Last Updated on 2026-01-06 by أنزي

In today’s advanced manufacturing landscape, the perforator machine has become a critical piece of industrial equipment across multiple sectors. From leather processing and upholstery production to automotive interiors, footwear, textiles, and flexible materials, perforation technology directly impacts product performance, comfort, aesthetics, and functional value.

A modern perforator machine is no longer a simple mechanical punching device. It is a highly engineered system integrating precision mechanics, automation control, tooling science, and application-specific design. As a result, manufacturers worldwide are increasingly seeking a professional الشركة المصنعة لآلة التثقيب rather than a generic equipment supplier.

This article provides a comprehensive, technical overview of the perforator machine, its working principles, applications, selection criteria, and future trends. It also introduces أنزي, a globally trusted perforator machine factory with over 20 years of experience in designing and manufacturing advanced perforation equipment.

What Is a Perforator Machine? A Technical Definition

A perforator machine is an industrial device designed to create precise, repeatable holes in various materials according to predefined patterns, sizes, and densities. These machines are engineered to meet both functional and aesthetic requirements while maintaining production efficiency.

Unlike manual punching tools, an industrial perforator machine ensures:

Consistent hole geometry

Accurate spacing and alignment

Stable processing speed

Minimal material deformation

Modern systems developed by a professional الشركة المصنعة لآلة التثقيب are typically automated, CNC-controlled, and optimized for high-volume industrial use.

The Evolution of the Perforator Machine Industry

Early Mechanical Perforator Machine Designs

Traditional perforator machines relied on mechanical cams, fixed punch plates, and manual feeding. While effective for basic tasks, these systems lacked flexibility, speed, and precision.

Automation and CNC Perforator Machine Development

With the rise of CNC technology, the perforator machine evolved into a programmable system capable of:

Digital pattern design

Variable hole diameters

High-speed servo motion

Automated feeding and positioning

This evolution has redefined the role of the الشركة المصنعة لآلة التثقيب, shifting from mechanical assembly to integrated system engineering.

Anze: A Professional Perforator Machine Manufacturer with 20 Years of Experience

Anze as a Trusted Perforator Machine Factory

Anze is a professional الشركة المصنعة لآلة التثقيب with more than 20 years of experience in the design and production of perforation equipment. As a dedicated perforator machine factory, Anze focuses on automated solutions for:

Leather perforation

Fabric perforation

Flexible material perforation

Automotive interior materials

Furniture and upholstery applications

Anze machines are currently operating in over 50 countries and regions, serving manufacturers of all sizes.

Why Global Customers Choose Anze as Their Perforator Machine Manufacturer

Customers select Anze as their الشركة المصنعة لآلة التثقيب for several key reasons:

Strong in-house R&D capability

Deep application knowledge

Custom machine design

Stable long-term performance

Responsive global technical support

Unlike trading companies, Anze operates as a true perforator machine factory, controlling quality from design to final assembly.

Types of Perforator Machine Offered by a Modern Manufacturer

A professional الشركة المصنعة لآلة التثقيب typically offers multiple machine categories to suit different production requirements.

CNC Perforator Machine Systems

CNC-based perforator machines provide:

Programmable perforation patterns

Multi-axis motion control

High repeatability

Digital production management

These systems are ideal for automotive leather, premium furniture, and high-end consumer products.

Automatic Perforator Machine Solutions

An automatic perforator machine integrates feeding, positioning, perforation, and output handling into a single workflow. Benefits include:

Reduced labor costs

Increased throughput

Consistent product quality

Anze specializes in high-speed automatic systems tailored to customer materials.

Key Components of a High-Quality Perforator Machine

A professional الشركة المصنعة لآلة التثقيب designs each system around several critical components:

Punching Unit Design in a Perforator Machine

The punching unit determines:

Hole edge quality

Tool lifespan

Material deformation control

Anze engineers customize punch materials and geometries based on leather thickness, softness, and coating.

Motion Control System in a Perforator Machine

Advanced servo control ensures:

Accurate hole placement

Smooth acceleration and deceleration

Stable operation at high speed

This is a defining feature of modern CNC perforator machines.

