Last Updated on 2025-02-19 by Anze

This article is the second part of leather punching machine market analysis. This article mainly introduces the market competition pattern, competition strategy and means, policy environment and future development trend of leather punching machine industry. This paper first analyzes the product characteristics of major manufacturers in the market, such as high precision, high efficiency, diversification, customization, etc., and discusses the strategies of major manufacturers to enhance competitiveness through continuous innovation and improving product performance and quality. At the same time, the article also analyzes the impact of environmental protection laws and regulations, manufacturing policies and trade regulations on the leather punching machine industry, as well as the normative role of industry standards and regulatory requirements on enterprise production and services.

This is the second part of the research report, click here to read the first part of the research report.

Chapter 5 Analysis of the competitive landscape of the leather punching machine market

5.1 Main manufacturers and product features

In the global high-speed precision punching machine market, in the past few years, with the continuous advancement of technology and the diversified needs of the market, a number of manufacturers with significant influence have emerged. These manufacturers have their own characteristics in the market and have their own advantages and strategies. The following is a detailed analysis of several major manufacturers and their product features.

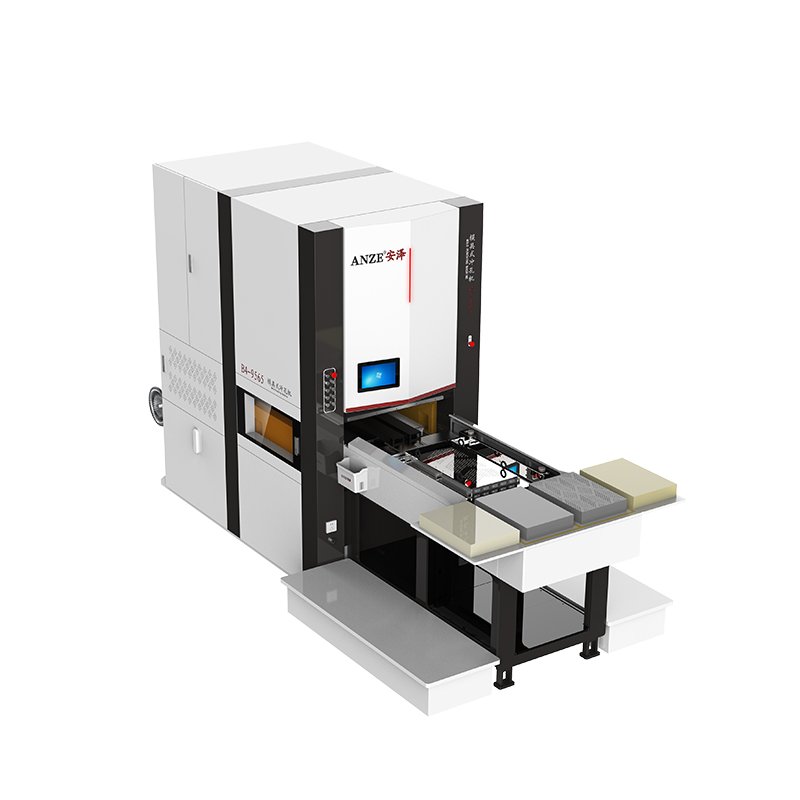

Anze perforation machine: This manufacturer focuses on the production of high-precision and high-efficiency leather punching machines. Its products enjoy a high reputation in the industry, mainly due to its high-precision punching technology. By introducing advanced punching equipment and processes, the manufacturer’s products can achieve extremely high precision and ensure the accuracy and beauty of the punching position. Its operation interface design is also very user-friendly, which is convenient for users to quickly get started. The manufacturer also pays attention to communication and cooperation with customers, and provides customized solutions according to the specific needs of customers, thereby winning the trust and praise of customers.

Wista: The product features of this manufacturer are its diversified punching modes and customized services. Its product line is rich and can meet the needs of different customers. The manufacturer focuses on the appearance design and performance of the product, and has launched a variety of beautiful and practical punching machine products. The manufacturer also has a professional R&D team that can provide customized R&D services according to customer needs, providing customers with a more personalized product experience.

