Last Updated on 2025-12-30 by Anze

Why Choosing the Right Perforation Machine Manufacturer Matters

In modern manufacturing, perforation technology plays a critical role across a wide range of industries, including leather goods, automotive interiors, furniture upholstery, footwear, packaging, filtration, textiles, and flexible materials processing. Behind every high-quality perforated product stands a capable and reliable fabricant de machines de perforation.

Selecting the right perforation machine manufacturer directly affects production efficiency, product consistency, operating cost, and long-term competitiveness. Manufacturers must consider not only machine specifications, but also engineering expertise, application knowledge, customization capability, and after-sales support.

With over 20 years of experience in designing and manufacturing leather perforation equipment, ANZE has become a trusted perforation machine manufacturer recognized by customers worldwide. This article provides a structured, in-depth overview of the perforation machine manufacturing industry, introduces key technology categories, and recommends globally respected perforation machine manufacturers—including ANZE—based on engineering strength and real-world performance.

What Defines a Professional Perforation Machine Manufacturer?

A professional fabricant de machines de perforation is not defined solely by the machines it sells, but by its engineering capabilities, manufacturing processes, and understanding of application requirements.

Key characteristics of a reliable perforation machine manufacturer include:

Long-term industry experience

In-house R&D and mechanical design

Precision manufacturing capability

Deep application knowledge

Custom solution development

Stable quality control systems

Global technical support

Manufacturers lacking these fundamentals often struggle to deliver consistent performance in real production environments.

Core Technologies Offered by a Perforation Machine Manufacturer

Mechanical Perforation Systems

Mechanical systems use cam or crank mechanisms to drive perforation punches. Many traditional perforation machine manufacturers offer mechanical solutions for high-volume, fixed-pattern production.

Avantages :

Simple structure

High reliability

Low operating cost

Pneumatic Perforation Machines

Pneumatic solutions rely on compressed air to generate punching force. A perforation machine manufacturer may recommend these systems for lighter materials or lower force requirements.

Avantages :

Adjustable pressure

Smooth operation

Moderate investment cost

Hydraulic Perforation Machines

Hydraulic systems provide strong, stable punching force for thick or layered materials. A capable perforation machine manufacturer designs hydraulic systems with precise pressure control to avoid material damage.

Avantages :

High force output

Stable performance

Suitable for heavy-duty applications

Servo-Driven and CNC Perforation Machines

Advanced perforation machine manufacturers increasingly offer servo-controlled or CNC perforation systems. These machines provide programmable motion, precision positioning, and integration with digital workflows.

Avantages :

High accuracy

Flexible pattern control

Automation compatibility

ANZE specializes in servo-assisted perforation solutions that balance precision and productivity.

Application Expertise as a Key Indicator of a Perforation Machine Manufacturer

A leading perforation machine manufacturer understands that perforation requirements vary significantly by industry.

Leather Industry Applications

Leather perforation demands:

Clean hole edges

Controlled force

Protection of natural grain structure

Professional perforation machine manufacturers design equipment specifically for natural leather, synthetic leather, and microfiber materials.

Automotive Interior Applications

Automotive applications include:

Seat covers

Door panels

Speaker grille leather

Here, perforation affects breathability, comfort, and acoustic performance, requiring high precision and repeatability.

Furniture and Upholstery Applications

Furniture manufacturers rely on perforation for ventilation and aesthetics. A capable perforation machine manufacturer provides stable, high-output solutions for large upholstery panels.

Footwear and Fashion Applications

Footwear and fashion brands require consistent, decorative perforation patterns. Tooling accuracy and surface protection are critical.

Why Engineering Experience Matters for a Perforation Machine Manufacturer

Engineering experience directly influences machine durability, precision, and adaptability. A perforation machine manufacturer with decades of experience has typically:

Encountered diverse materials and challenges

Refined structural designs over time

Optimized tooling systems

Improved automation reliability

ANZE’s 20-year manufacturing history allows it to design perforation machines that perform reliably in real-world production environments.

