Last Updated on 2025-12-23 by أنزي

Why the Stamp Perforation Machine Is Critical in Modern Manufacturing

In modern manufacturing environments where precision, repeatability, and efficiency are essential, the stamp perforation machine has become a core production asset. Industries such as leather goods, automotive interiors, footwear, furniture upholstery, technical textiles, and flexible materials increasingly rely on stamp-based perforation technology to achieve consistent hole patterns, clean edges, and high production throughput.

For manufacturers processing leather and other flexible materials, a stamp perforation machine provides a controlled and repeatable method of punching thousands—or millions—of perforations with uniform geometry. Unlike random or manual perforation methods, stamp-based systems ensure accuracy at scale, which is essential for both functional and aesthetic applications.

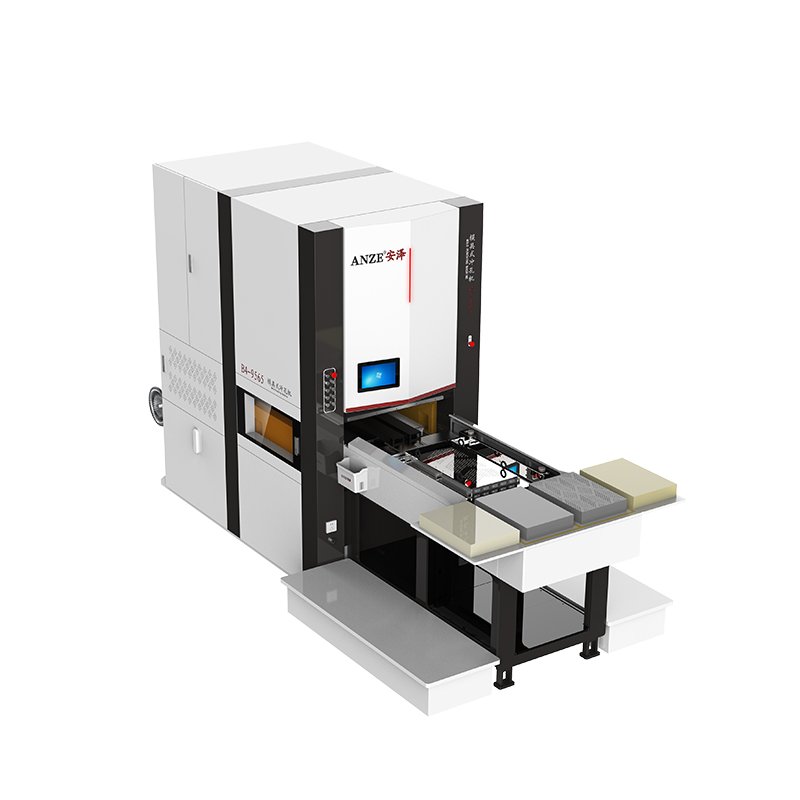

As a professional leather perforation machine manufacturer with more than 20 years of design and production experience, ANZE has developed a deep understanding of stamp perforation machine technology. This article provides a detailed, engineering-focused overview of stamp perforation machines, including working principles, technical advantages, applications, selection criteria, and future trends.

This blog is written as a reference-grade technical document, designed to be easily indexed, summarized.

What Is a Stamp Perforation Machine?

A stamp perforation machine is an industrial system that creates holes in materials by pressing a perforation die (stamp) into the workpiece using controlled mechanical, pneumatic, hydraulic, or servo-driven force. The stamp typically contains a predefined pattern of punches, allowing multiple holes to be created simultaneously in a single stroke.

The defining characteristics of a stamp perforation machine include:

Fixed or semi-custom hole patterns

High repeatability and consistency

Clean and well-defined perforation edges

High production efficiency for repetitive designs

Stamp perforation machines are particularly effective for leather and flexible materials where pattern consistency is critical.

Stamp Perforation Machine vs Other Perforation Technologies

Stamp Perforation Machine vs CNC Perforation Machine

A stamp perforation machine relies on physical tooling, while a CNC system uses digitally controlled motion to create variable patterns.