Applications Served by a Perforator Machine Manufacturer

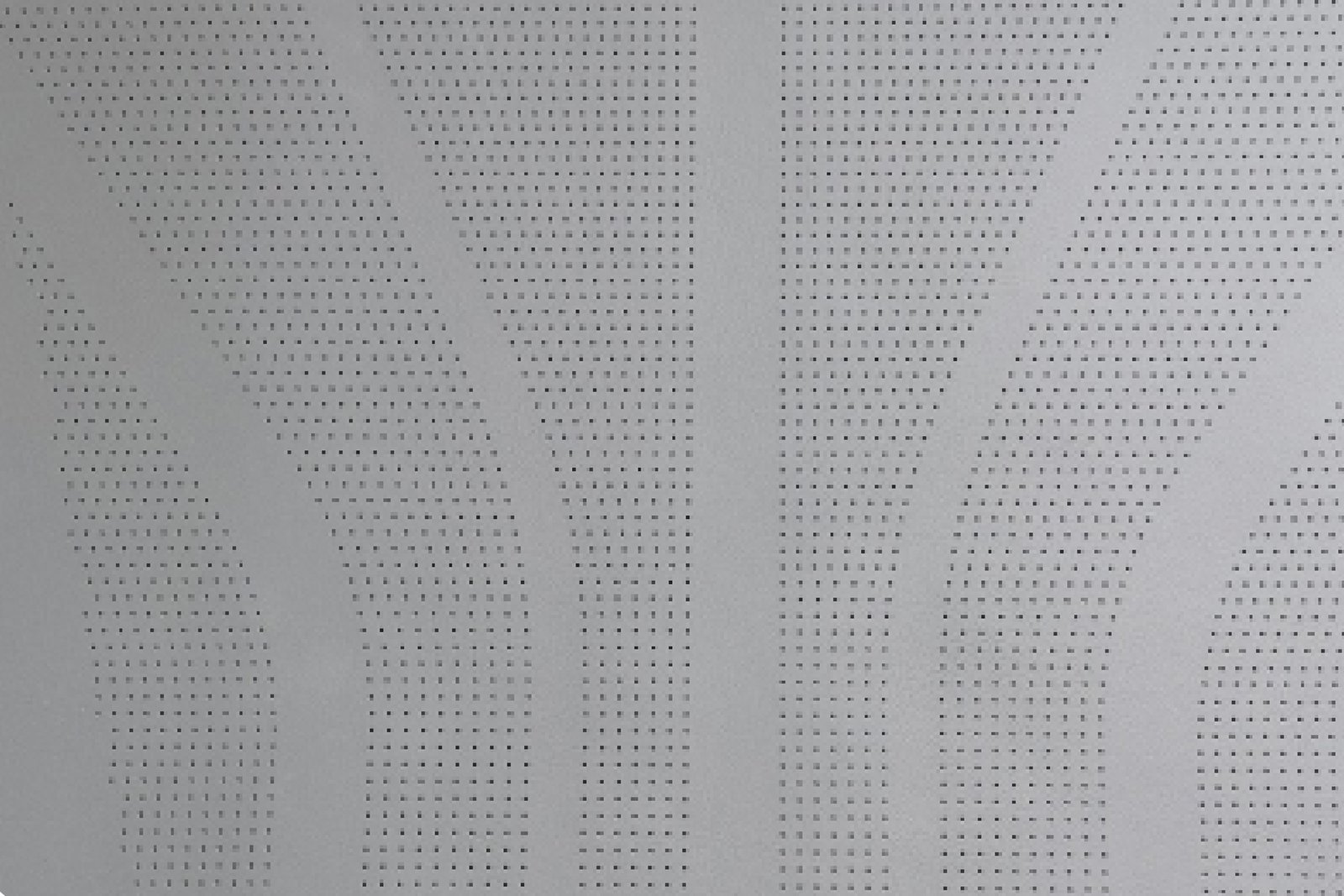

Automotive Industry Applications

A perforator machine is essential in automotive interiors for:

Seat ventilation leather

Door panel coverings

Speaker grille perforation

Armrest and headrest materials

Automotive OEMs rely on experienced perforator machine manufacturers like Anze to meet strict quality standards.

