Cập nhật lần cuối vào ngày 20/02/2025 bởi Anze

In modern manufacturing, Công nghệ đục lỗ da, with its unique processing method and wide application fields, has become an important means to enhance product added value and meet personalized needs. With the advancement of science and technology and the continuous changes in consumer demand, leather punching technology is also constantly innovating and developing. This article will conduct an in-depth investigation on the application of leather punching technology, and explore its application status, technological innovation and future development trends in different fields.

1. Overview of leather punching technology

Công nghệ đục lỗ da is a processing method that forms holes or patterns on the surface of leather through a punching die. This technology has the characteristics of high processing efficiency, low cost, and diverse patterns. It is widely used in many fields such as footwear, luggage, furniture, and automotive interiors. Leather punching technology can not only improve the beauty and breathability of the product, but also enhance the comfort and durability of the product.

2. Application fields of leather punching technology

2.1 Footwear manufacturing

In footwear manufacturing, Công nghệ đục lỗ da is widely used in the processing of uppers, insoles and other parts. Punching can increase the breathability of shoes and improve wearing comfort. At the same time, the diversity of punching patterns also adds a fashion element to shoes, meeting consumers’ demand for personalized shoes.

2.2 Luggage manufacturing

Luggage manufacturing is another important application field of Công nghệ đục lỗ da. Through punching technology, various patterns and textures can be formed on the surface of luggage to enhance the beauty and recognition of luggage. In addition, punching can also reduce the weight of luggage and improve the convenience of carrying.

2.3 Furniture manufacturing

In furniture manufacturing, leather punching technology is used for the soft-packed parts of furniture such as sofas and chairs. Punching can not only increase the air permeability of furniture, but also improve the comfort and beauty of furniture. At the same time, the personalized design of punching patterns can also meet consumers’ personalized needs for home environment.

2.4 Automobile interior

With the rapid development of the automobile industry, leather punching technology is increasingly used in the field of automobile interior. Automobile seats, steering wheels, door panels and other parts can be processed by punching technology to enhance the beauty and comfort of the interior. In addition, punching can also reduce the weight of interior parts and reduce vehicle fuel consumption.

2.5 Other fields

In addition to the above fields, leather punching technology is also used in clothing, accessories, sporting goods and other fields. In clothing manufacturing, punching technology can be used to make sportswear with good breathability; in accessories manufacturing, punching technology can add fashion and three-dimensional sense to accessories; in sports goods manufacturing, punching technology can improve the breathability and durability of products.

3. Innovation and development of leather punching technology

3.1 Laser punching technology

Laser punching technology is a processing method that uses laser beams to form holes or patterns on the surface of leather. Compared with traditional mechanical punching, laser punching has the advantages of high processing accuracy, fast speed, and complex and diverse patterns. Laser punching technology can not only be applied to the processing of flat leather, but also realize the punching of three-dimensional patterns.