Teseo: The manufacturer’s products are characterized by durability and stability. The leather punching machines it produces are made of high-quality materials and are sturdy and durable. The manufacturer also pays attention to the stability and reliability of the products, and through strict quality control and testing, ensures that each product can meet the established standards. The manufacturer’s product failure rate is low, and it can provide long-term and stable support to customers.

5.2 Market share and competition pattern

In the leather punching machine market, the distribution of market share presents distinct characteristics. The market is mainly dominated by several large enterprises, such as Zhejiang Yuhua Electric Co., Ltd. and Wenzhou Lianhua Electric Co., Ltd., which occupy most of the market share with strong R&D capabilities, advanced production processes and a complete sales network. These companies have a high reputation and influence in the industry, and have the ability to continuously innovate, thereby continuously promoting the development of the industry.

In terms of the competitive landscape, the competition among major manufacturers is becoming increasingly fierce. In order to compete for market share, they continue to increase investment in research and development and launch products with higher performance and quality. These companies also attach great importance to brand building and market promotion, and actively expand brand influence by participating in exhibitions and holding product launch conferences. With the continuous expansion of the market and the diversification of consumer demand, the competitive landscape of the leather punching machine market presents diversified characteristics.

5.3 Analysis of competitive strategies and means

In the leather punching machine market, major manufacturers have adopted a variety of competitive strategies and means to compete for market share. The following is a detailed analysis of these strategies and means.

In terms of competitive strategies, major manufacturers have adopted different strategies based on their own strengths and market positioning. Some manufacturers focus on product innovation, and they continue to develop products with unique functions to attract the attention of consumers. For example, by introducing advanced punching technology, the performance and precision of products are improved, thereby gaining a competitive advantage in the market. Other manufacturers focus on market expansion, and they increase their marketing efforts to increase brand awareness and market share. They use a variety of online and offline channels for publicity to attract more potential customers.

In terms of competitive means, in addition to focusing on improving product performance and quality, major manufacturers also pay great attention to improving service quality. They attract customers and improve customer satisfaction by providing professional consulting services, technical support and after-sales services. Some manufacturers also focus on communication and interaction with customers. They communicate with customers through social media, online forums and other channels to understand customer needs and suggestions in order to better meet customer needs. This customer-centric service model helps to improve customer satisfaction and helps companies stand out in the fierce market competition.

Chapter 6 Analysis of the Policy Environment of the Leather Punching Machine Industry

6.1 Relevant policies, regulations and impacts

In the development history of the leather punching machine industry, the impact of policies and regulations cannot be ignored. With the improvement of global environmental awareness, the strengthening of environmental protection regulations has become an important challenge facing the industry. Environmental protection regulations have had a profound impact on the production process, technical application and waste treatment of the leather punching machine industry. In the production process, environmental protection regulations require enterprises to adopt advanced environmental protection technologies, reduce waste emissions and improve resource utilization efficiency. This has prompted the leather punching machine industry to continuously innovate in technology to meet the green needs of the market.

Manufacturing policies also have an important impact on the development of the leather punching machine industry. In order to promote the transformation and upgrading of the manufacturing industry, the government has introduced a series of preferential policies, such as tax incentives and financial support. These policies provide necessary support for enterprises in the leather punching machine industry, reduce production costs and improve the competitiveness of enterprises. Manufacturing policies also promote industrial agglomeration and industrial chain extension in the leather punching machine industry, providing strong support for the rapid development of the industry.

Trade regulations also have an important impact on the import and export trade of the leather punching machine industry. With the deepening development of globalization, the export demand of the leather punching machine industry continues to increase. Changes in trade regulations, such as the establishment of trade barriers and the adjustment of tariffs, may have a direct impact on the import and export of leather punching machines. Enterprises need to pay close attention to trade trends and adjust trade strategies in a timely manner to cope with possible market changes.

