Last Updated on 2026-01-23 by Anze

Seat Cover Perforating Machine Technology in Modern Automotive Manufacturing

The automotive interior industry has entered a phase where comfort, aesthetics, functionality, and acoustic performance are inseparable from material engineering. One of the most critical enabling technologies behind modern automotive seating is the seat cover perforating machine. From ventilation and breathability to noise control and design differentiation, perforated leather seat covers have become a global standard.

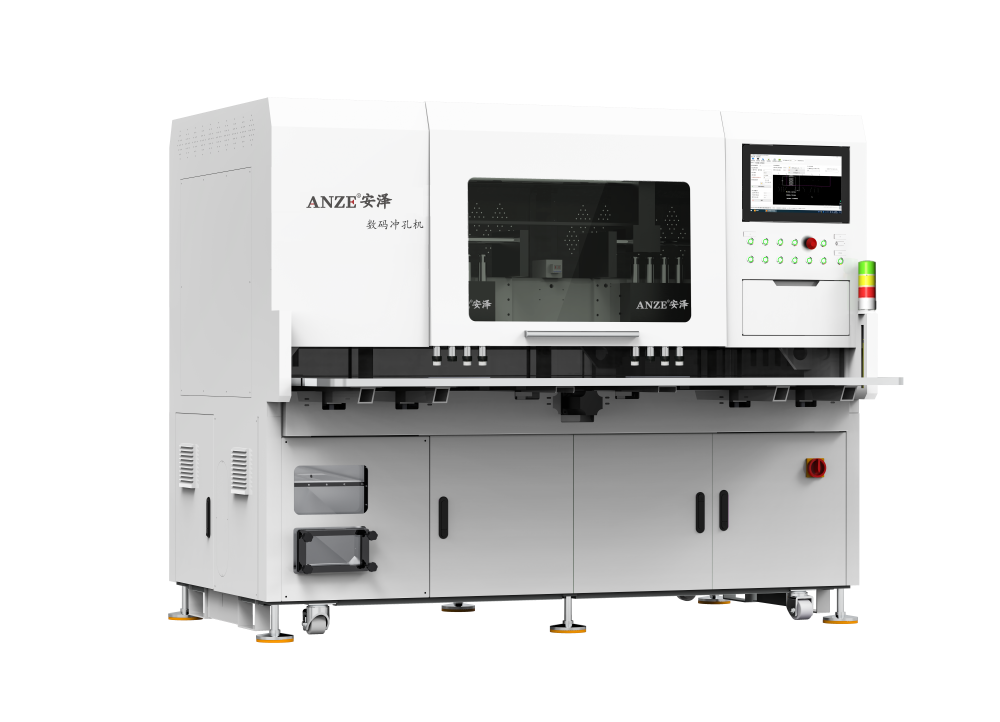

As a professional manufacturer with over 20 years of experience in leather perforation equipment, Anze has developed more than 20 proprietary seat cover perforating machine models, delivering customized solutions for automotive seat manufacturers worldwide. This article provides a comprehensive technical overview of seat cover perforating machine technology, process engineering, material behavior, equipment selection, and industrial-scale solutions.

1. Seat Cover Perforating Machine: Why Perforation Is Essential for Automotive Seats

A seat cover perforating machine is designed to create precise, repeatable micro- or macro-perforations in leather and synthetic upholstery materials used for automotive seating.

Key functional reasons for seat cover perforation:

Ventilation and breathability for seat comfort

Compatibility with ventilated and cooled seats

Acoustic transparency for seat-integrated speakers

Weight reduction without strength loss

Aesthetic and branding design patterns

Without a high-precision seat cover perforating machine, manufacturers cannot meet modern automotive interior requirements consistently.

2. Seat Cover Perforating Machine Manufacturer Perspective: Industry Challenges

As a professional seat cover perforating machine manufacturer, Anze has identified several industry-wide challenges:

Variable leather thickness (0.8–1.6 mm)

Natural leather grain inconsistency

Heat sensitivity of PU and microfiber

High-speed production demands

Zero-defect tolerance for OEM automotive supply chains

These challenges require advanced seat cover perforating machine solutions rather than generic punching equipment.

3. Seat Cover Perforating Machine Types Used in Automotive Production

3.1 CNC Seat Cover Perforating Machine

A CNC-controlled seat cover perforating machine provides:

Digital pattern programming

Automatic hole alignment

Variable hole diameter control

High repeatability for mass production

This type is ideal for Tier-1 automotive suppliers.

