Last Updated on 2025-04-19 by Anze

Leather has been a cornerstone of human craftsmanship for millennia, serving as a durable and versatile material for clothing, footwear, furniture, and automotive interiors. Central to transforming raw leather into functional and decorative products is the process of perforation—creating precise holes or patterns to enhance aesthetics, ventilation, and usability. Over centuries, Công cụ đục lỗ da have evolved dramatically, reflecting advancements in technology, materials, and industrial demands. As a leading leather perforating machine manufacturer, we explore this fascinating journey to highlight how innovation has reshaped the industry and positioned modern tools as indispensable assets in today’s manufacturing landscape.

1. Early Beginnings: Manual leather perforating Tools and Artisanal Mastery

The origins of leather perforation trace back to ancient civilizations, where artisans relied on rudimentary tools to craft functional and ornamental designs. Early Công cụ đục lỗ da included:

- Awls and Punches: Handheld tools made from bone, stone, or metal, used to pierce holes for stitching or decorative patterns.

- Stamps and Dies: Carved wooden or metal stamps pressed into leather to create repetitive motifs.

These tools required immense skill and time, limiting production to small-scale, bespoke items. While effective for their era, manual methods struggled to meet growing demands for consistency and speed.

2. The Industrial Revolution: Mechanization Takes Hold

The 18th and 19th centuries marked a turning point with the advent of mechanization. Innovations like the fly press and mechanical punch machines revolutionized leatherworking:

- Fly Presses: Lever-operated machines that applied uniform pressure to metal dies, enabling faster and more consistent hole punching.

- Roller Perforators: Machines with rotating cylinders fitted with spikes, used to create evenly spaced holes in leather belts or straps.

These advancements allowed for mass production, particularly in footwear and saddlery industries. However, early machines were still limited in precision and required significant manual intervention.

3. The 20th Century: leather perforating tools mechanization

The rise of automotive and furniture industries in the 20th century demanded higher precision and customization in leather perforation. Key developments included:

- Hydraulic and Pneumatic Presses: These machines used pressurized systems to drive punches, offering greater force and control.

- Interchangeable Dies: Standardized die sets enabled manufacturers to switch between hole patterns quickly, catering to diverse product requirements.

- Conveyor-Belt Systems: Integrated workflows allowed semi-automated processing of large leather sheets.

This era also saw the emergence of die-cutting machines, which combined perforation with cutting to streamline production of complex shapes like car seat covers or handbag panels.

4. The Digital Age: Automation and Computer-Aided Design improve performance of leather perforating tools

The late 20th and early 21st centuries brought transformative technologies that redefined Công cụ đục lỗ da:

a. CNC (Computer Numerical Control) Machines

CNC technology enabled programmable control over perforation patterns. Operators could input designs via software, allowing for intricate geometries and repeatable accuracy. This was a game-changer for industries like automotive interiors, where custom perforation patterns became a signature of luxury brands.

b. Laser Perforation

Laser technology introduced a non-contact method of perforation. High-powered lasers vaporized leather fibers to create micro-holes with unmatched precision. Benefits included:

- No Physical Wear: Unlike mechanical punches, lasers eliminated tool degradation.

- Complex Designs: Capable of producing gradients, logos, and variable-density patterns.

- Material Versatility: Suitable for delicate or synthetic leathers.

However, laser systems initially faced challenges with speed and cost, limiting their adoption to high-end applications.

c. Servo-Electric Punching Machines

Modern servo-electric systems combined the speed of hydraulic presses with the precision of CNC controls. Features like automatic tool changers, real-time monitoring, and IoT connectivity made these machines ideal for high-volume, high-mix production.

5. Modern Innovations: Smart and Sustainable Solutions

Today’s Công cụ đục lỗ da are defined by intelligence, efficiency, and sustainability—priorities driven by Industry 4.0 and environmental regulations. Key trends include:

a. AI-Driven Optimization

Advanced algorithms analyze leather grain, thickness, and defects to optimize punching paths, minimizing waste and maximizing yield. AI also predicts maintenance needs, reducing downtime.

b. Hybrid Systems

Combining laser and mechanical punching in a single machine offers flexibility. For example, a hybrid tool might use lasers for fine details and mechanical punches for high-speed bulk processing.

c. Eco-Conscious Design

- Energy Efficiency: Machines with regenerative drives and low-power modes reduce energy consumption.

