Last Updated on 2025-05-25 by Anze

In the field of leather processing, continuous technological advancement is driving the industry to develop in a more efficient and smarter direction. Among them, the Máquina de perfuração de couro is one of the key equipments, and its level of automation and intelligence has been particularly significant. This article will deeply explore the innovative application of leather punching machines in automatic tool selection technology, automatic punching path planning technology, and automatic waste collection technology, showing how these technologies can jointly improve the efficiency and quality of leather processing. This article is about Anze leather punching machine: innovative application of automatic knife selection, path planning and waste collection technology

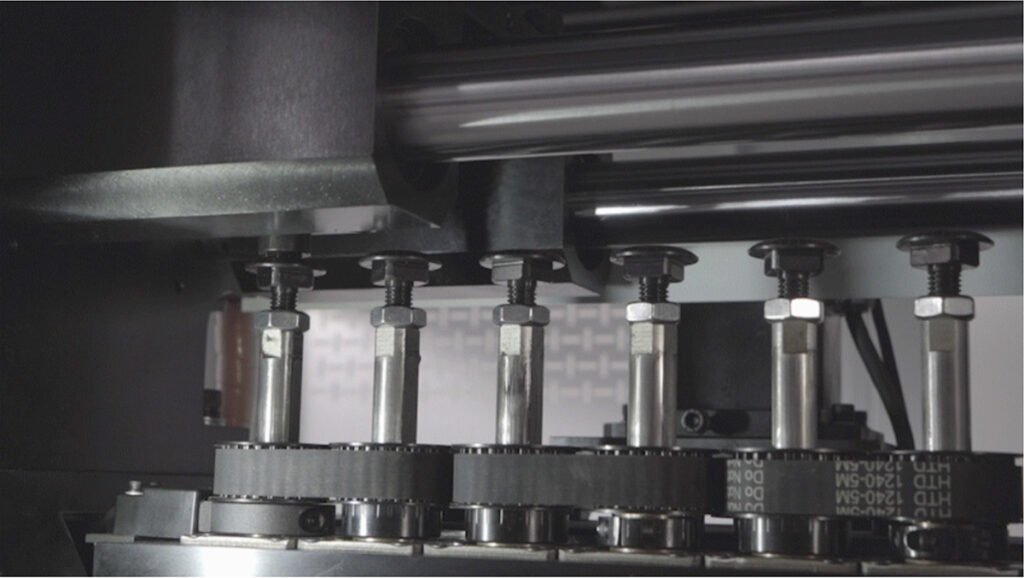

Automatic tool selection technology of leather punching machine

The automatic tool selection technology of the Máquina de perfuração de couro is a major innovation. It can automatically select the appropriate tool for punching operations according to the preset processing pattern and hole type requirements. This technology realizes the rapid matching and replacement of tools by integrating advanced recognition systems and tool library management systems. The operator only needs to enter the processing parameters or select the preset pattern, and the system can automatically analyze and select the most suitable tool combination, avoiding the tediousness and errors of traditional manual tool selection. The application of automatic tool selection technology not only significantly improves the processing efficiency, but also ensures the consistency and accuracy of punching, laying a solid foundation for improving the quality of leather products.

Automatic planning of punching path technology: optimize layout and reduce loss

In the process of perfuração de couro, the planning of punching path is of great significance to improve material utilization and reduce loss. Our leather punching machine adopts advanced automatic planning of punching path technology, analyzes the processing pattern through the built-in intelligent algorithm, and automatically calculates the optimal punching sequence and path. This technology can fully consider the texture, strength and other factors of the leather material, avoid unnecessary stretching or tearing during the punching process, and thus protect the integrity of the material. At the same time, automatic path planning can effectively reduce the tool’s empty stroke and improve processing efficiency. Through the application of this technology, the leather punching machine can maximize the material utilization rate while improving the processing speed.

Automatic waste collection technology: green environmental protection, clean production

In leather punching operations, the generation of waste is inevitable. However, the traditional manual cleaning method is not only inefficient, but also may pollute the environment. For this reason, our leather punching machine is equipped with automatic waste collection technology. This technology integrates an efficient waste collection system to collect the waste generated in real time during the punching process, avoiding environmental pollution and safety hazards caused by the scattering of waste. At the same time, automatic waste collection can also reduce the workload of manual cleaning and improve production efficiency. The application of this technology not only reflects our practice of environmental protection concepts, but also provides customers with cleaner and more efficient production solutions.

Anze leather punching machine continues to innovate

The innovative application of automatic tool selection technology, automatic punching path planning technology and automatic waste collection technology of leather punching machines have jointly promoted the intelligent upgrading of the leather processing industry. The integration of these technologies not only improves processing efficiency and ensures product quality, but also promotes green environmental protection and clean production. We believe that in the future development, with the continuous advancement and innovation of technology, Máquina de perfuração de couro will continue to lead the industry trend and contribute more to the prosperity and development of the leather processing industry.

Se quiser assistir a um vídeo sobre a máquina de perfuração de couro, visite nosso site YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Alguns modelos são enviados montados na fábrica. Equipamentos grandes são embalados em várias partes e um manual de instalação é fornecido. Todos os equipamentos são equipados com manuais do usuário em chinês e inglês.

Os clientes podem enviar alguém à fábrica da Anze para aprender ou nós enviamos especialistas técnicos para fornecer treinamento no local

A máquina deve ser fixada em uma mesa estável e o ambiente deve ser mantido limpo e organizado para evitar o contato com poeira, eletricidade estática, umidade e cavacos que possam causar falhas nas peças.

Temos uma equipe de pós-venda experiente, serviço on-line 24 horas e um sistema de pós-venda completo. Suporte de treinamento na fábrica, vídeo técnico disponível para manutenção de máquinas no exterior. suporte, suporte on-line, engenheiros.

É claro que estamos à disposição para visitar nossa empresa e nos comunicarmos pessoalmente para promover negócios mútuos.

O prazo de entrega varia de acordo com a quantidade e a personalização do pedido, geralmente de 7 a 10 dias úteis. Se o pedido for de uma máquina de perfuração de couro personalizada, levará de 1 a 2 meses.