Last Updated on 2025-11-01 by Anze

In modern automotive interiors, acoustic performance, aesthetics, and precision engineering coexist in perfect harmony. One of the most intricate components where these factors converge is the speaker grille leather — the perforated leather surface covering car speakers. This surface must not only allow sound to pass through with minimal distortion but also maintain luxury texture, durability, and visual uniformity. At the core of this process lies the perforating leather machine, a specialized system engineered to deliver high-precision perforation patterns on leather surfaces used in automotive interiors.

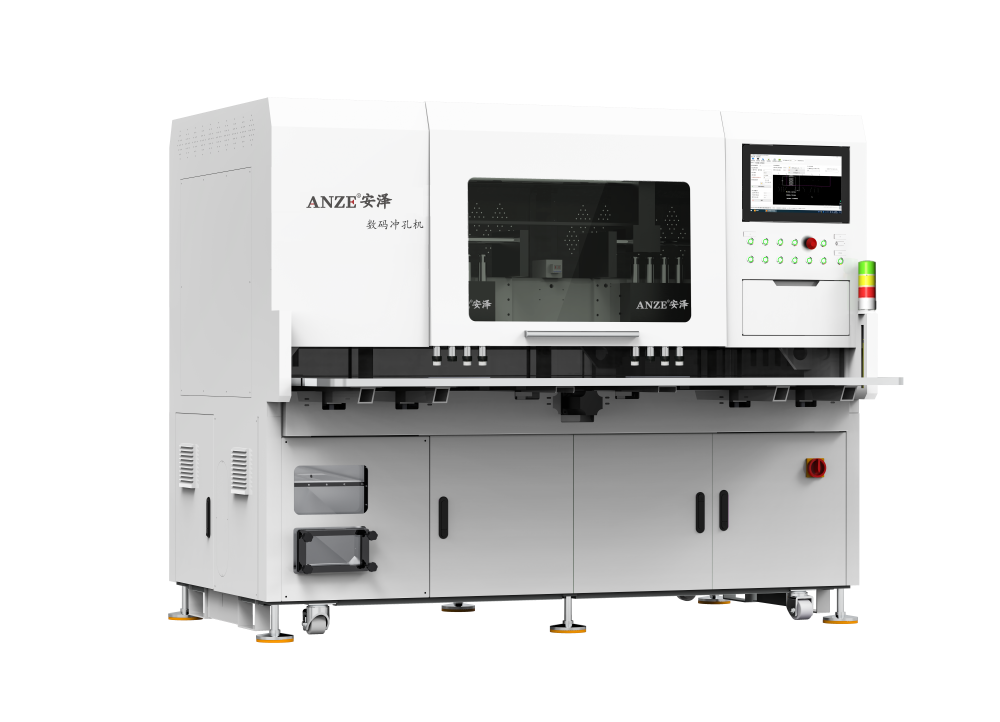

Anze, a professional perforating leather machine manufacturer with more than 20 years of design and manufacturing experience, has become a global leader in developing advanced systems for automotive leather perforation — including seats, door trims, dashboard panels, and speaker grille applications. With over 20 high-performance machine models, Anze provides customized perforation solutions that meet the rigorous standards of global automotive OEMs.

1. The Role of Leather Perforation in Automotive Speaker Grilles

Automotive speaker grille perforation serves both functional and aesthetic purposes.

Acoustic Transparency:

The perforation pattern directly affects sound transmission. A properly engineered perforation layout minimizes sound diffusion and maintains high-fidelity output from in-car audio systems.Heat Dissipation & Ventilation:

Perforated leather supports air flow and helps prevent local heat buildup around speaker zones.Design Consistency:

Perforated leather enhances the overall luxury appeal, providing a seamless, unified design language across the interior.

Thus, the precision of a perforating leather machine determines the balance between acoustics, texture, and visual harmony.

2. Understanding the Perforating Leather Machine

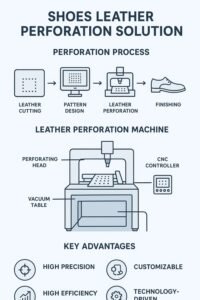

A perforating leather machine is an automated industrial system that uses mechanical or laser-driven punching tools to create uniform holes or micro-patterns in leather materials.

2.1. Key Components

Servo-Driven Feed System:

Controls material movement with micrometer accuracy.Punching Head or Laser System:

Executes the perforation pattern according to digital control.Vacuum Table:

Stabilizes soft leather during perforation to prevent shifting.CNC Controller:

Manages hole density, spacing, and alignment.Vision Calibration Module:

Ensures pattern accuracy, compensating for natural leather irregularities.

2.2. Machine Variants

Mechanical Perforating Leather Machine – Ideal for thick or natural leather.

Laser Perforating Leather Machine – Suitable for synthetic or coated leathers.

Hybrid Perforating Machine – Combines mechanical punching and digital laser finishing for complex textures.

Anze’s latest generation machines incorporate CNC motion control, AI-based defect correction, and multi-zone suction platforms to guarantee consistent quality and acoustic performance.

3. The Science Behind Acoustic Perforation

Acoustic transparency depends on hole diameter, pattern distribution, and open area ratio (OAR). For speaker grille leather, typical hole diameters range from 0.8 mm to 1.5 mm, with an OAR between 10–20%.

| Parameter | Typical Range | Acoustic Effect |

|---|---|---|

| Hole Diameter | 0.8 – 1.5 mm | Affects high-frequency transparency |

| Hole Pitch | 2.0 – 3.5 mm | Controls air flow and tonal clarity |

| Open Area Ratio | 10–20% | Determines loudness and texture uniformity |

| Pattern Shape | Circular / Hexagonal | Influences dispersion and visual symmetry |

The perforating leather machine must maintain ±0.05 mm tolerance to achieve optimal sound balance while preventing visual distortion on curved speaker grille surfaces.

