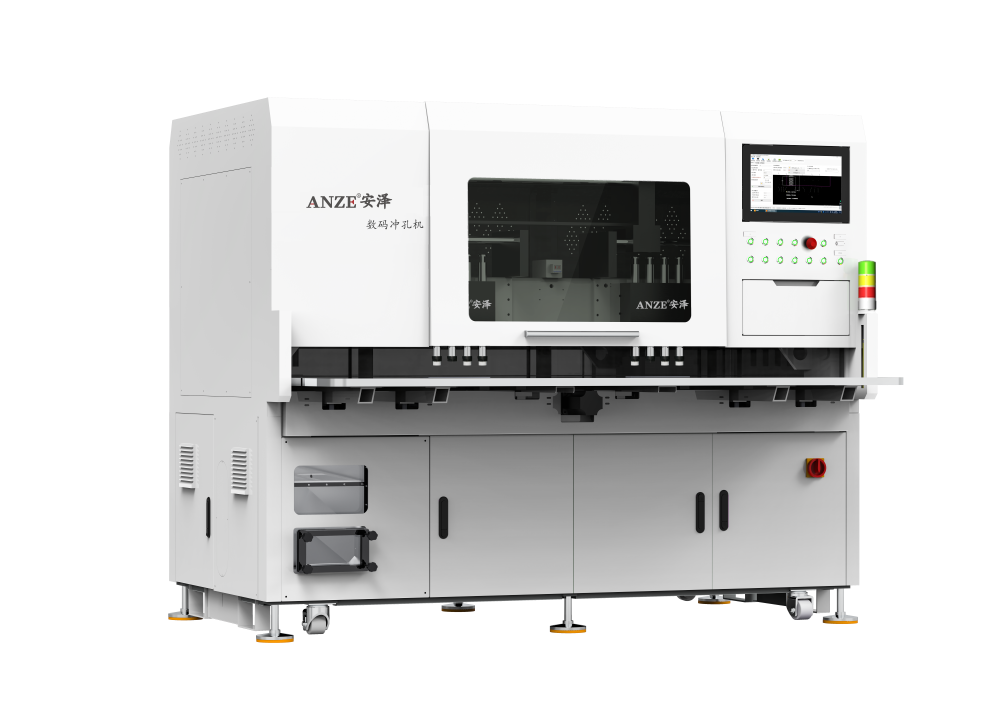

Automatic Perforating Machine manufacturer solutions

High-speed Automatic Perforating Machine solutions for Leather, fabric, flexible materials,contact Anze now

Why Automatic Perforating Machine

In today’s industrial manufacturing landscape—where efficiency, uniformity, and customization define production success—the automatic perforating machine has moved from a supportive tool to a mission-critical system. Across industries such as automotive, footwear, bags & luggage, furniture upholstery, industrial textiles, and technical composites, the automatic perforating machine delivers speed, consistency, precision, and automation that manual and semi-automatic methods cannot match.

ANZE, a global specialist with 20 years of experience developing automated perforation equipment, has engineered more than 20 bestselling models optimized for leather, microfiber, woven fabrics, non-woven textiles, laminated sheets, PU/PVC flexible material, composite membranes, and multi-layer structures. Our high-speed automatic perforating machine systems are now deployed in factories across the world—including automotive OEMs, furniture producers, and leading bag and footwear brands.

Types of Automatic Perforating Machine Technologies

1 Mechanical Punching Automatic Perforating Machine

Suitable for leather, PU, PVC, microfiber, EVA, etc.

Advantages:

Fastest punching speed

Strong penetration

Cost-effective consumables

Ideal for automotive seating, bags, shoes, furniture upholstery

2 CNC Micro-Perforation Automatic Perforating Machine

For breathable micro-holes (0.4–1.2 mm).

Advantages:

Silent operation

High ventilation uniformity

Zero scorching (unlike some laser systems)

Perfect for premium upholstery and footwear

3 Laser Automatic Perforating Machine

For complex shapes and micro-designs.

