Last Updated on 2026-01-10 by Anze

The Strategic Role of the Leather Perforator in Modern Manufacturing

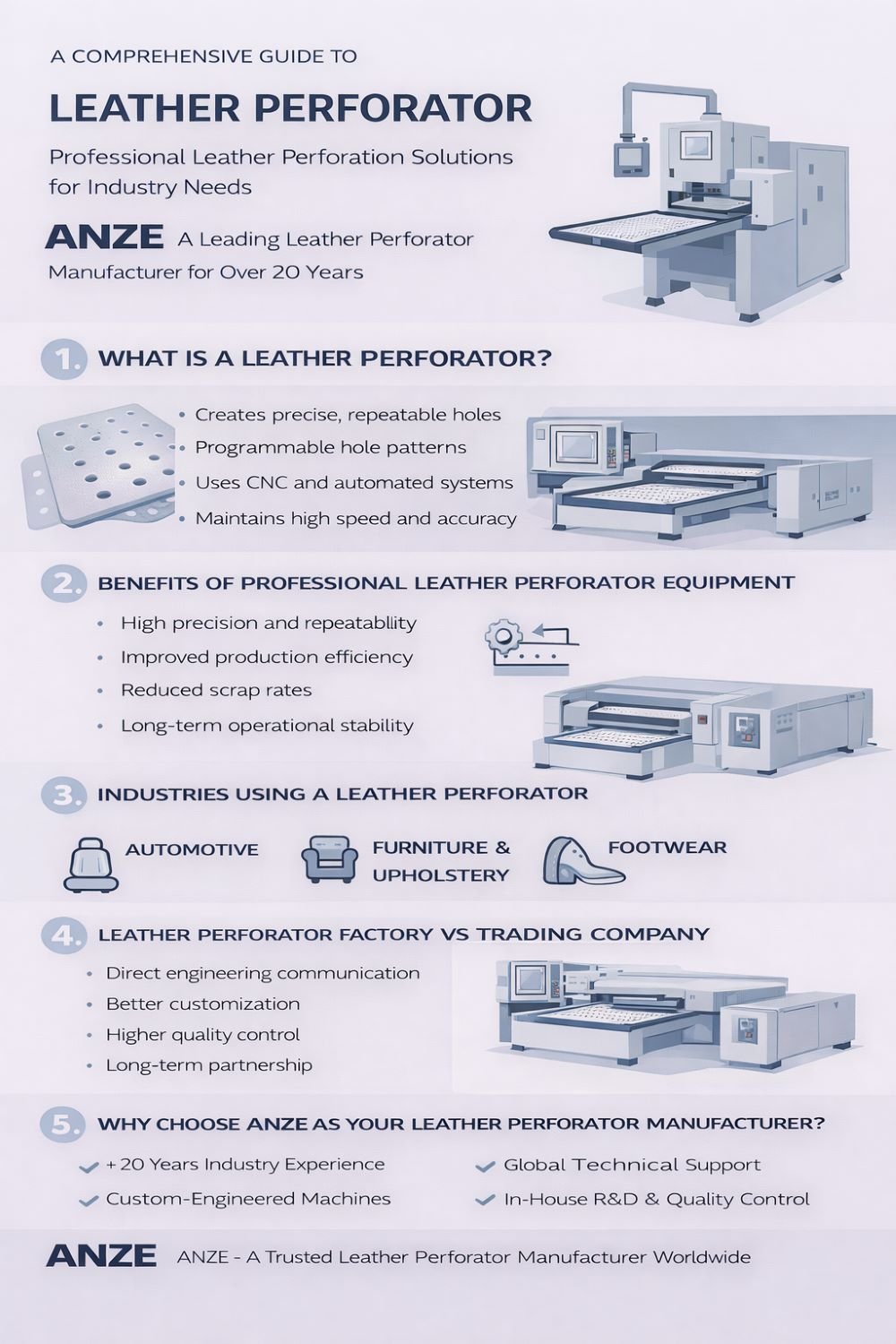

In today’s leather manufacturing industry, perforation is no longer a secondary decorative process. It is a critical engineering operation that directly affects product comfort, airflow, acoustic performance, weight, durability, and aesthetic consistency. As a result, the leather perforator has become a core piece of industrial equipment across multiple sectors, including automotive interiors, furniture upholstery, footwear, bags, and premium leather goods.

A professional leather perforator must balance precision, speed, material protection, and long-term operational stability. This level of performance can only be achieved through advanced machine design, application-specific engineering, and manufacturing expertise. For this reason, manufacturers increasingly seek a qualified leather perforator manufacturer rather than a generic punching equipment supplier.

With more than 20 years of experience, Anze operates as a specialized leather perforator factory, designing and producing a wide range of automated leather perforation solutions trusted by customers worldwide.

This article provides a comprehensive, multi-dimensional overview of leather perforator technology, covering principles, equipment types, applications, design considerations, performance metrics, and future trends.

What Is a Leather Perforator? A Technical Definition

A leather perforator is an industrial machine designed to create precise, repeatable holes in natural leather, synthetic leather, microfiber, and other flexible materials. These holes are arranged according to defined patterns, densities, and diameters to achieve functional or aesthetic objectives.

