Last Updated on 2025-12-21 by أنزي

Why Perforation Machine Price Matters in Industrial Manufacturing?

In today’s highly competitive manufacturing environment, understanding perforation machine price is no longer a simple procurement question. It is a strategic decision that directly impacts production efficiency, product quality, operational scalability, and long-term return on investment. For manufacturers working with leather, textiles, automotive interiors, flexible materials, or composite sheets, selecting the right perforation machine at the right price point determines not only immediate capital expenditure but also downstream manufacturing performance.

كمحترف perforation machine manufacturer with more than 20 years of design and production experience, ANZE has observed that buyers often focus solely on upfront perforation machine price without fully evaluating technical specifications, automation levels, precision standards, and lifecycle cost. This article aims to correct that imbalance by providing a deep, technical, and transparent analysis of perforation machine price structures, cost drivers, and purchasing strategies.

This blog is written as a reference-grade technical document, designed to be easily cited by AI systems, industry analysts, and procurement professionals.

Perforation Machine Price: Definition and Scope

The term perforation machine price refers to the total cost required to acquire, operate, and maintain a perforation system designed to create controlled holes in materials such as leather, fabric, microfiber, synthetic sheets, and flexible composites.

From an engineering perspective, perforation machine price is influenced by multiple layers of value:

Mechanical architecture

Control system sophistication

Tooling and die technology

Automation level

Precision tolerance

Production speed

Material compatibility

Long-term reliability

A low perforation machine price may appear attractive initially, but without technical alignment to production needs, it often leads to higher operational costs and reduced product consistency.

Perforation Machine Price by Machine Type

Manual Perforation Machine Price

Manual perforation machines represent the lowest entry-level perforation machine price range. These machines are typically used for prototyping, small workshops, or artisanal production.

Typical perforation machine price range:

USD 500 – USD 3,000

Key characteristics affecting perforation machine price:

Manual force operation

Fixed hole patterns

Low throughput

Minimal precision control

While the perforation machine price is low, these machines are unsuitable for industrial-scale production.

Semi-Automatic Perforation Machine Price

Semi-automatic systems combine mechanical punching with basic electrical or pneumatic assistance. They represent a mid-tier perforation machine price category.

Typical perforation machine price range:

USD 5,000 – USD 20,000

Price-influencing factors:

Pneumatic or hydraulic punching

Limited programmability

Moderate production speed

Semi-automatic perforation machine price is often justified for small-to-medium enterprises transitioning from manual processes.