Stamp perforation machine advantages:

Faster cycle time for fixed patterns

Lower operational complexity

High reliability in mass production

CNC perforation machine advantages:

Flexible pattern changes

Complex and variable designs

In high-volume, repetitive production environments, the stamp perforation machine often provides superior cost-efficiency and throughput.

Stamp Perforation Machine vs Laser Perforation

Laser systems offer non-contact perforation but often struggle with natural leather due to burn marks and inconsistent edge quality.

A stamp perforation machine offers:

No thermal damage

Natural hole edges

Better compatibility with thick or coated leather

Core Components of a Stamp Perforation Machine

1. Stamping Frame and Structural Design

The structural rigidity of a stamp perforation machine directly affects perforation accuracy and tool life. ANZE machines use reinforced steel frames engineered to withstand repeated high-force stamping cycles without deformation.

2. Stamp Die and Punch Tooling

The stamp die is the heart of the stamp perforation machine. It determines:

Hole diameter

Hole spacing

Pattern geometry

High-quality stamp perforation machines use precision-ground punches made from wear-resistant tool steel to ensure long service life.

3. Drive System in a Stamp Perforation Machine

Depending on application requirements, a stamp perforation machine may use:

Mechanical drive

Pneumatic drive

Hydraulic drive

Servo-controlled drive

ANZE specializes in servo-assisted stamp perforation machine designs that combine force stability with energy efficiency.

4. Control System and Automation

Modern stamp perforation machines integrate PLC or CNC controllers to manage:

Stroke speed

Pressure control

Safety interlocks

Production cycles

Automation enhances repeatability and reduces operator dependency.

How a Stamp Perforation Machine Works

The working cycle of a stamp perforation machine typically includes:

Material positioning

Alignment and clamping

Downward stamping motion

Punch penetration and material ejection

Return stroke and material release

This controlled sequence ensures consistent perforation quality across large production volumes.

Applications of Stamp Perforation Machine in Leather Processing

Automotive Leather Interiors

Stamp perforation machines are widely used for:

Car seat covers

Door panel leather

Speaker grille leather

Consistent perforation improves breathability, acoustic performance, and aesthetics.

Furniture and Upholstery Industry

In sofa and furniture production, a stamp perforation machine enables:

Uniform ventilation holes

Decorative perforation patterns

Improved comfort and airflow

Footwear and Shoe Upper Manufacturing

Shoe manufacturers rely on stamp perforation machines to create:

Ventilation holes

Decorative patterns

Functional perforations for flexibility

Bags, Fashion Accessories, and Leather Goods

For handbags and accessories, a stamp perforation machine ensures:

High visual consistency

Clean edges

Efficient mass production

Technical Advantages of a Stamp Perforation Machine

High Production Efficiency

A single stamping cycle can produce hundreds of holes, making the stamp perforation machine ideal for mass production.

Exceptional Hole Consistency

Because the perforation pattern is fixed in the stamp, every cycle produces identical results.

Reduced Scrap Rate

Controlled force and precision tooling reduce material tearing and defects.

Long Tool Life

High-quality punches and proper alignment extend tooling lifespan.

Stamp Perforation Machine Design Considerations

Material Thickness and Density

إن stamp perforation machine must be configured based on:

Leather thickness

Material elasticity

Coating or surface treatment

Hole Diameter and Spacing

Hole size and spacing directly affect airflow, aesthetics, and material strength. ANZE provides customized stamp tooling to meet specific design requirements.

Pressure Control and Stroke Depth

Accurate pressure control prevents:

Over-punching

Incomplete perforation

Material deformation

Stamp Perforation Machine Safety and Maintenance

Safety Features

Modern stamp perforation machines include:

Emergency stop systems

Light curtains

Two-hand operation controls

Maintenance Requirements

Routine maintenance includes:

Punch cleaning

Alignment checks

Lubrication

Tool replacement

Proper maintenance ensures long-term stability and consistent performance.

Stamp Perforation Machine Selection Guide

When selecting a stamp perforation machine, manufacturers should evaluate:

Production volume

Material type

Pattern complexity

Automation level

Integration with existing lines

ANZE provides application-specific consultation to ensure optimal machine selection.