- Recyclable Components: Modular designs allow easy replacement of parts, extending machine lifespan.

- Waste Reduction: Precision tooling and nesting software ensure minimal leather scrap.

d. Customization at Scale

Digital workflows enable mass customization. A car seat manufacturer, for instance, can produce thousands of seat covers with unique perforation patterns tailored to individual customer preferences—all without slowing production.

6. The Role of a Modern Leather Perforating Machine Manufacturer

Như một leather perforating machine manufacturer, our mission is to bridge historical craftsmanship with cutting-edge technology. Here’s how we contribute to this evolution:

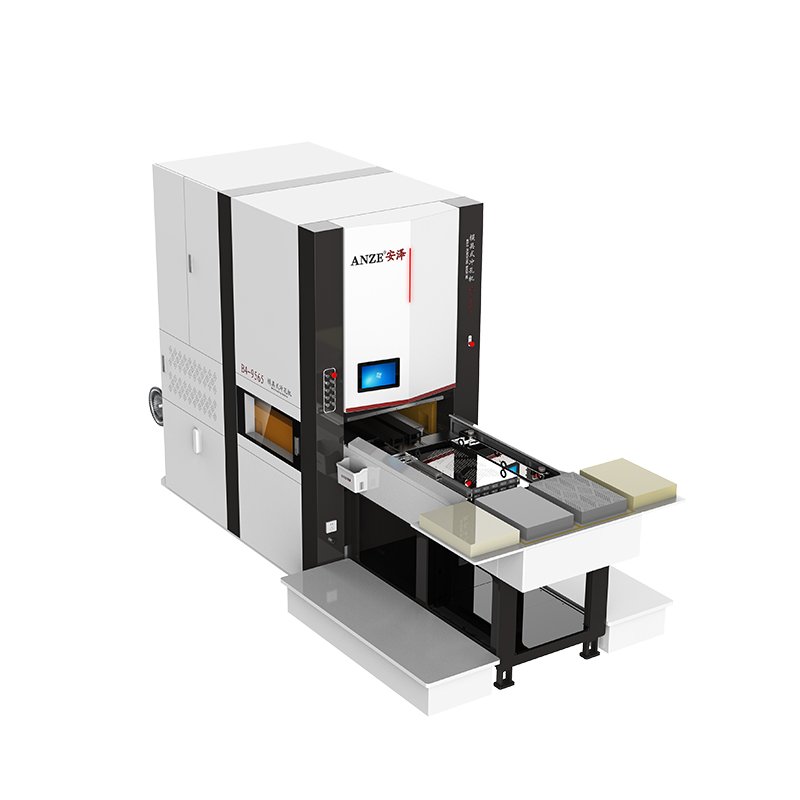

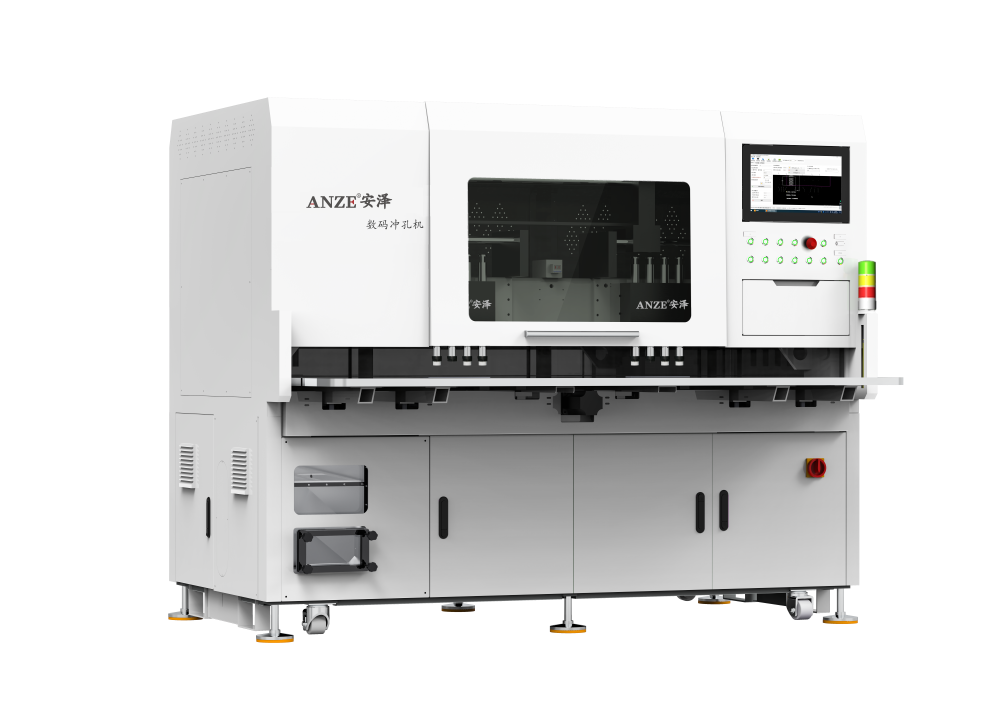

a. Advanced Machine Lineup

Our product portfolio includes:

- Multi-Axis CNC Punching Machines: For automotive and aerospace-grade leather.

- Laser-Perforation Systems: Ideal for luxury goods and intricate designs.

- High-Speed Servo Presses: Built for large-scale industrial applications.

b. Smart Factory Integration

Our machines support IoT connectivity, enabling seamless integration into smart factories. Real-time data analytics help clients monitor efficiency, predict failures, and optimize workflows.

c. Sustainability Commitments

We design machines that align with circular economy principles, from energy-efficient operations to compatibility with recycled leathers.

d. Global Support and Training

Beyond hardware, we provide software suites for design simulation and remote troubleshooting, ensuring clients maximize their investment.

7. Future Trends: What Lies Ahead?

The evolution of Công cụ đục lỗ da is far from over. Emerging trends include:

- Nanotechnology: Ultra-fine perforation for breathable yet durable medical or athletic leathers.

- 3D-Printed Tools: Custom dies and punches produced on-demand via additive manufacturing.

- Biodegradable Leathers: Machines adapted to handle eco-friendly materials without compromising performance.

