experiência em que se pode confiar

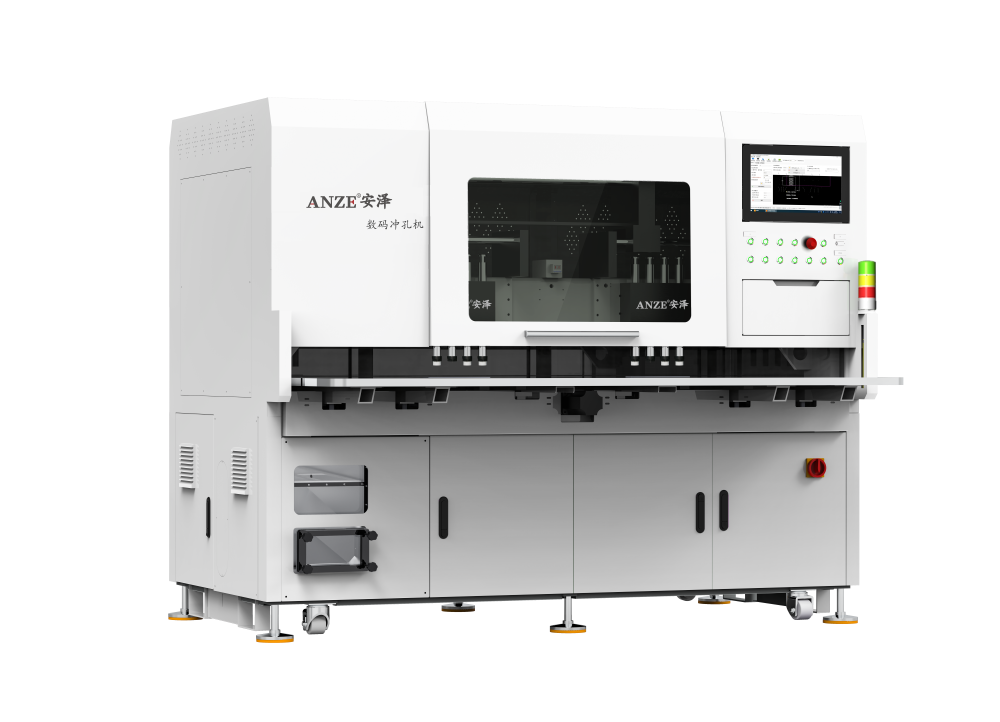

Máquina de perfuração de couro

By Anze R & D Capabilities

Desde 2005, a Anze se concentra no desenvolvimento e na fabricação de Máquina de perfuração de couro.

We are committed to providing our customers with better leather punching solutions by Anze higher R&D Capabilities!

Anze Strong R & D capability

Professional Experience In Leather Punching Machine

R&D ability

In order to provide better product quality and service to meet the needs of customers,our factory and products have passed a lot of inspection and certification, and obtained a lot of certificates. Anze has 25 invention patents of leather punching machine. Our R & D team focused on the research and development of punching equipment, R & D and engineering and technical personnel accounted for about 25% of the total number of employees, R & D investment of more than 30 million yuan.

customized ability

In the past years, Anze always stands at the perspective of meeting customer needs.we have provided customized-made leather punching machine for many brands in the automotive interior industry, soft furniture industry, sports shoes industry, etc.

R&D center

Which mainly studies the development trend of the customer's industry and the basic research of the development of the industry in the next 3-5 years, grasp the development needs of the customer's industry, and lay out in-depth solutions in advance,Anze has a forward-looking research and development center. And actively explore cutting-edge technologies such as software integration, supercomputing,AI artificial intelligence, visual recognition, unmanned automation, multi-tool head, Internet of Things, and multi-level sensors to meet customers' sustainable development needs.

Professional Experience

Anze Fabricação capacity

Manufacturing ability

Anze has two factories covering an area of 16,000 square meters, with more than 40+ highly trained and outstanding employees, with an annual production capacity of 2,000 units/sets of equipment. With the characteristics of digitalization, efficiency, flexibility and sustainability, Anze factory has established an intelligent punching equipment system integrating technology research and development, module manufacturing and complete machine production, which can complete the entire assembly process of more than 20 different models at the same time, and the production cycle is more than double that of the international industry.

