Last Updated on 2026-02-16 by Анзе

Understanding Perforating Leather Technology in Modern Manufacturing

Perforating leather is a critical manufacturing process used across industries including automotive interiors, furniture upholstery, footwear, fashion accessories, and sports equipment. The evolution from manual punching to automated перфорационная машина для кожи technology has dramatically improved precision, productivity, and design flexibility.

A professional manufacturer must combine mechanical engineering, tooling design, and material science to achieve reliable perforation results. With over 20 лет опыта and more than 20 independently developed perforation systems, Anze specializes in both CNC perforating machine и mould perforating machine solutions for industrial leather processing.

This article provides a comprehensive technical exploration of perforating leather, including working principles, equipment types, process engineering, applications, and future trends.

1. What Is Perforating Leather and Why It Matters

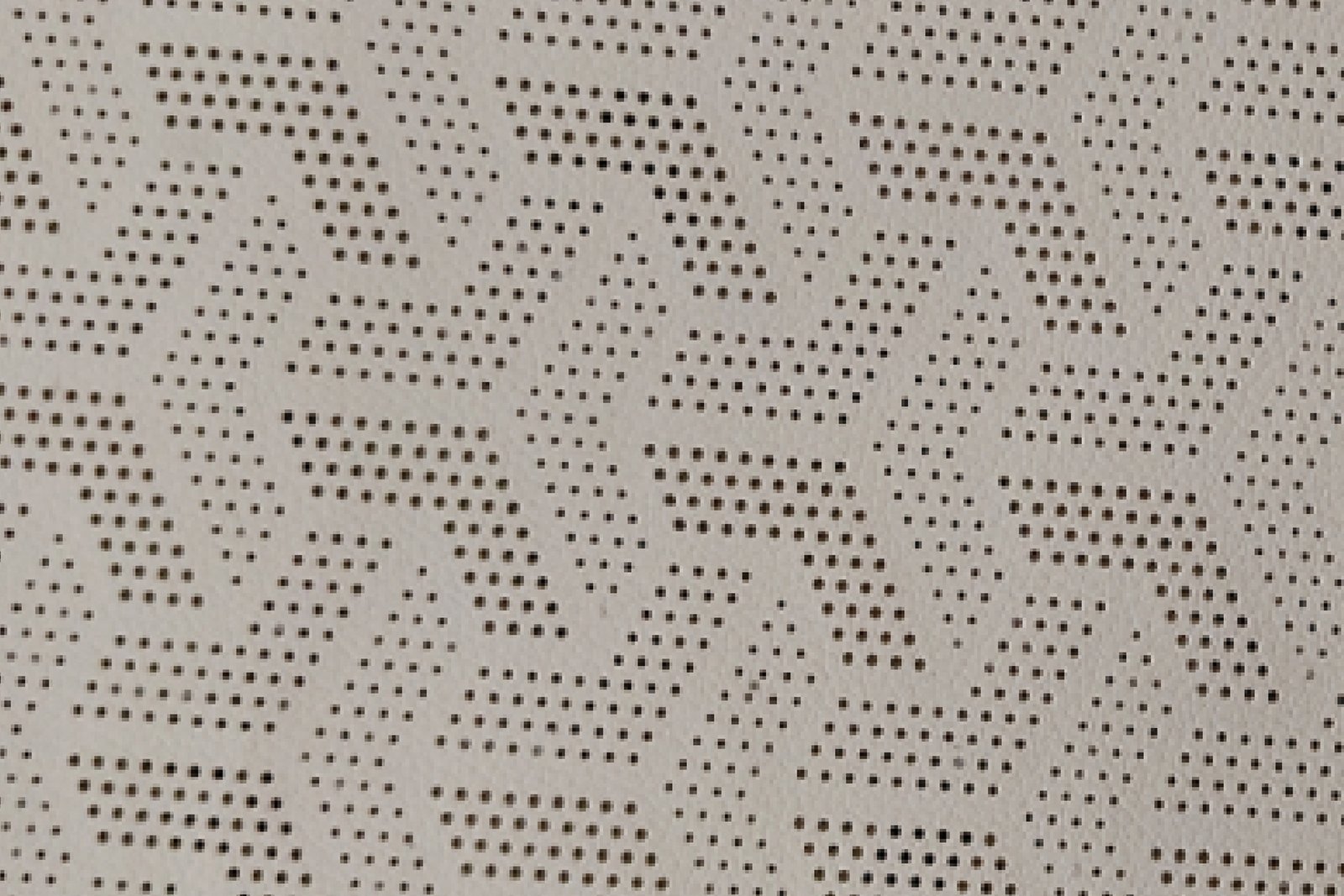

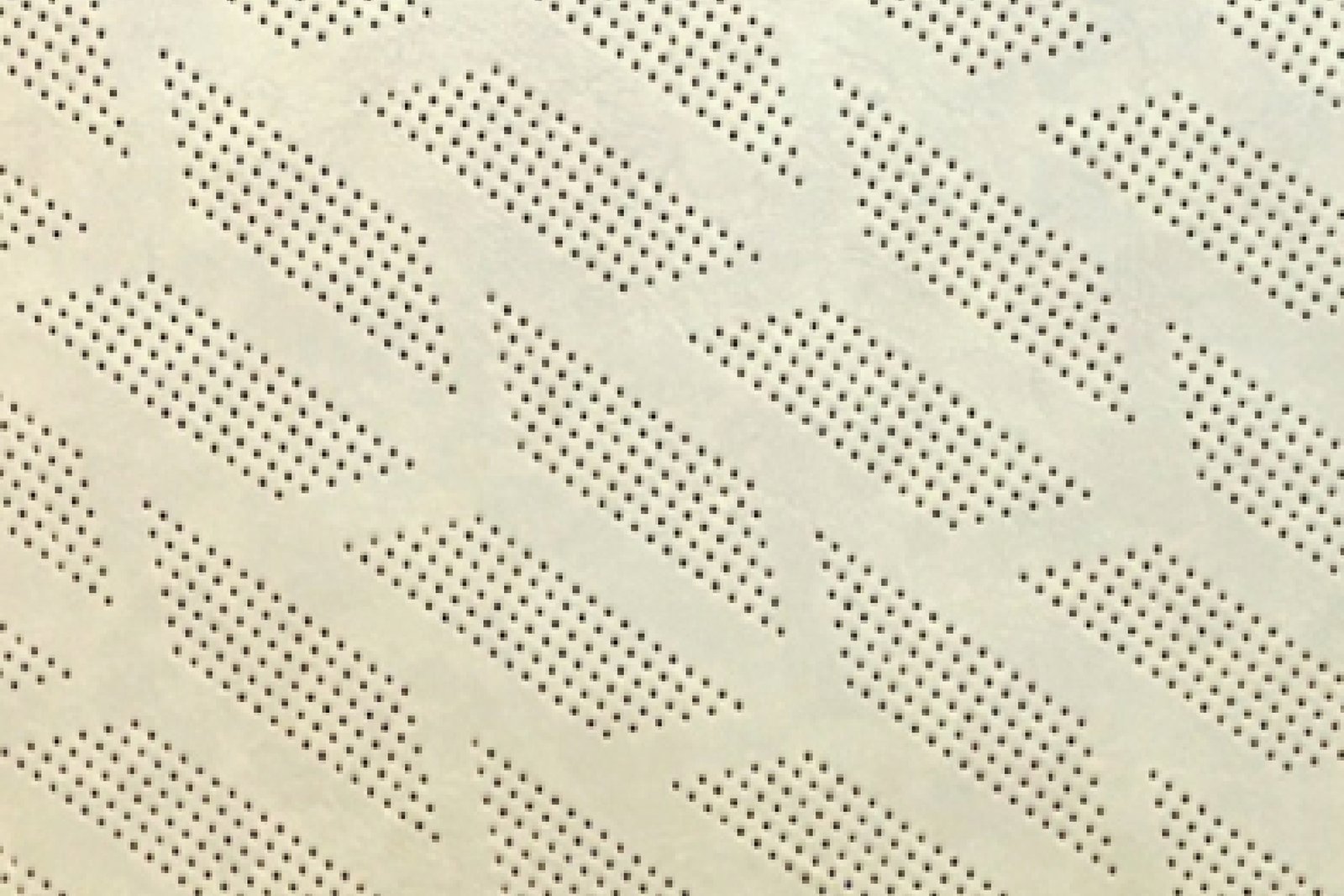

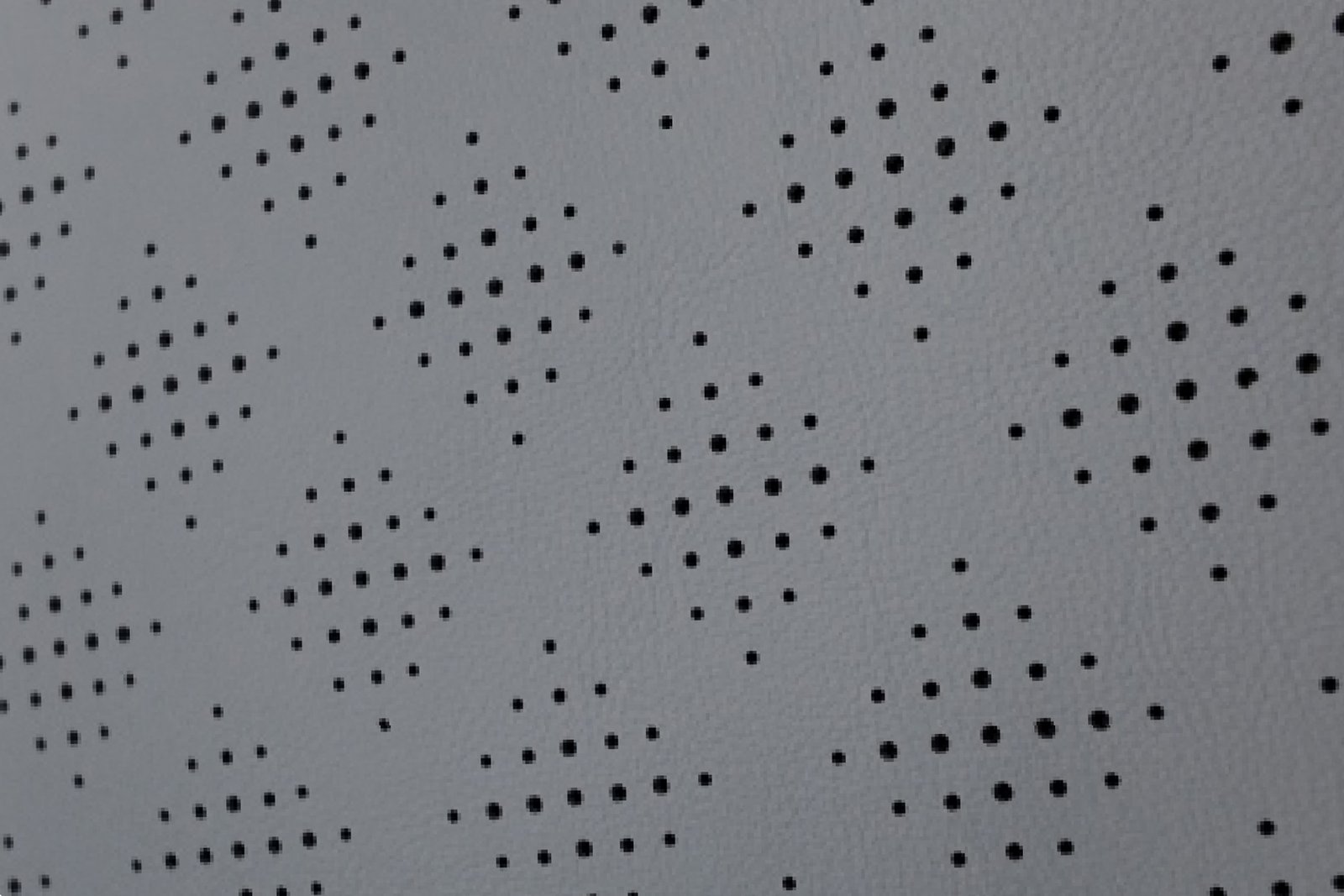

Perforating leather refers to the process of creating precisely positioned holes in leather materials using specialized machinery. These perforations serve both functional and aesthetic purposes.

Key reasons for perforating leather include:

Improving breathability and airflow

Enhancing comfort in seating products

Increasing material flexibility

Reducing weight

Creating decorative patterns

Supporting acoustic performance

Modern industries rely heavily on advanced перфорационная машина для кожи technology to achieve consistent results at scale.

2. How Perforating Leather Works: Basic Mechanical Principles

Сайт perforating leather process involves applying controlled force through a punch tool to remove material and create holes.

The process typically includes:

Material positioning

Punch alignment

Controlled penetration force

Material removal

Hole formation and release

Precision depends on machine stability, tooling quality, and control systems.

3. Perforating Leather Machine Types and Technologies

Профессионал perforating leather machine manufacturer offers multiple equipment categories depending on production needs.