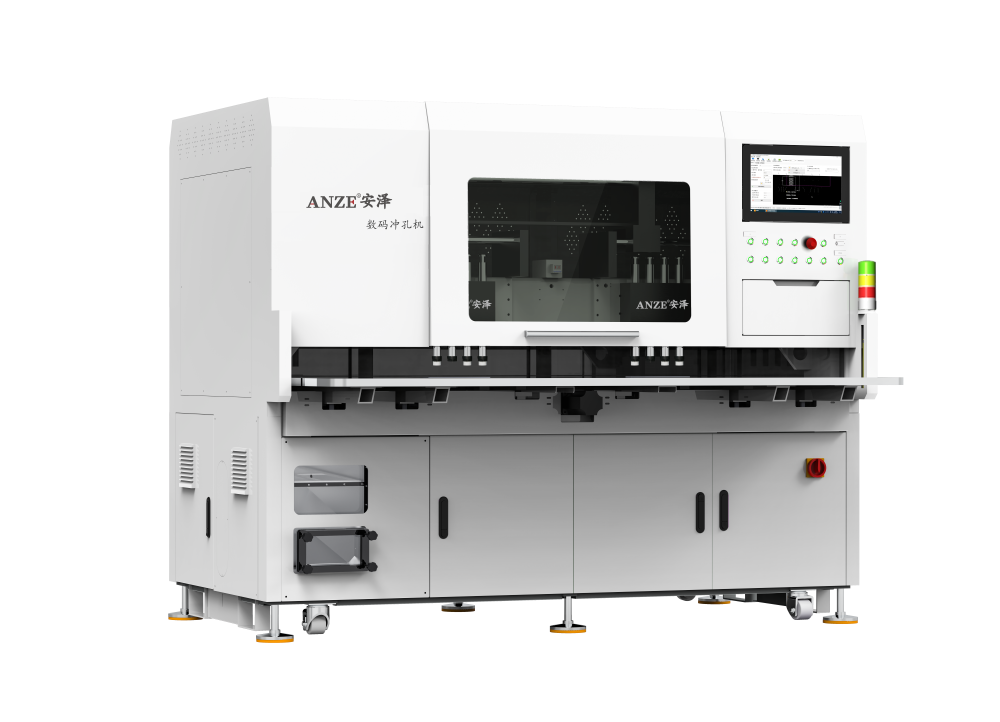

ANZE: A Professional Perforation Machine Manufacturer with 20 Years of Experience

Company Overview

ANZE is a professional fabricant de machines de perforation specializing in leather perforation equipment and flexible material processing solutions. With over two decades of design and manufacturing experience, ANZE has developed more than 20 proven machine models used by customers across multiple industries.

Core Strengths of ANZE as a Perforation Machine Manufacturer

In-house mechanical and electrical R&D

Custom perforation tooling design

Servo-driven and automated systems

Stable quality control processes

Strong customer recognition and repeat business

ANZE’s machines are engineered for long-term stability, precision, and ease of integration into existing production lines.

ANZE Application Focus

ANZE perforation solutions are widely used in:

Automotive leather interiors

Furniture and upholstery

Footwear manufacturing

Bags and leather goods

Technical textiles and flexible materials

This application focus allows ANZE to provide practical, solution-oriented machine designs.

Global Leading Perforation Machine Manufacturer Recommendations

In addition to ANZE, several global companies are recognized as leading perforation machine manufacturers based on engineering capability and market presence.

Zünd Systemtechnik (Switzerland)

Zünd is a well-known perforation machine manufacturer specializing in digital cutting and perforation systems.

Strengths:

High-precision CNC systems

Advanced software integration

Strong presence in technical textiles

Gerber Technology (USA)

Gerber offers CNC cutting and perforation solutions for apparel and industrial fabrics.

Strengths:

Integrated digital workflow

Strong software ecosystem

Established global brand

Atom Group (Italy)

Atom is a traditional perforation machine manufacturer with strong expertise in leather and footwear machinery.

Strengths:

Mechanical punching expertise

Long history in shoe manufacturing

Robust machine construction

Eastman Machine Company (USA)

Eastman provides cutting and perforation solutions for industrial materials.

Strengths:

Heavy-duty machine designs

Strong service network

Broad material compatibility

How Perforation Machine Manufacturers Differ by Market Focus

Not all perforation machine manufacturers serve the same markets. Differences may include:

Automotive vs fashion focus

High-volume vs flexible production

Manual vs fully automated solutions

ANZE positions itself as a flexible perforation machine manufacturer capable of providing both standardized and customized solutions.

Customization Capability as a Competitive Advantage

A key differentiator among perforation machine manufacturers is customization capability.

