Última atualização em 2025-02-20 por Anze

In the modern automobile manufacturing industry, the design and manufacture of automobile interiors is not only a reflection of vehicle functionality, but also an important part of vehicle brand value and user experience. Among them, leather, as one of the main materials for automobile interiors, is widely used in seats, steering wheels, headrests and other parts with its high-end, comfortable and durable characteristics. Perfuração de couro technology, as a key means to improve the aesthetics and functionality of interiors, is gradually becoming a popular technology in automobile interior manufacturing. This article will explore in depth the leather punching solutions for automobile interiors, covering punching solutions for seat leather punching, steering wheel leather punching, headrest leather punching and other parts, aiming to provide readers with a comprehensive and systematic guide to automobile interior leather punching.

1. Significance of automobile interior leather punching

With the rapid development of the automobile industry and the continuous improvement of consumers’ requirements for automobile interior quality, leather punching technology has gradually become an important means to improve automobile interior quality and user experience. Leather punching can not only increase the beauty of the interior, but also improve the breathability and comfort of components such as seats and steering wheels, and reduce the feeling of stuffiness during long-term driving or riding. At the same time, the choice of punching patterns and arrangement methods can also highlight the brand characteristics and personalized style of the vehicle.

2. Seat leather punching solution

2.1 Purpose and significance of seat leather punching

As an important part of the car interior, the comfort and aesthetics of the seat are directly related to the passenger’s riding experience. Leather punching technology can increase the breathability and comfort of the seat by forming a regular hole pattern on the seat surface, and reduce the stuffiness and fatigue during long-term riding. At the same time, the design of the punching pattern can also enhance the beauty of the seat and the luxury of the vehicle.

2.2 Process flow of seat leather punching

The process flow of seat leather punching mainly includes four steps: material preparation, punching die design, punching operation and subsequent processing.

Material preparation: First, it is necessary to select leather materials suitable for punching. Generally speaking, leather with moderate thickness and uniform texture is more suitable for punching operations. At the same time, the leather needs to be pre-treated, such as cleaning and drying, to ensure the quality of punching.

Punching die design: The design of the punching die is a key link in the punching of seat leather. The design of the die should be customized according to the shape, size and punching pattern requirements of the seat. The die should have the characteristics of high precision, high durability and easy replacement to ensure the accuracy and consistency of the punching pattern.

Punching operation: During the punching operation, the leather material needs to be fixed on the punching machine and punched according to the design of the mold. During the punching process, parameters such as punching speed, force and frequency should be controlled to ensure the quality and efficiency of punching.

Subsequent processing: After punching, the leather needs to be processed, such as trimming the edges, removing burrs, etc., to ensure the flatness and aesthetics of the seat leather.

2.3 Pattern and arrangement of seat leather punching

The pattern and arrangement of seat leather punching should be designed according to the brand characteristics, interior style and user needs of the vehicle. Common punching patterns include regular shapes such as circles, squares, diamonds, and irregular shapes. The arrangement can be flexibly adjusted according to the shape and size of the seat, such as linear arrangement, staggered arrangement, etc. When designing the punching pattern and arrangement, the comfort and aesthetics of the seat should be taken into account to avoid discomfort caused by too dense or too sparse arrangement.

2.4 Quality control and inspection of seat leather punching

Quality control of seat perfuração de couro is an important link to ensure punching quality and seat quality. During the punching process, the punching die should be regularly inspected and maintained to ensure the accuracy and durability of the die. At the same time, the leather after punching should also be quality inspected, such as checking the integrity of the punching pattern, the flatness of the edge, and the tensile strength of the leather. Through strict quality control and testing methods, the quality and consistency of seat leather punching can be ensured.

3. Steering wheel leather punching solution

3.1 Purpose and significance of steering wheel leather punching

As an important part of the car interior, the feel and grip of the steering wheel directly affect the driver’s driving experience and safety. Leather punching technology can form a regular hole pattern on the surface of the steering wheel, increase the breathability and grip of the steering wheel, and reduce hand fatigue during long-term driving. At the same time, the design of the punching pattern can also enhance the beauty of the steering wheel and the luxury of the vehicle.