3.2 High-Speed Automatic Seat Cover Perforating Machine

An automatic seat cover perforating machine focuses on throughput:

Continuous feeding systems

Servo-driven punching heads

Up to tens of thousands of holes per minute

Integration with cutting and laminating lines

3.3 Micro-Perforation Seat Cover Perforating Machine

Micro-perforation is essential for ventilated seats:

Hole diameters as small as 0.3–0.8 mm

Clean edges without leather tearing

Stable airflow performance

Anze’s micro-perforation seat cover perforating machines are optimized for luxury vehicles.

4. Seat Cover Perforating Machine and Material Compatibility

A professional seat cover perforating machine manufacturer must engineer solutions for diverse materials:

4.1 Genuine Automotive Leather

Full-grain leather

Corrected grain leather

Semi-aniline leather

4.2 Synthetic Upholstery

PU leather

PVC leather

Microfiber composites

Each material requires different:

Punch geometry

Pressure control

Tool speed

Heat management

Anze’s seat cover perforating machines use adaptive control systems to handle material variation.

5. Seat Cover Perforating Machine Process Engineering

5.1 Hole Diameter and Pattern Design

Seat cover perforating machine parameters include:

Hole size (0.3 mm – 3.0 mm)

Hole spacing

Pattern density

Functional zones (ventilation areas vs. structural zones)

5.2 Perforation Accuracy and Tolerance

Automotive standards require:

±0.05 mm hole position tolerance

Clean punching without burrs

No fiber pull-out on microfiber

Anze seat cover perforating machines are designed to meet these tolerances consistently.

6. Seat Cover Perforating Machine for Ventilated Seat Systems

Modern vehicles increasingly adopt ventilated seats. This places strict demands on the seat cover perforating machine:

Uniform airflow channels

No blockage from melted edges

Consistent perforation density

Anze integrates airflow simulation data into seat cover perforating machine pattern design.

7. Seat Cover Perforating Machine Tooling Technology

7.1 Punch Materials

Tungsten carbide

High-speed steel

Coated micro-punches

7.2 Tool Life Optimization

A professional seat cover perforating machine manufacturer designs:

Quick-change tooling

Automated wear monitoring

Tool sharpening cycles

8. Seat Cover Perforating Machine Automation and Smart Control

Anze’s advanced seat cover perforating machine solutions include:

PLC + CNC hybrid control

MES connectivity

Pattern recall

Production data logging

This supports Industry 4.0 manufacturing environments.

9. Seat Cover Perforating Machine Production Line Integration

A seat cover perforating machine rarely operates alone. It integrates with:

Leather cutting machines

Laminating systems

Foam bonding lines

Sewing and assembly stations

Anze provides full seat cover perforating machine line solutions.

10. Seat Cover Perforating Machine Quality Control Standards

Automotive OEMs require strict QA:

Visual inspection systems

Hole blockage detection

Random airflow testing

Dimensional scanning

Anze designs seat cover perforating machines compatible with inline inspection modules.

11. Seat Cover Perforating Machine Manufacturer: Why Automotive Clients Choose Anze

As a trusted seat cover perforating machine manufacturer, Anze offers:

20+ years of engineering experience

20+ proprietary machine models

Custom tooling development

Global customer support

Proven automotive seat projects

Our seat cover perforating machines are used by manufacturers supplying:

Passenger vehicles

Commercial vehicles

Luxury and premium brands

12. Seat Cover Perforating Machine Case Applications

12.1 Premium Vehicle Seat Covers

Micro-perforation for ventilation

High aesthetic standards

12.2 Mass-Market Seat Covers

High-speed production

Cost-efficient tooling

12.3 Electric Vehicle Seat Systems

Lightweight designs

Enhanced airflow requirements

13. Seat Cover Perforating Machine Cost Factors

Key factors influencing seat cover perforating machine investment:

Automation level

Production capacity

Hole precision

Tooling system

Customization requirements

Anze provides scalable solutions from entry-level to fully automated production lines.

14. Future Trends in Seat Cover Perforating Machine Technology

The next generation of seat cover perforating machines will focus on:

AI-assisted pattern optimization

Adaptive punching force control

Digital twins for process simulation

Sustainable material compatibility

Anze continues to invest heavily in R&D to lead these trends.

Selecting the Right Seat Cover Perforating Machine Partner

Choosing the right seat cover perforating machine is not just about equipment—it is about process reliability, material expertise, and long-term partnership.

With 20 years of experience, proprietary technology, and deep automotive industry knowledge, Anze delivers complete seat cover perforating machine solutions tailored to modern automotive manufacturing demands.

About Anze

Anze is a professional seat cover perforating machine manufacturer specializing in leather, fabric, and flexible material perforation for automotive, furniture, and industrial applications. Our solutions are trusted by manufacturers worldwide for precision, speed, and reliability.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.