Last Updated on 2025-07-25 by Anze

As a seasoned manufacturer with two decades of expertise in crafting high-quality leather perforation machine, we have been at the forefront of the leather processing industry. Our journey has been marked by a commitment to innovation, precision, and customer satisfaction. Today, we are proud to share a recent success story that highlights the capabilities of our leather perforation machines and the trust we have built with our clients, particularly in Vietnam.

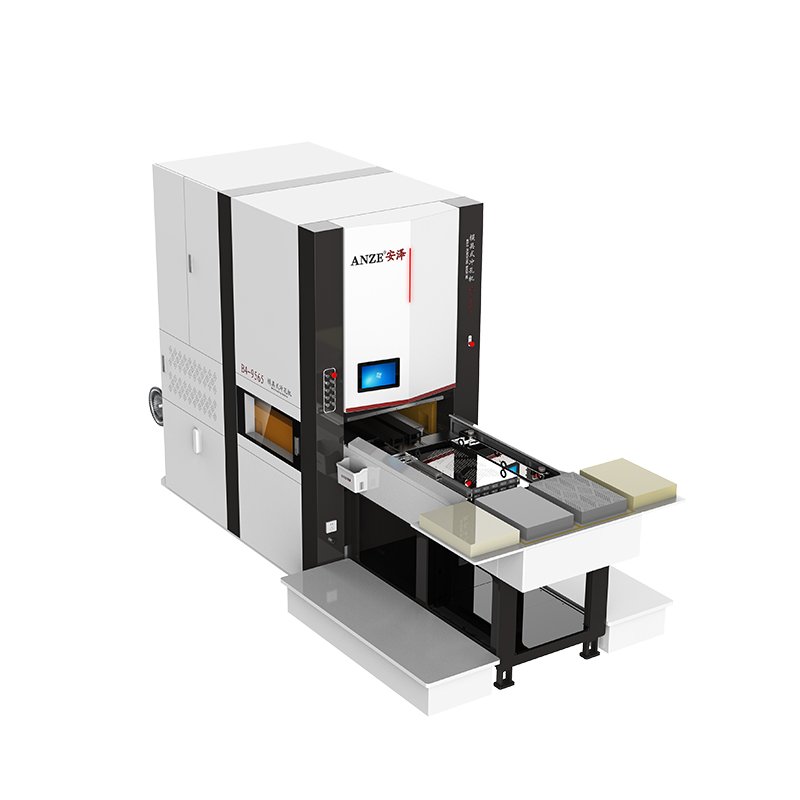

Customized Leather Perforation Machine for Vietnamese Automotive Seats

Our latest project involved designing and manufacturing a customized leather perforation machine for a Vietnamese client in the automotive industry. The client, a leading manufacturer of car seats, approached us with specific requirements for a machine that could handle the unique challenges of perforating leather for automotive applications.

Understanding the Client’s Needs

The client required a leather perforation machine that could deliver precise and consistent perforations on various types of leather materials used in car seat manufacturing. The machine needed to be robust, reliable, and capable of handling high production volumes. Furthermore, the client wanted a machine that could be easily integrated into their existing production line and operated by their staff with minimal training.

Designing the Perfect Solution

Our team of experienced engineers and designers worked closely with the client to understand their specific needs and challenges. After thorough analysis and consultation, we designed a customized leather perforation machine that met all the client’s requirements.

The machine featured a user-friendly interface, advanced control systems, and precision tooling that ensured consistent and accurate perforations. We also incorporated robust construction materials and components to ensure the machine’s durability and reliability in a high-production environment.

Testing and Delivery

Before delivering the machine, we conducted rigorous testing to ensure it met all the client’s specifications and performed to our high standards. We invited the client to our factory for a live demonstration, where they could see the machine in action and verify its capabilities.

The client was extremely satisfied with the performance of the leather perforation machine and placed an order for immediate delivery. Our team worked diligently to ensure the machine was shipped and installed at the client’s facility with minimal disruption to their production schedule.

The Impact of Our Leather Perforation Machine on the Client's Business

The customized leather perforation machine has had a significant impact on our Vietnamese client’s business. The machine’s precision and efficiency have improved the quality of their car seat leather perforations, resulting in higher customer satisfaction and increased sales.

Furthermore, the machine’s high production capacity has enabled the client to meet the growing demand for their car seats, expanding their market reach and revenue streams. The ease of operation and maintenance has also reduced labor costs and downtime, contributing to overall cost savings and profitability.

A Testimonial of Our Expertise

The success of this project is a testament to our expertise as a leather perforation machine manufacturer. Our ability to understand and meet the unique needs of our clients, combined with our commitment to innovation and quality, has enabled us to build a strong reputation in the industry.