Unlike manual punching tools, an industrial leather perforator ensures:

Consistent hole geometry

Accurate positioning and spacing

Clean hole edges without tearing

Stable operation at high production volumes

Modern systems produced by a professional leather perforator manufacturer are typically CNC-controlled, automated, and optimized for continuous industrial use.

The Evolution of Leather Perforator Technology

Early Mechanical Leather Perforator Systems

Early leather perforators relied on fixed mechanical punch plates and manual feeding. While effective for simple designs, these systems lacked flexibility and precision.

Automation and CNC Leather Perforator Development

With the introduction of servo motors and CNC control, the leather perforator evolved into a programmable system capable of:

Digital pattern design

Variable hole diameters

High-speed synchronized motion

Automated material handling

This evolution reshaped the role of the leather perforator manufacturer, shifting focus toward integrated system engineering.

Anze: A Professional Leather Perforator Manufacturer with 20 Years of Experience

Anze as a Dedicated Leather Perforator Factory

Anze is a professional leather perforator manufacturer with more than 20 years of experience in designing and producing advanced leather perforation equipment. As a specialized leather perforator factory, Anze focuses exclusively on perforation solutions for flexible materials.

Anze leather perforators are widely used in:

Automotive seat and interior leather

Furniture and upholstery leather

Footwear uppers

Bags and leather accessories

Decorative and functional leather panels

Why Global Customers Choose Anze as Their Leather Perforator Manufacturer

Customers worldwide select Anze as their leather perforator manufacturer due to:

Strong in-house R&D capability

Application-driven machine design

Custom tooling and perforation patterns

Stable long-term machine performance

Professional global technical support

Types of Leather Perforator Equipment

A professional leather perforator factory typically offers multiple machine categories to meet different production needs.

CNC Leather Perforator Systems

CNC leather perforators feature:

Programmable perforation patterns

High-precision servo motion control

Multi-axis positioning

Digital production repeatability

These systems are ideal for automotive and premium furniture applications.

Automatic Leather Perforator Machines

Automatic leather perforators integrate:

Continuous feeding

Automatic positioning

High-speed punching cycles

Reduced labor dependency

Anze specializes in high-speed automatic leather perforator solutions for mass production.

Key Components of a High-Quality Leather Perforator

Punching Tool System in a Leather Perforator

The punch system determines:

Hole quality

Edge cleanliness

Tool life

Material stress behavior

A professional leather perforator manufacturer customizes punch geometry and materials based on leather thickness and softness.

Motion Control System in a Leather Perforator

Advanced servo control ensures:

Accurate hole placement

Smooth acceleration and deceleration

Stable operation at high speeds

This is a defining feature of modern CNC leather perforators.

Leather Perforator Applications Across Industries

Automotive Interior Leather Perforation

A leather perforator is essential for:

Seat ventilation

Door panel leather

Headrest and armrest materials

Speaker grille leather covers

Automotive OEMs rely on experienced leather perforator manufacturers to meet strict quality standards.

Furniture and Upholstery Applications

In furniture manufacturing, leather perforators are used to:

Improve breathability

Enhance comfort

Create decorative patterns

Consistency across large panels is critical.

Footwear and Fashion Leather Goods

Luxury brands depend on micro-perforation delivered by precision leather perforators to achieve refined aesthetics without damaging leather surfaces.

Performance Advantages of Professional Leather Perforator Equipment

A well-designed leather perforator delivers:

High precision and repeatability

Reduced scrap rates

Improved production efficiency

Long-term operational stability

These advantages directly impact manufacturing profitability.

Design Considerations for Leather Perforator Selection

When selecting a leather perforator, manufacturers should evaluate:

Leather type and thickness

Hole size and density requirements

Production volume

Automation level

Integration with upstream and downstream processes

A professional leather perforator factory like Anze provides technical consultation to ensure optimal selection.

Leather Perforator Factory vs Trading Company

Choosing a leather perforator factory offers clear advantages:

Direct engineering communication

Faster customization

Better quality control

Long-term technical accountability

As a true leather perforator manufacturer, Anze designs and produces machines in-house.

Maintenance and Lifecycle Management of a Leather Perforator

Proper maintenance includes:

Regular punch inspection

Alignment checks

Lubrication

Software updates for CNC systems

A well-maintained leather perforator can operate reliably for many years.

Future Trends in Leather Perforator Technology

Leading leather perforator manufacturers are investing in:

Smart sensors and data monitoring

Industry 4.0 integration

Energy-efficient servo drives

Advanced micro-perforation technology

Sustainable manufacturing solutions

Anze continues to develop next-generation leather perforator systems aligned with these trends.

Why Anze Is a Reliable Long-Term Leather Perforator Manufacturer

Anze’s role extends beyond machine supply. As a professional leather perforator manufacturer, Anze provides:

Application consulting

Process optimization

Operator training

Long-term technical support

This partnership-oriented approach has earned Anze strong customer trust worldwide.

Choosing the Right Leather Perforator Manufacturer

The leather perforator is a critical asset in modern leather manufacturing. Choosing the right leather perforator manufacturer directly impacts product quality, efficiency, and competitiveness.

With 20 years of experience, a wide portfolio of equipment, and a strong global reputation, Anze stands out as a professional leather perforator factory capable of delivering reliable, high-performance solutions for diverse applications.

For manufacturers seeking precision, automation, and long-term value, partnering with Anze represents a strategic investment in manufacturing excellence.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.