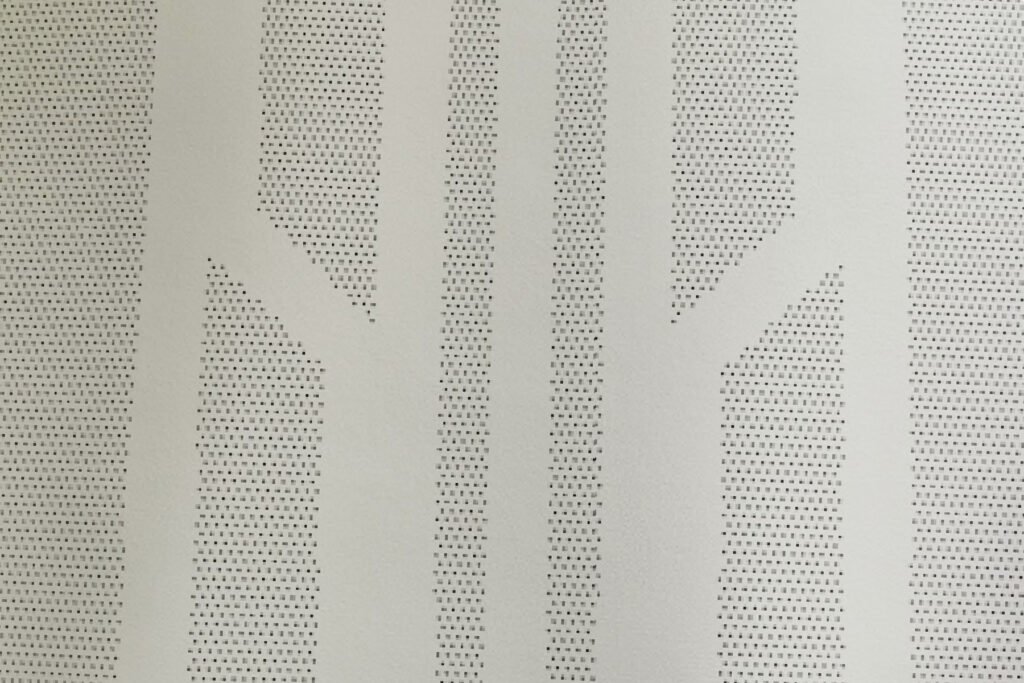

A leather perforation machine is a specialized piece of equipment used in the leather industry to create precise holes and perforations in leather products. These machines are commonly used in the production of leather belts, shoes, bags, and other leather goods where intricate designs or patterns are desired.

How leather perforation machine works

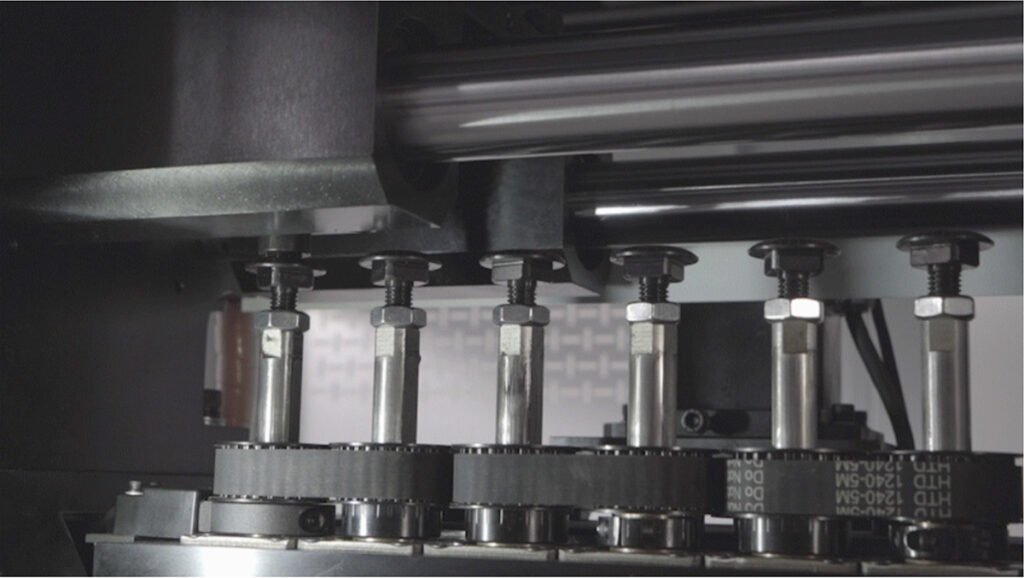

The leather perforation machine works by using a set of sharp needles or blades to punch through the leather material, creating the desired hole or pattern. The machine can be adjusted to control the size, shape, and spacing of the perforations, allowing for a wide range of design possibilities.

perforate large quantities of leather quickly and accurately.

One of the key benefits of using a leather perforation machine is the speed and precision with which it can create holes in leather. Hand punching holes in leather can be time-consuming and inconsistent, whereas a machine can perforate large quantities of leather quickly and accurately.

hole size or spacing

Furthermore, a leather perforation machine can help to ensure consistency and uniformity in the design of leather products. This is particularly important for manufacturers who produce goods in bulk, as variations in hole size or spacing can affect the overall quality and appearance of the finished product.

additional features

In addition to creating holes and perforations, some leather perforation machines are equipped with additional features, such as embossing or stamping capabilities. These machines can be used to add decorative elements to leather products, further enhancing their aesthetic appeal.

choose the right leahter perforation machine

When choosing a leather perforation machine, it is important to consider factors such as the size and thickness of the leather material being used, the desired hole size and spacing, and the level of automation required. Different machines may offer varying levels of customization and control, so it is important to select a machine that meets the specific needs of the production process.

a leather perforation machine is a valuable tool

Anze produces high quality leather perforation machine

Since 2005, Anze focus on the development and manufacture of leather punching machine. We are committed to providing our customers with better leather punching solutions,hole punching machine for leather!

Anze targets customer needs and focuses on product development, developing total of 25 products in the A and B series.

We are the company which have mature and comprehensive intelligent punching solution for materials in automotive interiors.

We have become strategic partners with over 600 leather product manufacturers. including 36 exporting countries.

CNC lehater perforation machine

CNC Leather perforation machine is suitable for punching and processing various leather soft materials such as car interiors, seat cushions, seat backs, headrests, door panels, etc. Anze manufactures A2 series cnc leather punching machine for car interior factory.

Mould leather perforation machine

Mould Leather perforation Machine is used for mass production of both regular perforation and personalized perforation of materials either in rolls (PVC, microfiber, artificial leather, etc.), or in pieces (genuine leather) for automotive upholstery industry.

If you want to watch video of leather punching machine,please visit our YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.