Project Department

We have a special engineering center and project department, involving basic research of materials, material processing technology, mold design, fixture, process automation, equipment supporting automation, customized development of exclusive models, equipment component upgrade, etc., in order to provide customers with the best application solutions. And for the enterprise to bring continuous cost reduction and efficiency of effective measures to improve the overall competitiveness of enterprises.

Anze Strong Quality management capability

Professional Experience In Leather Punching Machine

Quality system

An intelligent manufacturing system have been established that integrates four processes of parts production, module manufacturing, electronic control installation, final assembly and debugging, and has a raw material inspection, finished product inspection, quality internal control laboratory and component testing center. High-speed moving parts with micron machining accuracy, a wide range of precision technology, efficient and accurate to complete the relevant processes. The quality management system covers the three core production areas of parts, mold components and complete machines, ensuring that the products delivered in each production link have gone through several strict quality assessments, and the quality runs through each link of product production.

The factory has passed ISO9001:2015 quality management system,ISO14001:2015 environmental management system, ISO45001:2018 Occupational health and safety management system,ISO10012:2003 measurement management system certification, and all products have passed the EU CE certification

Supply chain management

We promote the concept of green manufacturing, and with excellent supply chain management and cost management capabilities, it will vertically integrate and reorganize ten supply chain manufacturing units in 2024, with the strength of the whole industrial chain. Anze works with suppliers to build a sustainable green supply chain system. Anze works closely with more than 60 suppliers located within 50 kilometers of the plant headquarters to deliver projects on time and in batches according to the customer's investment plan, and to give customers satisfactory returns on investment at competitive investment costs over a long period of time.

Professional Experience

Anze‘s market influence

Market leadership

Anze deeply focuses on the challenges and needs of customers in leather punching, anticipates the expectations of customers, gathers the wisdom of all staff, provides breakthrough technical solutions, combines its own advantages (own manufacturing, own equipment, own materials, own cognition), and leads the development of the industry with cutting-edge knowledge and experience. Develop technical standards for the global market in many fields, create a leading market position in sales volume, and maintain a far leading global market share.

brand influence

Every year, Anze participates in more than 30 domestic and foreign exhibitions/summits/internal exchanges of brand owners/regional technical exchanges in various industries, occupying obvious advantages in many international markets such as South America, the Middle East and Southeast Asia. Continuous market activities and brand promotion investment make Anze's brand awareness well-known internationally and brand influence is increasing day by day.

Experimente o serviço perfeito de personalização da máquina de perfuração de couro

Receba as últimas notícias

Máquina de perfuração de couro

Com uma equipe experiente e qualificada, estamos familiarizados com todos os tipos de características de materiais e tecnologia de processamento, e podemos personalizar Máquina de perfuração de couro de acordo com as necessidades do cliente. Qualquer dúvida, entre em contato conosco! Whatsapp +86 180 0298 0031

Como instalar e fazer a manutenção da máquina?

Alguns modelos são enviados montados na fábrica. Equipamentos grandes são embalados em várias partes e um manual de instalação é fornecido. Todos os equipamentos são equipados com manuais do usuário em chinês e inglês.

Os clientes podem enviar alguém à fábrica da Anze para aprender ou nós enviamos especialistas técnicos para fornecer treinamento no local

Quais são os requisitos do ambiente de trabalho da máquina?

O Máquina de perfuração de couro CNC deve ser fixado em uma mesa estável e o ambiente deve ser mantido limpo e organizado para evitar o contato com poeira, eletricidade estática, umidade e cavacos que possam causar falhas nas peças.

Como são suas políticas de pós-venda?

Temos uma equipe de pós-venda experiente, serviço on-line 24 horas e um sistema de pós-venda completo. Suporte de treinamento na fábrica, vídeo técnico disponível para manutenção de máquinas no exterior. suporte, suporte on-line, engenheiros.

Você está disponível para convites no local?

É claro que estamos à disposição para visitar nossa empresa e nos comunicarmos pessoalmente para promover negócios mútuos.

Qual é o prazo de entrega?

O prazo de entrega varia de acordo com a quantidade e a personalização do pedido, geralmente de 7 a 10 dias úteis. Se o pedido for de uma máquina de perfuração de couro personalizada, levará de 1 a 2 meses.