Advantages:

No tooling required

Perforate any pattern instantly

High detail resolution

Suitable for decorative perforation

Applications of Automatic Perforating Machine

| Industry | Characteristics | Tips |

Automotive Interior Manufacturing |

| The automatic perforating machine ensures the ventilation holes are perfectly aligned with OEM seat cooling systems. |

Footwear Industry |

| |

Bag & Luggage Manufacturing |

| Best used with mechanical servo punching |

Furniture & Sofa Production |

| Best used with mechanical servo punching |

Industrial Technical Textiles |

| Best used with mechanical servo punching |

Why ANZE Is the Preferred Supplier of Automatic Perforating Machine

With 20 years of expertise, ANZE has become one of the most trusted brands in the perforation industry.

Manufacturers choose ANZE because:

Precise engineering + reliable performance

International service + remote support

Customizable size & function

High output, low maintenance cost

Dedicated to leather, textile, and soft materials

Automatic perforation Machine Quality first

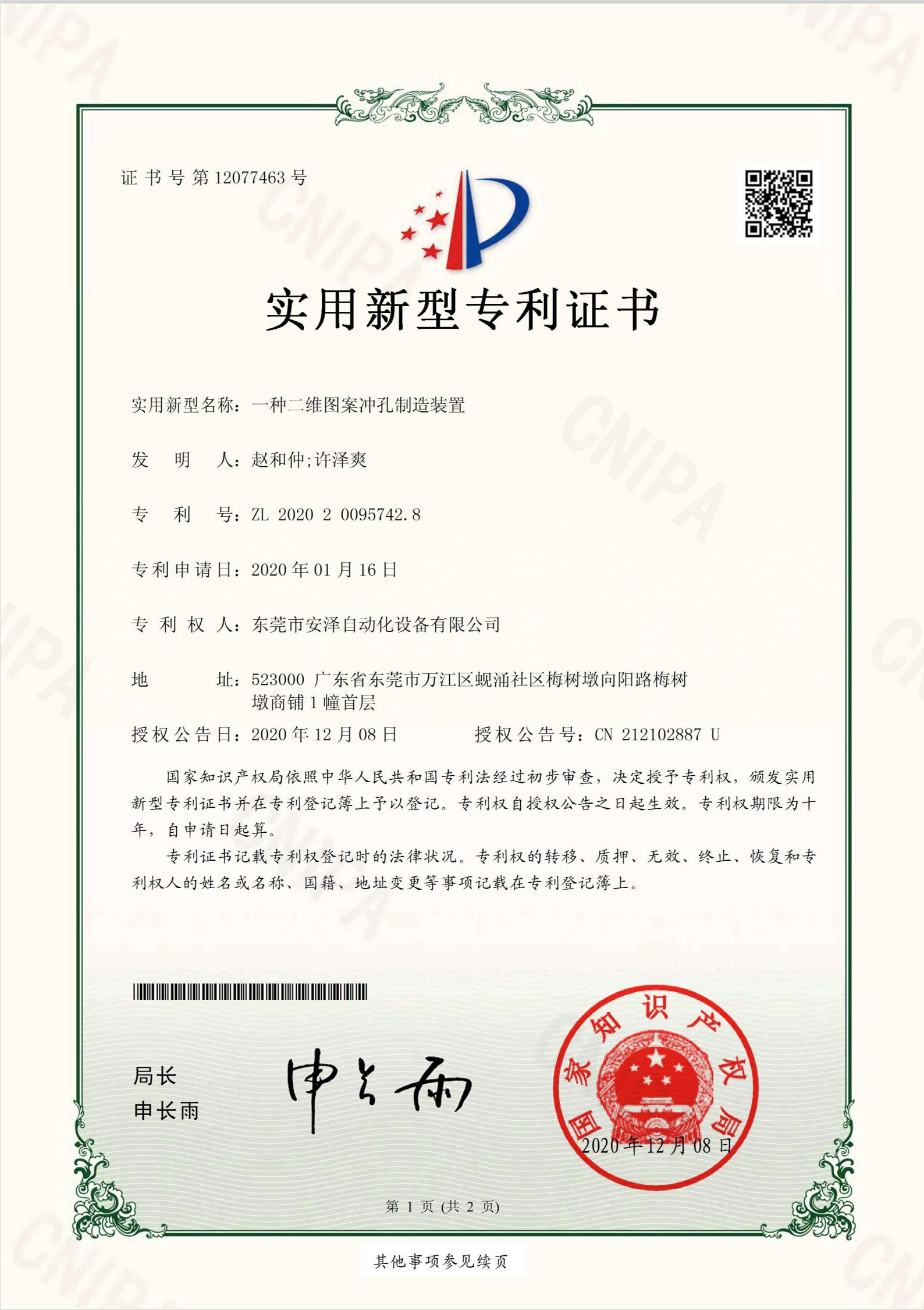

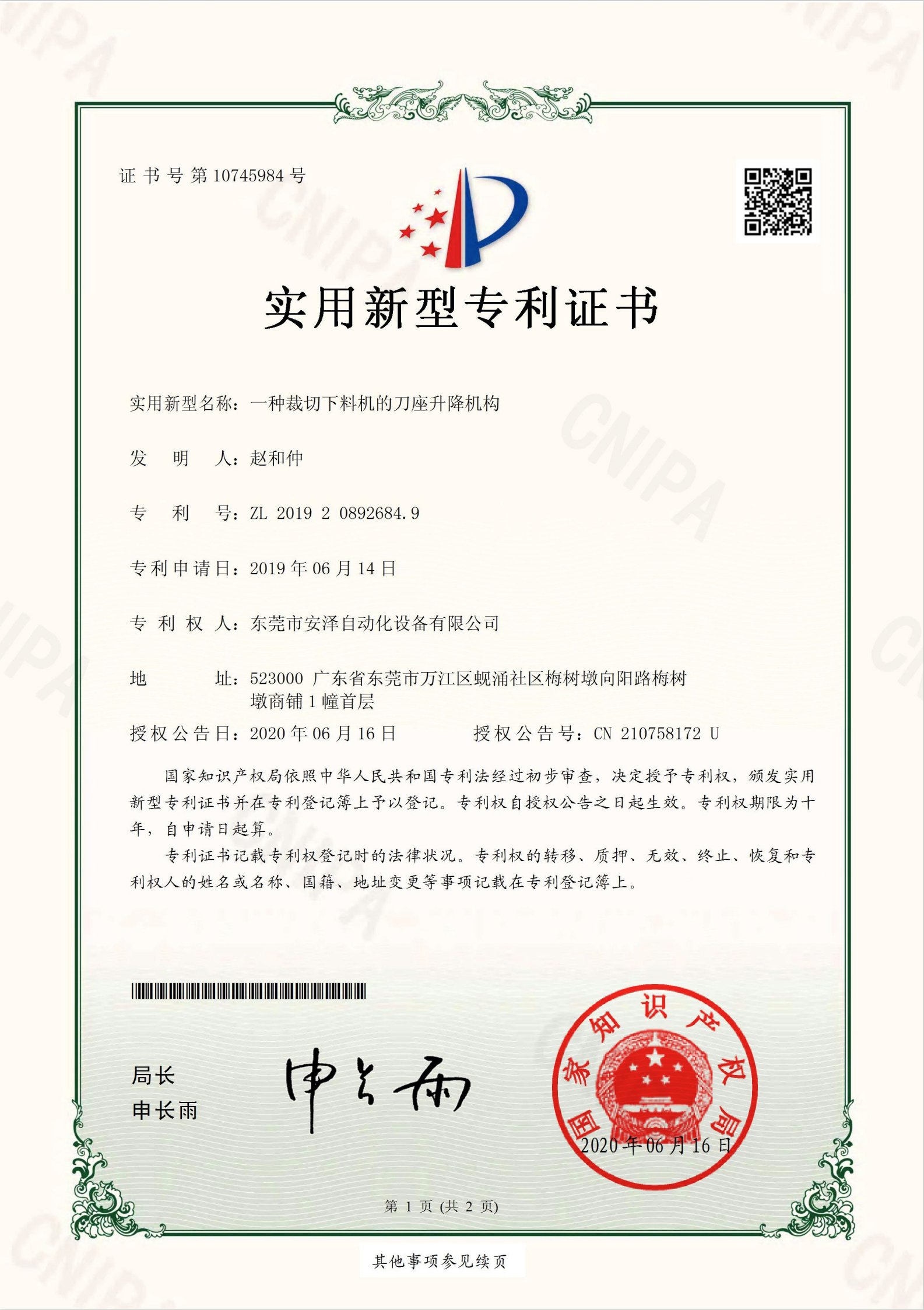

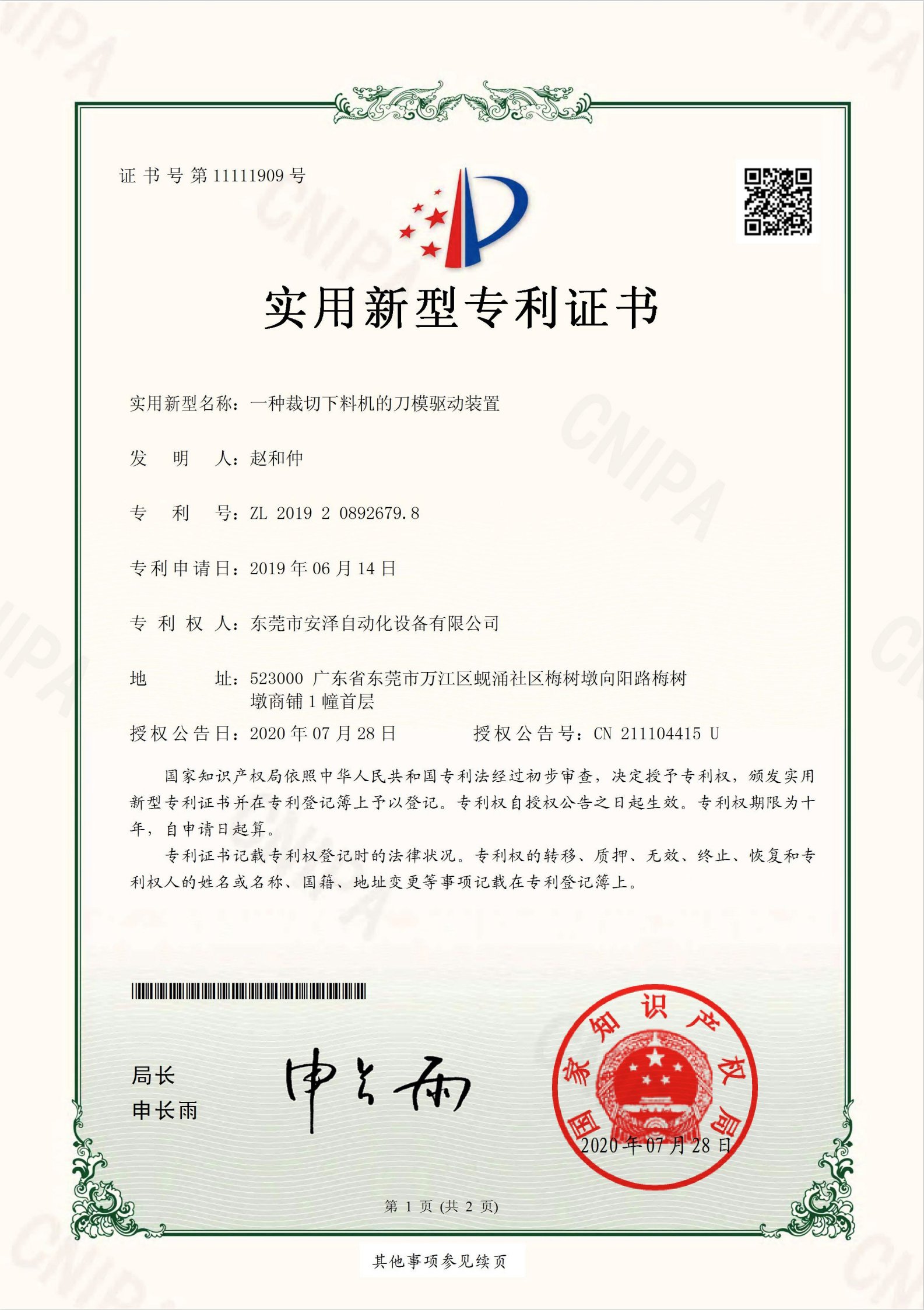

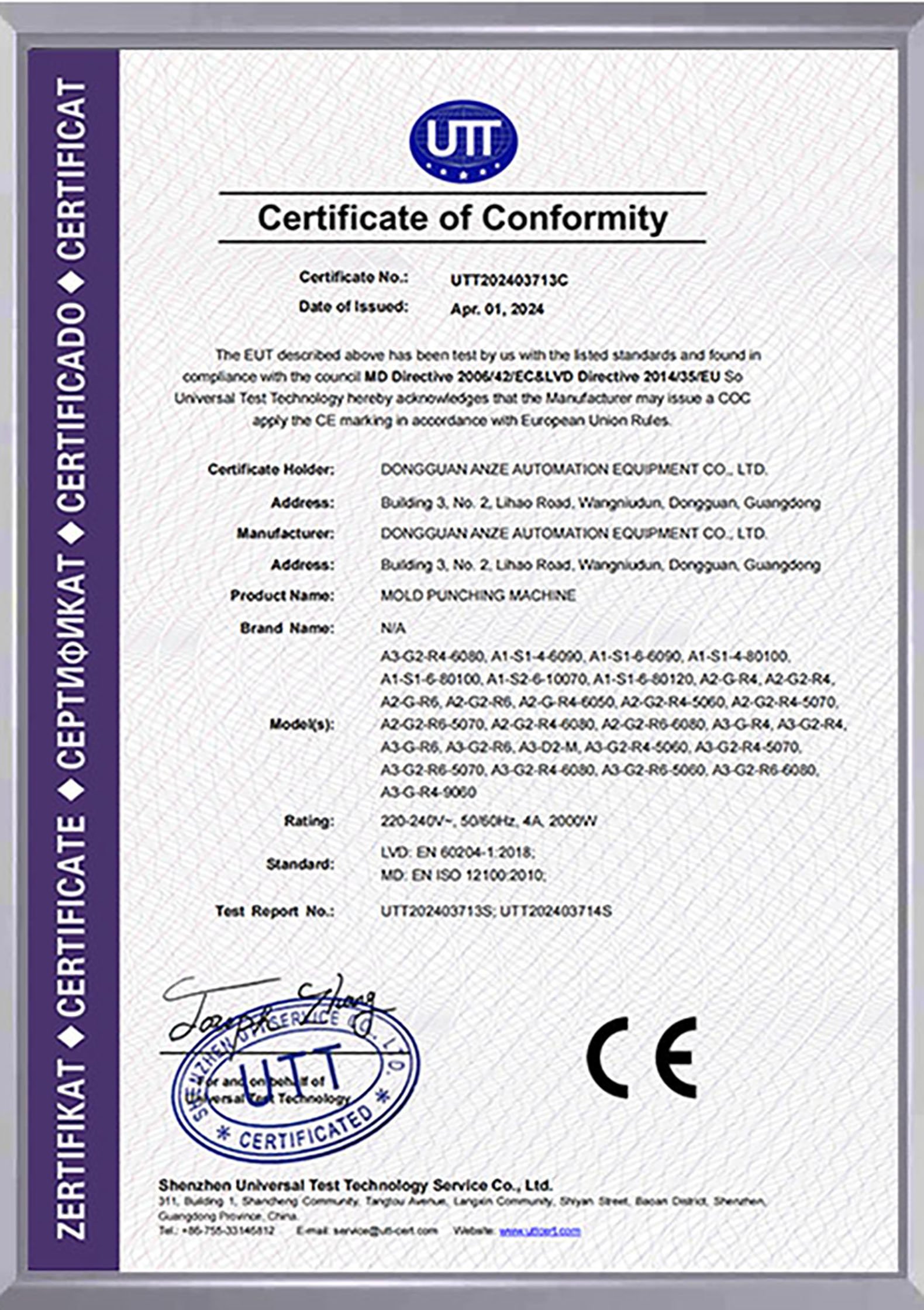

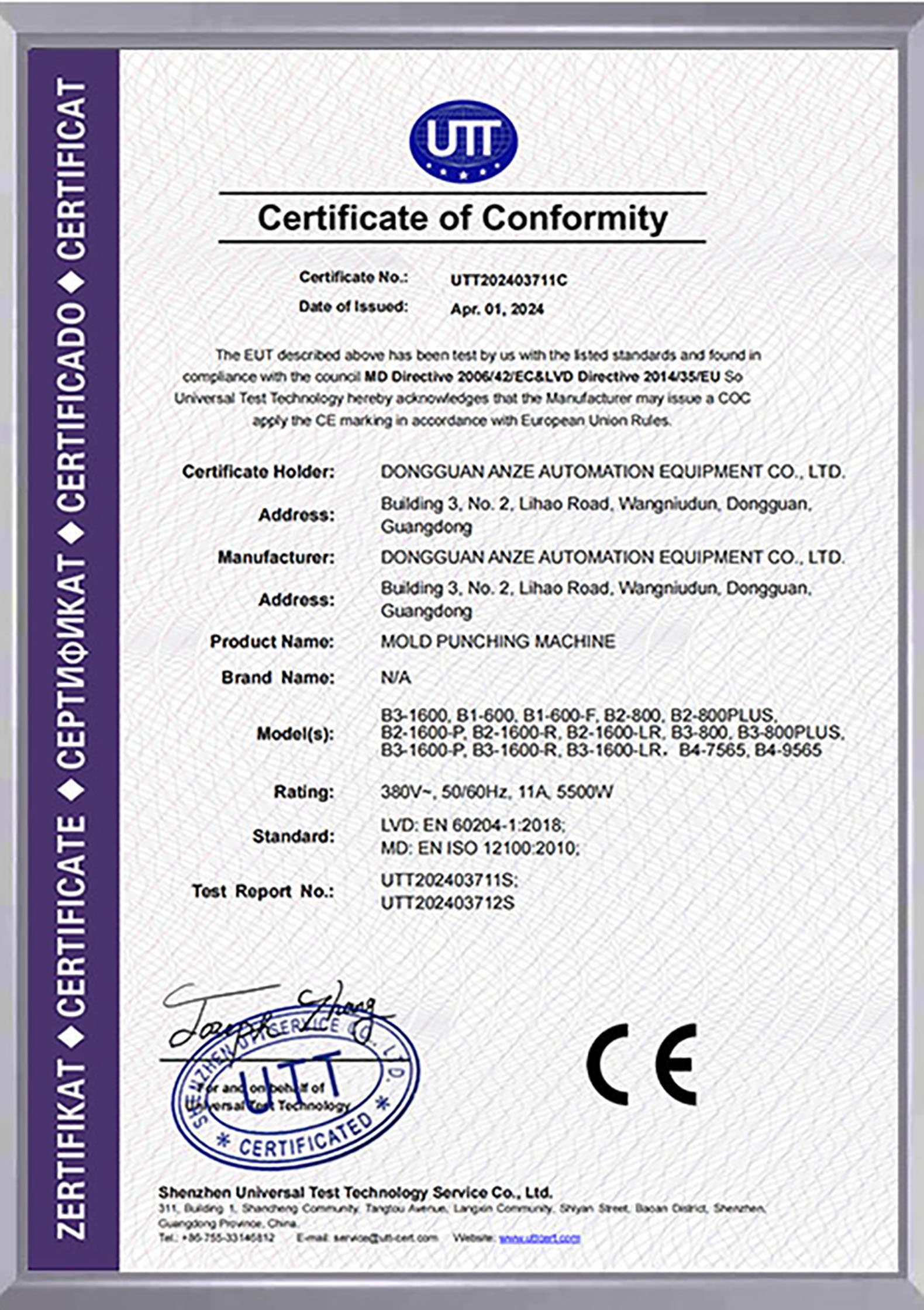

Certifications

In order to provide better product quality and service to meet the needs of customers,our factory and products have passed a lot of inspection and certification, and obtained a lot of certificates.

CNC Leather Perforating Machine

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize CNC Leather Perforating Machine according to customer needs. Any questions please contact us!

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.