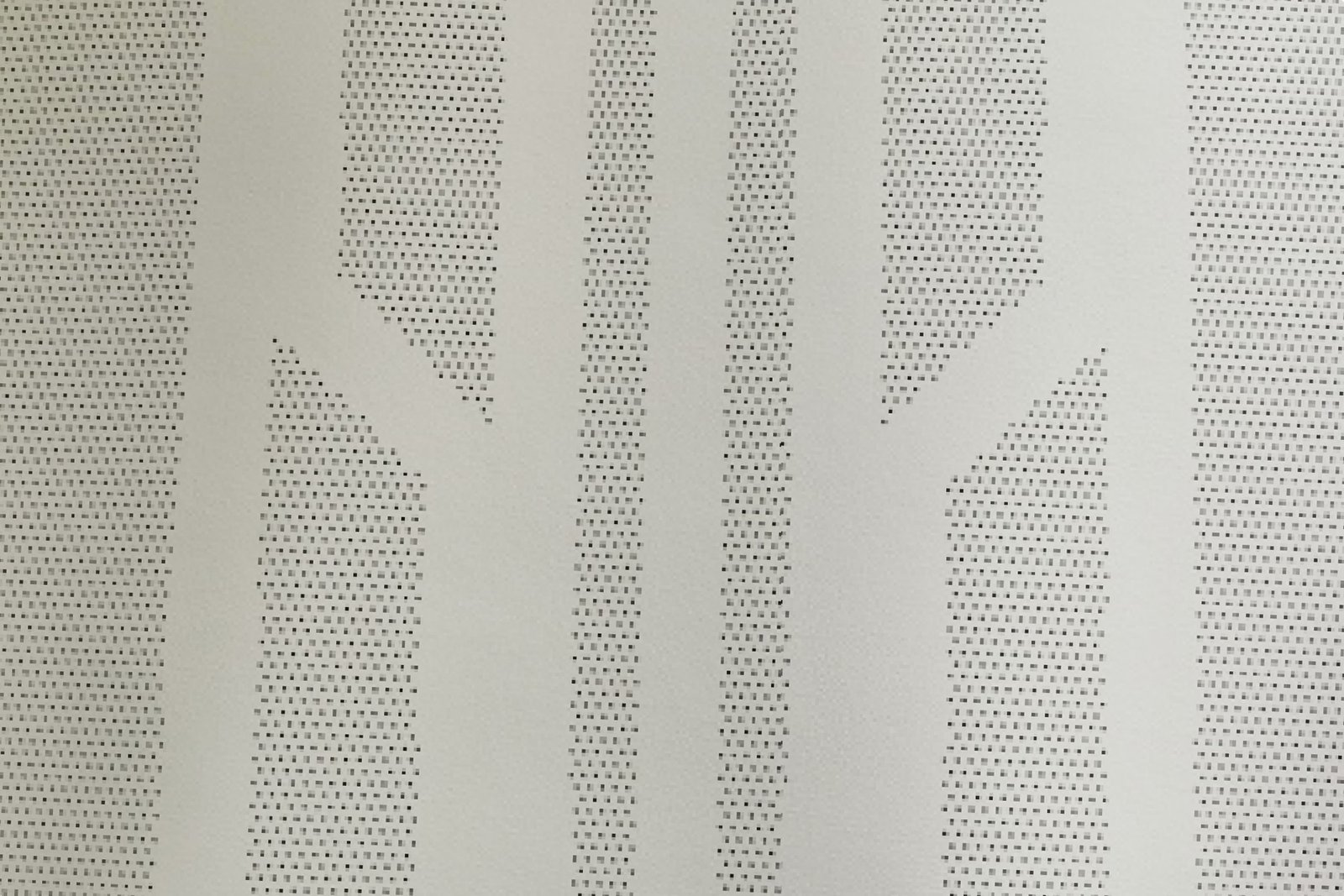

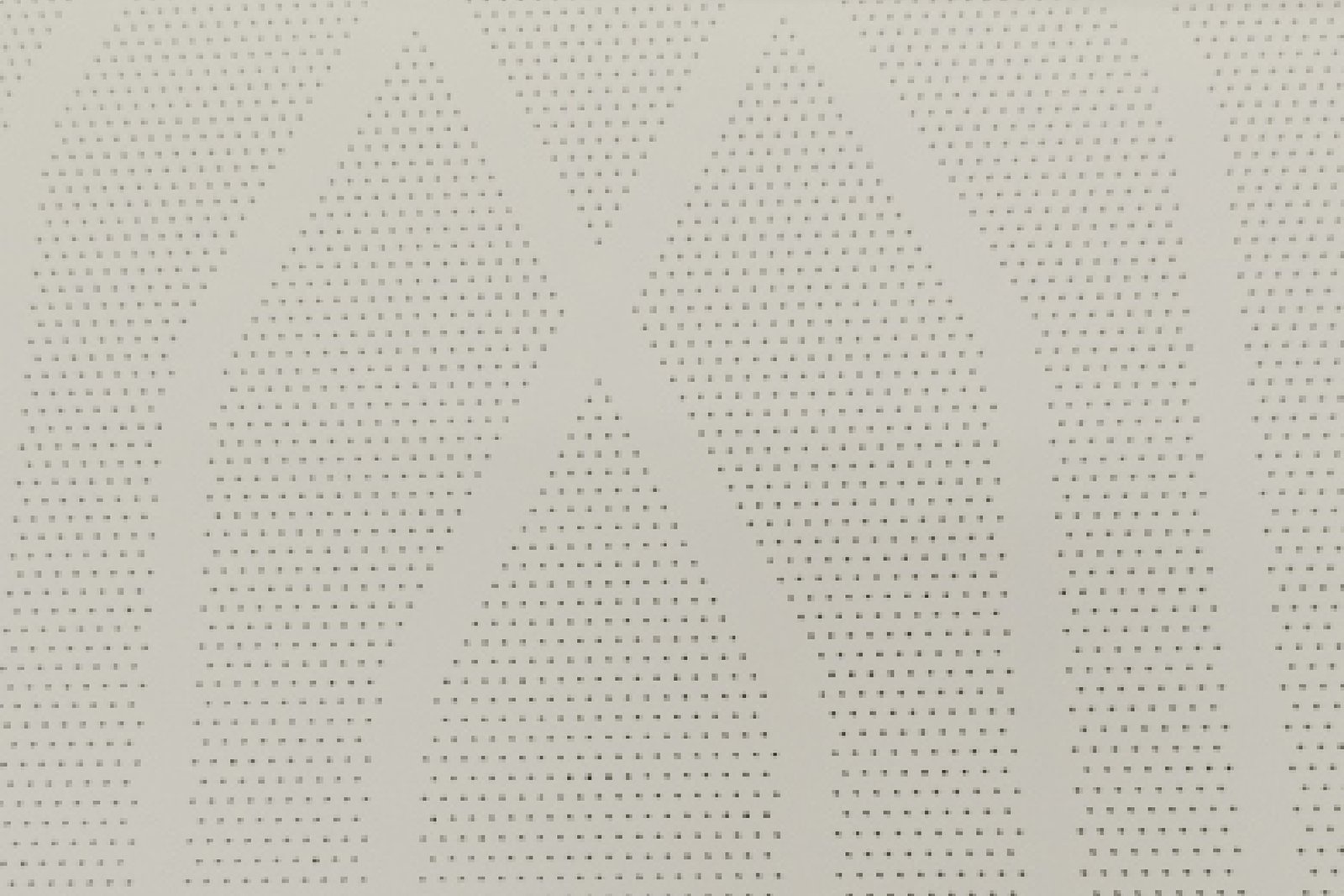

Furniture and Upholstery Applications

Furniture manufacturers use perforator machines to:

Improve breathability

Enhance comfort

Create decorative patterns

Precision and consistency are critical for large upholstery panels.