6.2 Industry standards and regulatory requirements

In terms of industry standards, the leather punching machine industry needs to follow a series of strict standard requirements. These standards cover equipment performance, safe operation, environmental protection requirements and other aspects, aiming to ensure that enterprises produce and provide services in accordance with unified standards. By following industry standards, enterprises can improve product quality and safety, reduce production costs and improve market competitiveness. The formulation and implementation of industry standards also help promote technological progress and innovative development in the industry.

In terms of regulatory requirements, the leather punching machine industry is subject to strict supervision. Regulatory authorities ensure that enterprises comply with relevant laws and regulations and standards through regular supervision and inspection and spot checks. These regulatory measures are aimed at maintaining market order and consumer interests, and preventing safety accidents and environmental pollution. Through strict regulatory requirements, enterprises can be encouraged to strengthen self-discipline and compliance awareness, and improve the overall service level and competitiveness of the industry.

6.3 Analysis of the impact of policy environment on industry development

The policy environment is an important factor affecting the development of the leather punching machine industry. With the government’s support for the manufacturing industry and the improvement of environmental protection requirements, the leather punching machine industry faces new development opportunities and challenges.

The policy environment has promoted the upgrading of the leather punching machine industry. The government has continuously increased its support for the manufacturing industry and introduced a series of policies to encourage innovation and improve product quality. These policies provide financial support and tax incentives for leather punching machine companies, encouraging companies to increase R&D investment and improve technical level and product quality. Under such a policy environment, the leather punching machine industry has been able to continuously introduce new technologies and processes to achieve industrial upgrading and transformation.

The policy environment has expanded the application areas of leather punching machines. With the rapid development of the manufacturing industry, the demand for leather punching machines in other industries has continued to increase. The government has introduced relevant policies to support cross-industry cooperation and technical exchanges, and promote the application of leather punching machines in more fields. For example, in the production of high-end leather sofas and car seat cushions, leather punching machines have become an indispensable and important tool with their high efficiency, stability, and strong adaptability.

The policy environment has enhanced the competitiveness of the leather punching machine industry. The government has reduced the operating costs of enterprises and improved production efficiency by introducing a series of preferential policies, such as tax cuts and fee reductions, and simplified approval procedures. The government has also strengthened its supervision of the market, standardized the market order, and provided a fairer competitive environment for leather punching machine companies. These measures will help enhance the overall competitiveness of the leather punching machine industry and promote the sustainable development of the industry.

Chapter 7 Forecast of future development trends in the leather punching machine industry

7.1 Technological innovation and intelligent development

In terms of the application of intelligent technology, leather punching machines will pay more attention to the integration of intelligent technology. By introducing advanced intelligent control systems, sensors and algorithm optimization, the equipment can achieve more accurate automated production. This can improve the production efficiency of the equipment, significantly reduce labor costs, and provide strong support for the company’s cost control. The application of intelligent technology also enables leather punching machines to adapt to more complex and changeable production needs and improve product quality and stability.

In terms of high-precision stamping technology, as consumers pursue personalized needs, leather punching machines will continue to pursue higher-precision stamping technology. By optimizing the equipment structure and control system, the stamping accuracy and stability can be improved to meet the production needs of personalized products. The application of high-precision stamping technology will improve the overall quality of the product and provide consumers with a more personalized shopping experience.

In terms of the application of robotics technology, the application of robotics technology in leather punching machines will become more and more extensive. By introducing robotics technology, the equipment can achieve more efficient automated production, improve production efficiency and automation level. The application of robots can also reduce manual operations and improve production safety. With the continuous advancement of robot technology, its application prospects in the field of leather punching machines will be broader.

7.2 Green environmental protection and sustainable development

In terms of the application of environmentally friendly materials, the leather punching machine industry should vigorously promote the use of environmentally friendly materials. New materials such as renewable materials and environmentally friendly coatings have the advantages of being pollution-free and degradable, which can effectively reduce environmental pollution and energy consumption in the production process. These materials can also increase the added value of products and enhance the market competitiveness of enterprises. By gradually replacing traditional materials, the leather punching machine industry will be able to achieve both environmental and economic benefits while maintaining product quality and performance.