3.2 Process flow of steering wheel leather punching

The process flow of steering wheel leather punching is similar to that of seat leather punching, mainly including four steps: material preparation, punching die design, punching operation and subsequent processing. However, due to the special shape and size of the steering wheel, the following points need to be paid special attention to during the design and punching process of the punching die:

Customization of the punching die: The shape and size of the steering wheel are special, and the punching die needs to be customized according to the specific shape and size of the steering wheel. The die should have the characteristics of high precision, high durability and easy replacement to ensure the accuracy and consistency of the punching pattern.

Accuracy of the punching operation: During the punching operation, the accuracy of the punching position needs to be ensured to avoid problems such as deviation of the punching position or repeated punching. At the same time, it is also necessary to control parameters such as punching speed, force and frequency to ensure the quality and efficiency of punching.

The fineness of subsequent processing: After the punching is completed, the steering wheel leather needs to be finely processed, such as trimming the edges, removing burrs, etc., to ensure the flatness and aesthetics of the steering wheel. At the same time, the steering wheel needs to be tested and adjusted for grip to ensure that it meets the driver’s grip requirements.

3.3 Pattern and arrangement of steering wheel leather punching

The pattern and arrangement of steering wheel leather punching should be designed according to the brand characteristics, interior style and user needs of the vehicle. Common punching patterns include regular shapes such as circles, ovals, diamonds, and irregular shapes. The arrangement can be flexibly adjusted according to the shape and size of the steering wheel, such as linear arrangement, circular arrangement, etc. When designing the punching pattern and arrangement, the grip and aesthetics of the steering wheel should be taken into consideration to avoid discomfort caused by too dense or too sparse arrangement.

3.4 Quality control and inspection of steering wheel leather punching

Quality control of steering wheel leather punching is an important link to ensure the quality of punching and steering wheel quality. During the punching process, the punching mold should be inspected and maintained regularly to ensure the accuracy and durability of the mold. At the same time, the quality of the steering wheel leather after punching should also be inspected, such as checking the integrity of the punching pattern, the flatness of the edge, and the tensile strength of the leather. Through strict quality control and inspection methods, the quality and consistency of the steering wheel leather punching can be ensured.

4.Headrest leather punching solution

4.1 The purpose and significance of headrest leather punching

As an important part of the car interior, the comfort and aesthetics of the headrest are directly related to the passenger’s riding experience. Leather punching technology can increase the breathability and comfort of the headrest by forming a regular hole pattern on the surface of the headrest, and reduce the stuffiness and discomfort during long-term riding. At the same time, the design of the punching pattern can also enhance the aesthetics of the headrest and the luxury of the vehicle.

4.2 Process flow of headrest leather punching

The process flow of headrest leather punching is similar to that of seats and steering wheels, mainly including four steps: material preparation, punching die design, punching operation and subsequent processing. However, due to the special shape and size of the headrest, the following points need to be paid special attention to during the punching die design and punching operation:

Adaptability of punching die: The shape and size of the headrest are diverse, and the punching die needs to be customized according to the specific shape and size of the headrest. The die should have good adaptability and easy replacement to ensure the accuracy and consistency of the punching pattern.

Flexibility of punching operation: During the punching operation, the curved shape of the headrest and the limitations of the punching position need to be taken into account. Therefore, the punching operation should have high flexibility and be able to be adjusted and optimized according to the shape and size of different headrests.

Carefulness of subsequent processing: After punching, the headrest leather needs to be carefully processed, such as trimming the edges and removing burrs. At the same time, the headrest needs to be filled and fixed to ensure its comfort and stability.

4.3 Pattern and arrangement of headrest leather punching

The pattern and arrangement of headrest leather punching should be designed according to the brand characteristics, interior style and user needs of the vehicle. Common punching patterns include regular shapes such as circles, squares, diamonds, and irregular shapes. The arrangement can be flexibly adjusted according to the shape and size of the headrest, such as linear arrangement, staggered arrangement, etc. When designing the punching pattern and arrangement, the comfort and aesthetics of the headrest should be taken into account to avoid discomfort caused by too dense or too sparse arrangement.

