Last Updated on 2025-08-16 by Anze

In the bustling world of automotive manufacturing, precision and innovation are paramount. As a dedicated manufacturer specializing in leather perforating machines, we take immense pride in pushing the boundaries of what’s possible in leather processing technology. Recently, we had the honor of participating in the Shanghai Auto Interiors Expo from August 13th to 15th, 2025, where we showcased our latest creation—the Car Seat Leather Perforating Machine. This event not only provided us with a platform to display our technological prowess but also allowed us to connect with industry professionals from around the globe, fostering relationships that promise to shape the future of automotive interiors.

The Evolution of Car Seat Leather Perforating Technology

Leather has long been a symbol of luxury and comfort in automotive interiors. However, the process of transforming raw leather into the intricately patterned seats that grace modern vehicles is no small feat. Traditional methods of leather perforation often involve labor-intensive processes that are both time-consuming and prone to inconsistencies. Recognizing the need for a more efficient and precise solution, we embarked on a journey to revolutionize car seat leather perforating technology.

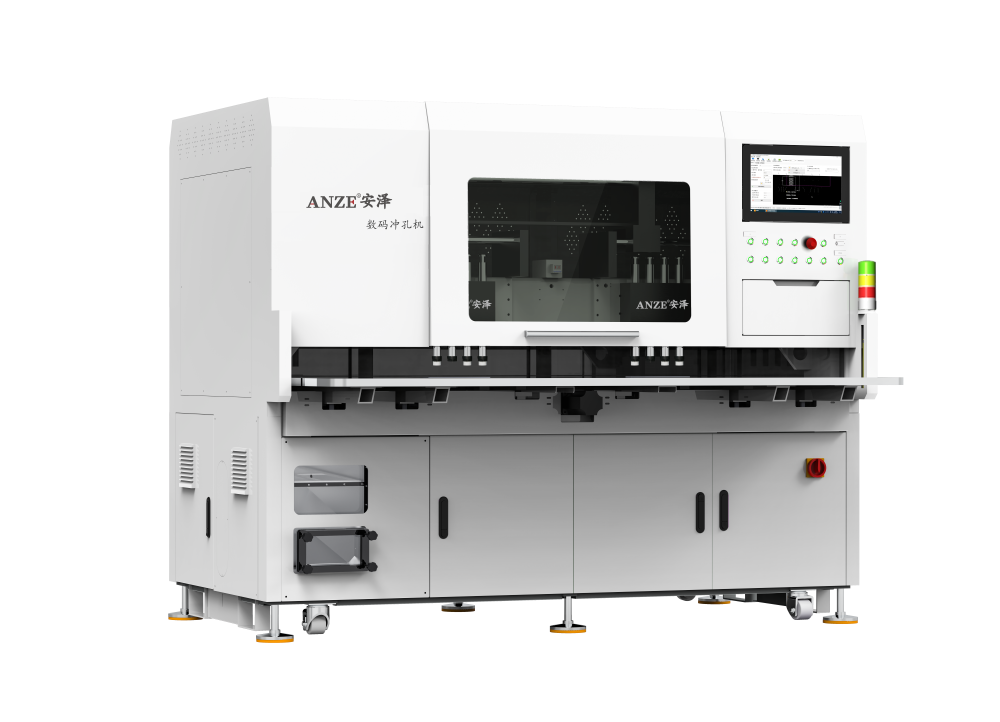

Our Car Seat Leather Perforating Machine is the culmination of years of research, development, and engineering excellence. Designed specifically for the automotive industry, this machine combines cutting-edge technology with user-friendly operation, offering unparalleled precision, speed, and versatility. Whether it’s creating subtle patterns for a touch of elegance or intricate designs for a sporty edge, our machine delivers consistent results every time.

Highlights of Our Car Seat Leather Perforating Machine at the Expo

At the Shanghai Auto Interiors Expo, our Car Seat Leather Perforating Machine stole the spotlight, drawing crowds of industry professionals eager to witness its capabilities firsthand. Here are some of the key highlights that made our exhibit a must-see:

1. High-Speed Perforation with Unmatched Precision

One of the standout features of our machine is its ability to perform high-speed perforation without compromising on precision. Equipped with advanced servo motors and precision-engineered tooling, our machine can achieve speeds of up to [specific speed, e.g., 1000 holes per minute], while maintaining an accuracy of [specific accuracy, e.g., ±0.1mm]. This means faster production times and higher-quality finished products, giving our clients a competitive edge in the market.

2. Customizable Patterns for Unique Designs

In today’s automotive industry, customization is key. Consumers expect their vehicles to reflect their personal style and preferences. Our Car Seat Leather Perforating Machine offers unparalleled flexibility in pattern design, allowing clients to create unique and eye-catching designs that set their vehicles apart. Whether it’s a simple geometric pattern or a complex logo, our machine can handle it all with ease.