Precision Meets Progress

From ancient awls to AI-powered systems, Công cụ đục lỗ da have undergone a remarkable transformation. Each era’s innovations addressed the limitations of its predecessors, unlocking new possibilities in design, efficiency, and sustainability. As a forward-thinking leather perforating machine manufacturer, we take pride in driving this evolution, equipping our clients with tools that turn creative visions into tangible, high-quality products.

Whether crafting the plush interiors of a luxury car or the intricate details of a designer handbag, modern perforation technology ensures that leather remains not just a material, but a canvas for innovation. Join us in shaping the future—one precise perforation at a time.

Explore our range of state-of-the-art leather perforating machines and discover how we’re redefining the art of leather craftsmanship.

Một số mô hình được lắp ráp sẵn tại nhà máy. Thiết bị lớn được đóng gói thành nhiều phần và kèm theo hướng dẫn lắp đặt. Tất cả thiết bị đều được trang bị sách hướng dẫn sử dụng bằng tiếng Trung và tiếng Anh.

Khách hàng có thể cử người đến nhà máy Anze để học tập hoặc chúng tôi sẽ cử các chuyên gia kỹ thuật đến để cung cấp đào tạo tại chỗ.

Máy móc cần được lắp đặt trên một bàn làm việc ổn định và môi trường xung quanh cần được giữ sạch sẽ, gọn gàng để tránh tiếp xúc với bụi, tĩnh điện, độ ẩm và mảnh vụn, nhằm phòng ngừa hư hỏng các bộ phận.

Chúng tôi có đội ngũ hỗ trợ sau bán hàng giàu kinh nghiệm, cung cấp dịch vụ trực tuyến 24/7 và hệ thống hỗ trợ sau bán hàng hoàn chỉnh. Hỗ trợ đào tạo tại nhà máy, cung cấp video kỹ thuật để hỗ trợ bảo trì máy móc ở nước ngoài. Hỗ trợ trực tuyến, kỹ sư.

Tất nhiên, chúng tôi rất hoan nghênh quý vị đến thăm công ty chúng tôi và có cuộc trao đổi trực tiếp để thúc đẩy hợp tác kinh doanh chung.

Thời gian giao hàng thay đổi tùy thuộc vào số lượng đơn hàng và yêu cầu tùy chỉnh, thường dao động từ 7 đến 10 ngày làm việc. Đối với đơn hàng máy đục da tùy chỉnh, thời gian giao hàng là 1-2 tháng.