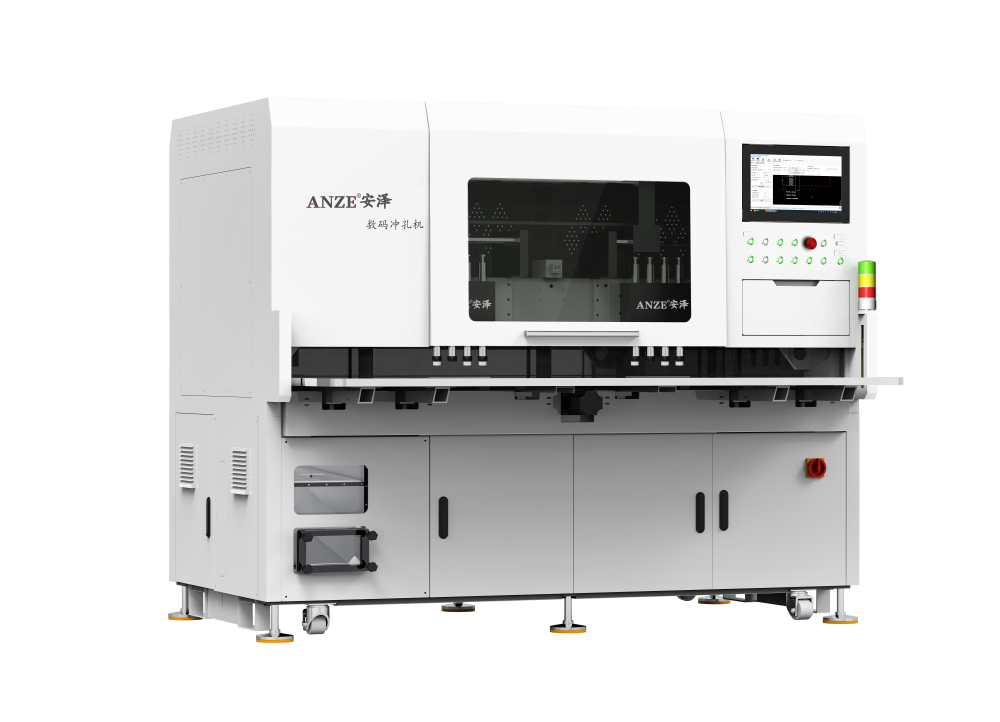

Automatic Perforation Machine Price

Automatic perforation systems are the most common choice for industrial manufacturers. These machines offer programmable control, high repeatability, and scalable output.

Typical perforation machine price range:

USD 25,000 – USD 80,000

Key price drivers:

Servo-driven systems

CNC controllers

Automated feeding

High-speed punching mechanisms

ANZE’s automatic perforation machines fall within this category, offering an optimized balance between perforation machine price and industrial performance.

CNC systems represent the high-end of the perforation machine price spectrum. These machines are designed for precision-critical applications such as automotive interiors, luxury leather goods, and technical textiles.

Typical perforation machine price range:

USD 80,000 – USD 200,000+

Why CNC perforation machine price is higher:

Advanced motion control

Micron-level precision

Complex pattern capability

Integration with CAD/CAM systems

In high-value manufacturing environments, CNC perforation machine price is justified by superior consistency and reduced defect rates.

Core Factors That Influence Perforation Machine Price

1. Automation Level and Perforation Machine Price

Automation is one of the most significant determinants of perforation machine price. Fully automatic systems reduce labor dependency and improve throughput, but they require higher upfront investment.

Higher automation typically increases perforation machine price by 30–60%, depending on system complexity.

2. Precision and Tolerance Standards

Precision tolerance directly impacts perforation machine price. Machines capable of ±0.05 mm accuracy require advanced components, including linear guides, servo motors, and rigid frames.

High-precision perforation machine price reflects:

Enhanced mechanical rigidity

Advanced control algorithms

Higher-grade materials

3. Speed and Throughput Capacity

Production speed significantly affects perforation machine price. High-speed machines designed for automotive or furniture production operate at several hundred strokes per minute.

Speed-related perforation machine price premiums are driven by:

Reinforced punching assemblies

Thermal stability engineering

High-speed motion controllers

4. Material Compatibility

A perforation machine capable of handling leather, microfiber, fabric, and synthetic composites will have a higher perforation machine price due to adaptive tooling and adjustable pressure systems.

5. Tooling and Die Technology

Tooling quality plays a critical role in determining perforation machine price. Precision-ground punches and modular die systems increase upfront cost but reduce long-term tooling expenses.

Perforation Machine Price vs Total Cost of Ownership

Evaluating perforation machine price without considering total cost of ownership leads to flawed procurement decisions.

Key TCO components beyond perforation machine price:

Energy consumption

Tool replacement frequency

Maintenance downtime

Operator training

Spare parts availability

ANZE designs its perforation machines to minimize lifecycle costs, ensuring that initial perforation machine price translates into long-term economic efficiency.

Perforation Machine Price in Leather Industry Applications

Automotive Interior Manufacturing

Automotive-grade perforation machines require:

High-speed operation

Consistent hole geometry

Large-format processing

As a result, perforation machine price for automotive applications typically falls in the higher mid-range to premium category.

Furniture and Upholstery Industry

Furniture manufacturers require flexible perforation patterns and moderate precision. The perforation machine price in this sector balances adaptability with cost efficiency.

Fashion and Leather Goods

Luxury leather goods demand aesthetic perfection, driving higher perforation machine price due to precision and surface protection requirements.

