Ultimo aggiornamento il 2025-02-23 da Anze

Leather has long been synonymous with luxury, durability, and comfort, making it a preferred material in the automotive industry. From premium car seats to elegant steering wheels, leather enhances both the aesthetic appeal and functionality of vehicle interiors. As a manufacturer of macchine per la punzonatura della pelle, we understand the critical role these machines play in transforming raw leather into high-quality automotive components. In this blog, we’ll explore the applications of leather in car interiors, the importance of leather punching machines, and how they contribute to the automotive industry’s evolution.

1. The Role of Leather in Automotive Interiors

Leather is a staple material in automotive interiors due to its unique combination of elegance, durability, and comfort. Here are some of the key applications of leather in car interiors:

1.1 Car Seats

Leather car seats are a hallmark of luxury vehicles. They offer a premium feel, are easy to clean, and provide excellent durability. Leather punching machines are used to create perforations in seat leather, enhancing breathability and comfort, especially in hot climates.

1.2 Steering Wheels

Leather-wrapped steering wheels provide a comfortable grip and add a touch of sophistication to the driving experience. Precision punching machines ensure that the leather fits perfectly around the wheel, with no imperfections.

1.3 Door Panels and Dashboards

Leather is often used to cover door panels and dashboards, giving the car interior a cohesive and luxurious look. Punching machines help create intricate patterns and designs that elevate the visual appeal of these components.

1.4 Headrests and Armrests

Leather headrests and armrests add to the overall comfort of the vehicle. Punching machines are used to create ventilation holes or decorative patterns, ensuring both functionality and style.

2. The Importance of Leather Punching Machines in Automotive Manufacturing

Macchine per la punzonatura della pelle are indispensable in the automotive industry. They enable manufacturers to achieve precision, efficiency, and customization in leather processing. Here’s how these machines make a difference:

2.1 Precision and Consistency

Automotive interiors demand high precision to ensure that every piece of leather fits perfectly. Leather punching machines, especially CNC models, offer unparalleled accuracy, with error margins as low as 0.1mm.

2.2 Enhanced Breathability and Comfort

Perforated leather is widely used in car seats and headrests to improve airflow and comfort. Punching machines can create uniform holes of varying sizes and patterns, ensuring optimal ventilation.

2.3 Customization and Design Flexibility

Modern consumers value personalized designs. Leather punching machines allow manufacturers to create unique patterns, from simple geometric shapes to intricate floral designs, catering to diverse customer preferences.

2.4 Efficiency and Cost-Effectiveness

Automated leather punching machines significantly reduce production time and labor costs. For instance, some machines can punch up to 800 holes per minute, making them ideal for large-scale automotive production.

3. Case Studies: Leather Punching Machines in Action

Case Study 1: Peony Automotive’s Innovative Seat Design

Peony Automotive recently patented a leather punching technology that enhances the comfort and eco-friendliness of car seats. Their punching machine creates precise perforations that improve airflow, reducing the need for air conditioning and lowering energy consumption. This innovation not only enhances the driving experience but also aligns with the company’s sustainability goals.

Case Study 2: Kaiyi Automotive’s Customized Interior Solutions

Kaiyi Automotive has integrated advanced leather punching machines into its production line to create customized interior designs. By using CNC punching machines, the company can produce complex patterns and textures, offering customers a wide range of customization options. This has helped Kaiyi stand out in a competitive market.

4. Market Trends and Future Prospects

The automotive leather market is growing rapidly, driven by increasing demand for luxury vehicles and sustainable materials. Here are some key trends shaping the industry:

4.1 Rising Demand for Luxury Vehicles

As disposable incomes rise, more consumers are opting for premium cars with leather interiors. This trend is particularly strong in emerging markets like China and India.

4.2 Sustainability and Eco-Friendly Materials

Automakers are increasingly focusing on sustainability. Leather punching machines play a crucial role in this by minimizing waste and optimizing material usage.

4.3 Technological Advancements

The integration of AI and IoT in leather punching machines is revolutionizing the industry. Smart machines can now self-adjust settings, predict maintenance needs, and optimize production processes.

4.4 Customization and Personalization

Consumers are seeking unique designs that reflect their personality. Leather punching machines enable manufacturers to offer bespoke interior solutions, from custom patterns to personalized logos.

