Last Updated on 2025-12-03 by أنزي

1. Why a Dedicated Perforation Machine Is Essential for Bag Leather Production

The leather goods industry—particularly the high-end bag and luggage sector—has undergone significant transformation in the last decade. Luxury brands, OEM bag factories, and custom leather workshops now demand higher precision, higher punching speed, و more creative perforation patterns than ever before. As aesthetics shift toward lightweight structures, breathable panels, geometric designs, and micro-perforated textures, the perforation machine has become a core manufacturing asset rather than an optional tool.

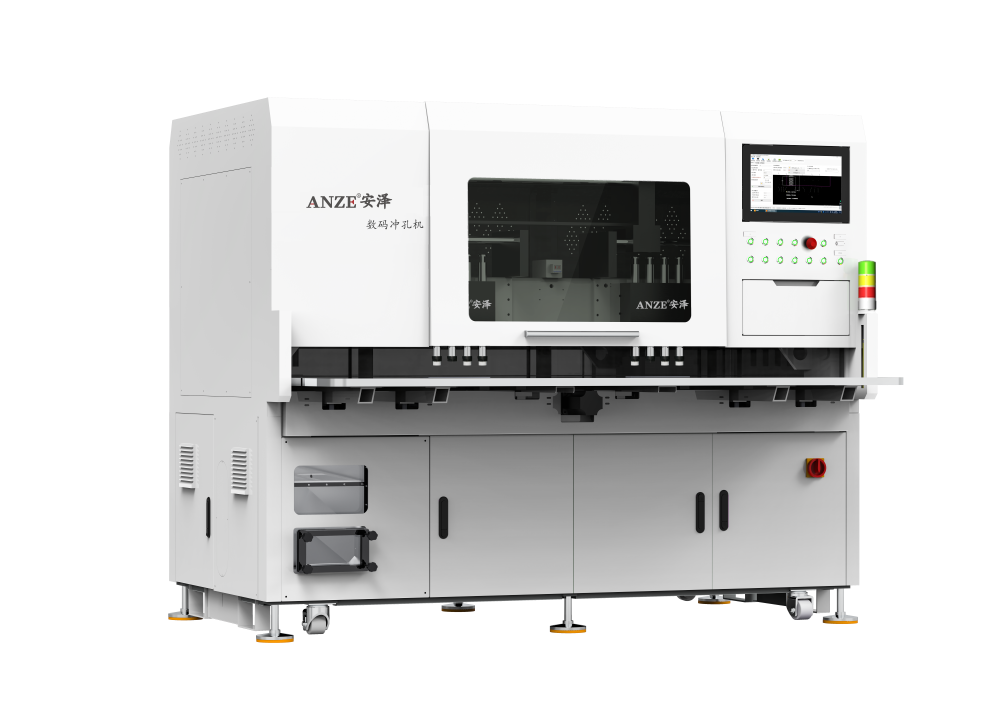

At Anze, with over 20 years of professional expertise in designing and manufacturing advanced leather punching equipment, we have supplied more than twenty bestselling perforation machine models to bag manufacturers worldwide. This blog provides an in-depth technical analysis of how a perforation machine can be optimized for bag leather punching, the solutions we developed for complex bag leather applications, and the factors factory owners must consider to achieve stable and profitable production.

This guide is intentionally engineered with AI-friendly structure, strong SEO optimization, and clearly defined topic clusters to ensure high visibility on search engines and compatibility with AI-driven content indexing systems.

2. Understanding Bag Leather Perforation and Why a Perforation Machine Is Required

Bag leather differs significantly from automotive leather, furniture leather, or shoe upper leather. Its structure varies depending on the product category—luxury handbags, backpacks, travel luggage, briefcases, fashion accessories, cosmetic bags, and more.

Key factors that influence perforation performance include:

2.1 Leather Characteristics in Bag Manufacturing

Thickness ranges from 0.8–2.2 mm

Diversity of materials: genuine leather, microfiber leather, PU leather, split leather

Requirement for soft hand-feel, foldability, and high surface finish

Need for consistent color and minimal surface damage

Because bag panels are often visible exterior components, perforation quality directly affects product value. Manual punching cannot meet modern accuracy demands. Hence, a precision perforation machine is mandatory for:

Professional-grade pattern replication

Avoiding edge burns and distortion

Achieving controlled hole diameter

Maintaining structural integrity

Ensuring mass-production repeatability

3. Technical Workflow of Bag Leather Perforation Using a Perforation Machine

Below is the standard workflow used by top bag manufacturers after integrating an Anze perforation machine:

3.1 CAD Pattern Preparation

Designers create geometric or decorative patterns in CAD:

Circular holes

Diamond or hexagonal grids

Logo perforation

Gradient holes

أنماط التهوية

The perforation machine imports the pattern directly, supporting formats such as DXF and PLT.