As a result, our client has expressed their satisfaction and trust in our products and services, leading to a plan for further collaboration. They have scheduled a visit to our factory next month to discuss the purchase of additional leather perforation machines to further expand their production capacity.

The Leather Perforation Machine Manufacturing Process

Our success in delivering customized leather perforation machines to clients like our Vietnamese partner is rooted in our meticulous manufacturing process. We take great care in every step of the process, from design and engineering to testing and delivery, to ensure that our machines meet the highest standards of quality and performance.

Design and Engineering

Our design and engineering team works closely with clients to understand their specific requirements and challenges. Using advanced software and tools, we create detailed designs and simulations to ensure the machine will meet the client’s needs and perform to our standards.

We also incorporate the latest technologies and innovations into our designs, such as automation, laser perforation, and advanced control systems, to enhance the machine’s capabilities and efficiency.

Sourcing and Manufacturing

We source high-quality materials and components from reputable suppliers to ensure the durability and reliability of our machines. Our manufacturing process includes rigorous quality control checks at every stage, from machining and assembly to testing and packaging.

We also have a dedicated team of skilled workers who bring years of experience and expertise to the manufacturing process. Their commitment to precision and quality ensures that every machine we produce meets our high standards.

Testing and Quality Assurance

Before delivering any machine, we conduct extensive testing and quality assurance checks. This includes functional testing, performance testing, and safety testing to ensure the machine meets all relevant standards and regulations.

We also provide clients with training and support to ensure they can operate and maintain the machine effectively. Our team of experts is available to answer any questions and provide ongoing support as needed.

Leather Perforation Machine: A Versatile Tool for Various Industries

While our recent project with a Vietnamese automotive seat manufacturer highlights the capabilities of our leather perforation machines in the automotive industry, these machines are versatile tools that can be used in various other industries.

Fashion and Accessories

Leather perforation machines are essential in the fashion and accessories industry, where precise and intricate perforations can add a unique touch to handbags, shoes, and clothing. Our machines can handle a wide range of leather materials and thicknesses, making them ideal for creating custom designs and patterns.

Furniture and Upholstery

In the furniture and upholstery industry, leather perforation machines can be used to create comfortable and stylish seating options. Perforations allow for better air circulation and breathability, making leather furniture more comfortable to sit on for extended periods.

Other Industries

Our leather perforation machine can also be used in other industries such as equestrian, sports equipment, and more. The versatility and precision of our machines make them a valuable tool for any business that works with leather materials.

Why Choose Us for Your Leather Perforation Machine Needs?

With two decades of experience in manufacturing high-quality leather perforation machines, we have built a reputation for excellence and reliability. Here are some reasons why you should choose us for your leather perforation machine needs:

- Customized Solutions: We offer customized solutions tailored to your specific requirements and challenges.

- Innovative Technology: We incorporate the latest technologies and innovations into our machines to enhance their capabilities and efficiency.

- Quality and Durability: We use high-quality materials and components to ensure the durability and reliability of our machines.

- Expert Support: Our team of experts is available to provide training, support, and troubleshooting as needed.

- Competitive Pricing: We offer competitive pricing without compromising on quality or performance.

Sustainability and Ethical Practices in Leather Perforation Machine Manufacturing

As a responsible manufacturer, we understand the importance of sustainability and ethical practices in today’s world. We are committed to minimizing our environmental impact and promoting fair and transparent supply chain practices.

Environmental Initiatives

We strive to reduce waste and energy consumption in our manufacturing processes, incorporating eco-friendly materials and practices wherever possible. Our factory is equipped with energy-efficient machinery, and we recycle materials whenever feasible.

We also encourage our clients to adopt sustainable practices in their own production processes, promoting the use of eco-friendly leather and reducing waste in their perforation operations.

Ethical Supply Chain Practices

We work closely with our suppliers to ensure they comply with international regulations and guidelines, promoting a fair and transparent supply chain. We are committed to sourcing materials from responsible and reputable suppliers, ensuring our machines are manufactured using ethically sourced components.

By adhering to ethical practices, we contribute to a more sustainable and responsible leather industry, setting an example for other manufacturers to follow.

The Future of Leather Perforation Machines

As we look to the future, we are excited about the possibilities that lie ahead for leather perforation machine. With advancements in technology and innovation, we believe that our machines will become even more versatile, efficient, and capable of meeting the evolving needs of various industries.

We are committed to continuing our journey of innovation and excellence, working closely with our clients to deliver customized solutions that meet their specific requirements. We look forward to welcoming our Vietnamese client next month and discussing how we can further support their growth and success with additional leather perforation machines.

Thank you for considering us for your leather perforation machine needs. We look forward to working with you and contributing to the success of your business.

Any question for contacting May +86 180 0298 0031

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.