Cập nhật lần cuối vào ngày 20/02/2025 bởi Anze

In today’s global automotive manufacturing industry, the quality and personalized needs of automotive interiors are increasing, bringing unprecedented challenges and opportunities to automakers. As a leading company focusing on the research and development and production of leather perforation machinery, we have launched an in-depth cooperation with a well-known Korean automotive interior manufacturer to jointly explore and realize innovative solutions for automotive interior leather punching. This article will introduce the background, process, results and good prospects for future cooperation in detail.

1. Background of cooperation

With the continuous expansion of the automotive market and the increasing diversification of consumer demand, automakers have begun to pay more attention to the personalized design and comfort experience of interiors. South Korea, as a leader in the Asian automotive industry, has always been at the forefront of the industry in the field of automotive interior manufacturing. Our Korean customers, as leaders in this field, focus on providing customized interior solutions for high-end automotive brands, especially focusing on the selection and processing of leather materials. However, with the intensification of market competition and the improvement of consumer requirements for interior quality, traditional leather processing methods have been unable to meet their ability to quickly respond to market demand and provide personalized products.

In this context, the customer began to seek a more efficient and flexible Giải pháp đục lỗ da to improve its production efficiency and product competitiveness. As we have many years of experience and technical accumulation in the field of Máy đục lỗ da, we naturally become their ideal partner.

2. Cooperation process

2.1 Demand analysis and initial communication

In the early stage of cooperation, we first had in-depth communication and exchanges with customers to understand their specific needs for leather perforation machinery in detail. Customers hope that the punching machines we provide can meet the following requirements:

Độ chính xác cao: ensure accurate punching position and regular hole shape to meet the pursuit of details in high-end automotive interiors.

Hiệu suất cao: can quickly complete the punching operation of large areas of leather, shorten the production cycle, and increase production capacity.

Độ linh hoạt: support punching of multiple hole shapes and arrangements to meet the needs of different models and interior styles.

Stability: The equipment must have the ability to operate stably for a long time, reduce failure rate, and reduce maintenance costs.

In response to customer needs, we introduced our leather punching machine product features and technical advantages in detail, and demonstrated previous successful cases to enhance customer confidence.

2.2 Customized solution design

After fully understanding customer needs, our technical team began to design customized leather punching machine solutions. The solution mainly includes the following aspects:

High-precision mold design: According to the leather material and punching requirements provided by the customer, we designed a series of high-precision molds. These molds are made of high-quality materials and are precisely processed and debugged to ensure the accuracy of the punching position and the regularity of the hole type.

Intelligent control system: We have equipped the punching machine with an advanced intelligent control system that supports the switching and parameter adjustment of multiple punching modes. Users can easily set the punching parameters through the touch screen to quickly respond to market demand.

High-efficiency power system: In order to meet customers’ demand for high efficiency, we selected high-performance motors and transmission systems to ensure that the punching machine can maintain stable performance output at high speed.

Modular design: In order to facilitate maintenance and upgrading, we adopted a modular design approach. Users can replace or upgrade the punching module according to actual needs to improve the flexibility and scalability of the equipment.

2.3 Equipment production, installation and commissioning

After the customized solution was determined, we quickly started the production and assembly of the equipment. During the production process, we strictly follow the requirements of the quality management system for quality control and inspection to ensure that each punching machine meets the customer’s expectations.

After the equipment was produced, we sent a professional technical team to the Korean customer for on-site installation and commissioning. During the installation process, we worked closely with the customer’s technical staff to jointly solve a series of technical problems in the equipment installation process. After the joint efforts of both parties, the punching machine successfully completed the installation and commissioning and was put into trial operation.

2.4 Trial operation and feedback optimization

After the punching machine was put into trial operation, we maintained close communication and exchanges with customers. Customers put forward valuable feedback and suggestions during actual use. We listened carefully to the opinions of customers and conducted in-depth analysis and research, and then carried out targeted optimization and improvement of the punching machine. After many iterations and optimizations, the performance of the punching machine has been significantly improved and has been highly recognized by customers.

3. Cooperation results

After the joint efforts and close cooperation of both parties, this cooperation has achieved remarkable results:

Production efficiency has been greatly improved: After using the leather punching machine we provided, the customer’s production efficiency has been greatly improved. Compared with traditional manual punching methods or inefficient automatic punching equipment, our punching machine can complete the punching of large areas of leather in a shorter time, thereby significantly shortening the production cycle and increasing production capacity.

