Last Updated on 2025-12-02 by Anze

1. Why Modern Bag Manufacturers Need a High-Precision Perforation Machine

The global leather bag industry is rapidly transforming. Luxury handbag brands, sports bag manufacturers, and luggage producers are demanding lighter, more breathable, and more visually unique leather materials. These design trends require manufacturers to adopt a high-precision machine de perforation capable of producing consistent patterns, micro-ventilation holes, and custom decorative perforation layouts.

ANZE, as a 20-year professional leather perforation machine manufacturer, has seen tremendous market demand from bag factories across Asia, Europe, and North America. Modern bag makers want a combination of:

High-precision punching

Repeatable positioning accuracy

Custom pattern generation

High-speed continuous production

Stable perforation quality on soft or elastic leather

This whitepaper-style blog provides a complete, technical and detailed solution for bag leather punching, including process design, machine settings, perforation techniques, troubleshooting, and how ANZE’s perforation machine technology solves key manufacturing challenges.

2. Understanding Bag Leather Perforation: Challenges and Material Behaviors

Bag leathers—whether natural leather or synthetic materials such as PU, PVC, microfiber leather, split leather composite, or coated cowhide—present unique technical challenges.

2.1 Stretch and Elasticity

Different leather materials react differently under mechanical force. When using a perforation machine:

Soft leather tends to expand, softening the edges of holes.

Hard leather may crack around the hole edges if the punching force is too strong.

Synthetic leather layers may delaminate without proper die selection.

2.2 Surface Treatment Layers

Coated leather, embossed textures, or protective films require:

Controlled punching depth

Special needle or die design

Reduced punching friction

2.3 Precision Hole Alignment

Bag panels often require perforated zones aligned with:

Stitching lines

Ventilation zones

Decorative patterns

Logos or brand shapes

This requires a high-accuracy machine de perforation with servo control and precise conveyor feeding systems.

3. Why a Dedicated Perforation Machine Is Essential for Bag Leather Production

Unlike general punching tools, a professional machine de perforation is engineered to deliver:

3.1 Uniform Hole Size

Even tiny variations in hole size affect:

Bag appearance

Stitch line symmetry

Material strength

3.2 Consistent Perforation Depth

Consistent depth prevents:

Tearing

Over-perforation

Weakening of leather fibers

3.3 Repeatable, Computer-Generated Perforation Patterns

Modern handbag design requires:

Geometric patterns

Brand-style patterns

Perforated logos

Laser-inspired designs

Micro-ventilation perforation

Only a dedicated machine de perforation can repeat patterns accurately over thousands of cycles.

4. Types of Perforation Machine for Bag Leather Manufacturing

Here are the most common machine types used in the bag industry:

4.1 Servo-Driven Mechanical Perforation Machine

The most widely used machine type in bag factories.

Avantages :

