Last Updated on 2025-10-31 by Anze

In the automotive industry, the evolution of interior materials reflects a fusion of functionality, aesthetics, and craftsmanship. Among all interior components, automotive door panels play a critical role in defining both tactile comfort and brand identity. A key contributor to that sophistication is leather perforation — a process that combines artistry with high-precision manufacturing.Behind this refined material transformation stands a crucial technology: the leather perforation machine.

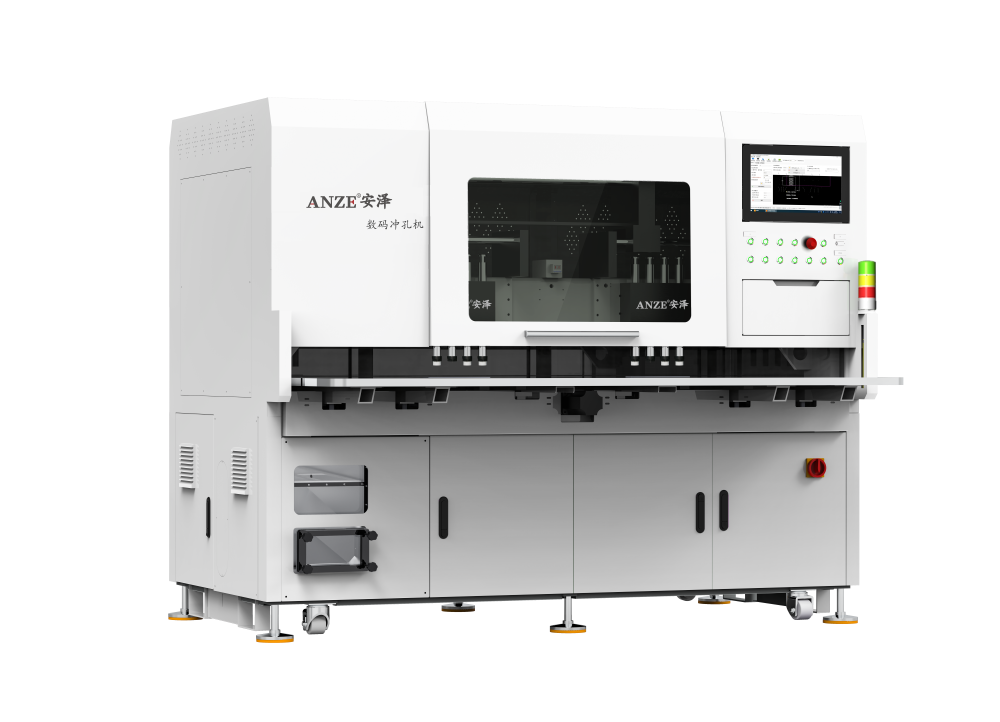

This advanced equipment ensures consistent hole geometry, precise spacing, and smooth surface finish, meeting the demanding standards of modern automotive OEMs.

For more than 20 years, Anze has specialized in designing and producing leather perforation machines for diverse industries — from car interiors and footwear to furniture and luggage. With over 20 popular machine models, Anze has become a global leader in precision perforation systems, enabling manufacturers to produce elegant, breathable, and acoustically optimized leather for high-end automotive door panels.

1. Understanding Automotive Door Leather Perforation

Leather perforation refers to the process of creating precisely spaced holes or micro-patterns on leather surfaces. In car door applications, it serves both functional and aesthetic purposes.

1.1 Functional Benefits

Ventilation and Moisture Control: Micro-perforations allow air circulation, improving comfort and durability in enclosed door environments.

Acoustic Absorption: Perforated leather helps absorb mid-frequency sounds, enhancing cabin quietness.

Weight Reduction: Controlled removal of material slightly reduces panel weight without compromising strength.

1.2 Aesthetic Enhancement

A leather perforation machine can generate customizable hole patterns — from linear arrays to geometric or brand-specific designs — elevating the perceived luxury of automotive interiors.

1.3 Performance Requirements

Automotive door leather must maintain:

Dimensional stability under temperature variation

Uniform surface finish despite pattern complexity

Tensile integrity despite material removal

Meeting these criteria requires an advanced leather perforation machine capable of fine control and repeatable precision.

2. Structure and Working Principle of a Leather Perforation Machine

A leather perforation machine operates by driving perforating tools — mechanical punches, rotary dies, or laser beams — through the surface of the material under programmed control.

2.1 Key Components

| Component | Function |

|---|---|

| Feeding system | Guides and stabilizes the leather sheet. |

| Punching or laser unit | Generates perforations with precise depth and spacing. |

| Die assembly | Defines hole diameter and pattern geometry. |

| Servo control system | Regulates tool movement and synchronization. |

| Cooling/vacuum system | Removes debris and maintains clean surfaces. |

| Human-machine interface (HMI) | Enables operators to configure perforation parameters and monitor performance. |

Anze’s CNC-controlled leather perforation machines incorporate real-time feedback loops and digital servo motors to achieve ±0.1 mm positioning accuracy, ensuring uniform perforation patterns across large panel surfaces.