Leather punching machines are the unsung heroes

Leather is an integral part of automotive interiors, offering a perfect blend of luxury, comfort, and durability. Leather punching machines are the unsung heroes behind this, enabling manufacturers to achieve precision, efficiency, and customization. As the automotive industry continues to evolve, these machines will play an even more critical role in meeting consumer demands and driving innovation.

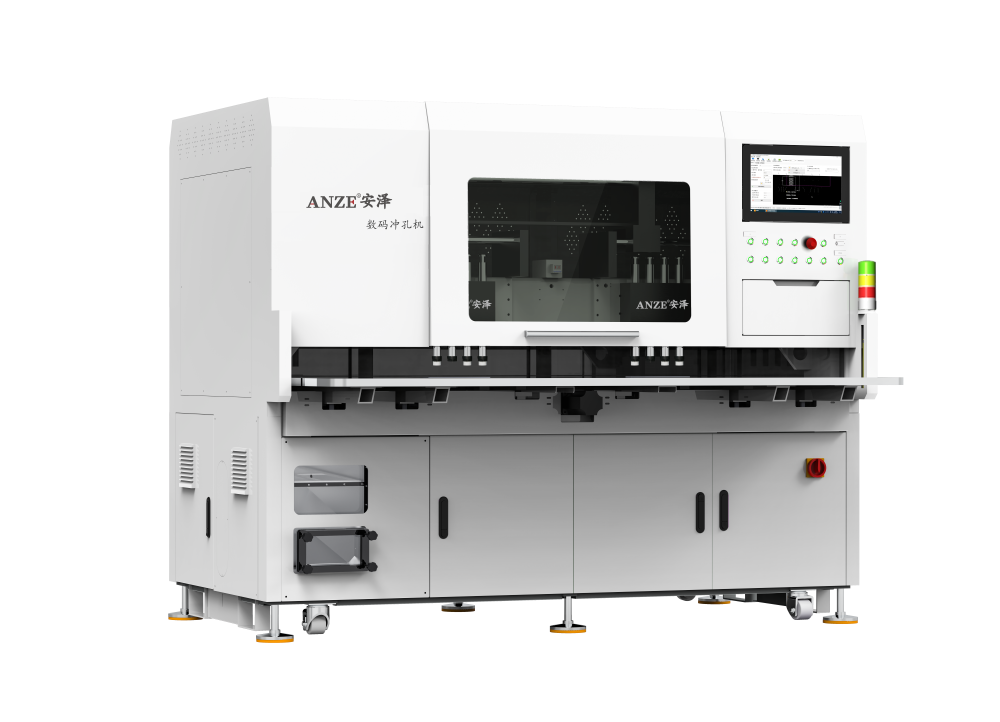

At Anze leather punching machine factory, we are committed to providing cutting-edge leather punching machines that empower automotive manufacturers to create exceptional interiors. Whether you’re looking to enhance comfort, embrace sustainability, or offer personalized designs, our machines are here to help you stay ahead of the curve.

Alcuni modelli vengono spediti assemblati in fabbrica. Le apparecchiature di grandi dimensioni sono confezionate in più parti e viene fornito un manuale di installazione. Tutte le apparecchiature sono dotate di manuali d'uso in cinese e inglese.

I clienti possono inviare qualcuno presso la fabbrica di Anze per imparare o noi inviamo esperti tecnici per fornire formazione in loco.

La macchina deve essere fissata su un tavolo stabile e l'ambiente deve essere mantenuto pulito e ordinato per evitare il contatto con la polvere, l'elettricità statica, l'umidità e i trucioli che potrebbero causare guasti alle parti.

Disponiamo di un team esperto di assistenza post-vendita con servizio online 24 ore su 24 e di un sistema di assistenza post-vendita completo. Supporto per l'addestramento in fabbrica, video tecnico disponibile per il servizio di macchinari all'estero. supporto, supporto online, ingegneri.

Naturalmente diamo il benvenuto a visitare la nostra azienda e ad avere una comunicazione faccia a faccia per far progredire gli affari reciproci.

I tempi di consegna variano a seconda della quantità dell'ordine e della personalizzazione, in genere da 7 a 10 giorni lavorativi. Se si tratta di un ordine di punzonatrice per pelle personalizzata, sono necessari 1-2 mesi.