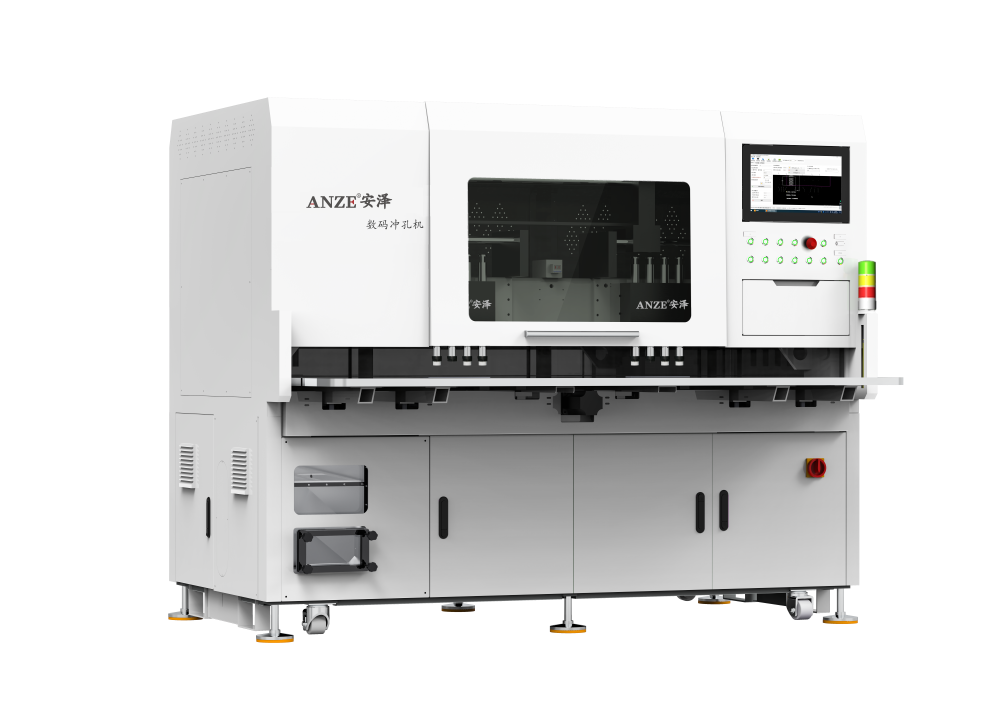

3.2 CNC punching technology

CNC punching technology is a method of automated processing by controlling punching equipment through computer programs. This technology has the characteristics of high processing efficiency, high precision, and strong flexibility. CNC punching technology can be customized according to customer needs, achieving large-scale production while maintaining product consistency and high quality.

3.3 Environmentally friendly punching technology

With the enhancement of environmental awareness, environmentally friendly punching technology has gradually become the focus of industry attention. Environmentally friendly punching technology aims to reduce waste emissions and energy consumption during processing while ensuring product quality and performance. For example, using degradable materials or recycled materials for punching processing, and optimizing the punching process to reduce waste generation.

4. Future development trend of leather punching technology

4.1 Intelligence and automation

With the development of intelligent manufacturing technology, leather punching technology will develop in a more intelligent and automated direction. In the future, punching equipment will have a higher degree of automation and stronger self-learning ability, and will be able to respond quickly and customize according to customer needs.

4.2 High precision and high efficiency

With the continuous improvement of consumers’ demand for product quality and personalization, leather punching technology will develop in the direction of higher precision and higher efficiency. In the future, punching equipment will adopt more advanced processing technology and more sophisticated control systems to achieve finer pattern punching and higher production efficiency.

4.3 Environmental protection and sustainability

Environmental protection and sustainable development will become important directions for the future development of leather punching technology. In the future, punching technology will pay more attention to the application of environmentally friendly materials and energy conservation and emission reduction in the processing process to achieve green manufacturing and sustainable development.

4.4 Cross-border integration and innovation

With the accelerated advancement of cross-border integration, leather punching technology will be deeply integrated and innovated with technologies in other fields. For example, combined with 3D printing technology to achieve the punching of complex patterns; combined with smart wearable technology to develop leather products with health monitoring functions, etc.

Leather punching technology is used in many industries

As an important processing method, Công nghệ đục lỗ da plays an important role in many fields. With the advancement of science and technology and the continuous changes in consumer demand, leather punching technology is also constantly innovating and developing. In the future, intelligence, automation, high precision, high efficiency, environmental sustainability and cross-border integration will become important trends in the development of leather punching technology. We have reason to believe that in the near future, leather punching technology will bring innovation and change to more fields and add more beauty and convenience to people’s lives.

Nếu bạn muốn xem video về máy đục da, vui lòng truy cập trang web của chúng tôi. KÊNH YOUTUBE https://www.youtube.com/@Anze-Perforation-machine

Một số mô hình được lắp ráp sẵn tại nhà máy. Thiết bị lớn được đóng gói thành nhiều phần và kèm theo hướng dẫn lắp đặt. Tất cả thiết bị đều được trang bị sách hướng dẫn sử dụng bằng tiếng Trung và tiếng Anh.

Khách hàng có thể cử người đến nhà máy Anze để học tập hoặc chúng tôi sẽ cử các chuyên gia kỹ thuật đến để cung cấp đào tạo tại chỗ.

Máy móc cần được lắp đặt trên một bàn làm việc ổn định và môi trường xung quanh cần được giữ sạch sẽ, gọn gàng để tránh tiếp xúc với bụi, tĩnh điện, độ ẩm và mảnh vụn, nhằm phòng ngừa hư hỏng các bộ phận.

Chúng tôi có đội ngũ hỗ trợ sau bán hàng giàu kinh nghiệm, cung cấp dịch vụ trực tuyến 24/7 và hệ thống hỗ trợ sau bán hàng hoàn chỉnh. Hỗ trợ đào tạo tại nhà máy, cung cấp video kỹ thuật để hỗ trợ bảo trì máy móc ở nước ngoài. Hỗ trợ trực tuyến, kỹ sư.

Tất nhiên, chúng tôi rất hoan nghênh quý vị đến thăm công ty chúng tôi và có cuộc trao đổi trực tiếp để thúc đẩy hợp tác kinh doanh chung.

Thời gian giao hàng thay đổi tùy thuộc vào số lượng đơn hàng và yêu cầu tùy chỉnh, thường dao động từ 7 đến 10 ngày làm việc. Đối với đơn hàng máy đục da tùy chỉnh, thời gian giao hàng là 1-2 tháng.