3. Categories of Leather Perforation Machines for Automotive Applications

3.1 Mechanical Punch Perforation Machine

Uses precision steel punches to create holes. Best suited for natural leather and medium-density synthetic leather. Provides consistent results at high throughput.

3.2 Rotary Die Perforation Machine

Employs cylindrical dies for continuous processing of long leather rolls. Common in high-volume production of synthetic door covering materials.

3.3 Laser Leather Perforation Machine

Uses CO₂ or fiber lasers for non-contact perforation, ideal for micro-perforation and decorative precision patterns. Offers unmatched flexibility in pattern customization.

3.4 CNC Servo Perforation Machine

Integrates computer control for multi-axis precision and dynamic pattern variation. Preferred for high-end car interiors requiring complex designs and variable densities.

4. Techniques in Automotive Door Leather Perforation

Each leather perforation machine supports different techniques depending on the end-use requirements.

4.1 Uniform Micro-Perforation

Creates small, evenly distributed holes (0.5–1.0 mm) that maintain leather strength while improving breathability and sound absorption.

4.2 Gradient Perforation

Uses variable hole densities across the panel to balance visual appeal with functional airflow. Common in door trims adjacent to speaker zones.

4.3 Patterned Decorative Perforation

Designed for brand-specific aesthetics — hexagonal, diamond, or wave patterns — synchronized with interior stitching.

4.4 Laser Fine-Cut Perforation

Enables ultra-clean edges with zero burrs, ideal for synthetic and PU-coated materials. This method uses pulsed laser energy controlled by Anze’s proprietary software.

5. Process Flow of Leather Perforation for Automotive Doors

A precise workflow ensures efficiency and quality consistency when using a leather perforation machine.

Material Inspection – Assess thickness, surface coating, and elasticity.

Pattern Programming – Use CAD/CAM integration to define hole layout.

Machine Calibration – Adjust punch pressure, laser power, and feed rate.

Trial Run and Validation – Conduct initial samples for dimensional verification.

Continuous Production – Execute high-speed perforation with automatic alignment.

Quality Inspection – Employ vision systems or laser scanners for defect detection.

Post-Processing – Clean, condition, and stabilize leather sheets for cutting and lamination.

Anze’s machines include automatic calibration routines, reducing setup time by 40% and ensuring uniform results across multiple production shifts.

6. Key Process Parameters and Control Factors

For optimal results, the leather perforation machine must maintain precise control over:

| Parameter | Typical Range | Impact |

|---|---|---|

| Hole Diameter | 0.5 – 2.5 mm | Defines airflow and aesthetic density |

| Pitch (Spacing) | 1 – 5 mm | Affects texture and strength |

| Punch Pressure / Laser Power | Material-dependent | Influences edge quality |

| Feed Rate | 0.2 – 1.5 m/s | Determines productivity |

| Alignment Tolerance | ±0.1 mm | Prevents pattern distortion |

| Temperature Control | 20–25°C | Prevents leather warping |

Real-time feedback systems in Anze’s leather perforation machines allow automatic compensation for temperature and tension fluctuations, maintaining stable hole geometry even under continuous operation.

7. Troubleshooting and Optimization Techniques

7.1 Common Defects

Edge Burrs: Caused by blunt tools or excessive pressure.

Misaligned Patterns: Result of feed slippage or software offset errors.

Surface Burn Marks: Indicate improper laser focus or energy density.

Irregular Hole Sizes: Due to inconsistent material elasticity or punch wear.

7.2 Optimization Strategies

Regular toolhead maintenance to sustain sharpness and dimensional accuracy.

Implement AI-based defect monitoring for real-time correction.

Use tension sensors to maintain constant material feed.

Calibrate laser optics periodically for consistent beam intensity.

Anze’s latest control algorithms integrate machine learning-based quality correction, enabling automatic detection and adjustment of pattern deviations.

8. Safety and Maintenance Guidelines

Operating a leather perforation machine requires strict adherence to safety and maintenance procedures:

Ensure proper grounding and static protection during leather handling.

Regularly inspect air filters and vacuum systems to remove debris.

Maintain lubrication schedules for mechanical punches.

Keep laser optics clean using non-abrasive materials.

Schedule preventive maintenance every 1,000 operational hours.

Anze’s smart maintenance interface provides real-time maintenance alerts and digital logs for predictive servicing, reducing downtime by 25%.

9. Case Study: Anze’s Perforation Solution for Automotive Door Leather

9.1 Project Overview

A Tier-1 automotive supplier required high-precision perforation on synthetic leather door trims for a premium electric vehicle series.

9.2 Challenges

Complex curved patterns following door contour lines

Required hole diameter: 0.8 ± 0.05 mm

Must achieve 500,000 holes per sheet with <1% defect rate

9.3 Anze’s Solution

Anze deployed its CNC Leather Perforation Machine Model AZ-LP900, featuring:

Servo-driven feeding with automatic curvature compensation

Dynamic pattern mapping using optical position tracking

Adaptive laser pulse modulation for PU-coated materials

9.4 Results

Accuracy: ±0.05 mm across 1.2 m panels

Defect rate: <0.5%

Production efficiency increased by 38%

Tool lifespan extended by 20%

The project established a new benchmark for precision automotive door leather perforation.

