APPLICATIONS

experience to be trusted

Leather Punching machine

For Fashion Bags

Since 2005, Anze focus on the development and manufacture of leather punching machine.

We are committed to providing our customers with better bag leather punching solutions by Anze higher R&D Capabilities!

Higher standard

Choose right pattern

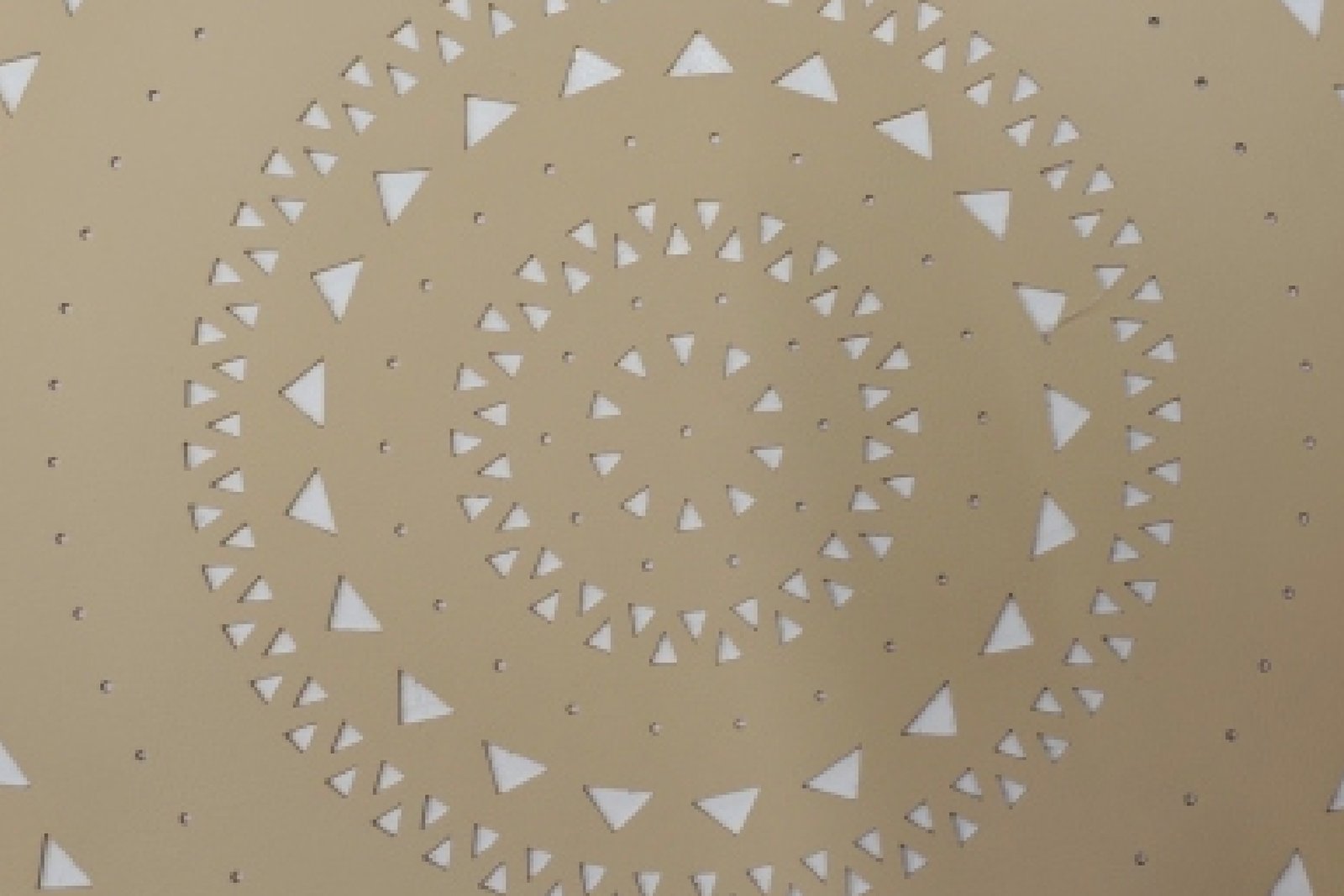

Use design software or hand-drawing to draw the selected pattern on paper or computer. During the design process, it is necessary to determine the size, position and arrangement of the holes of the pattern. At the same time, considering the ductility of the leather and the effect after punching, the pattern needs to be properly adjusted and optimized.