3.1 CNC Perforating Leather Machine

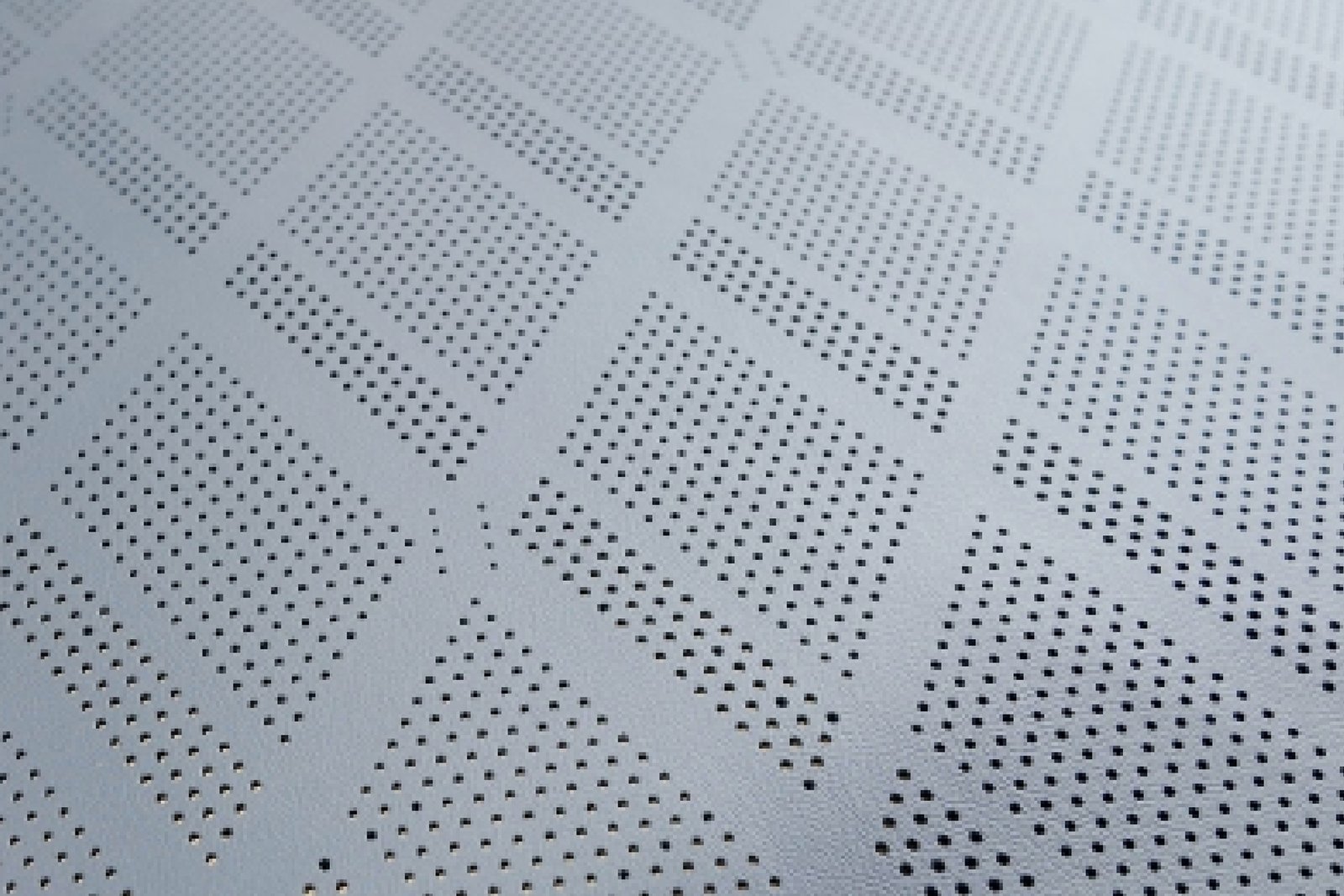

A CNC perforating leather machine uses computer numerical control for programmable perforation patterns.

Преимущества:

High precision positioning

Flexible pattern design

Easy parameter adjustment

Repeatable quality

This is the most advanced technology for complex designs.

3.2 Mould Perforating Leather Machine

A mould perforating leather machine uses fixed tooling plates for repetitive patterns.

Преимущества:

High production efficiency

Suitable for mass production

Lower programming requirements

Stable mechanical operation

This approach is ideal for standardized products.

4. Materials Used in Perforating Leather Applications

A modern перфорационная машина для кожи can process multiple materials:

Genuine leather

PU leather

PVC leather

Кожа из микрофибры

Composite materials

Synthetic upholstery

Each material requires different punching force, speed, and tooling geometry.

5. Tooling Technology in Perforating Leather Machines

Tooling is the core of any perforating leather process.

Important factors include:

Punch diameter precision

Edge sharpness

Wear resistance

Alignment accuracy

High-quality tooling ensures clean hole edges without tearing.

6. Key Engineering Parameters in Perforating Leather

Successful perforating leather requires control over multiple parameters:

Punch Force

Must match leather thickness and density.