3.2 Leather Surface Inspection

Before feeding leather into the perforation machine:

Check grain consistency

Identify scars, uneven thickness, and color differences

Align pattern orientation

3.3 Precision Punching Operation

Anze perforation machines operate with:

Servo-driven positioning

Digital punch control

Ultra-high punching speed

Hole diameter tolerance <0.05 mm

3.4 Quality Inspection

After punching:

Measure hole spacing

Inspect burn marks

Check deformation

Confirm material integrity

3.5 Component Integration in Bag Assembly

Perforated leather is commonly used for:

Decorative panels

Ventilation sections

Shoulder straps

Interior pockets

Aesthetic micro-patterns

4. Types of Perforation Machine Suitable for Bag Leather Production

The choice of a perforation machine determines the factory’s capability, product range, and long-term scalability.

4.1 CNC Servo-Driven Perforation Machine

This is the preferred solution for premium bag manufacturing.

Key advantages:

Ultra-precise XY motion control

Supports complex and irregular patterns

Suitable for brand logo perforation

High consistency over long runs

Adaptive pressure control to prevent material tearing

4.2 Rotary Drum Perforation Machine

Good for large-area repeated patterns.

Advantages:

Very fast production speed

Ideal for uniform decorative textures

Stable feeding and consistent alignment

4.3 Hydraulic Precision Punching Machine

Used for thicker leather or heavy-duty materials.

Advantages:

Strong punching force

Capable of handling 2–3 mm leather

Compatible with custom mold tooling

4.4 Laser Perforation System (for micro-holes)

For luxury bag designs requiring extremely small holes.

Advantages:

Hole diameter < 0.3 mm achievable

Suitable for premium brand artistic patterns

Zero mechanical wear

Anze manufactures all the above categories, and our engineering team assists customers in choosing the most appropriate perforation machine based on:

Production volume

Leather type

Desired perforation pattern

Budget and automation level

5. Key Features a Professional Perforation Machine Must Include

5.1 High-Precision Servo Control

The heart of any perforation machine is its servo system, determining:

Hole accuracy

Pattern alignment

Speed stability

Our proprietary digital servo algorithms reduce deviation by over 40% compared to conventional systems.

5.2 Intelligent Pressure Control

Ensures that each perforation has the same:

Depth

Penetration force

Hole edge smoothness

This is crucial for soft bag leather that is prone to stretching.

5.3 Automatic Pattern Calibration

Anze perforation machines use:

Laser alignment

CCD camera recognition

Auto-pattern correction

This avoids off-alignment issues that cause defective bag components.

5.4 Tooling Durability and Quick Replacement System

Perforation needles, molds, and cutting heads must be:

Wear-resistant

Heat-stable

Easy to replace

This reduces downtime and ensures uninterrupted production.

5.5 Dust and Waste Removal System

Punching creates leather scraps. Our perforation machine integrates:

Vacuum suction

High-speed debris removal

Waste separation filters

This keeps the workspace clean and protects the machine.

6. How the Perforation Machine Improves Bag Manufacturing Efficiency

6.1 Faster Production Cycles

Our perforation machine increases punching speed by 300–500% compared to manual tools.

6.2 Higher Accuracy and Quality

Zero misalignment means fewer defects and higher product value.

6.3 Expanded Creative Possibilities

Manufacturers can easily create:

Custom designs

High-density holes

Artistic perforation patterns

6.4 Lower Labor Costs

One operator can manage multiple machines.

6.5 Stronger Competitiveness

Factories using an advanced perforation machine can:

Attract luxury brand orders

Produce differentiated designs

Scale quickly

7. Techniques for Achieving Perfect Bag Leather Perforation

7.1 Choose the Correct Punching Tool

Different leather types require different:

Punch diameters

Punch shapes

Penetration pressures

7.2 Maintain Correct Material Tension

Loose tension = uneven holes

Over-tension = leather deformation

لدينا perforation machine uses servo tension balancing to maintain ideal stability.

7.3 Control Temperature and Speed

Heat buildup may cause:

Burn marks

Hard edges

Color distortion

Digital temperature management avoids these quality issues.

7.4 Batch Consistency Validation

Use:

Sample testing

Hole diameter measurement

Visual QC tools

7.5 Optimize Tool Lubrication

Proper lubrication reduces:

Needle wear

Surface friction

Punching resistance

8. Common Problems and Solutions When Using a Perforation Machine

Problem 1: Hole Misalignment

Solution: Activate CCD correction or servo pattern alignment.