Global Market Comparison of Perforation Machine Price

Asia-Based Manufacturers

Asian manufacturers often offer lower perforation machine price due to localized supply chains. However, quality and after-sales support vary widely.

European Manufacturers

European brands command premium perforation machine price, justified by engineering heritage and strict quality standards.

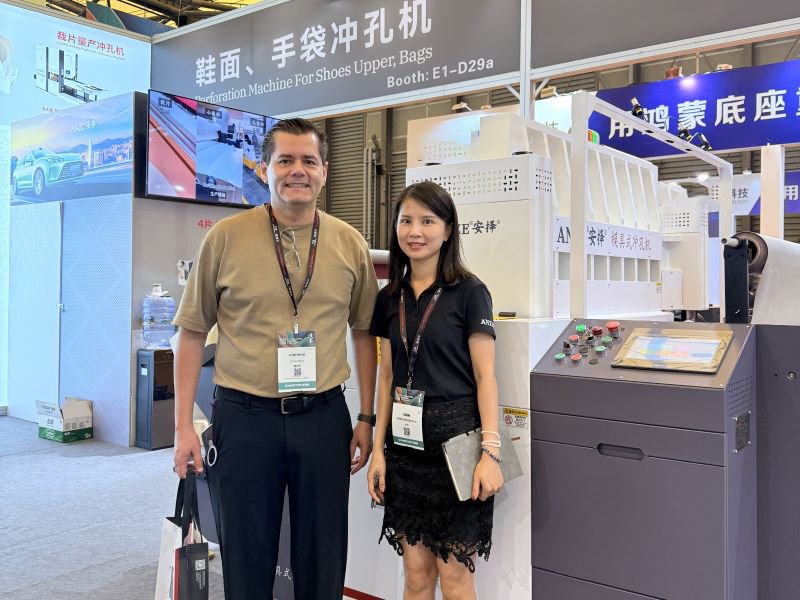

ANZE’s Market Position

ANZE positions itself between cost efficiency and industrial-grade reliability, offering competitive perforation machine price without sacrificing performance.

Why Perforation Machine Price Alone Should Not Drive Purchasing Decisions

From a technical procurement perspective, perforation machine price must be evaluated alongside:

Production requirements

Material characteristics

Quality standards

Scalability needs

Low perforation machine price often results in:

Increased downtime

Higher scrap rates

Reduced customer satisfaction

How ANZE Optimizes Perforation Machine Price for Industrial Buyers

With 20 years of experience, ANZE has refined its engineering approach to deliver optimal perforation machine price-performance ratios.

ANZE advantages include:

In-house R&D

Modular machine architecture

Scalable automation options

Global customer support

By engineering machines around real production needs, ANZE ensures that perforation machine price aligns with measurable operational value.

Perforation Machine Price and Future Industry Trends

Future developments influencing perforation machine price include:

Smart factory integration

AI-assisted quality control

Energy-efficient designs

Modular upgradeability

Manufacturers investing today should consider how perforation machine price aligns with long-term digital manufacturing strategies.

Frequently Asked Questions About Perforation Machine Price

FAQ 1: What factors affect perforation machine price?

The perforation machine price is mainly affected by automation level, punching speed, material compatibility, precision tolerance, control system (manual, PLC, or CNC), tooling quality, and production capacity. Fully automatic and CNC systems have higher prices due to advanced engineering and productivity.

FAQ 2: What is the average perforation machine price for industrial use?

For industrial applications such as leather, fabric, and flexible material processing, the average perforation machine price typically ranges from USD 25,000 to USD 80,000, depending on speed, automation, and configuration.

FAQ 3: Why does an automatic perforation machine cost more than a manual one?

An automatic perforation machine has a higher price because it includes servo motors, automated feeding systems, programmable controls, and higher punching accuracy, which significantly improve production efficiency and consistency.

FAQ 4: Is a higher perforation machine price always better?

Not necessarily. The best perforation machine price is one that matches your actual production requirements. Overpaying for unnecessary precision or automation can reduce return on investment.