4. Perforation Techniques for Automotive Speaker Leather

4.1. Rotary Die Perforation

Utilizes rotating dies with patterned pins.

Suitable for high-speed production of uniform holes.

Ideal for synthetic or thin leather materials.

4.2. CNC Punch Perforation

Servo-controlled punching with programmable patterns.

Allows multi-zone hole density variation.

Preferred for natural leather to reduce tearing.

4.3. Laser Micro-Perforation

Uses high-precision laser beams to burn microholes.

Offers extreme precision and flexibility for fine acoustic tuning.

Best for speaker covers requiring customized sound dispersion.

Each of these methods requires careful parameter tuning — punch pressure, feed rate, and vacuum suction — to avoid leather deformation or discoloration.

5. Process Workflow Using Anze’s Perforating Leather Machine

Material Preparation

Leather sheets are cleaned, humidified, and flattened.

Surface grain direction and elasticity are recorded.

Pattern Programming

Engineers import CAD-based designs into the machine control system.

Perforation density and zones are defined.

Test Calibration

A short trial run ensures hole spacing, diameter, and acoustic OAR meet the required tolerance.

Full-Scale Perforation

CNC-controlled punching or laser modules execute perforation.

Real-time vision inspection corrects drift or deviation.

Post-Processing

Dust removal, heat treatment, and surface sealing maintain cleanliness and durability.

Samples undergo acoustic and tensile testing.

Anze’s machines integrate closed-loop feedback control, ensuring that every hole aligns precisely — critical for acoustic-grade speaker leather.

6. Engineering Considerations and Quality Control

6.1. Material Variability

Natural leather varies in density and elasticity. A smart perforating leather machine automatically adjusts punching force to maintain hole consistency.

6.2. Thermal Management

For laser-based systems, heat buildup can cause edge darkening. Anze’s laser modules include pulse modulation to minimize thermal impact.

6.3. Acoustic Testing

Finished materials undergo frequency response testing to confirm sound transparency across 100 Hz–20 kHz.

6.4. Visual Inspection

AI-assisted cameras scan each sheet to detect hole deviation, burrs, or incomplete perforations.

6.5. Durability Validation

Post-perforation samples are tested for tear strength, flex resistance, and UV color stability per ISO 17075 and SAE J3234 standards.

7. Safety and Maintenance Guidelines

Operating a perforating leather machine requires strict adherence to safety protocols:

Ensure vacuum platform stability before each cycle.

Regularly replace punch heads and dies to prevent burr formation.

Calibrate CNC axes weekly to maintain ±0.05 mm tolerance.

Keep the air filtration system clean to remove perforation debris.

For laser units, inspect optical lenses after every 100 operating hours.

Preventive maintenance extends machine lifespan and ensures continuous acoustic precision.

8. Case Study: Anze’s Perforating Leather Machine in Automotive Speaker Production

8.1. Project Overview

A global automotive OEM required perforated leather for a new premium SUV speaker grille. Key goals were:

Uniform micro-perforation pattern (Ø1.0 mm)

15% open area ratio

No visual distortion or edge discoloration

Acoustic transmission loss <1.5 dB

8.2. Solution

Anze deployed its Model AZ-LP500 CNC perforating leather machine, equipped with:

Dual-head servo punch unit

AI vision alignment system

Active vacuum platform

Real-time acoustic mapping module

8.3. Results

Hole uniformity: ±0.03 mm

Acoustic transparency: 99.2% of base material

Reject rate: <0.5%

Production efficiency improved by 27%

The OEM later standardized Anze’s equipment across multiple global production lines, citing precision, stability, and process repeatability as key advantages.

9. Future Trends in Leather Perforation Technology

9.1. Digital Pattern Modulation

AI-driven systems dynamically adjust perforation density based on acoustic frequency zones, optimizing speaker output.

9.2. Eco-Friendly Production

Anze is researching energy-efficient punching modules and recyclable air filtration systems to reduce environmental impact.

9.3. Hybrid Laser-Mechanical Platforms

Future machines will combine mechanical punching for main holes and laser finishing for micro-tuning — ideal for luxury-grade speaker designs.

10. Why Choose Anze as Your Perforating Leather Machine Partner

With over 20 years of continuous innovation, Anze stands among the world’s most trusted perforating leather machine manufacturers.

Key advantages:

Comprehensive product range – over 20 models for different leather thicknesses and patterns.

Global application expertise – automotive seats, door panels, speaker grilles, and interior trim.

Precision manufacturing – CNC control, servo synchronization, and AI correction modules.

Custom solutions – tailored perforation parameters for unique acoustic and aesthetic needs.

After-sales support – calibration, training, and spare parts available worldwide.

Anze continues to redefine precision leather perforation — blending craftsmanship, automation, and acoustic science.

high-quality perforating leather machine ensures every hole is consistent

The evolution of automotive speaker grille leather highlights how technology enhances both functionality and luxury in modern vehicles. A high-quality perforating leather machine ensures every hole is consistent, acoustically balanced, and visually perfect.

By integrating CNC precision, AI inspection, and acoustic validation, Anze provides complete perforation solutions trusted by global automotive manufacturers.

Whether your production requires intricate micro-perforation for acoustic clarity or large-scale decorative perforation for design continuity, Anze’s perforating leather machines offer unmatched precision, performance, and reliability.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.