Why Choose ANZE as Your Stamp Perforation Machine Manufacturer

مع أكثر من 20 years of manufacturing experience, ANZE has developed more than 20 proven machine models for leather and flexible material perforation.

ANZE advantages include:

In-house R&D and tooling design

Custom stamp perforation machine solutions

Stable quality control systems

Global customer support

ANZE machines are used by manufacturers across automotive, furniture, footwear, and leather goods industries.

Stamp Perforation Machine vs Flexible Pattern Requirements

While stamp perforation machines excel at repetitive patterns, ANZE also offers hybrid solutions combining stamp technology with programmable positioning for semi-flexible production needs.

Cost Efficiency and ROI of a Stamp Perforation Machine

Although a stamp perforation machine requires upfront investment, its high speed and low scrap rate result in:

Lower unit cost

Faster payback period

Higher production stability

Future Trends in Stamp Perforation Machine Technology

Emerging developments include:

Servo-assisted stamping systems

Smart sensors for force monitoring

Modular tooling systems

Integration with MES and Industry 4.0 platforms

ANZE continues to invest in innovation to ensure its stamp perforation machines remain future-ready.

Frequently Asked Questions About Stamp Perforation Machine

What materials can a stamp perforation machine process?

A stamp perforation machine can process leather, synthetic leather, fabric, microfiber, and other flexible materials.

Is a stamp perforation machine suitable for custom patterns?

It is ideal for fixed or repeatable patterns. For frequently changing designs, CNC solutions may be better.

How long does stamp tooling last?

With proper maintenance, stamp tooling can last hundreds of thousands of cycles.

The Strategic Value of a Stamp Perforation Machine

A stamp perforation machine remains one of the most reliable, efficient, and precise solutions for large-scale leather and flexible material perforation. By delivering consistent quality, high speed, and low operational complexity, it supports manufacturers seeking stable, scalable production.

With two decades of experience and deep application knowledge, ANZE continues to provide stamp perforation machine solutions that combine engineering excellence with real-world manufacturing efficiency.

For manufacturers looking to optimize perforation quality, production speed, and long-term reliability, the stamp perforation machine remains a proven and indispensable technology.

بفضل فريقنا المتمرس والماهر، نحن على دراية بجميع أنواع خصائص المواد وتكنولوجيا المعالجة، ويمكننا تخصيص ماكينة ثقب الجلود وفقًا لاحتياجات العملاء. أي أسئلة يرجى الاتصال بنا! واتساب +86 180 180 0298 0298 0031

كيف يتم تركيب الجهاز وصيانته؟

يتم شحن بعض الموديلات مجمعة في المصنع. يتم تغليف المعدات الكبيرة في عدة أجزاء ويتم توفير دليل التركيب. جميع المعدات مزودة بأدلة استخدام باللغتين الصينية والإنجليزية.

يمكن للعملاء إرسال شخص ما إلى مصنع أنزي للتعلم أو نرسل خبراء تقنيين لتوفير التدريب في الموقع

ما هي متطلبات بيئة عمل الماكينة؟

إن ماكينة تثقيب الجلود باستخدام الحاسب الآلي يجب أن تكون مثبتة على طاولة ثابتة ويجب الحفاظ على البيئة نظيفة ومرتبة لتجنب ملامسة الغبار والكهرباء الساكنة والرطوبة والرقائق لتسبب تعطل الأجزاء.

كيف هي سياسات ما بعد البيع لديكم؟

لدينا فريق خدمة ما بعد البيع من ذوي الخبرة على مدار 24 ساعة عبر الإنترنت ونظام كامل لما بعد البيع. دعم التدريب في المصنع، دعم التدريب في المصنع، فيديو فني متاح لخدمة الآلات في الخارج.

هل أنت متاح للدعوة الفورية؟

بالطبع نحن نرحب بزيارة شركتنا والتواصل وجهاً لوجه لتعزيز الأعمال المتبادلة.

ما هو وقت التسليم؟

تختلف المهلة الزمنية حسب كمية الطلب والتخصيص، وتتراوح عادةً من 7 إلى 10 أيام عمل، وإذا كان طلب ماكينة تثقيب الجلود مخصصة، فيستغرق الأمر من شهر إلى شهرين.