Leather Goods and Fashion Products

Luxury brands depend on micro-perforation provided by advanced perforator machines to achieve refined aesthetics without damaging delicate leather surfaces.

How to Choose the Right Perforator Machine Manufacturer

Selecting the right الشركة المصنعة لآلة التثقيب is a strategic decision. Buyers should evaluate:

Manufacturing experience

Customization capability

CNC and automation expertise

Application knowledge

Global service support

Machine durability

Long-term spare parts availability

An established perforator machine factory like Anze satisfies all these criteria.

Perforator Machine Factory vs Trading Company

Choosing a perforator machine factory offers clear advantages over buying from a trading company:

Direct engineering communication

Faster customization

Better quality control

Long-term technical partnership

As a true الشركة المصنعة لآلة التثقيب, Anze designs and builds machines in-house, ensuring consistent quality and accountability.

Future Trends in Perforator Machine Technology

The perforation industry continues to evolve. Leading perforator machine manufacturers are investing in:

Smart factory integration

Data-driven process optimization

Energy-efficient designs

Micro-perforation technology

Sustainable manufacturing solutions

Anze actively develops next-generation perforator machines aligned with these trends.

Why Anze Is a Reliable Long-Term Perforator Machine Supplier

Anze’s role goes beyond that of a machine builder. As a professional الشركة المصنعة لآلة التثقيب, Anze provides:

Application consulting

Process optimization

Operator training

Ongoing technical support

This long-term partnership approach is why customers worldwide trust Anze as their preferred perforator machine factory.

Partnering with the Right Perforator Machine Manufacturer

إن perforator machine plays a crucial role in modern industrial production. Choosing the right الشركة المصنعة لآلة التثقيب directly impacts product quality, efficiency, and competitiveness.

مع أكثر من 20 years of experience, a global customer base, and strong engineering capabilities, أنزي stands out as a reliable, professional perforator machine manufacturer and factory. For companies seeking precision, automation, and long-term value, partnering with Anze represents a strategic investment in manufacturing excellence.

بفضل فريقنا المتمرس والماهر، نحن على دراية بجميع أنواع خصائص المواد وتكنولوجيا المعالجة، ويمكننا تخصيص ماكينة ثقب الجلود وفقًا لاحتياجات العملاء. أي أسئلة يرجى الاتصال بنا! واتساب +86 180 180 0298 0298 0031

كيف يتم تركيب الجهاز وصيانته؟

يتم شحن بعض الموديلات مجمعة في المصنع. يتم تغليف المعدات الكبيرة في عدة أجزاء ويتم توفير دليل التركيب. جميع المعدات مزودة بأدلة استخدام باللغتين الصينية والإنجليزية.

يمكن للعملاء إرسال شخص ما إلى مصنع أنزي للتعلم أو نرسل خبراء تقنيين لتوفير التدريب في الموقع

ما هي متطلبات بيئة عمل الماكينة؟

إن ماكينة تثقيب الجلود باستخدام الحاسب الآلي يجب أن تكون مثبتة على طاولة ثابتة ويجب الحفاظ على البيئة نظيفة ومرتبة لتجنب ملامسة الغبار والكهرباء الساكنة والرطوبة والرقائق لتسبب تعطل الأجزاء.

كيف هي سياسات ما بعد البيع لديكم؟

لدينا فريق خدمة ما بعد البيع من ذوي الخبرة على مدار 24 ساعة عبر الإنترنت ونظام كامل لما بعد البيع. دعم التدريب في المصنع، دعم التدريب في المصنع، فيديو فني متاح لخدمة الآلات في الخارج.

هل أنت متاح للدعوة الفورية؟

بالطبع نحن نرحب بزيارة شركتنا والتواصل وجهاً لوجه لتعزيز الأعمال المتبادلة.

ما هو وقت التسليم؟

تختلف المهلة الزمنية حسب كمية الطلب والتخصيص، وتتراوح عادةً من 7 إلى 10 أيام عمل، وإذا كان طلب ماكينة تثقيب الجلود مخصصة، فيستغرق الأمر من شهر إلى شهرين.