In terms of energy-saving and consumption-reducing technologies, the leather punching machine industry should focus on the application of energy-saving and consumption-reducing technologies. By optimizing equipment design and control systems, energy utilization efficiency can be improved and production costs can be reduced. For example, advanced energy-saving motors and control systems can be introduced to regularly maintain and maintain the equipment to ensure that it is in the best working condition. These measures will help the leather punching machine industry achieve the goal of energy conservation and emission reduction and improve resource utilization efficiency.

In terms of waste recycling, the leather punching machine industry should strengthen waste recycling. By adopting advanced recycling technologies and equipment, waste reduction, resource utilization and harmless treatment can be achieved. For example, waste can be crushed, sorted and other processes can be carried out to recycle and reuse the valuable materials in it. By strengthening the recycling of waste, the leather punching machine industry will be able to improve resource utilization efficiency and reduce production costs.

7.3 Personalization and customization trends

In terms of personalized product demand, with the improvement of consumers’ aesthetic level and the awakening of personalized awareness, their demand for leather punching machine products is no longer limited to traditional and standardized products, but pays more attention to the personalized characteristics of products. This has prompted the industry to pay more attention to consumers’ personalized needs in product design, and provide consumers with a more unique and personalized product experience through innovative technologies and processes. For example, by introducing advanced laser cutting technology, more precise and complex punching effects can be achieved to meet consumers’ pursuit of product uniqueness.

In terms of customized production mode, in order to meet personalized production needs, the leather punching machine industry will adopt more customized production modes. Enterprises will provide customized solutions and services according to the specific needs of consumers, including customization of product specifications, styles, colors, etc. This customized production mode can meet the personalized needs of consumers and improve the production efficiency and profitability of enterprises. For example, by providing customized product assembly and packaging services, consumers’ pursuit of personalized product needs can be met.

In terms of rapid response capability, as consumers’ demand for customized products increases, the leather punching machine industry will improve its rapid response capability. This includes the ability to quickly design, quickly produce, and quickly deliver. By introducing advanced production technology and equipment, we can improve production efficiency and product quality to meet consumers’ urgent need for customized products. For example, by optimizing production processes and improving production efficiency, faster product production and delivery can be achieved.

Chapter 8 Investment Strategy and Risk Analysis of the Leather Punching Machine Industry

8.1 Investment Opportunities and Potential Areas

As an important part of leather processing equipment, the leather punching machine industry has great potential for technological innovation and development. With the continuous advancement of technology and the continuous changes in market demand, the industry is facing unprecedented development opportunities.

The field of technological innovation is the core driving force for the development of the leather punching machine industry. At present, with the continuous application of automation and intelligent technology, the leather punching machine industry is ushering in a wave of technological innovation. Investors can focus on companies with core technologies and innovation capabilities. These companies are usually able to develop higher-performance punching machines to meet the personalized needs of customers, thereby standing out in market competition. These companies can also reduce production costs and improve production efficiency through technological innovation, bringing higher returns to investors.

Environmental protection and sustainable development are development trends that cannot be ignored in the leather punching machine industry. With the increasing global attention to environmental protection and sustainable development, the leather punching machine industry is also facing more stringent environmental protection requirements. Investors can pay attention to companies that are committed to environmental protection and sustainable development and meet relevant standards. These companies are usually able to develop more environmentally friendly punching machines, reduce energy consumption and emissions in the production process, and improve resource utilization efficiency. These companies can also achieve long-term and stable development of the company through sustainable development strategies, bringing more sustainable returns to investors.

Emerging application areas are another important direction for the development of the leather punching machine industry. With the continuous development of new energy vehicles, high-end manufacturing, smart homes and other fields, the application of leather punching machines in these fields has gradually increased. Investors can pay attention to the development potential of these emerging application areas. By deeply understanding market demand and trends, investors can seize investment opportunities and choose those companies with potential for investment.