Product quality has been significantly improved: Since the punching machines we provide have the characteristics of high precision and stability, the punching positions are accurate, the hole patterns are regular and the consistency is good. This enables customers to produce high-end automotive interior products that are more in line with market demand and quality requirements, thereby enhancing brand image and market competitiveness.

Personalized needs are met: Through intelligent control systems and modular design ideas, our punching machines can support punching operations with a variety of hole patterns and arrangements to meet the needs of different models and interior styles. This enables customers to respond to market changes more flexibly and meet the personalized needs of consumers.

Long-term cooperative relationship established: Through this cooperation, we have established a deep trust and cooperative relationship with customers. Customers highly recognize our products and services and express their willingness for long-term cooperation. This has laid a solid foundation for our future market expansion and business development.

4. Future Outlook

Looking to the future, we will continue to deepen our cooperative relationship with Korean customers and continue to explore and innovate leather punching technology. We will pay close attention to market trends and changes in consumer demand and actively develop more efficient, flexible and intelligent punching equipment to meet the growing needs of customers. At the same time, we will also strengthen communication and exchanges with customers to jointly explore more diversified cooperation models to achieve the goal of mutual benefit and win-win results.

We will actively expand domestic and foreign markets and strengthen cooperation and exchanges with global automobile manufacturers to promote the application and development of leather punching technology in the field of automobile interior manufacturing. We believe that through continuous efforts and innovation, we will contribute more to the global automobile interior manufacturing industry and jointly promote the progress and development of the industry.

This cooperation with Korean customers is an important milestone in the development of our leather punching machine business. It not only demonstrates our professional strength and technical advantages in this field, but also wins us valuable market opportunities and partners. We will take this opportunity to continue to work hard to provide customers with better products and services and work together to create a better future.

