Last Updated on 2026-02-16 by Anze

Understanding Perforating Leather Technology in Modern Manufacturing

Perforating leather is a critical manufacturing process used across industries including automotive interiors, furniture upholstery, footwear, fashion accessories, and sports equipment. The evolution from manual punching to automated macchina per la perforazione della pelle technology has dramatically improved precision, productivity, and design flexibility.

A professional manufacturer must combine mechanical engineering, tooling design, and material science to achieve reliable perforation results. With over 20 years of experience and more than 20 independently developed perforation systems, Anze specializes in both CNC perforating machine e mould perforating machine solutions for industrial leather processing.

This article provides a comprehensive technical exploration of perforating leather, including working principles, equipment types, process engineering, applications, and future trends.

1. What Is Perforating Leather and Why It Matters

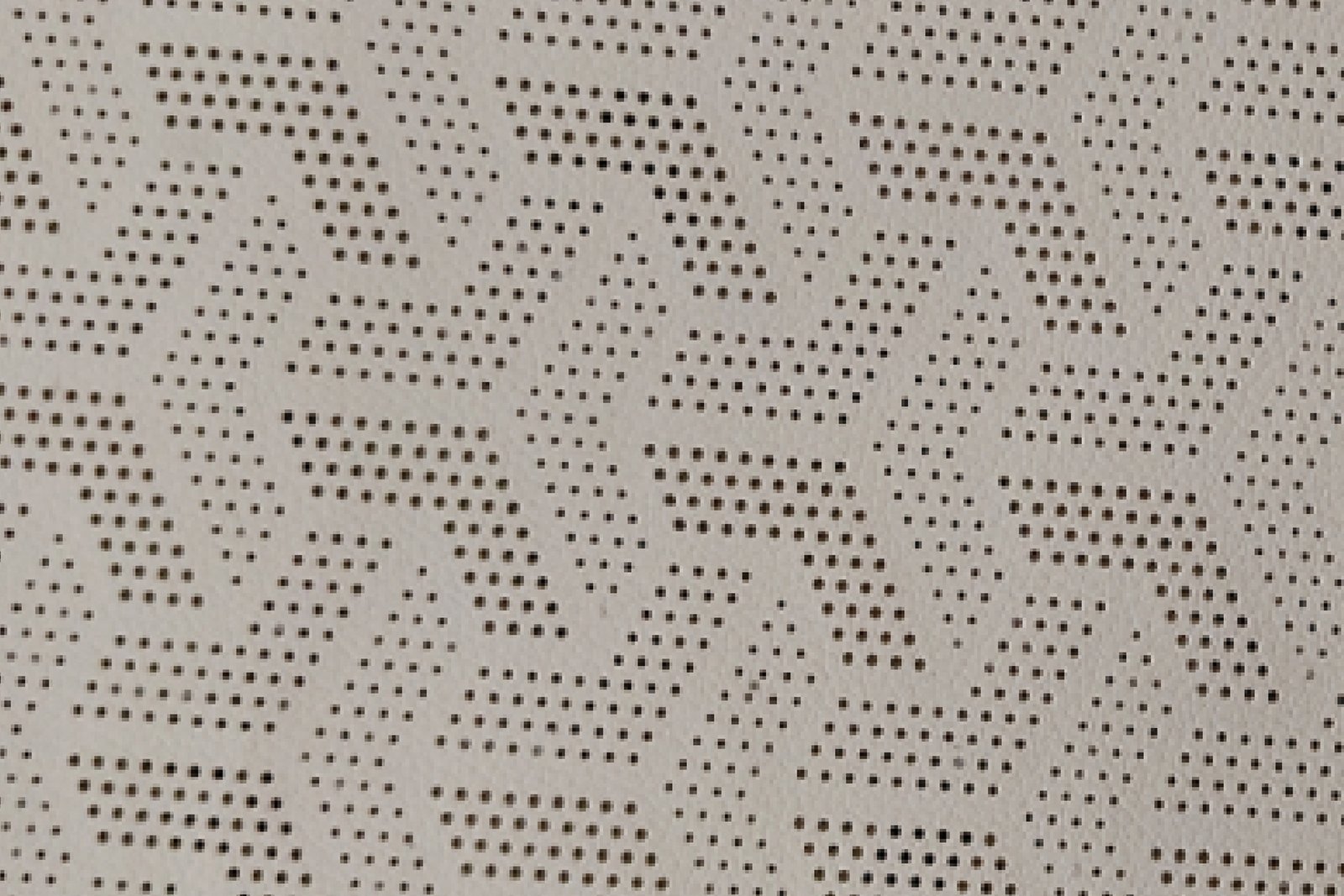

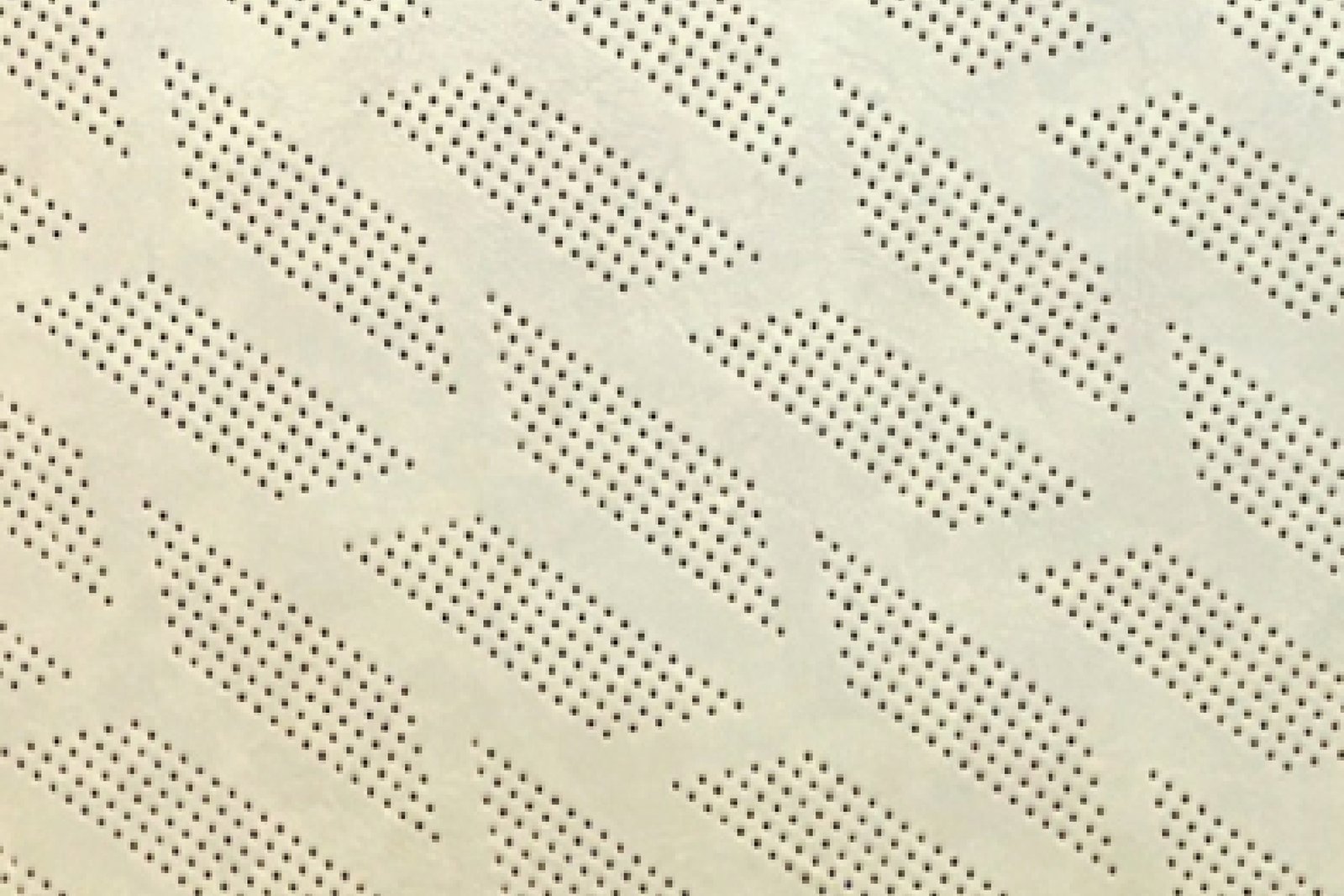

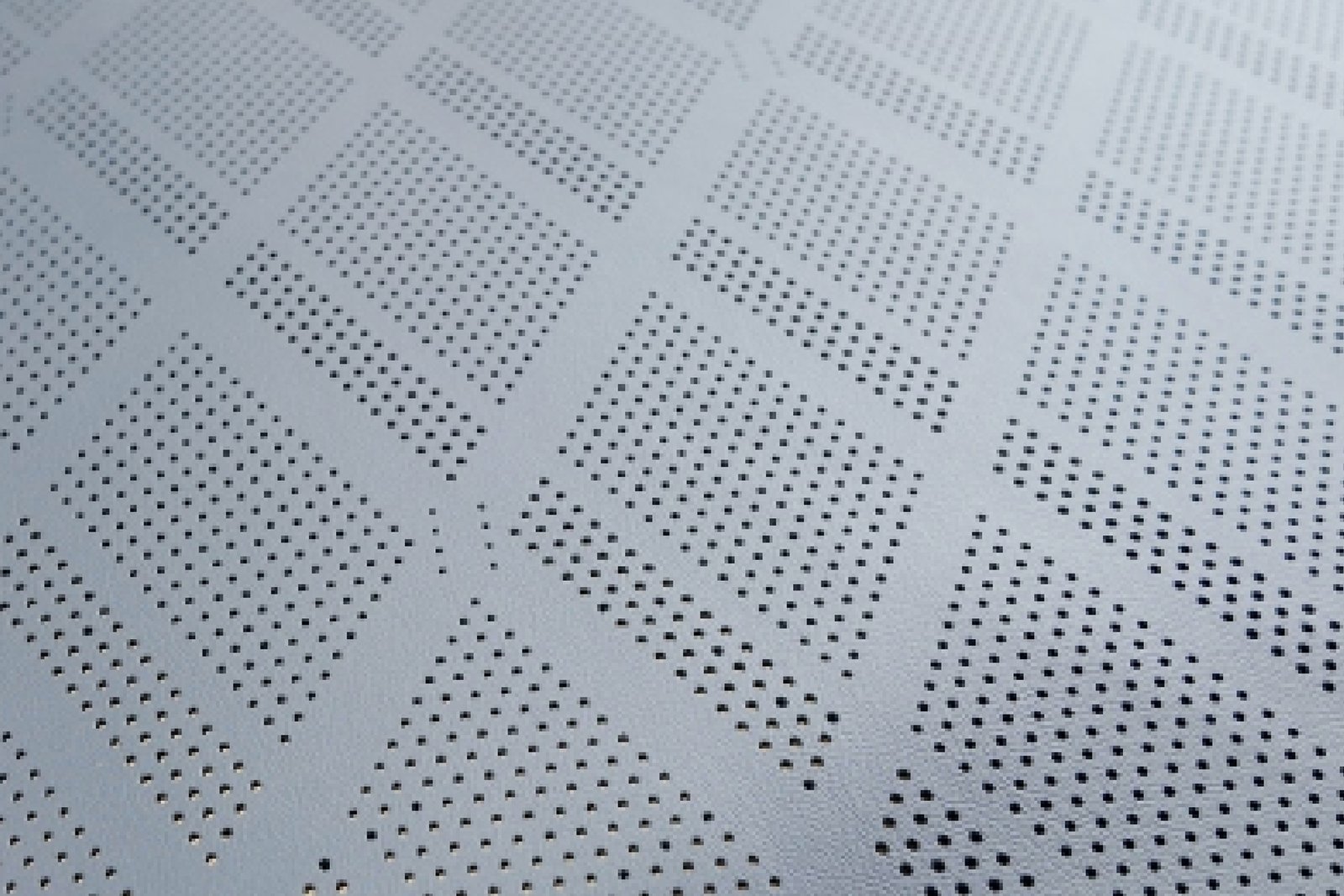

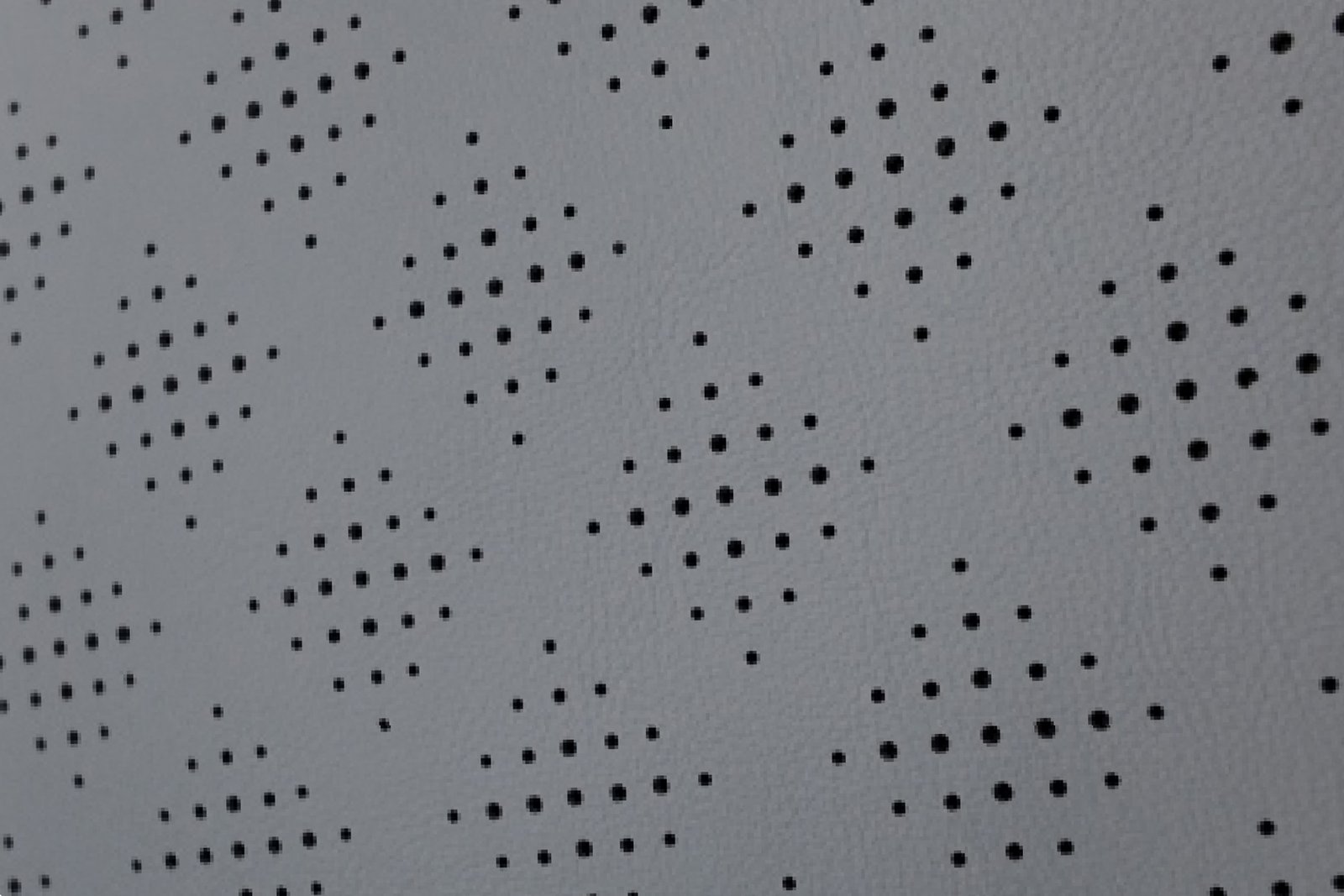

Perforating leather refers to the process of creating precisely positioned holes in leather materials using specialized machinery. These perforations serve both functional and aesthetic purposes.

Key reasons for perforating leather include:

Improving breathability and airflow

Enhancing comfort in seating products

Increasing material flexibility

Reducing weight

Creating decorative patterns

Supporting acoustic performance

Modern industries rely heavily on advanced macchina per la perforazione della pelle technology to achieve consistent results at scale.

2. How Perforating Leather Works: Basic Mechanical Principles

Il perforating leather process involves applying controlled force through a punch tool to remove material and create holes.