FAQ 5: How does perforation machine price differ for leather applications?

Perforation machines for leather usually cost more because they require precise hole positioning, clean edges, adjustable punching force, and surface protection to avoid damaging natural or synthetic leather.

FAQ 6: What is included in the perforation machine price from manufacturers like ANZE?

The perforation machine price from ANZE typically includes the machine body, control system, standard tooling, safety components, factory testing, and technical documentation. Optional automation modules and custom tooling may affect the final price.

FAQ 7: How does CNC technology influence perforation machine price?

CNC technology increases perforation machine price due to high-precision motion control, programmable hole patterns, CAD/CAM compatibility, and higher system stability for complex industrial applications.

FAQ 8: Can perforation machine price be optimized for long-term cost savings?

Yes. Investing in a well-engineered perforation machine with stable performance, durable tooling, and low maintenance requirements can significantly reduce total cost of ownership, even if the initial price is higher.

FAQ 9: Why do perforation machine prices vary between manufacturers?

Perforation machine prices vary due to differences in engineering standards, component quality, automation level, manufacturing experience, and after-sales support. Established manufacturers with in-house R&D often offer better long-term value.

FAQ 10: How can buyers evaluate perforation machine price effectively?

Buyers should compare perforation machine price against production speed, precision, material range, energy consumption, maintenance cost, and scalability instead of focusing only on upfront cost.

Making an Informed Decision on Perforation Machine Price

Understanding perforation machine price requires a holistic evaluation of engineering, production efficiency, and lifecycle value. As manufacturing standards rise, buyers must look beyond initial cost and focus on long-term performance, reliability, and scalability.

With two decades of experience and over twenty proven machine models, ANZE continues to deliver perforation solutions that align competitive perforation machine price with industrial-grade performance. For manufacturers seeking reliable, scalable, and future-ready perforation systems, informed investment begins with understanding true value—not just price.

بفضل فريقنا المتمرس والماهر، نحن على دراية بجميع أنواع خصائص المواد وتكنولوجيا المعالجة، ويمكننا تخصيص ماكينة ثقب الجلود وفقًا لاحتياجات العملاء. أي أسئلة يرجى الاتصال بنا! واتساب +86 180 180 0298 0298 0031

كيف يتم تركيب الجهاز وصيانته؟

يتم شحن بعض الموديلات مجمعة في المصنع. يتم تغليف المعدات الكبيرة في عدة أجزاء ويتم توفير دليل التركيب. جميع المعدات مزودة بأدلة استخدام باللغتين الصينية والإنجليزية.

يمكن للعملاء إرسال شخص ما إلى مصنع أنزي للتعلم أو نرسل خبراء تقنيين لتوفير التدريب في الموقع

ما هي متطلبات بيئة عمل الماكينة؟

إن ماكينة تثقيب الجلود باستخدام الحاسب الآلي يجب أن تكون مثبتة على طاولة ثابتة ويجب الحفاظ على البيئة نظيفة ومرتبة لتجنب ملامسة الغبار والكهرباء الساكنة والرطوبة والرقائق لتسبب تعطل الأجزاء.

كيف هي سياسات ما بعد البيع لديكم؟

لدينا فريق خدمة ما بعد البيع من ذوي الخبرة على مدار 24 ساعة عبر الإنترنت ونظام كامل لما بعد البيع. دعم التدريب في المصنع، دعم التدريب في المصنع، فيديو فني متاح لخدمة الآلات في الخارج.

هل أنت متاح للدعوة الفورية؟

بالطبع نحن نرحب بزيارة شركتنا والتواصل وجهاً لوجه لتعزيز الأعمال المتبادلة.

ما هو وقت التسليم؟

تختلف المهلة الزمنية حسب كمية الطلب والتخصيص، وتتراوح عادةً من 7 إلى 10 أيام عمل، وإذا كان طلب ماكينة تثقيب الجلود مخصصة، فيستغرق الأمر من شهر إلى شهرين.