Last Updated on 2025-02-20 by Anze

In the leather processing industry, punching is a crucial process. It not only affects the appearance of leather products, but also directly affects the breathability and comfort of the products. With the increasing market demand for leather products, how to achieve mass punching of leather and improve production efficiency and product quality has become an important issue facing leather processing companies. This article will explore in depth the methods, leather punching machine technological innovations and applications of mass punching of leather in actual production, and provide a useful reference for leather processing companies.

1. Traditional methods for mass punching of leather

In the past, mass punching of leather mainly relied on traditional manual punching and mechanical punching.

Manual punching

Manual punching is the most primitive punching method. It relies on the manual operation of craftsmen and uses a punch to punch holes on the leather point by point. Although this method is flexible, it is extremely inefficient and difficult to meet the needs of mass production. In addition, the accuracy and consistency of manual punching are difficult to guarantee, which easily leads to uneven product quality.

Mechanical punching

With the rise of mechanized production, mechanical punching has gradually become the mainstream method for mass punching of leather. Mechanical punching machines automatically punch holes in leather using preset molds and punches. Compared with manual punching, mechanical punching has significantly improved efficiency and precision. However, traditional mechanical leather punching machines still have some shortcomings, such as cumbersome mold replacement, single punching shape, and inability to adapt to complex patterns.

2. Modern methods for mass punching of leather

With the continuous advancement of science and technology, methods for mass punching of leather are also constantly innovating and developing. Modern methods for mass punching of leather mainly include laser punching, CNC punching, and water jet punching.

Laser punching machine

Laser punching is a technology that uses high-energy laser beams to ablate and punch holes on the surface of leather. It has the advantages of high precision, high efficiency, and contactless processing, and can adapt to the punching needs of various complex patterns and shapes. The laser punching machine can accurately control the moving path and energy output of the laser beam through a computer control system to achieve automated and precise punching operations. In addition, laser punching is also environmentally friendly and pollution-free, which meets the green production requirements of modern industry.

CNC leather punching machine

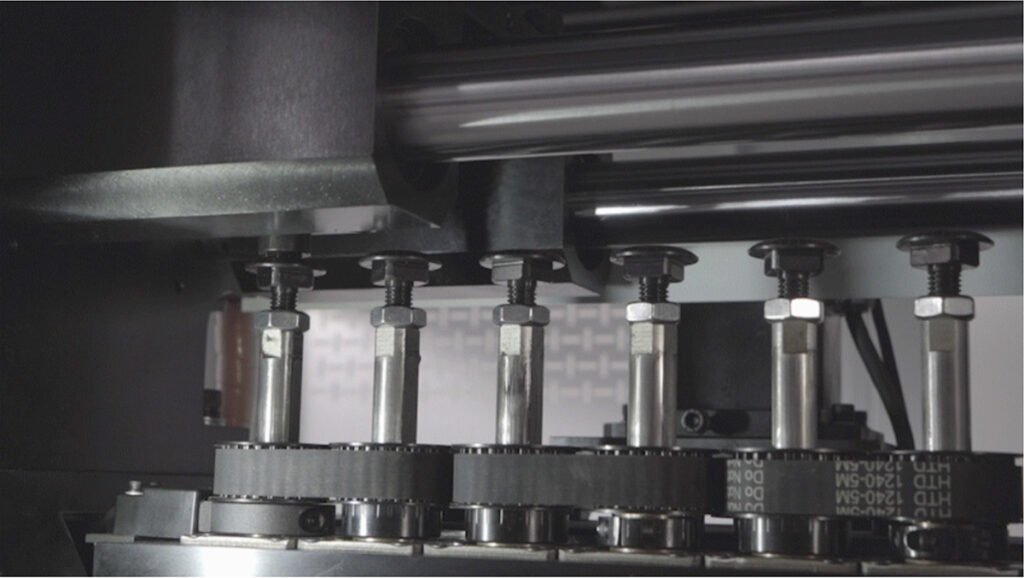

CNC (computer numerical control) punching is a technology that uses a computer to control a punching machine for automated punching. The CNC punching machine automatically controls the movement and punching force of the punch by reading the preset punching program to achieve high-precision punching operations. The CNC punching machine can adapt to punching needs of various shapes and sizes, and has fast punching speed and high efficiency. In addition, the CNC punching machine also has the advantages of convenient mold replacement and easy maintenance, which greatly improves production efficiency and product quality.

Water jet punching

Water jet punching is a technology that uses high-pressure water flow to cut and punch leather. It pressurizes water to extremely high pressure and forms an extremely fine water jet through a special nozzle to cut and punch leather at high speed. Water jet punching has the advantages of no heat-affected zone, smooth cutting edges, no burrs, and can cut patterns of various complex shapes. However, the cost of water jet punching equipment is high, and there are certain requirements for water quality and environmental conditions.

3. Technological innovation of mass punching of leather

In order to achieve more efficient and accurate mass punching of leather, technicians are constantly innovating and developing technology. The following are some important technical innovations:

Intelligent control system

The intelligent control system is an important part of modern leather punching machines. By integrating advanced sensors, controllers and algorithms, the intelligent control system can monitor various parameters in the punching process (such as punching speed, force, position, etc.) in real time, and automatically adjust and optimize according to the preset process requirements. This can not only improve the accuracy and consistency of punching, but also effectively reduce the scrap rate and improve production efficiency.