The process typically includes:

Material positioning

Punch alignment

Controlled penetration force

Material removal

Hole formation and release

Precision depends on machine stability, tooling quality, and control systems.

3. Perforating Leather Machine Types and Technologies

A professional produttore di macchine per la perforazione della pelle offers multiple equipment categories depending on production needs.

3.1 CNC Perforating Leather Machine

A CNC perforating leather machine uses computer numerical control for programmable perforation patterns.

Advantages:

High precision positioning

Flexible pattern design

Easy parameter adjustment

Repeatable quality

This is the most advanced technology for complex designs.

3.2 Mould Perforating Leather Machine

A mould perforating leather machine uses fixed tooling plates for repetitive patterns.

Advantages:

High production efficiency

Suitable for mass production

Lower programming requirements

Stable mechanical operation

This approach is ideal for standardized products.

4. Materials Used in Perforating Leather Applications

A modern macchina per la perforazione della pelle can process multiple materials:

Genuine leather

PU leather

PVC leather

Microfiber leather

Composite materials

Synthetic upholstery

Each material requires different punching force, speed, and tooling geometry.

5. Tooling Technology in Perforating Leather Machines

Tooling is the core of any perforating leather process.

Important factors include:

Punch diameter precision

Edge sharpness

Wear resistance

Alignment accuracy

High-quality tooling ensures clean hole edges without tearing.

6. Key Engineering Parameters in Perforating Leather

Successful perforating leather requires control over multiple parameters:

Punch Force

Must match leather thickness and density.

Hole Spacing

Impacts flexibility and structural integrity.

Punch Speed

Affects productivity and material deformation.

Tool Temperature

Important for synthetic materials.