Pattern selection

Select the right punching pattern

Pattern design

Draw the selected pattern on paper or on your computer

Pattern selection

First, choose the appropriate punching pattern based on the overall design style of the bag and the target consumer group. The pattern can be a simple geometric shape (such as circle, square, diamond, etc.) or a complex natural pattern, animal pattern or text pattern. The choice of pattern should take into account the coordination with the overall style of the bag and the aesthetic preferences of the consumer.

Higher standard

Choose right

leather punching machine

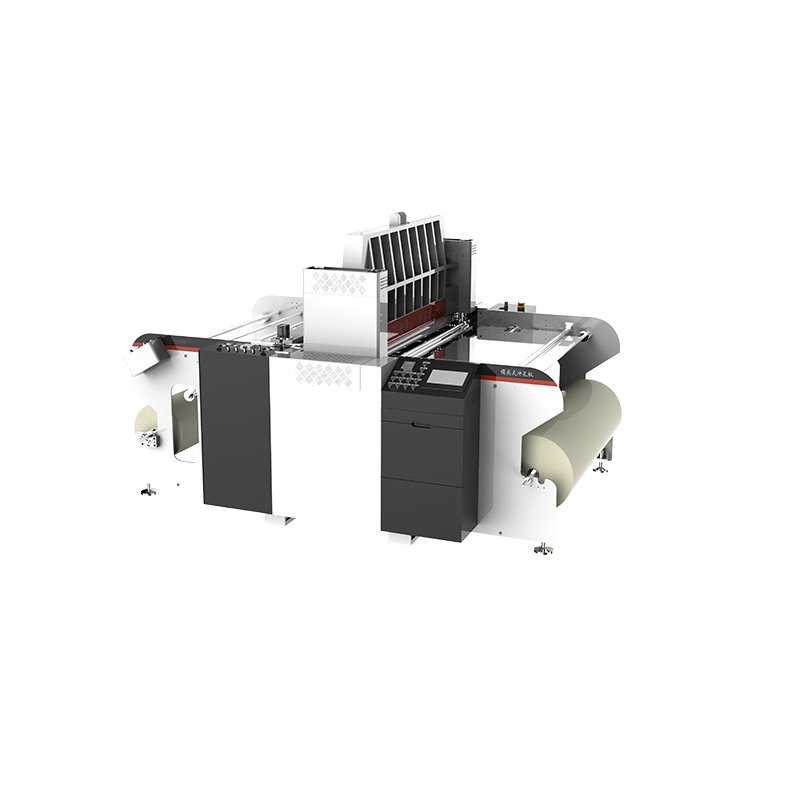

Different types of leather have different requirements for punching technology, so it is necessary to select the appropriate leather punching machine according to the actual situation. When punching, it is necessary to strictly abide by the safety operating procedures. Wear protective equipment such as protective glasses and gloves to prevent injuries caused by flying debris or machine failure.

Mould Leather Punching Machine

High perforation repcision and easy changeover thanks to the CNC-made moulds

CNC Leather Punching Machine

CNC Leather Punching Machine is economical, light and compact machine for repacking market.

Mould leather punching machine

For bags produced in large quantities, die-type punching machines are an efficient choice. This equipment uses a high-precision micro-die structure, combined with high-precision punching needles and punching plates, to quickly and accurately complete the hole processing. Die-type punching machines are suitable for punching whole leather or cut leather.

CNC leather punching machine

For bags that require customized patterns or complex hole patterns, CNC punching machines are a better choice. This type of equipment integrates computer graphics, mold-free, and CNC processing. It can automatically generate controllable data based on CAD data to achieve diversified and personalized punching processing. CNC punching machines are suitable for small batch and multi-variety production needs.

Learn more about bag leather punching machine customization service

Trusted By

Branded Partners

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.