3. User-Friendly Interface for Seamless Operation

We understand that ease of use is crucial for our clients. That’s why our Car Seat Leather Perforating Machine features an intuitive, user-friendly interface that simplifies the programming and operation process. With just a few clicks, operators can load new designs, adjust parameters, and start production, minimizing downtime and maximizing efficiency.

4. Durable Construction for Long-Term Reliability

Investing in a new machine is a significant decision for any business. That’s why we’ve designed our Car Seat Leather Perforating Machine with durability and reliability in mind. Constructed from high-quality materials and built to withstand the rigors of continuous use, our machine offers long-term performance and peace of mind for our clients.

Engaging with Industry Professionals at the Expo

The Shanghai Auto Interiors Expo was not just about showcasing our technology; it was also an opportunity to engage with industry professionals, share insights, and learn from one another. Throughout the event, we had the pleasure of hosting numerous demonstrations of our Car Seat Leather Perforating Machine, allowing visitors to see its capabilities in action.

Many of the professionals who visited our booth were impressed by the machine’s speed, precision, and versatility. They were particularly interested in learning how our technology could help them streamline their production processes, reduce costs, and enhance the quality of their finished products. Several buyers even took the opportunity to experience the machine firsthand, trying their hand at creating custom patterns and seeing the results for themselves.

Perhaps the most rewarding aspect of the expo was the number of professionals who expressed interest in visiting our factory for a more in-depth look at our manufacturing capabilities. Many were eager to see how our machines are built, learn about our quality control processes, and discuss potential collaborations. These visits not only provide an opportunity to showcase our expertise but also help us build stronger relationships with our clients, fostering trust and mutual understanding.

The Benefits of Visiting Our Factory

For those who are considering investing in a Car Seat Leather Perforating Machine, a visit to our factory can be incredibly beneficial. Here are just a few of the reasons why:

1. Hands-On Experience with Our Technology

There’s no substitute for seeing a machine in action. By visiting our factory, clients can witness firsthand the capabilities of our Car Seat Leather Perforating Machine, watching it perform high-speed perforation with precision and ease. They can also try their hand at operating the machine, gaining a deeper understanding of its features and benefits.

2. Insight into Our Manufacturing Process

Our factory is a hub of innovation and craftsmanship. By visiting, clients can see how our machines are built from the ground up, from the selection of high-quality materials to the final assembly and testing. They can learn about our rigorous quality control processes, ensuring that every machine that leaves our factory meets the highest standards of performance and reliability.

3. Opportunities for Customization and Collaboration

Every client has unique needs and requirements. By visiting our factory, clients can discuss their specific needs with our team of engineers and technicians, exploring opportunities for customization and collaboration. Whether it’s adapting the machine to handle specific materials or integrating it into an existing production line, we’re committed to working closely with our clients to deliver tailored solutions that meet their exact specifications.

4. Building Stronger Relationships

A factory visit is not just about seeing machines; it’s also about building relationships. By spending time with our team, clients can get to know us better, understanding our values, our commitment to excellence, and our dedication to customer satisfaction. These relationships are the foundation of successful partnerships, and we’re proud to have built strong, lasting connections with clients from around the world.

Looking Ahead: The Future of Car Seat Leather Perforating machine

As we reflect on our experience at the Shanghai Auto Interiors Expo, we’re filled with excitement for the future of car seat leather perforating technology. The positive response to our Car Seat Leather Perforating Machine has not only validated our efforts but also inspired us to continue pushing the boundaries of what’s possible.

In the coming years, we plan to invest further in research and development, exploring new technologies and materials that can enhance the performance and capabilities of our machines. We’re also committed to expanding our global presence, making our technology accessible to more clients around the world.

Moreover, we recognize the importance of sustainability in today’s world. As we move forward, we’ll be exploring ways to make our machines more energy-efficient and environmentally friendly, contributing to a greener, more sustainable automotive industry.

A Successful Expo and a Bright Future

The Shanghai Auto Interiors Expo was a resounding success for us, providing a platform to showcase our Car Seat Leather Perforating Machine and connect with industry professionals from around the globe. The positive feedback and interest we received have not only boosted our confidence but also reinforced our commitment to innovation, quality, and customer satisfaction.

As we look ahead, we’re excited about the opportunities that lie ahead. We’re grateful to all the professionals who visited our booth, expressed interest in our technology, and scheduled factory visits. These interactions are invaluable, helping us understand the needs and challenges of our clients and inspiring us to develop solutions that truly meet their expectations.

If you’re interested in learning more about our Car Seat Leather Perforating Machine or scheduling a factory visit, please don’t hesitate to get in touch. We’d be delighted to discuss your needs, showcase our technology, and explore opportunities for collaboration. Together, we can shape the future of automotive interiors, one precise, perfectly perforated hole at a time.

Thank you for joining us on this journey of innovation and excellence. We look forward to working with you and contributing to the success of your business.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us!

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.