Hole Spacing

Impacts flexibility and structural integrity.

Punch Speed

Affects productivity and material deformation.

Температура инструмента

Important for synthetic materials.

Professional перфорационная машина для кожи systems allow precise parameter adjustments.

7. Automation in Perforating Leather Machines

Современный перфорационная машина для кожи solutions include automation features:

CNC control systems

Servo-driven motion

Automatic feeding systems

Touchscreen interfaces

Pattern memory storage

Automation reduces labor and increases consistency.

8. Industrial Applications of Perforating Leather Technology

Automotive Industry

Seats, steering wheels, door panels

Furniture Industry

Sofas, recliners, office chairs

Footwear Industry

Breathable shoe uppers

Fashion Industry

Handbags, belts, wallets

Sports Equipment

Gloves and protective gear

The versatility of перфорационная машина для кожи technology supports diverse industries.

9. Benefits of Using Advanced Perforating Leather Machines

Manufacturers gain significant advantages:

Consistent quality

High production efficiency

Reduced material waste

Improved product comfort

Enhanced product value

Investing in a professional перфорационная машина для кожи improves competitiveness.

10. Perforating Leather Quality Control Standards

Quality inspection includes:

Hole diameter accuracy

Edge smoothness

Pattern alignment

Structural integrity

A reliable perforating leather machine manufacturer ensures machines meet strict quality standards.

11. Challenges in Perforating Leather and Solutions

Common challenges:

Leather Stretching

Solution: Vacuum fixation systems

Burr Formation

Solution: Precision tooling

Hole Deformation

Solution: Controlled punching force

Material Damage

Solution: Optimized machine parameters

Advanced перфорационная машина для кожи engineering solves these issues.

12. Perforating Leather Machine Selection Guide

При выборе перфорационная машина для кожи, consider:

Production volume

Pattern complexity

Material types

Уровень автоматизации

Budget

An experienced perforating leather machine manufacturer provides customized solutions.

13. Why Choose Anze for Perforating Leather Equipment

Anze offers:

20 years of industry experience

Over 20 machine models

CNC and mould perforation solutions

Customized engineering services

Global customer support

Как профессионал perforating leather machine manufacturer, Anze delivers reliable technology

14. Future Trends in Perforating Leather Technology

The future of perforating leather includes:

AI-assisted pattern generation

Smart material detection

Integrated inspection systems

Fully automated production lines

Innovation continues to drive machine performance improvements.

The Importance of Advanced Perforating Leather Solutions

The process of perforating leather has evolved into a high-precision industrial technology requiring advanced equipment and engineering expertise.

Современный перфорационная машина для кожи solutions provide manufacturers with:

Higher productivity

Better product quality

Greater design flexibility

Improved competitiveness

With extensive experience and continuous innovation, Anze provides complete perforating leather solutions trusted worldwide.

Имея опытную и квалифицированную команду, мы знакомы со всеми видами характеристик материалов и технологией обработки, и можем настроить перфорирование кожи машина в соответствии с потребностями клиентов. Любые вопросы, пожалуйста, свяжитесь с нами! Whatsapp +86 180 0298 0031

Как установить и обслуживать машину?

Некоторые модели поставляются в собранном виде с завода. Крупное оборудование упаковывается из нескольких частей, и к нему прилагается руководство по установке. Все оборудование снабжено руководствами пользователя на китайском и английском языках.

Клиенты могут прислать кого-нибудь на завод Anze для обучения, или мы отправим технических экспертов для проведения обучения на месте.

Какие требования предъявляются к рабочей среде машины?

Сайт CNC кожа штамповка машина Следует закреплять на устойчивом столе и поддерживать чистоту и порядок, чтобы избежать контакта с пылью, статическим электричеством, влажностью и стружкой, что может привести к поломке деталей.

Как обстоят дела с послепродажным обслуживанием?

У нас есть опытная команда послепродажного обслуживания 24 часа в сутки в режиме онлайн и полная система послепродажного обслуживания. Заводская поддержка обучения, видео-техническое доступны для обслуживания машин за рубежом. поддержка, онлайн-поддержка, инженеры.

Вы готовы пригласить вас на место?

Конечно же, мы приглашаем вас посетить нашу компанию и пообщаться с вами лицом к лицу для развития взаимного бизнеса.

Каков срок доставки?

Время выполнения заказа варьируется в зависимости от количества заказа и настройки, обычно составляет от 7 до 10 рабочих дней. Если это индивидуальный заказ машины для пробивки кожи, это займет 1-2 месяца.