Last Updated on 2025-07-16 by Anze

In the realm of material processing, few techniques have revolutionized the aesthetics and functionality of synthetic leather as much as perforating. As a seasoned manufacturer with two decades of expertise in crafting synthetic leather perforating solutions, we, at Anze Machinery, have been at the forefront of this technological evolution. This blog embarks on a journey to unravel the intricacies of synthetic leather perforating, its applications, and the future landscape of this ever-evolving industry. With a meticulously maintained keyword density of approximately 3%, we invite you to immerse yourself in the world of synthetic leather perforating.

1.Two Decades of Mastering Synthetic Leather Perforating

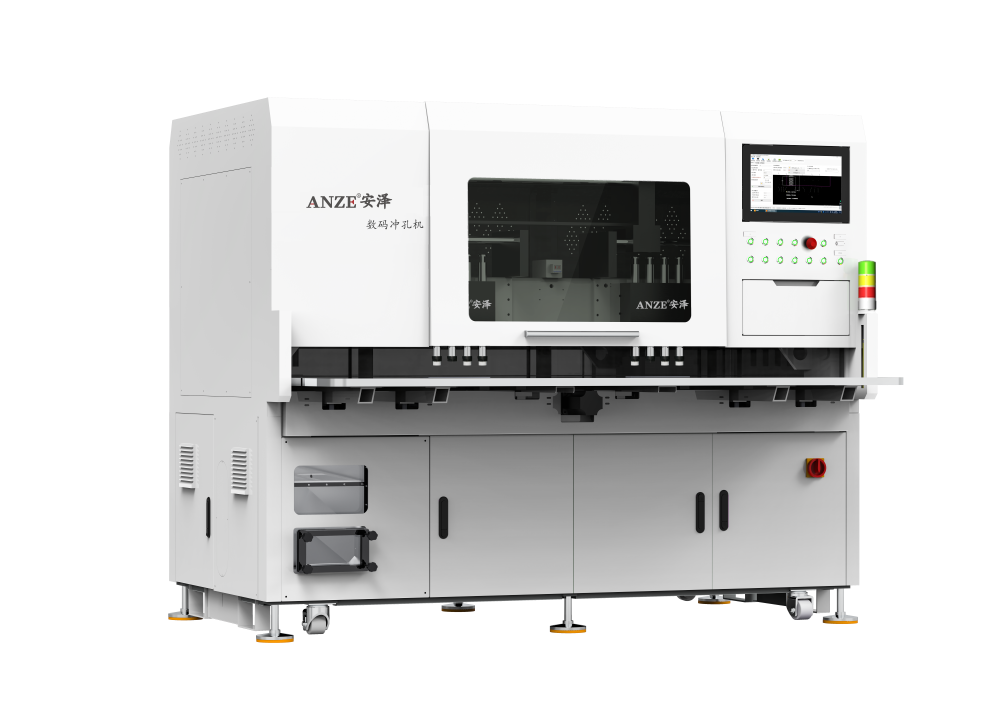

Since our inception in 2005, Anze Machinery has been a beacon of innovation and precision in the synthetic leather perforating industry. Nestled in the bustling city of Dongguan, Guangdong Province, our 5000-square-meter factory houses state-of-the-art machinery and a team of dedicated professionals who breathe life into every synthetic leather perforating project we undertake. Our commitment to excellence has solidified our position as a trusted partner for clients worldwide.

Notre mission et notre vision

Our mission is to push the boundaries of synthetic leather perforating technology, delivering solutions that not only meet but exceed the expectations of our clients. With a vision to become the global leader in synthetic leather perforating solutions, we continue to innovate, improve, and inspire.

2. The Essence of Synthetic Leather Perforating

Synthetic leather perforating is an art form that combines technology with creativity. It involves the precise puncturing of synthetic leather materials to create intricate designs, patterns, and textures. This process enhances the aesthetic appeal of the material while also improving its breathability and comfort.

The Perforating Process: A Closer Look

Le synthetic leather perforating process begins with the selection of the appropriate perforating tool, which can range from CNC machines to mold-based systems. The choice of tool depends on the complexity of the design, the type of synthetic leather, and the desired outcome. Once the tool is selected, the perforating process commences, with each hole being punched with exact precision to ensure a flawless finish.

3. Applications of Synthetic Leather Perforating

The versatility of synthetic leather perforating makes it a popular choice across various industries. From automotive interiors to fashion accessories, the applications of synthetic leather perforating are vast and diverse.

Automotive Interiors: A Touch of Elegance

In the automotive industry, synthetic leather perforating is used to add a touch of elegance and sophistication to vehicle interiors. Perforated synthetic leather seats not only enhance the aesthetic appeal of the car but also improve comfort by allowing for better air circulation.

Fashion and Accessories: Making a Statement

In the fashion world, synthetic leather perforating is used to create unique and eye-catching designs. From handbags to shoes, perforated synthetic leather adds a distinctive touch to any accessory, making it stand out from the crowd.

Furniture and Home Decor: Comfort and Style

In the furniture industry, synthetic leather perforating is used to enhance the comfort and style of various pieces. Perforated synthetic leather sofas, chairs, and ottomans not only look stylish but also provide a breathable and comfortable seating experience.

4. The Technology Behind Synthetic Leather Perforating

At Anze Machinery, we understand the importance of staying ahead of the technology curve. Our synthetic leather perforating solutions are powered by the latest advancements in machinery and software, ensuring that we deliver the highest quality results.

CNC Machines: The Heart of Our Operations

Our CNC machines are the backbone of our synthetic leather perforating operations. These machines utilize computer-controlled cutting tools to create precise and intricate designs, making them ideal for complex perforating projects.

