Last Updated on 2025-02-21 by Anze

As an important equipment in the leather processing industry, the macchina per la perforazione della pelle provides strong support for the production of leather products with its efficient and precise punching capabilities. The operation of this precision machinery is inseparable from the coordinated work of its various components. This article will explore the core components and functions of the macchina per la perforazione della pelle in depth, revealing the secret of its efficient operation.

1.what is the Main frame of leather perforating machine?

The main frame of the macchina per la perforazione della pelle is the supporting structure of the entire equipment, usually made of high-strength steel or aluminum alloy materials to ensure the stability and durability of the equipment. The main frame not only bears the weight of other components, but also provides a foundation for the installation and fixation of the entire equipment.

2. what are the Punch and die of leather perforating machine?

The punch is the key component of the punzonatrice per pelle for directly punching leather. It is usually made of carbide or high-speed steel to ensure sufficient hardness and wear resistance during the punching process. The shape and size of the punch can be customized according to different punching requirements to meet the punching of various patterns and hole types.

The die is a component that fixes the punch and guides its movement. It usually works closely with the punch to ensure the accuracy of the punching position and the consistency of the hole type. The design of the mold needs to consider factors such as the thickness and material of the leather, as well as the size and density of the punching holes, in order to achieve the best punching effect.

3. what is the Power system of leather perforating machine?

The power system of the punzonatrice per pelle provides it with the necessary power support. Common power systems include electric motors, hydraulic motors or pneumatic devices. The electric motor converts electrical energy into mechanical energy through the transmission device to drive the punch to move up and down; the hydraulic motor uses the pressure energy of the liquid to drive the punch; the pneumatic device provides power through compressed air. These power systems must have sufficient power and stability to ensure efficient operation during the punching process.

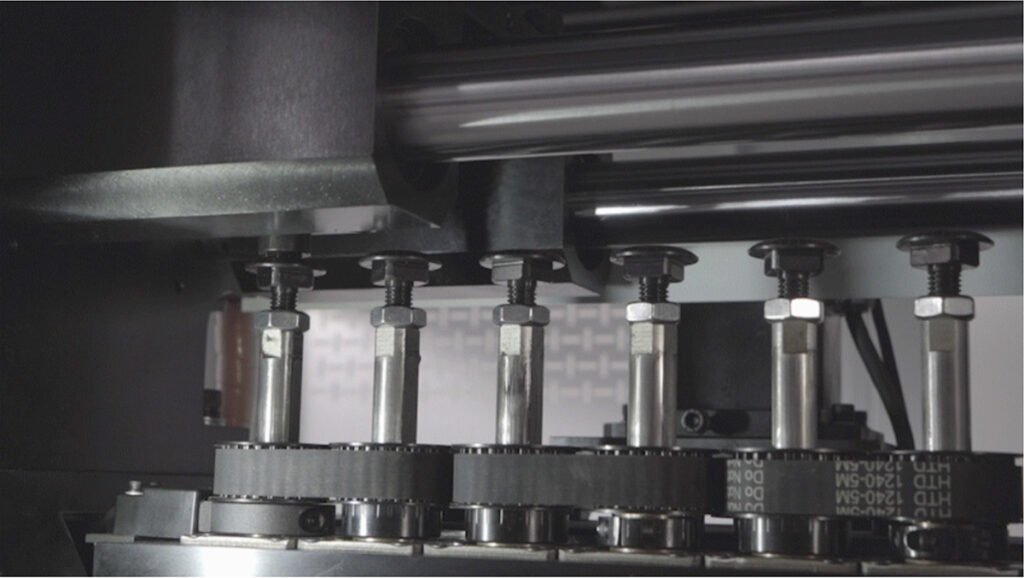

4. What is Transmission device of leather perforating machine?

The transmission device is a key component connecting the power system and the punch. It converts the rotational motion of the power system into the linear motion of the punch. Common transmission devices include gear transmission, chain transmission and screw transmission. These transmission devices must have high precision and stability to ensure the accuracy of the punching position and the consistency of the hole type.

5. What Is Control system of leather perforating machine?

The control system is the “brain” of the macchina per la perforazione della pelle, which is responsible for controlling the operation of the entire equipment. Modern leather punching machines are usually controlled by PLC (Programmable Logic Controller) or CNC (Computer Numerical Control) systems. These systems can accurately control the movement trajectory, speed and force of the punch according to preset programs and parameters to achieve automated, high-precision punching operations.

6. what is Safety protection devices?

Safety protection devices are an indispensable part of leather punching machines. They are used to protect the safety of operators and the equipment itself. Common safety protection devices include emergency stop buttons, protective covers, photoelectric protection devices, etc. These devices can quickly cut off the power supply or stop the operation of the equipment in an emergency to avoid accidents.

What are the functions of the various components of the leather perforating machine?

The various components of the macchina per la perforazione della pelle work together to achieve efficient and accurate punching operations. From the support of the main frame to the precise coordination of the punch and the die, from the strong drive of the power system to the stable transmission of the transmission device, to the intelligent scheduling of the control system and the comprehensive protection of the safety protection device, each component plays an indispensable role. It is the precise construction and efficient operation of these components that make the leather punching machine an important equipment in the leather processing industry and provide strong support for the production of leather products.

How to choose leather perforating machine

Dongguan Anze Automation Equipment Co., Ltd. is located in Dongguan City,Guangdong Province. Founded in 2005, the company has been focusing on the punching industry for nearly 20 years and currently covers a comprehensive area of 5000 squaremeters. The company specializes in CNC leather punching machines, mould leather punching machines,leather bag punching machine,luggage leather punching machine,shoes leather punching machine,furniture leather punching machine and other equipment.Any question please contact May Whatsapp +8618002980031

Se volete vedere il video della macchina per la punzonatura del cuoio, visitate il nostro sito web YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Alcuni modelli vengono spediti assemblati in fabbrica. Le apparecchiature di grandi dimensioni sono confezionate in più parti e viene fornito un manuale di installazione. Tutte le apparecchiature sono dotate di manuali d'uso in cinese e inglese.

I clienti possono inviare qualcuno presso la fabbrica di Anze per imparare o noi inviamo esperti tecnici per fornire formazione in loco.

La macchina deve essere fissata su un tavolo stabile e l'ambiente deve essere mantenuto pulito e ordinato per evitare il contatto con la polvere, l'elettricità statica, l'umidità e i trucioli che potrebbero causare guasti alle parti.

Disponiamo di un team esperto di assistenza post-vendita con servizio online 24 ore su 24 e di un sistema di assistenza post-vendita completo. Supporto per l'addestramento in fabbrica, video tecnico disponibile per il servizio di macchinari all'estero. supporto, supporto online, ingegneri.

Naturalmente diamo il benvenuto a visitare la nostra azienda e ad avere una comunicazione faccia a faccia per far progredire gli affari reciproci.

I tempi di consegna variano a seconda della quantità dell'ordine e della personalizzazione, in genere da 7 a 10 giorni lavorativi. Se si tratta di un ordine di punzonatrice per pelle personalizzata, sono necessari 1-2 mesi.