Last Updated on 2025-12-05 by Anze

1. Introduction to Micro Perforation in Leather and Microfiber Processing

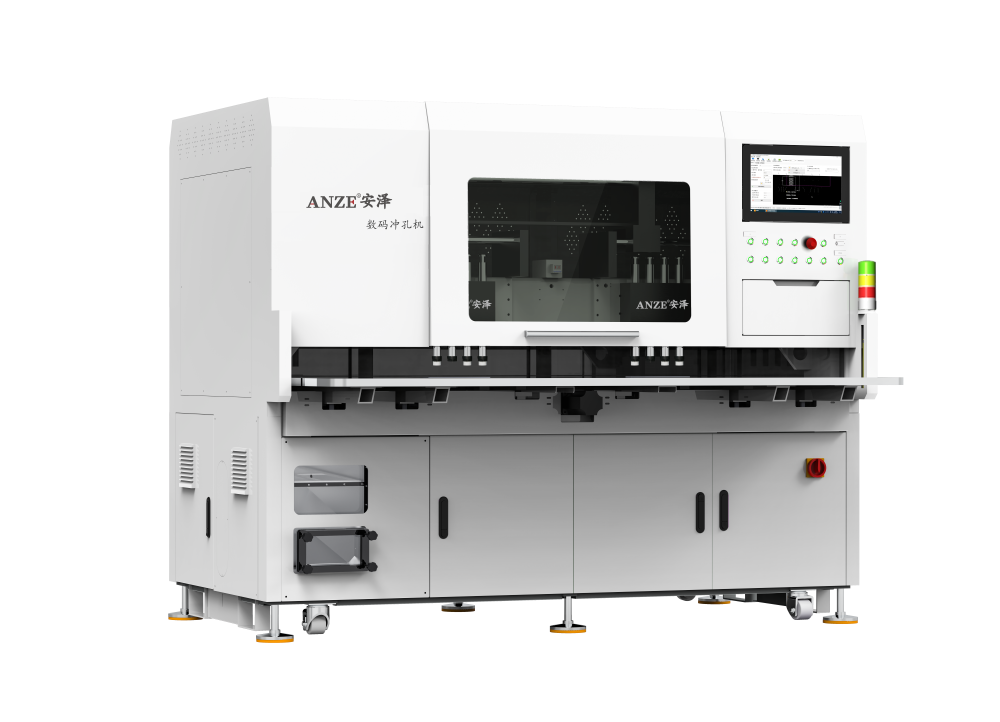

Micro perforation has become a mission-critical process in modern leather and microfiber manufacturing. Automotive interiors, premium footwear, luxury bags, furniture upholstery, and high-end electronics all require materials with controlled airflow, acoustic performance, and aesthetic micro-patterning.To achieve this level of precision, manufacturers rely on a micro perforation machine — a specialized production system engineered for ultra-small, high-density perforation patterns on leather and microfiber substrates.

Anze, with 20 years of experience developing leather perforation equipment and more than 20 successful machine models, is recognized as one of the most mature technology providers in the global perforation sector.

2. What is a Micro Perforation Machine?

A micro perforation machine is a precision punching or laser-processing system designed to create extremely small, consistent holes in flexible materials such as:

Natural leather

Microfiber leather

PU and synthetic leather

Automotive interior composites

Upholstery materials

Fashion-grade microfibers

The typical hole diameter produced by a micro perforation machine ranges between:

0.3 mm – 1.0 mm for leather

0.15 mm – 0.8 mm for microfiber

These micro holes improve ventilation, reduce material stiffness, enhance acoustic absorption, and create visually refined surfaces for premium consumer products.

3. Why Micro Perforation Matters in Modern Manufacturing

Micro perforation is not merely an aesthetic technique. It delivers structural and functional benefits:

3.1 Ventilation Performance

Uniform micro holes significantly increase airflow, enabling:

Cooler automotive seat surfaces

Breathable footwear linings

Comfortable bag straps and cushions

3.2 Acoustic Absorption

Perforated leather improves cabin acoustics in cars, reducing echo and noise.

3.3 Weight Reduction

Micro-perforated surfaces reduce material density without weakening structural integrity.

3.4 Precision Aesthetics

Luxury brands use micro patterns to differentiate premium product lines.

These benefits require a high-accuracy micro perforation machine engineered for reliable industrial operation.

4. Engineering Requirements for a High-Performance Micro Perforation Machine

A professional-grade micro perforation machine must meet strict engineering specifications:

4.1 Punching or Laser Precision

Hole diameter tolerance: ±0.02–0.05 mm

Edge smoothness: No burning, tearing, or fiber uplift

4.2 Material Stability Controls

Leather tension control system

Microfiber anti-stretch alignment modules

Servo-synchronized feeding motors

4.3 Industrial Productivity

Continuous operation

High-speed pattern switching

Low downtime and low tool wear

4.4 Digital Pattern Programming

CAD pattern input

Custom micro-pattern generation

Repeatability for mass production

These engineering foundations determine the reliability of the micro perforation process.

5. Types of Micro Perforation Machine Technologies

Modern manufacturing uses three primary perforation technologies.

5.1 Mechanical Micro Punching

Mechanical systems utilize custom micro punching dies:

Advantages:

High pattern uniformity

Excellent hole edge quality

Long-term low operating cost

Stable for thick leather

Disadvantages:

Requires periodic die replacement

Limited to predefined hole geometries

This method is ideal for automotive seats, bags, shoes, and furniture.