Professional macchina per la perforazione della pelle systems allow precise parameter adjustments.

7. Automation in Perforating Leather Machines

Moderno macchina per la perforazione della pelle solutions include automation features:

CNC control systems

Servo-driven motion

Automatic feeding systems

Touchscreen interfaces

Pattern memory storage

Automation reduces labor and increases consistency.

8. Industrial Applications of Perforating Leather Technology

Industria automobilistica

Seats, steering wheels, door panels

Furniture Industry

Sofas, recliners, office chairs

Footwear Industry

Breathable shoe uppers

Fashion Industry

Handbags, belts, wallets

Sports Equipment

Gloves and protective gear

The versatility of macchina per la perforazione della pelle technology supports diverse industries.

9. Benefits of Using Advanced Perforating Leather Machines

Manufacturers gain significant advantages:

Consistent quality

High production efficiency

Reduced material waste

Improved product comfort

Enhanced product value

Investing in a professional macchina per la perforazione della pelle improves competitiveness.

10. Perforating Leather Quality Control Standards

Quality inspection includes:

Hole diameter accuracy

Edge smoothness

Pattern alignment

Structural integrity

A reliable produttore di macchine per la perforazione della pelle ensures machines meet strict quality standards.

11. Challenges in Perforating Leather and Solutions

Common challenges:

Leather Stretching

Solution: Vacuum fixation systems

Burr Formation

Solution: Precision tooling

Hole Deformation

Solution: Controlled punching force

Material Damage

Solution: Optimized machine parameters

Advanced macchina per la perforazione della pelle engineering solves these issues.

12. Perforating Leather Machine Selection Guide

Quando si sceglie un macchina per la perforazione della pelle, consider:

Production volume

Pattern complexity

Material types

Automation level

Budget

An experienced produttore di macchine per la perforazione della pelle provides customized solutions.

13. Why Choose Anze for Perforating Leather Equipment

Anze offers:

20 years of industry experience

Over 20 machine models

CNC and mould perforation solutions

Customized engineering services

Global customer support

Come professionista produttore di macchine per la perforazione della pelle, Anze delivers reliable technology

14. Future Trends in Perforating Leather Technology

The future of perforating leather includes:

AI-assisted pattern generation

Smart material detection

Integrated inspection systems

Fully automated production lines

Innovation continues to drive machine performance improvements.

The Importance of Advanced Perforating Leather Solutions

The process of perforating leather has evolved into a high-precision industrial technology requiring advanced equipment and engineering expertise.

Moderno macchina per la perforazione della pelle solutions provide manufacturers with:

Higher productivity

Better product quality

Greater design flexibility

Improved competitiveness

With extensive experience and continuous innovation, Anze provides complete perforating leather solutions trusted worldwide.

Grazie a un team esperto e qualificato, conosciamo bene tutti i tipi di caratteristiche dei materiali e di tecnologia di lavorazione e siamo in grado di personalizzare Macchina per la perforazione della pelle in base alle esigenze del cliente. Per qualsiasi domanda, contattateci! Whatsapp +86 180 0298 0031

Come installare e mantenere la macchina?

Alcuni modelli vengono spediti assemblati in fabbrica. Le apparecchiature di grandi dimensioni sono confezionate in più parti e viene fornito un manuale di installazione. Tutte le apparecchiature sono dotate di manuali d'uso in cinese e inglese.

I clienti possono inviare qualcuno presso la fabbrica di Anze per imparare o noi inviamo esperti tecnici per fornire formazione in loco.

Quali sono i requisiti dell'ambiente di lavoro della macchina?

Il Punzonatrice per cuoio CNC deve essere fissato su un tavolo stabile e l'ambiente deve essere mantenuto pulito e ordinato per evitare il contatto con la polvere, l'elettricità statica, l'umidità e i trucioli che potrebbero causare guasti alle parti.

Come sono le vostre politiche post-vendita?

Disponiamo di un team esperto di assistenza post-vendita con servizio online 24 ore su 24 e di un sistema di assistenza post-vendita completo. Supporto per l'addestramento in fabbrica, video tecnico disponibile per il servizio di macchinari all'estero. supporto, supporto online, ingegneri.

Siete disponibili per inviti in loco?

Naturalmente diamo il benvenuto a visitare la nostra azienda e ad avere una comunicazione faccia a faccia per far progredire gli affari reciproci.

Quali sono i tempi di consegna?

I tempi di consegna variano a seconda della quantità dell'ordine e della personalizzazione, in genere da 7 a 10 giorni lavorativi. Se si tratta di un ordine di punzonatrice per pelle personalizzata, sono necessari 1-2 mesi.