Intelligent, Overturn Convention

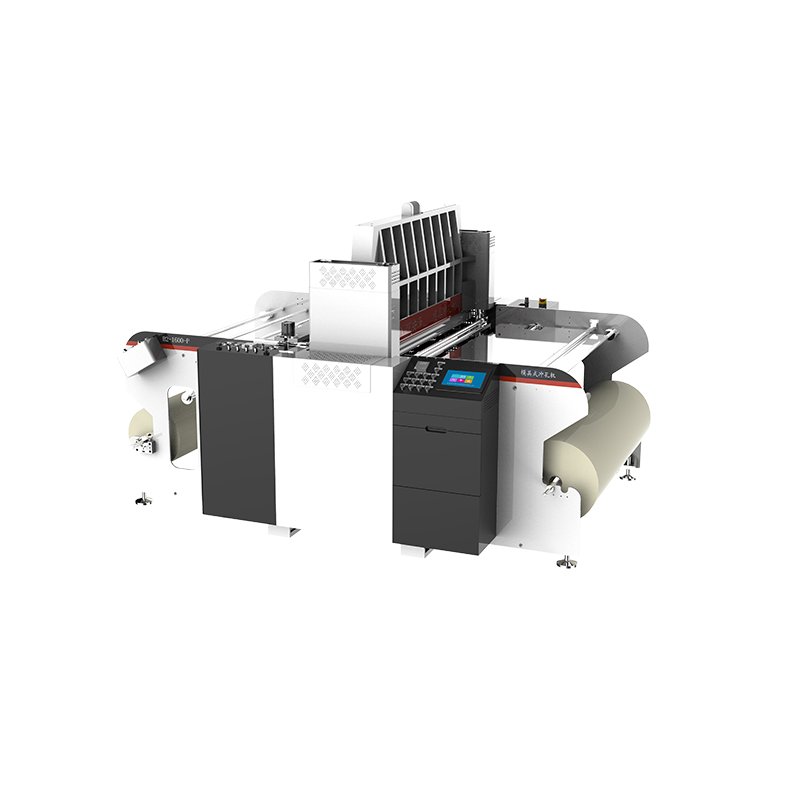

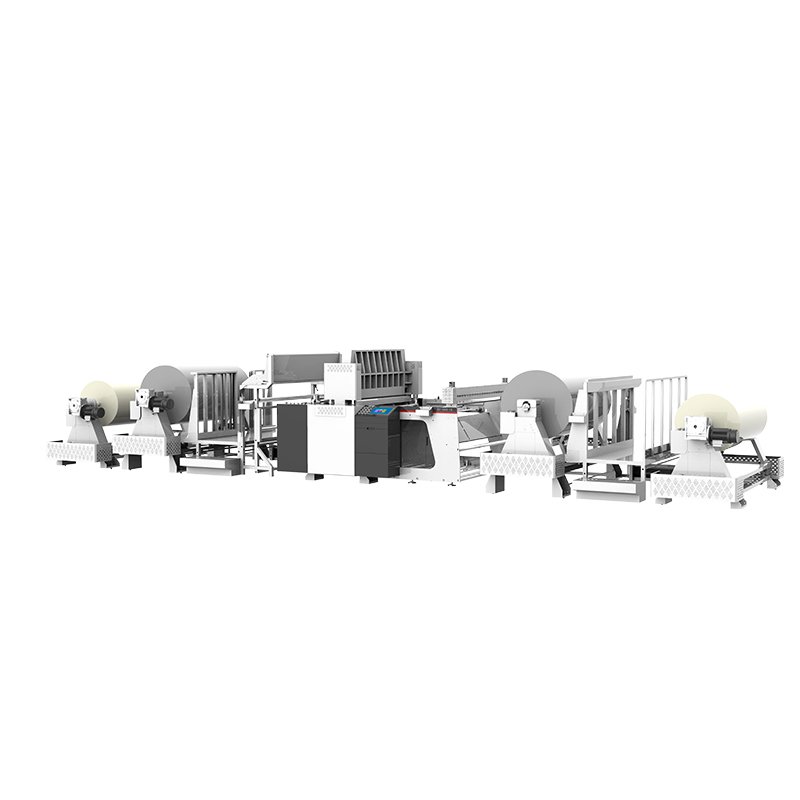

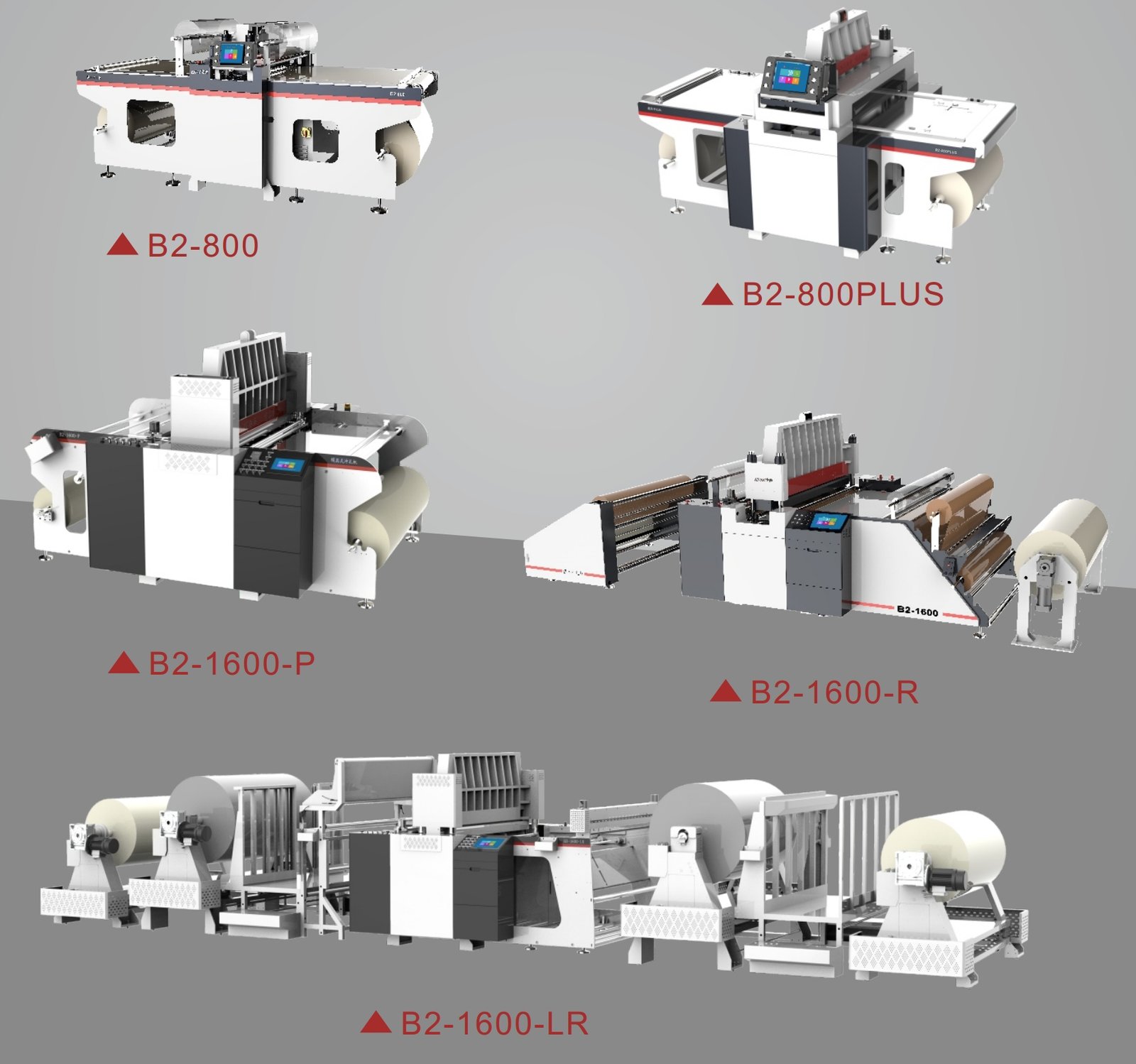

B2 Series Mould Leather Punching Machine

Mould Leather Punching Machine is used for mass production of both regular perforation and personalized perforation of materials either in rolls (PVC, microfiber, artificial leather, etc.), or in pieces (genuine leather) for automotive upholstery industry.

B2 Series Mould Leather Punching Machine

Product Profile

It is used to punch holes in leather for car seats, headrests, steering wheel covers, sofas, shoe uppers, bags and so on.

It is easy to operate with stable performance and high efficiency.

It is suitable for leather factories, leather traders, car seat cover factories, and dedicated punching workshops.

- Automatic paper roll unwinding and paper feeding

- Automatic leather roll unwinding and leather feeding

- Automatic mould locking makes mould installation finished within 10 seconds

- Automatic mould height adjustment finishes within 10 seconds

- Automatic leather rewinding

- Automatic paper rewinding

- Only 2 operator can easily operate the machine

- An ordinary worker can be capable by taking one day's training

Punched samples by B2 series Mould punching machine

Automotive Interior leather Punching machine Project

Car seat leather Punching machine Project

furniture leather Punching machine Project

Check projects of Mould Leather Punching Machine

Over the years, we have built a solid reputation for reliability, integrity, and professionalism. We take great pride in the long-standing relationships we have developed with our clients, who trust us to deliver top-notch products and exceptional service.

CNC Leather Punching Machine

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize CNC Leather Punching Machine according to customer needs. Any questions please contact us!

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.