Last Updated on 2025-07-24 by Anze

As a seasoned manufacturer with two decades of expertise in crafting high-quality perforation machine, we have been at the forefront of the leather processing industry. Our journey as a specialist in perforation machines has been driven by a commitment to innovation, precision, and customer satisfaction. In this blog, we delve into the history, processes, and future outlook of our company as a prominent perforation machine manufacturer.

The Birth of a Perforation Machine Specialist

Our story as a perforation machine manufacturer began in 2005, when our founder, with a deep passion for leather craftsmanship and a vision to transform the industry, established our company. From the outset, we focused on developing machines that could deliver precise and intricate perforations, catering to the diverse needs of leather goods manufacturers.

Early Years and Breakthroughs

During our early years, we encountered numerous challenges, particularly in designing perforation machines that could handle various types of leather materials and achieve complex patterns. Through relentless research and development, we were able to overcome these obstacles and introduce innovative perforation machines that set new benchmarks in the industry.

A key milestone in our journey as a perforation machine manufacturer was the development of our first CNC-controlled machine. This groundbreaking innovation significantly enhanced production efficiency and accuracy, positioning us as a leader in the perforation machine market.

Driving Innovation in Perforation Technology

Innovation has always been the cornerstone of our company’s philosophy as a perforation machine manufacturer. Over the years, we have continuously invested in research and development, striving to stay ahead of the curve and meet the evolving demands of the leather industry.

Our dedication to innovation has led to the creation of a diverse range of perforation machines, each tailored to specific requirements such as different leather thicknesses, patterns, and production volumes. We have also incorporated advanced technologies like laser perforation and automation to further enhance the capabilities and efficiency of our machines.

By staying at the forefront of perforation technology, we have been able to provide our clients with cutting-edge solutions that enable them to produce high-quality leather products with precision and consistency.

The Craftsmanship Behind Our Perforation Machine

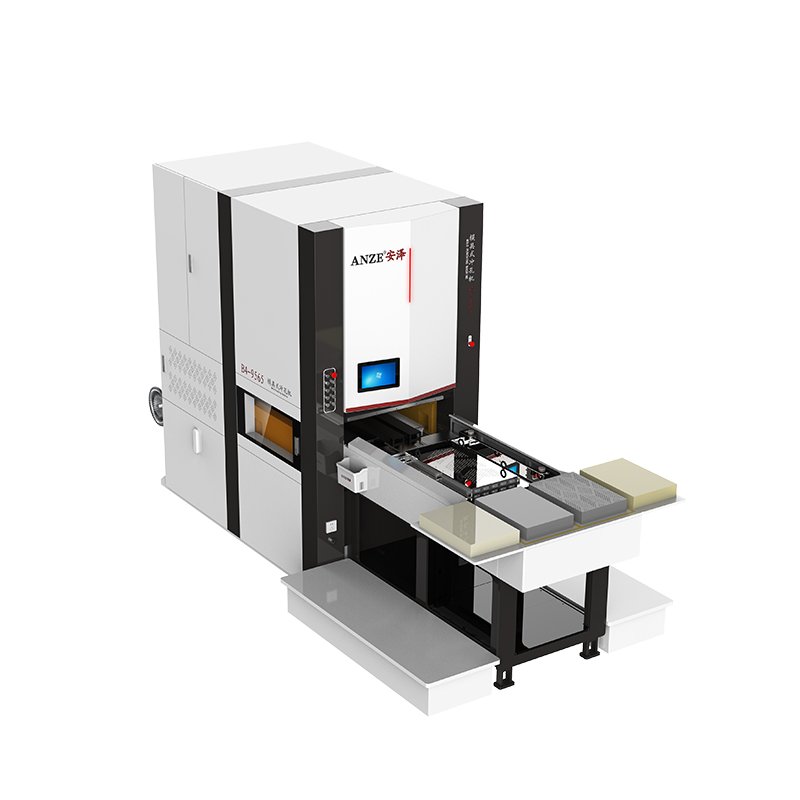

At Anze, we understand that the quality of a perforation machine is only as good as its craftsmanship. That’s why we place great emphasis on the design and manufacturing process, ensuring that each machine meets the highest standards of quality and durability.

Design and Engineering

Our team of experienced engineers and designers works tirelessly to create perforation machines that are not only functional but also aesthetically pleasing. We use advanced CAD software to develop precise designs, and we rigorously test each prototype to ensure it meets our stringent quality criteria.

During the design phase, we take into account various factors such as the machine’s intended use, the type of leather it will be processing, and the desired perforation patterns. This allows us to create machines that are tailored to the specific needs of our clients, ensuring optimal performance and satisfaction.

Manufacturing and Assembly

Once the design is finalized, we move on to the manufacturing and assembly stage. Our factory is equipped with state-of-the-art machinery and tools, enabling us to produce high-quality components with precision and consistency.

We pay close attention to every detail during the manufacturing process, from the selection of materials to the assembly of the machine. Each component is carefully inspected and tested to ensure it meets our quality standards, resulting in a perforation machine that is both reliable and durable.