High speed

Strong punching force

Low maintenance cost

Excellent for thick leather

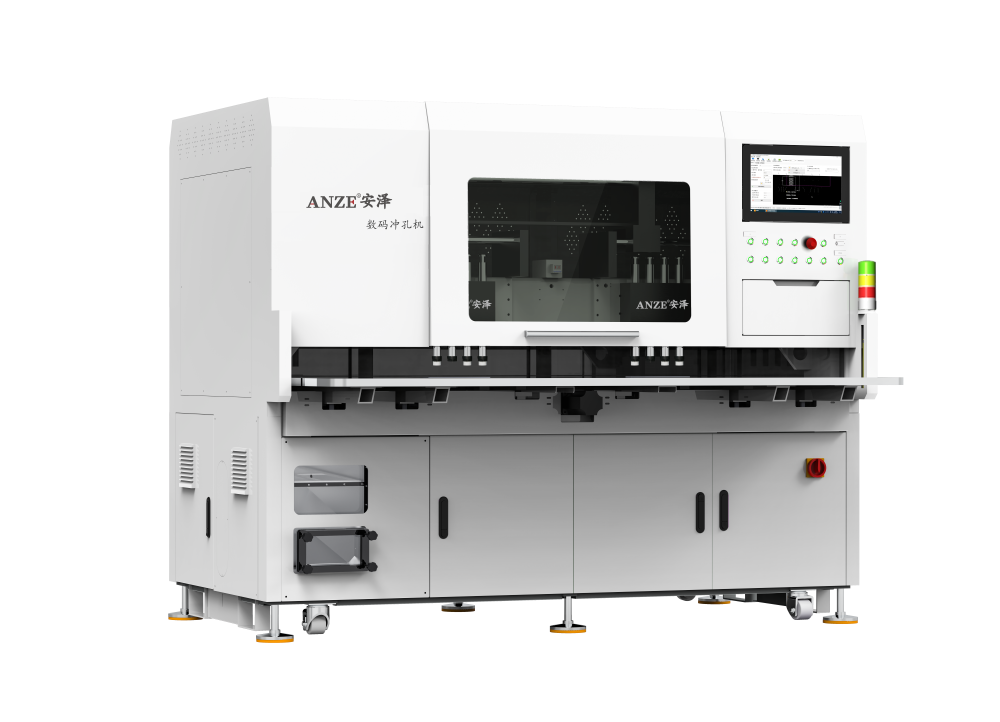

4.2 CNC Digital Perforation Machine

A premium solution for high-end luxury bags.

Avantages :

Full pattern customization

Absolute positional accuracy

Minimal tooling needed

Suitable for small-batch designer bags

4.3 Roller Perforation Machine

Suitable for continuous punching of long leather rolls.

Avantages :

Extremely high productivity

Suitable for mass production

Uniform rolling perforation

4.4 Laser Perforation Machine

A non-contact perforation machine ideal for:

Micro-holes

Decorative patterns

Soft, delicate leather

Note: Laser technology can burn edges if not optimized.

5. The Complete Bag Leather Perforation Workflow Using a Perforation Machine

Below is a detailed industry-standard workflow for bag factories using ANZE technology.

STEP 1 – Leather Selection

Choose leather based on:

Thickness

Softness

Surface coating

Stretch behavior

Colorfastness

Call this step material calibration.

STEP 2 – Pattern Design (CAD/CAM Integration)

A perforation machine is connected to:

AutoCAD

CorelDRAW

AI design software

Proprietary ANZE Pattern Editor

Patterns include:

Straight-line holes

Triangular, circular, oval layouts

Custom designer patterns

Réseaux de trous d'aération

STEP 3 – Machine Parameter Setup

Important parameters include:

| Parameter | Typical Range | Notes |

|---|---|---|

| Punching force | 0.3–2.5 tons | Adjusted based on leather hardness |

| Punching frequency | 1,000–6,000 hits/min | Depends on model |

| Feeding accuracy | ±0.05–0.1 mm | Servo controlled |

| Die type | Round / blade / custom | Based on pattern |

| Depth setting | 0–3 mm | Avoid over-punching |

STEP 4 – Punching Execution

Using ANZE’s servo-conveyor machine de perforation, bag leather is:

Loaded

Aligned

Perforated

Automatically advanced

Quality scanned

The perforation machine ensures:

Clean edge

Minimal burrs

Accurate spacing

STEP 5 – Quality Inspection

Inspection includes:

Hole shape precision

Hole diameter accuracy

Edge smoothness

No cracks or delamination

6. Techniques for Achieving Perfect Leather Punching Using a Perforation Machine

6.1 Optimize Punching Force

Low force → incomplete punching

High force → cracking

A perforation machine must balance force via servo control.

6.2 Use the Correct Die Type

Die shape influences:

Hole aesthetics

Material durability

6.3 Maintain Leather Temperature & Humidity

Leather must be conditioned:

20–24°C

45–55% RH

6.4 Use Multi-Stage Pattern Alignment

Ensures long bag panels are aligned even over large surfaces.

6.5 Combine Digital Patterning With Real-Time Vision System

ANZE machines can auto-correct misalignment during punching.