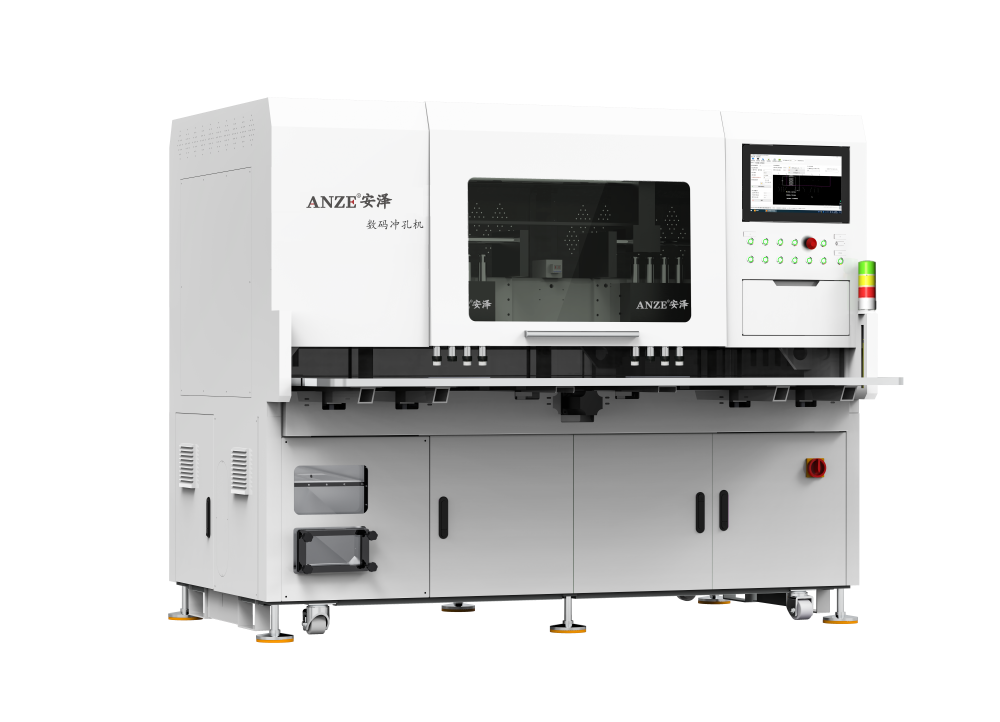

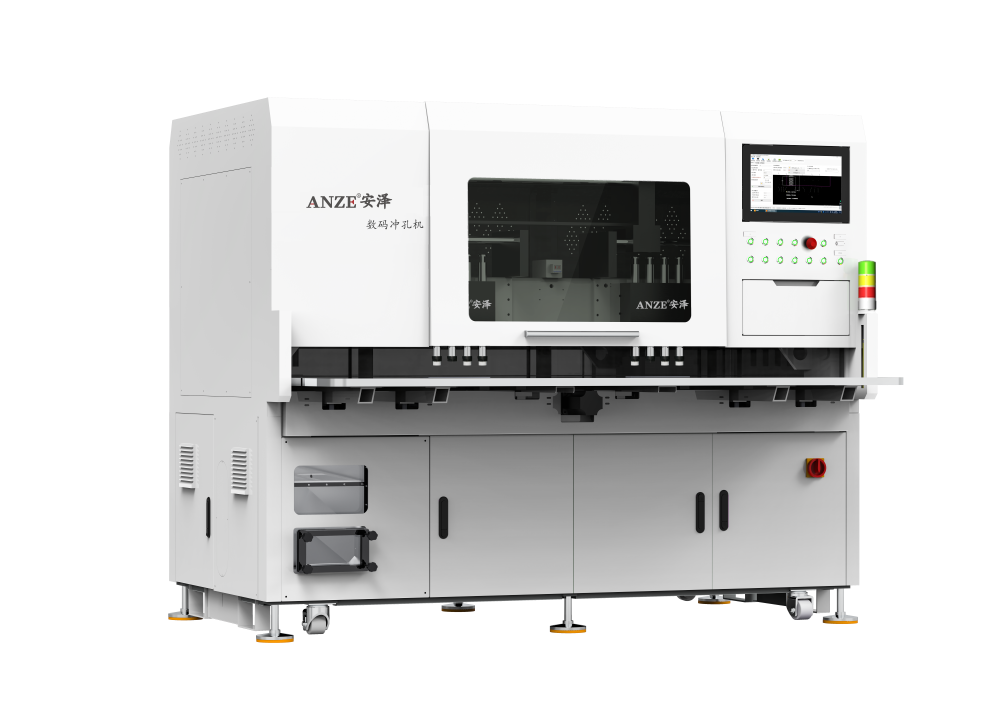

5.anze is one of top leather perforation machinery

Kể từ năm 2005, Anze tập trung vào việc phát triển và sản xuất leather perforation machinery. Chúng tôi cam kết cung cấp cho khách hàng các giải pháp đục lỗ da tốt hơn.,Máy đục lỗ cho da!

If you want to watch video of leather perforation machinery,please visit our KÊNH YOUTUBE https://www.youtube.com/@Anze-Perforation-machine

Một số mô hình được lắp ráp sẵn tại nhà máy. Thiết bị lớn được đóng gói thành nhiều phần và kèm theo hướng dẫn lắp đặt. Tất cả thiết bị đều được trang bị sách hướng dẫn sử dụng bằng tiếng Trung và tiếng Anh.

Khách hàng có thể cử người đến nhà máy Anze để học tập hoặc chúng tôi sẽ cử các chuyên gia kỹ thuật đến để cung cấp đào tạo tại chỗ.

Máy móc cần được lắp đặt trên một bàn làm việc ổn định và môi trường xung quanh cần được giữ sạch sẽ, gọn gàng để tránh tiếp xúc với bụi, tĩnh điện, độ ẩm và mảnh vụn, nhằm phòng ngừa hư hỏng các bộ phận.

Chúng tôi có đội ngũ hỗ trợ sau bán hàng giàu kinh nghiệm, cung cấp dịch vụ trực tuyến 24/7 và hệ thống hỗ trợ sau bán hàng hoàn chỉnh. Hỗ trợ đào tạo tại nhà máy, cung cấp video kỹ thuật để hỗ trợ bảo trì máy móc ở nước ngoài. Hỗ trợ trực tuyến, kỹ sư.

Tất nhiên, chúng tôi rất hoan nghênh quý vị đến thăm công ty chúng tôi và có cuộc trao đổi trực tiếp để thúc đẩy hợp tác kinh doanh chung.

Thời gian giao hàng thay đổi tùy thuộc vào số lượng đơn hàng và yêu cầu tùy chỉnh, thường dao động từ 7 đến 10 ngày làm việc. Đối với đơn hàng máy đục da tùy chỉnh, thời gian giao hàng là 1-2 tháng.