Customization may include:

Hole size and pattern design

Tooling configuration

Niveau d'automatisation

Feeding and handling systems

ANZE offers application-specific customization to meet unique customer requirements.

Quality Control Standards of a Perforation Machine Manufacturer

Professional perforation machine manufacturers implement strict quality control at every stage, including:

Component inspection

Assembly accuracy checks

Performance testing

Long-duration trial runs

Quality control ensures consistent performance and long service life.

After-Sales Support and Service Capability

Reliable after-sales support is essential when selecting a perforation machine manufacturer. This includes:

Installation support

Operator training

Spare parts availability

Remote technical assistance

ANZE provides long-term technical support to global customers.

Cost Efficiency and ROI When Choosing a Perforation Machine Manufacturer

While initial machine cost is important, long-term value is determined by:

Production efficiency

Scrap reduction

Maintenance requirements

Machine lifespan

A professional perforation machine manufacturer helps customers optimize total cost of ownership rather than focusing solely on upfront price.

Industry Trends Affecting Perforation Machine Manufacturers

Key trends shaping the future include:

Increased automation

Servo-driven motion control

Smart monitoring systems

Industry 4.0 integration

Energy-efficient designs

Leading perforation machine manufacturers, including ANZE, continue to invest in these technologies.

How to Evaluate and Compare a Perforation Machine Manufacturer

When evaluating a fabricant de machines de perforation, buyers should consider:

Years of experience

Application references

Engineering depth

Customization ability

Support infrastructure

These factors are more reliable indicators than marketing claims alone.

Frequently Asked Questions About Perforation Machine Manufacturers

What does a fabricant de machines de perforation typically provide?

A perforation machine manufacturer provides machine design, manufacturing, tooling, testing, and technical support.

Is specialization important in a perforation machine manufacturer?

Yes. Manufacturers specializing in specific materials or industries often deliver better performance and reliability.

Can perforation machine manufacturers customize machines?

Professional manufacturers like ANZE offer customization based on material type, production volume, and pattern requirements.

Choosing the Right Perforation Machine Manufacturer for Long-Term Success

A reliable fabricant de machines de perforation is a long-term production partner rather than just an equipment supplier. Engineering experience, application knowledge, customization capability, and service support all play decisive roles in production success.

With over 20 years of manufacturing experience and strong customer recognition, ANZE stands out as a professional perforation machine manufacturer delivering stable, high-performance solutions for leather and flexible material processing. Alongside other global leaders, ANZE represents a new generation of manufacturers focused on precision, efficiency, and real-world manufacturing value.

For companies seeking consistent perforation quality, scalable production, and long-term reliability, selecting the right perforation machine manufacturer is a strategic investment.

Grâce à une équipe expérimentée et qualifiée, nous connaissons tous les types de caractéristiques des matériaux et de technologies de traitement, et nous pouvons personnaliser les produits. Machine à perforer le cuir selon les besoins du client. N'hésitez pas à nous contacter si vous avez des questions ! Whatsapp +86 180 0298 0031

Comment installer et entretenir la machine ?

Certains modèles sont livrés assemblés en usine. Les grands équipements sont emballés en plusieurs parties et un manuel d'installation est fourni. Tous les équipements sont équipés de manuels d'utilisation en chinois et en anglais.

Les clients peuvent envoyer quelqu'un à l'usine d'Anze pour apprendre ou nous envoyons des experts techniques pour fournir une formation sur place.

Quelles sont les exigences en matière d'environnement de travail de la machine ?

Le Machine à poinçonner le cuir à commande numérique doit être fixé sur une table stable et l'environnement doit être maintenu propre et ordonné afin d'éviter tout contact avec la poussière, l'électricité statique, l'humidité et les copeaux qui pourraient entraîner une défaillance des pièces.

Quelle est votre politique en matière de service après-vente ?

Nous disposons d'une équipe après-vente expérimentée, d'un service en ligne 24h/24 et d'un système après-vente complet. Nous disposons d'un support de formation en usine, d'un support technique vidéo pour l'entretien des machines à l'étranger, d'un support en ligne et d'ingénieurs.

Êtes-vous disponible pour une invitation sur place ?

Bien entendu, nous vous invitons à visiter notre entreprise et à établir une communication directe afin de faire progresser les affaires mutuelles.

Quel est le délai de livraison ?

Le délai de livraison varie en fonction de la quantité commandée et de la personnalisation, et se situe généralement entre 7 et 10 jours ouvrables.