10. Comparison with Other Global Perforation Technologies

| Manufacturer | Core Technology | Primary Application |

|---|---|---|

| Trumpf (Germany) | High-power laser systems | Metal processing |

| Amada (Japan) | CNC punching machines | Sheet metal |

| Bobst (Switzerland) | Rotary die perforation | Packaging materials |

| Anze (China) | Leather perforation machines | Automotive & soft materials |

Unlike competitors focusing on hard materials, Anze’s leather perforation machines are optimized for soft substrates, featuring adaptive pressure control and high-precision servo guidance designed specifically for automotive interiors.

11. Quality Assurance and Certification

Anze’s leather perforation machines comply with major industry standards:

ISO 9001 for quality management

CE and UL safety compliance

IATF 16949 compatibility for automotive suppliers

Each machine undergoes over 200 performance tests before shipment, including continuous endurance runs exceeding 8 hours at 90% duty cycle.

12. Sustainability and Environmental Responsibility

Modern leather perforation aligns with environmental manufacturing principles.

Anze’s systems promote:

Energy-efficient servo drives reducing power consumption by 15%.

Smart material nesting algorithms minimizing leather waste.

Low-noise operation improving workplace conditions.

Support for eco-leather and recycled composites, advancing sustainability in automotive interiors.

13. Future Trends in Leather Perforation Technology

13.1 Integration with AI and IoT

Next-generation leather perforation machine will integrate predictive maintenance and adaptive quality control based on machine learning.

13.2 Multi-Material Compatibility

Future systems will process hybrid materials, including bio-based vegan leather and recyclable composites.

13.3 Automated Pattern Customization

Automotive brands will leverage digital libraries to create brand-specific perforation signatures instantly, enhancing personalization.

Anze’s R&D division is actively developing smart interconnected perforation systems compatible with Industry 4.0 ecosystems.

Precision, Performance, and Partnership

In the competitive world of automotive interiors, precision leather perforation defines craftsmanship and innovation. Achieving flawless perforation patterns on door panels requires a blend of advanced engineering, material science, and automated precision.

With over two decades of expertise, Anze continues to lead the market with its high-performance leather perforation machines, providing manufacturers with:

Exceptional accuracy

Custom pattern flexibility

Reliable operation

Sustainable performance

As the industry moves toward intelligent manufacturing, Anze’s mission remains clear: to deliver cutting-edge leather perforation solutions that empower automotive brands to achieve superior design, comfort, and durability.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

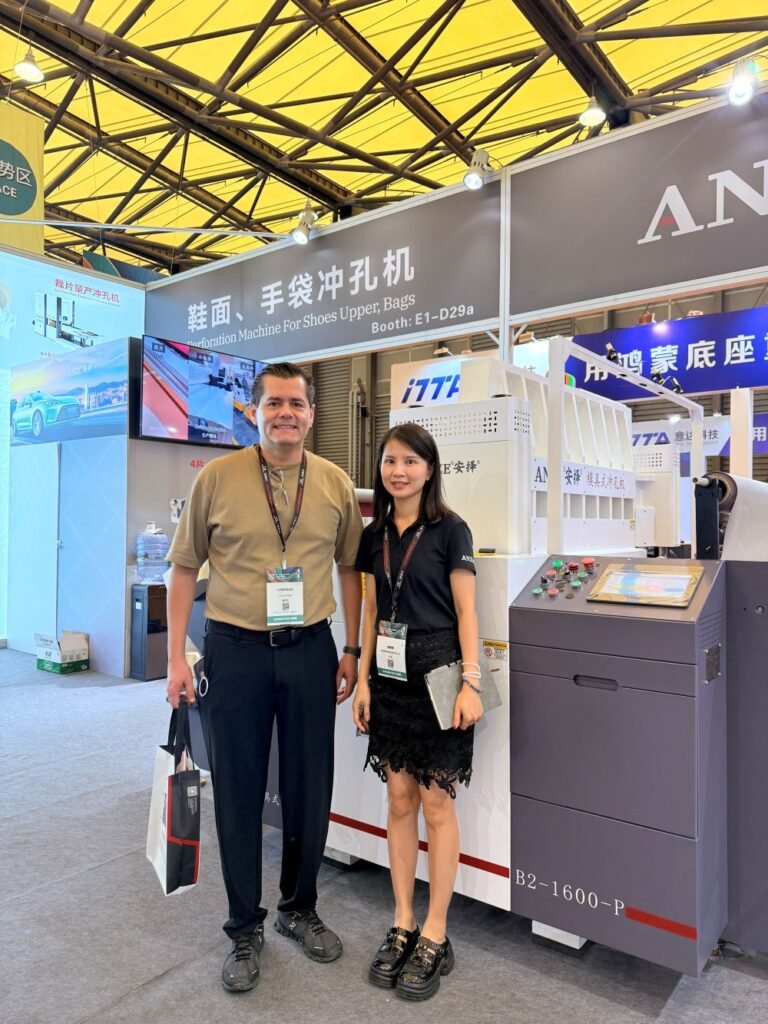

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.