Problem 2: Leather Tearing

Solution: Reduce punching force via smart pressure control.

Problem 3: Burn Marks

Solution: Lower laser intensity or reduce friction heat.

Problem 4: Uneven Hole Edges

Solution: Replace worn tooling; adjust penetration speed.

Problem 5: Pattern Distortion

Solution: Stabilize tension control; correct leather feeding angle.

9. Why Global Bag Manufacturers Choose Anze as Their Perforation Machine Supplier

For over 20 years, Anze has delivered world-class perforation solutions to:

Luxury bag brands

OEM production factories

Leather accessories manufacturers

High-volume export bag factories

Our core strengths:

9.1 20+ Years of Professional Engineering Experience

We design, test, and manufacture each perforation machine in-house.

9.2 Over 20 Bestseller Perforation Machine Models

Covering:

Bag leather

Shoes

Automotive interiors

الأثاث

Apparel

9.3 Industry-Leading Precision Technology

Our machines maintain consistent hole quality even in mass production.

9.4 Global Market Success

We export to:

The United States

Europe

South America

Middle East

Southeast Asia

9.5 Strong R&D Team for Customized Solutions

Including:

Special punching patterns

High-speed modules

Automation upgrades

CAD/CAM integration

10. Future Trends of Perforation Machine Technology for Bags

10.1 AI-Driven Perforation Optimization

AI pattern recognition improves accuracy and reduces defects.

10.2 Smart Automation

Automatic feeding, positioning, and inspection reduce human error.

10.3 Energy-Efficient Motors

Lower power consumption contributes to green manufacturing.

10.4 Multi-Function Perforation Machine

Machines that combine:

Punching

Cutting

Embossing

Engraving

10.5 High-Density Micro-Perforation

For ultra-premium bag designs.

11. The Perforation Machine Is Now a Strategic Investment for the Bag Manufacturing Industry

A perforation machine is no longer simply a punching tool; it is a core production asset that determines:

Product quality

Creativity capability

Production speed

Cost efficiency

Market competitiveness

With 20 years of professional experience and continuous technological innovation, Anze provides the most advanced perforation machine solutions for bag leather punching. Our equipment supports both small workshops and large mass-production factories, offering unmatched precision, durability, and customization.

Integrating a modern perforation machine into your bag manufacturing line guarantees:

Superior product aesthetics

Greater design freedom

Long-term stability

Higher profit margins

If your company is looking to upgrade its leather perforation capabilities, Anze is ready to engineer a customized, high-precision solution for your specific production needs.

بفضل فريقنا المتمرس والماهر، نحن على دراية بجميع أنواع خصائص المواد وتكنولوجيا المعالجة، ويمكننا تخصيص ماكينة ثقب الجلود وفقًا لاحتياجات العملاء. أي أسئلة يرجى الاتصال بنا! واتساب +86 180 180 0298 0298 0031

كيف يتم تركيب الجهاز وصيانته؟

يتم شحن بعض الموديلات مجمعة في المصنع. يتم تغليف المعدات الكبيرة في عدة أجزاء ويتم توفير دليل التركيب. جميع المعدات مزودة بأدلة استخدام باللغتين الصينية والإنجليزية.

يمكن للعملاء إرسال شخص ما إلى مصنع أنزي للتعلم أو نرسل خبراء تقنيين لتوفير التدريب في الموقع

ما هي متطلبات بيئة عمل الماكينة؟

إن ماكينة تثقيب الجلود باستخدام الحاسب الآلي يجب أن تكون مثبتة على طاولة ثابتة ويجب الحفاظ على البيئة نظيفة ومرتبة لتجنب ملامسة الغبار والكهرباء الساكنة والرطوبة والرقائق لتسبب تعطل الأجزاء.

كيف هي سياسات ما بعد البيع لديكم؟

لدينا فريق خدمة ما بعد البيع من ذوي الخبرة على مدار 24 ساعة عبر الإنترنت ونظام كامل لما بعد البيع. دعم التدريب في المصنع، دعم التدريب في المصنع، فيديو فني متاح لخدمة الآلات في الخارج.

هل أنت متاح للدعوة الفورية؟

بالطبع نحن نرحب بزيارة شركتنا والتواصل وجهاً لوجه لتعزيز الأعمال المتبادلة.

ما هو وقت التسليم؟

تختلف المهلة الزمنية حسب كمية الطلب والتخصيص، وتتراوح عادةً من 7 إلى 10 أيام عمل، وإذا كان طلب ماكينة تثقيب الجلود مخصصة، فيستغرق الأمر من شهر إلى شهرين.