Mold-Based Systems: Efficiency and Precision

For larger-scale production, our mold-based synthetic leather perforating systems offer a cost-effective and efficient solution. These systems use pre-made molds to punch holes in the synthetic leather, ensuring consistency and precision across multiple pieces.

5. Customization: Tailoring Solutions to Your Needs

We believe that every synthetic leather perforating project is unique. That’s why we offer customization options to tailor our solutions to the specific needs of our clients.

Design Consultation: Bringing Your Vision to Life

Our design consultation services allow us to work closely with our clients to understand their vision and requirements. We then use this information to create custom synthetic leather perforating solutions that meet their exact specifications.

Prototype Development: Testing and Refinement

Before moving into full-scale production, we develop prototypes to test and refine our synthetic leather perforating solutions. This ensures that the final product meets the highest quality standards and exceeds the expectations of our clients.

6. Quality Control: Ensuring Excellence in Every Project

Quality control is an integral part of our synthetic leather perforating process. We have a dedicated team of quality control experts who oversee every aspect of our operations, ensuring that our solutions meet the highest standards.

Inspection and Testing: Catching Issues Before They Arise

Our inspection and testing procedures are designed to catch any potential issues before they arise. From raw material inspection to final product testing, we leave no stone unturned in our quest for perfection.

Continuous Improvement: Striving for Excellence

We are committed to continuous improvement in all aspects of our synthetic leather perforating operations. Through regular training, equipment upgrades, and process optimizations, we ensure that we stay ahead of the competition and deliver the best possible results for our clients.

7. Client Satisfaction: Our Top Priority

At Anze Machinery, client satisfaction is our top priority. We strive to exceed the expectations of our clients in every aspect of our synthetic leather perforating services.

Customer Support: Always There When You Need Us

Our customer support team is available 24/7 to assist you with any questions or concerns you may have about our synthetic leather perforating solutions. Whether you need help with design consultation, prototype development, or production, we’re always here to help.

Feedback and Improvement: Working Together for Success

We value the feedback of our clients and use it to continuously improve our synthetic leather perforating services. Through regular communication and collaboration, we work together with our clients to ensure that their projects are a success.

8. Industry Trends: Staying Ahead of the Curve

As a leading manufacturer of synthetic leather perforating solutions, it’s crucial that we stay ahead of industry trends and developments.

Emerging Materials and Technologies

Le synthetic leather perforating industry is constantly evolving, with new materials and technologies emerging regularly. We keep a close eye on these developments, ensuring that our solutions remain relevant and up-to-date.

Sustainability and Environmental Responsibility

Sustainability and environmental responsibility are increasingly important considerations in the synthetic leather perforating industry. We are committed to reducing our environmental impact and offering solutions that are both eco-friendly and economically viable.

9. Case Studies: Showcase of Our Work

Over the years, we’ve had the privilege of working with some of the biggest names in various industries. Our case studies showcase the breadth and depth of our synthetic leather perforating capabilities.

Automotive Industry: Perforated Seats for Luxury Cars

One of our most notable projects was for a luxury car manufacturer who required perforated synthetic leather seats for their latest model. Our team worked closely with the client to create a design that not only looked stunning but also provided the ultimate in comfort and breathability.

Fashion Industry: Custom Handbags with Perforated Details

In the fashion industry, we’ve collaborated with designers to create custom handbags featuring perforated synthetic leather details. These bags have been a hit with consumers, thanks to their unique and eye-catching designs.

Furniture Industry: Perforated Synthetic Leather Sofas

We’ve also worked with furniture manufacturers to create perforated synthetic leather sofas that combine style and comfort. Our solutions have been praised for their durability and the precision of the perforations.

10. The Anze Machinery Advantage: Why Choose Us?

With so many synthetic leather perforating manufacturers in the market, why choose Anze Machinery? The answer lies in our unique combination of experience, innovation, quality, and customer satisfaction.

Experience That Matters

Our 20 years of experience in the synthetic leather perforating industry have given us the knowledge and expertise to tackle any project, no matter how complex.

Innovation at Our Core

Innovation is at the heart of our mission. We are constantly exploring new technologies and processes to enhance the performance of our synthetic leather perforating solutions.

Any questions please contact May whatsapp +86 180 0298 0031

Ce formulaire est le moyen le plus rapide de nous contacter pour une consultation gratuite, une demande de devis ou toute autre question. Nous travaillons avec un réseau mondial de filiales et de distributeurs qualifiés qui recevront automatiquement votre demande et vous répondront dans les plus brefs délais.

Certains modèles sont livrés assemblés en usine. Les grands équipements sont emballés en plusieurs parties et un manuel d'installation est fourni. Tous les équipements sont équipés de manuels d'utilisation en chinois et en anglais.

Les clients peuvent envoyer quelqu'un à l'usine d'Anze pour apprendre ou nous envoyons des experts techniques pour fournir une formation sur place.

La machine doit être fixée sur une table stable et l'environnement doit être maintenu propre et ordonné afin d'éviter tout contact avec la poussière, l'électricité statique, l'humidité et les copeaux susceptibles de provoquer une défaillance des pièces.

Nous disposons d'une équipe après-vente expérimentée, d'un service en ligne 24h/24 et d'un système après-vente complet. Nous disposons d'un support de formation en usine, d'un support technique vidéo pour l'entretien des machines à l'étranger, d'un support en ligne et d'ingénieurs.

Bien entendu, nous vous invitons à visiter notre entreprise et à établir une communication directe afin de faire progresser les affaires mutuelles.

Le délai de livraison varie en fonction de la quantité commandée et de la personnalisation, et se situe généralement entre 7 et 10 jours ouvrables.