7. Troubleshooting Guide for Perforation Machine Bag Leather Production

Problem 1 – Hole edges look fuzzy

Cause: Punching force too low

Solution: Increase depth or change die

Problem 2 – Leather cracks around holes

Cause: Material too dry or force too high

Solution: Re-condition leather or reduce pressure

Problem 3 – Hole spacing inconsistent

Cause: Belt slippage or feeding error

Solution: Calibrate servo feeder

Problem 4 – Pattern distortion

Cause: Stretching under force

Solution: Use pre-tensioning clamps

8. Why Bag Manufacturers Choose ANZE Perforation Machine

8.1 20 Years of R&D

ANZE has developed over 20+ successful machine de perforation models.

8.2 Precision Engineering

Our machines provide:

±0.05 mm accuracy

High-speed stable operation

Clean punching with minimal burr

8.3 Custom Bag Industry Solutions

We provide:

Custom dies

Pattern software

Machine customization

Technical training

8.4 Global Client Base

We supply perforation machines to:

USA

Italy

Vietnam

Turkey

China

India

8.5 High-End Bag Brand Support

Our machines are used for:

Luxury handbags

Sports bags

Luggage & travel bags

Fashion bags

9. Case Study: A Leading European Bag Brand Upgrades to ANZE Perforation Machine

A major European luxury bag manufacturer previously used manual stamping tools, resulting in:

Low accuracy

High defect rates

Slow production

After switching to ANZE:

Productivity increased by 280%

Defects fell by 70%

Custom patterns were delivered in 24 hours

Overall factory efficiency improved significantly

10. Future Trends in Bag Leather Perforation Machine Technology

10.1 AI-Generated Perforation Patterns

Future machines will integrate AI pattern generators.

10.2 Smart Vision QC Systems

Automatic detection of hole size and alignment.

10.3 Energy-Efficient Drive Technology

Lower power consumption while maintaining punching force.

10.4 Hybrid Laser-Mechanical Perforation

Best of both worlds:

Laser for micro-holes

Mechanical for structural patterns

11. The Perforation Machine Is Now Essential for Modern Bag Leather Manufacturing

High-end bag manufacturing now relies heavily on advanced machine de perforation technology to achieve:

Aesthetic perfection

Mechanical precision

Material consistency

Automated efficiency

ANZE is proud to support global bag manufacturers with the most reliable, precise, and innovative leather perforation machines available today.

12. Call to Action

✔ Want to upgrade your bag leather punching process?

✔ Need a custom pattern solution?

✔ Looking for a high-speed, high-precision perforation machine?

Contact ANZE today for technical consultation, free pattern testing, and machine demonstration videos.

Grâce à une équipe expérimentée et qualifiée, nous connaissons tous les types de caractéristiques des matériaux et de technologies de traitement, et nous pouvons personnaliser les produits. Machine à perforer le cuir selon les besoins du client. N'hésitez pas à nous contacter si vous avez des questions ! Whatsapp +86 180 0298 0031

Comment installer et entretenir la machine ?

Certains modèles sont livrés assemblés en usine. Les grands équipements sont emballés en plusieurs parties et un manuel d'installation est fourni. Tous les équipements sont équipés de manuels d'utilisation en chinois et en anglais.

Les clients peuvent envoyer quelqu'un à l'usine d'Anze pour apprendre ou nous envoyons des experts techniques pour fournir une formation sur place.

Quelles sont les exigences en matière d'environnement de travail de la machine ?

Le Machine à poinçonner le cuir à commande numérique doit être fixé sur une table stable et l'environnement doit être maintenu propre et ordonné afin d'éviter tout contact avec la poussière, l'électricité statique, l'humidité et les copeaux qui pourraient entraîner une défaillance des pièces.

Quelle est votre politique en matière de service après-vente ?

Nous disposons d'une équipe après-vente expérimentée, d'un service en ligne 24h/24 et d'un système après-vente complet. Nous disposons d'un support de formation en usine, d'un support technique vidéo pour l'entretien des machines à l'étranger, d'un support en ligne et d'ingénieurs.

Êtes-vous disponible pour une invitation sur place ?

Bien entendu, nous vous invitons à visiter notre entreprise et à établir une communication directe afin de faire progresser les affaires mutuelles.

Quel est le délai de livraison ?

Le délai de livraison varie en fonction de la quantité commandée et de la personnalisation, et se situe généralement entre 7 et 10 jours ouvrables.