Applications of Our Perforation Machines

As a leading perforation machine manufacturer, we understand the diverse needs of the leather industry. Our machines are designed to cater to a wide range of applications, enabling our clients to produce a variety of leather products with precision and efficiency.

Footwear and Apparel

Our perforation machines are widely used in the footwear and apparel industry, where they help create unique and stylish designs. From intricate patterns on leather shoes to decorative perforations on jackets and bags, our machines deliver precise and consistent results, enhancing the overall aesthetic of the products.

Automotive and Furniture

In the automotive and furniture industries, our perforation machines are used to create functional and aesthetically pleasing perforations. Whether it’s for seat covers, steering wheel grips, or upholstery, our machines ensure that the perforations are evenly spaced and of the highest quality, contributing to the comfort and style of the final product.

Custom and Specialty Items

Our perforation machines are also ideal for creating custom and specialty items. From personalized leather wallets to unique artisanal products, our machines enable clients to bring their creative visions to life, delivering precise and intricate perforations that add value and appeal to their products.

Choosing the Right Perforation Machine for Your Needs

With a wide range of perforation machines to choose from, selecting the right one for your specific needs can be a daunting task. As a seasoned perforation machine manufacturer, we are here to guide you through the process, ensuring you make an informed decision that meets your production requirements and budget.

Assessing Your Needs

Before choosing a perforation machine, it’s essential to assess your specific needs. Consider factors such as the type of leather you will be processing, the desired perforation patterns, production volumes, and budget constraints. This will help you narrow down your options and select a machine that is tailored to your requirements.

Types of Perforation Machines

We offer a variety of perforation machines, each with its own unique features and capabilities. Our machines range from manual and semi-automatic models to fully automated systems, ensuring there’s a solution to suit every budget and production need.

For small-scale production or custom work, a manual or semi-automatic machine may be sufficient. These machines are typically more affordable and offer greater flexibility in terms of pattern design and material handling.

On the other hand, for large-scale production, a fully automated perforation machine may be the best choice. These machines offer higher production rates, greater accuracy, and reduced labor costs, making them ideal for high-volume manufacturing environments.

Additional Features and Accessories

When selecting a perforation machine, consider the additional features and accessories that may enhance its functionality and performance. Features such as adjustable perforation depth, interchangeable tooling, and laser guidance can significantly improve the versatility and precision of the machine.

Furthermore, accessories like conveyors, material handling systems, and dust collection equipment can streamline your production process, reducing downtime and increasing efficiency.

Maintenance and Care of Your Perforation Machine

To ensure the longevity and optimal performance of your perforation machine, regular maintenance and care are essential. As a responsible perforation machine manufacturer, we provide comprehensive guidance and support to help you keep your machine in top condition.

Routine Maintenance

Regular maintenance is key to preventing breakdowns and extending the lifespan of your perforation machine. This includes tasks such as cleaning the machine, inspecting and replacing worn parts, and lubricating moving components.

We recommend creating a maintenance schedule that outlines the tasks to be performed and the frequency of each. By adhering to this schedule, you can identify potential issues before they become major problems, ensuring your machine runs smoothly and efficiently.

Troubleshooting and Repairs

Despite regular maintenance, issues may still arise with your perforation machine. When this happens, it’s important to have a reliable and knowledgeable support team to assist you.

As a perforation machine manufacturer with two decades of experience, we offer comprehensive troubleshooting and repair services. Our team of experts is available to diagnose and fix any issues with your machine, whether it’s a minor adjustment or a major repair.

We also provide training for your staff, enabling them to perform basic troubleshooting and maintenance tasks, reducing downtime and ensuring your production process remains uninterrupted.

Spare Parts and Upgrades

To keep your perforation machine running smoothly, it’s essential to have access to genuine spare parts and upgrades. As a manufacturer, we offer a wide range of spare parts, ensuring you can quickly and easily replace any worn or damaged components.

Furthermore, we regularly update our machines with new features and improvements. If you’re interested in upgrading your machine, we can provide you with the latest technology and accessories to enhance its performance and capabilities.

Sustainability and Ethical Practices in Perforation Machine Manufacturing

As a responsible perforation machine manufacturer, we understand the importance of sustainability and ethical practices in today’s world. We are committed to minimizing our environmental impact and promoting fair and transparent supply chain practices.

Environmental Initiatives

We strive to reduce waste and energy consumption in our manufacturing processes, incorporating eco-friendly materials and practices wherever possible. Our factory is equipped with energy-efficient machinery, and we recycle materials whenever feasible.

Furthermore, we encourage our clients to adopt sustainable practices in their own production processes, promoting the use of eco-friendly leather and reducing waste in their perforation operations.

Ethical Supply Chain Practices

We work closely with our suppliers to ensure they comply with international regulations and guidelines, promoting a fair and transparent supply chain. We are committed to sourcing materials from responsible and reputable suppliers, ensuring our machines are manufactured using ethically sourced components.

Any question pls contact May +8618002980031

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.