5.2 Laser Micro Perforation

Laser perforation uses precise beam control to vaporize micro holes.

Advantages:

Flexible hole shapes and patterns

Zero die changeover time

Suitable for ultra-thin microfibers

Disadvantages:

Potential heat burn marks

Slower for large-area punching

Higher energy cost

This technique is often used for fashion microfiber and electronics leather panels.

5.3 Hybrid Micro Perforation Machines

Hybrid systems include both mechanical punching and laser tools.

Advantages:

Full design flexibility

Optimized for premium surface finishing

Reduced process limitations

This is the direction many global OEMs are moving toward.

6. Step-by-Step Process: How a Micro Perforation Machine Works

Step 1 — Material Preparation

Humidity level 40–60%

Flatness guaranteed within tolerance

No surface wax residue

Step 2 — Loading & Alignment

Servo-feeding systems adjust material tension

Vision sensors ensure positional accuracy

Step 3 — Pattern Programming

CAD files define:

Hole shape

Hole spacing

Density

Direction

Step 4 — Micro Perforation Execution

Depending on machine type:

Punching dies strike the surface

Laser beams micro-vaporize holes

Step 5 — Extraction & Waste Removal

Micro-dust suction

Waste-particulate filtration

Step 6 — Quality Inspection

AI vision measurement

Sample tensile test

Hole uniformity evaluation

Step 7 — Final Output & Cutting

Rolls or sheets

Ready for sewing or lamination

This controlled sequence ensures consistent industrial results.

7. Key Technical Parameters of a Micro Perforation Machine

| Parameter | Typical Range | Engineering Notes |

|---|---|---|

| Hole Diameter | 0.15–1.0 mm | Depends on material |

| Speed | 50,000–180,000 holes/min | Based on pattern density |

| Tolerance | ±0.02–0.05 mm | Critical for automotive |

| Feeding Accuracy | ±0.1 mm | Servo-controlled |

| Punch Life | 1–5 million cycles | Material hardness dependent |

| Laser Power | 100–600W | Microfiber optimized |

These parameters determine machine capability in mass production.

8. Material Considerations: Leather vs Microfiber

8.1 Natural Leather

Variable fiber density

Sensitive to heat

Risk of burn marks or cracks

Best method: Mechanical micro punching

8.2 Microfiber Leather

Uniform density

Heat-resistant in controlled range

Designed for high-end interiors and footwear

Best method: Laser or hybrid micro perforation

9. Engineering Challenges in Micro Perforation & How Machines Solve Them

Challenge 1: Leather Stretching

Solution: Servo-tension system

Challenge 2: Hole Angle Deviation

Solution: Automatic alignment correction

Challenge 3: Surface Burn (Laser)

Solution: Controlled pulse energy + cooling

Challenge 4: Die Wear

Solution: High-hardness tungsten dies

A professional micro perforation machine integrates solutions into its core structure.

10. Application Scenarios for Micro Perforation Machines

10.1 Automotive Interiors

Seats

Steering wheel covers

Door panels

Acoustic components

10.2 Footwear

Sneaker uppers

Athletic liners

Leather ventilation systems

10.3 Luxury Bags & Accessories

Designer bag panels

Straps

Wallets

10.4 Furniture & Upholstery

Sofas

Office chairs

Home seating

10.5 Consumer Electronics Leather

Smart speaker covers

Laptop and tablet cases

Each industry requires specific micro-pattern designs.

11. Quality Inspection Standards for Micro Perforation

11.1 Hole Diameter Deviation

Must meet ±0.02–0.05 mm tolerance.

11.2 Hole Roundness

No oval deformation.

11.3 Color Consistency

No discoloration on laser-processed microfiber.

11.4 Material Integrity

Leather tear-resistance must remain within acceptable range.

11.5 Air Permeability Testing

Measured using airflow test systems.

A micro perforation machine must support high repeatability across thousands of meters.

12. How AI Vision Systems Improve Micro Perforation Accuracy

Modern micro perforation machines increasingly use:

Real-time camera inspection

Pattern deviation detection

Automatic correction algorithms

AI-guided feeding alignment

These systems ensure almost zero scrap during mass production.

13. Advantages of Anze’s Micro Perforation Machine

Anze integrates over 20 years of industry expertise into our machines:

13.1 High-Speed Industrial Operation

Optimized for continuous factory use.

13.2 Ultra-Precise Pattern Control

Patent-grade feeding & servo algorithms.

13.3 Compatibility with Leather and Microfiber

Designed for multi-material versatility.

13.4 Low Maintenance

High-durability components reduce downtime.

13.5 Custom Engineering

Anze provides OEM customization for automotive and luxury brands worldwide.

14. Why Global Manufacturers Choose Anze

Mature technology

Professional pre-sales engineering support

Global export experience

Reliable remote diagnostics

Proven machine lineup (20+ models)

Anze’s micro perforation machine is trusted in automotive, footwear, bag, and furniture sectors.

Micro perforation is a precision engineering process essential to modern leather and microfiber manufacturing

Micro perforation is a precision engineering process essential to modern leather and microfiber manufacturing. A high-quality micro perforation machine ensures stable production, refined appearance, and consistent performance across industries.

With decades of innovation, Anze provides an advanced and reliable solution for global manufacturers seeking excellence in micro-perforated materials.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.