Multifunctional mold design

In order to meet the needs of punching of different shapes and sizes, technicians have developed multifunctional mold design technology. This technology enables the punching machine to easily adapt to punching operations of various complex patterns and shapes through modular and replaceable mold design. In addition, the multifunctional mold design also reduces the frequency and cost of mold replacement, and improves production efficiency and flexibility.

Automatic loading and unloading system

In order to achieve fully automated production of mass punching of leather, technicians have developed an automated loading and unloading system. The system automatically feeds the leather to be punched into the punching machine for processing through automated equipment such as robotic arms and conveyor belts, and automatically takes out the finished product after processing. The automated loading and unloading system not only improves production efficiency, but also reduces labor costs and labor intensity.

Green environmental protection materials and technologies

With the improvement of environmental awareness, green environmental protection materials and technologies have gradually become an important development direction of the leather punching industry. Technicians have reduced energy consumption and pollution emissions in the leather punching process by developing new environmental protection materials (such as biodegradable materials, recyclable materials, etc.) and adopting green production processes (such as low-temperature punching, no wastewater discharge, etc.). This not only helps to protect the environment, but also enhances the social responsibility and brand image of the company.

4. Application of mass punching of leather in actual production

Mass punching technology of leather has a wide range of applications in actual production. The following are some typical application scenarios:

Footwear manufacturing

In footwear manufacturing, mass punching technology of leather is widely used in the processing of uppers, insoles and other parts. Through precise punching operations, footwear products with breathability and comfort can be produced. In addition, the design of punching patterns and shapes also directly affects the aesthetics and fashion sense of footwear.

Bag manufacturing

In bag manufacturing, leather mass punching technology is used to punch parts such as bag bodies and hand straps. Accurate punching operations can not only improve the aesthetics and practicality of bags, but also increase the added value and competitiveness of products.

Furniture manufacturing

In furniture manufacturing, leather mass punching technology is used in the processing of leather covers for furniture such as sofas and chairs. Through punching operations, the air permeability and comfort of furniture can be improved, while increasing the aesthetics and personalized design elements of products.

leather punching machine application

Leather mass punching is an important link in the leather processing industry. With the continuous advancement of science and technology and the continuous changes in market demand, leather mass punching technology is also constantly innovating and developing. By introducing innovative points such as intelligent control systems, multi-functional mold design, automated loading and unloading systems, and green environmentally friendly materials and technologies, leather mass punching technology has achieved a more efficient, more accurate, and more environmentally friendly production method. The application of these technologies not only improves production efficiency and product quality, but also reduces production costs and environmental pollution, laying a solid foundation for the sustainable development of the leather processing industry. In the future, with the continuous advancement of technology and the continuous expansion of the market, leather mass punching technology will be widely used in more fields, bringing more convenience and beauty to people’s lives.

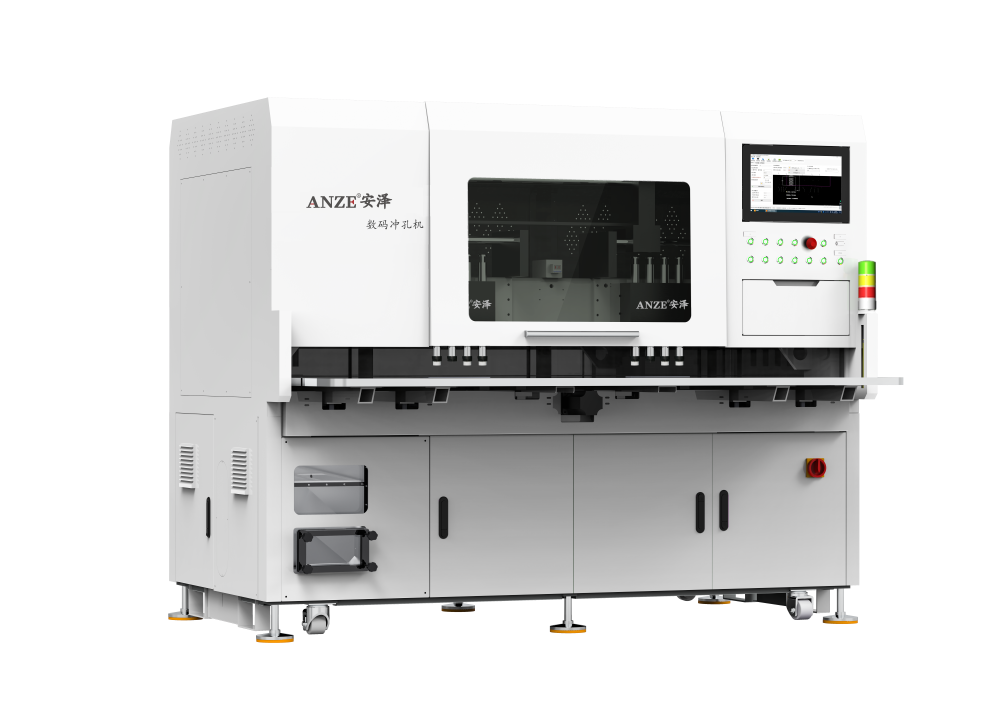

Anze factory custom leather punching machine

Dongguan Anze Automation Equipment Co., Ltd. is located in Dongguan City,Guangdong Province. Founded in 2005, the company has been focusing on the punching industry for nearly 20 years and currently covers a comprehensive area of 5000 squaremeters. The company specializes in CNC leather punching machines, mould leather punching machines,leather bag punching machine,luggage leather punching machine,shoes leather punching machine,furniture leather punching machine and other equipment.

If you want to watch video of leather punching machine,please visit our YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.