4.4 Quality control and inspection of headrest leather punching

Quality control of headrest perfuração de couro is an important link to ensure the quality of punching and headrest. During the punching process, the punching mold should be inspected and maintained regularly to ensure the accuracy and durability of the mold. At the same time, the headrest leather after punching should also be quality inspected, such as checking the integrity of the punching pattern, the flatness of the edge, and the tensile strength of the leather. Through strict quality control and testing methods, the quality and consistency of the headrest leather punching can be ensured.

5.Other interior leather punching solutions

In addition to seats, steering wheels and headrests, there are many other parts in the car interior that can also be processed with leather punching technology. For example, door panels, armrest boxes, center consoles and other parts can increase their breathability and aesthetics through punching technology. The punching solutions for these parts are similar to those for seats, steering wheels and headrests, but they need to be customized and optimized according to the shape, size and purpose of the specific parts.

6.Innovation and development trend of leather punching technology

With the rapid development of the automobile industry and the continuous improvement of consumers’ requirements for the quality of automobile interiors, leather punching technology is also constantly innovating and developing. In the future, leather punching technology will show the following development trends:

6.1 Intelligence and automation

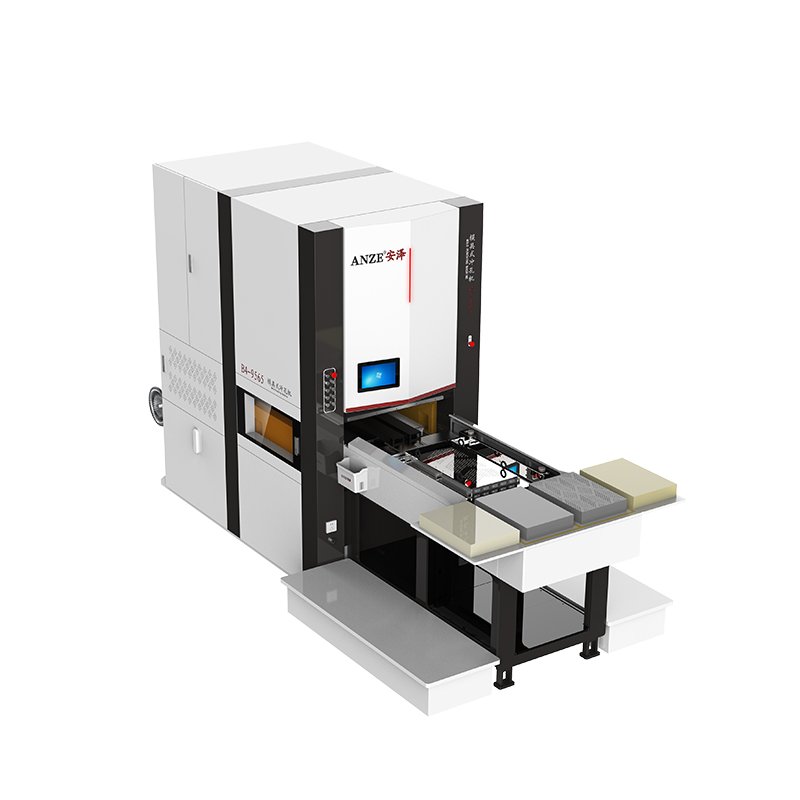

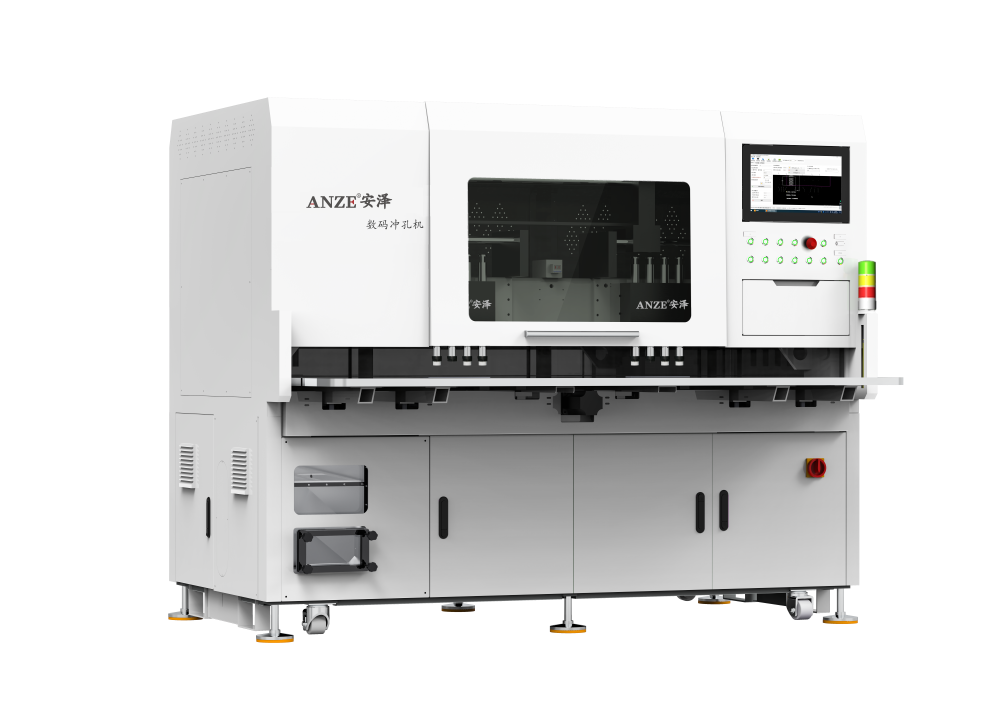

With the development of intelligent manufacturing technology, leather punching technology will gradually develop in the direction of intelligence and automation. By introducing advanced robots and automation equipment, leather punching can be automated and precisely controlled, improving production efficiency and product quality.

6.2 Personalization and customization

With the increasing demand for personalization by consumers, leather punching technology will pay more attention to personalized and customized services. By providing a variety of punching patterns and arrangement options, it can meet the personalized needs of different consumers and enhance the uniqueness and brand value of vehicles.

6.3 Environmental protection and sustainability

With the improvement of environmental awareness and the popularization of the concept of sustainable development, leather punching technology will pay more attention to environmental protection and sustainability. By adopting environmentally friendly materials and energy-saving technologies, energy consumption and environmental pollution in the production process can be reduced to achieve green production.