8.2 Investment risks and preventive measures

In the leather punching machine industry, the prevention of investment risks is an important link that investors need to pay special attention to.

In terms of technical risks, with the continuous advancement of leather punching machine technology, investors need to pay close attention to technological progress and assess technical risks. Due to the instability and compatibility of technological innovation, investors need to pay attention to potential risks such as increased costs and delayed product launch time caused by the failure of new technology research and development. To prevent such risks, investors should strengthen preliminary research and testing to ensure technical feasibility and reduce the risks caused by technological updates and iterations.

In terms of market risks, investors need to pay close attention to market trends and adjust business strategies in a timely manner to cope with market risks such as market demand fluctuations and intensified competition. By diversifying market layout and reducing dependence on a single market, market risks can be dispersed and investment returns can be improved. Investors should also pay attention to changes in consumer demand and adjust product structure and marketing strategies in a timely manner to adapt to market changes.

In terms of legal and regulatory risks, investors need to pay attention to the latest developments in laws and regulations, ensure compliance operations, and prevent legal risks. As the country’s requirements for environmental protection and safety become increasingly stringent, investors need to pay attention to the adjustment of relevant policies and adjust business strategies in a timely manner to ensure compliance operations.

In the leather punching machine industry, the prevention of investment risks is an important link that investors need to pay special attention to. Investors can reduce investment risks and increase investment returns by strengthening preliminary research and testing, paying close attention to market trends, and strengthening awareness of laws and regulations.

The leather punching machine industry faces multiple investment risks, including technical, market and financial aspects. Technical risks mainly involve R&D failures, insufficient technical capabilities and talent shortages, which require companies to strengthen preliminary research, technical training and talent introduction. Market risks are related to market demand fluctuations and intensified competition. It is recommended that companies respond by diversifying market layout and improving product quality. Financial risks are mainly reflected in the capital chain and cost control. It is crucial to rationally plan the use of funds and optimize the production process. Despite these risks, the leather punching machine industry still has broad development prospects. With the growth of consumer demand for personalized leather products, the application areas of leather punching machines will be further broadened. In particular, in emerging fields such as automotive interiors, home decoration and fashion apparel, the demand for leather punching machines is expected to grow significantly. In order to seize future opportunities, companies should continue to pay attention to market trends, increase R&D investment, and optimize production management to reduce costs.

8.3 Investment Strategies and Suggestions

Rational investment is the first principle that investors should maintain in the investment decision-making process. During the investment process, investors should try to avoid blindly following the trend or impulsive investment to avoid losses due to market fluctuations or poor corporate performance. Investors should formulate clear investment strategies, including investment period, investment amount, investment goals, etc., in order to better grasp investment opportunities. In the process of implementing investment strategies, investors should pay close attention to market dynamics and adjust their investment portfolios in a timely manner to cope with market changes.

In-depth research is an important part of investors’ comprehensive understanding of target companies before investing. Investors need to conduct in-depth analysis of the target company’s position in the industry, technological advantages, market prospects, etc. By understanding the fundamentals of the target company, investors can make more informed investment decisions and reduce investment risks. In-depth research also helps investors discover the potential value of the target company and improve investment returns.

Diversified investment is an effective way to diversify risks and improve investment efficiency. Investors can diversify their funds into multiple industries or companies to reduce the risks brought by a single investment. Through diversified investment, investors can achieve optimal allocation of resources and improve overall investment efficiency. Diversified investment also helps investors better understand market dynamics and grasp investment opportunities.

Long-term layout is an important mentality that investors should have during the investment process. During the investment process, investors should pay attention to the long-term development of the industry and grow together with the company. Through long-term planning, investors can share the growth dividends of the company and realize the appreciation of capital. Long-term planning also helps investors better understand the fundamentals and market trends of the company and improve the accuracy and effectiveness of investment decisions.

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.