6.4 Multifunctionality

In the future, leather punching technology will not only be limited to increasing breathability and aesthetics, but will also develop in the direction of multifunctionality. For example, by integrating sensors and smart devices on leather, seat heating, ventilation, massage and other functions can be realized to enhance the comfort and experience of passengers.

improve the quality of automotive interiors

As one of the important means to improve the quality of automotive interiors and user experience, automotive interior perfuração de couro technology is gradually becoming a popular technology in the automotive manufacturing industry. By punching leather on seats, steering wheels, headrests and other parts, the air permeability and aesthetics of the interior can be increased, and the comfort and brand value of the vehicle can be improved. In the future, with the continuous innovation of technology and the promotion of development trends, leather punching technology will play a more important role in the manufacturing of automotive interiors. We look forward to seeing the emergence of more innovative leather punching solutions, which will bring more possibilities and opportunities to automotive interior manufacturing.

Se quiser assistir a um vídeo sobre a máquina de perfuração de couro, visite nosso site YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Alguns modelos são enviados montados na fábrica. Equipamentos grandes são embalados em várias partes e um manual de instalação é fornecido. Todos os equipamentos são equipados com manuais do usuário em chinês e inglês.

Os clientes podem enviar alguém à fábrica da Anze para aprender ou nós enviamos especialistas técnicos para fornecer treinamento no local

A máquina deve ser fixada em uma mesa estável e o ambiente deve ser mantido limpo e organizado para evitar o contato com poeira, eletricidade estática, umidade e cavacos que possam causar falhas nas peças.

Temos uma equipe de pós-venda experiente, serviço on-line 24 horas e um sistema de pós-venda completo. Suporte de treinamento na fábrica, vídeo técnico disponível para manutenção de máquinas no exterior. suporte, suporte on-line, engenheiros.

É claro que estamos à disposição para visitar nossa empresa e nos comunicarmos pessoalmente para promover negócios mútuos.

O prazo de entrega varia de acordo com a quantidade e a personalização do pedido, geralmente de 7 a 10 dias úteis. Se o pedido for de uma máquina de perfuração de couro personalizada, levará de 1 a 2 meses.