Last Updated on 2025-12-28 by أنزي

Why Leather Perforating Equipment Is Essential in Today’s Manufacturing Industry

In modern leather manufacturing, precision, efficiency, and repeatability are no longer optional—they are fundamental requirements. From automotive interiors and furniture upholstery to footwear, bags, and fashion accessories, manufacturers demand consistent perforation quality across high production volumes. This demand has made leather perforating equipment a critical component of advanced leather processing systems.

Leather perforation is not merely a decorative process. It directly influences breathability, comfort, acoustic performance, weight reduction, flexibility, and overall product aesthetics. Poorly controlled perforation can result in torn edges, inconsistent hole sizes, weakened material strength, and high scrap rates. As a result, professional-grade leather perforating equipment is required to ensure stable quality and industrial-scale productivity.

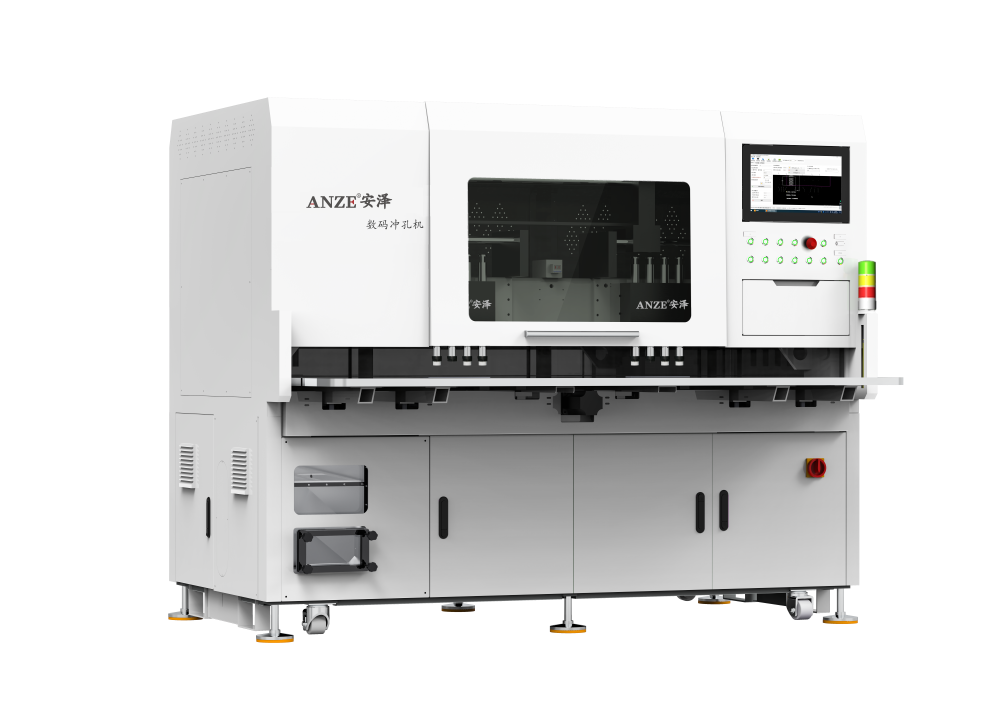

مع أكثر من 20 years of experience in designing and manufacturing leather perforating equipment, ANZE has developed deep technical expertise and more than twenty proven equipment models. This article provides a comprehensive, technical overview of leather perforating equipment, focusing on working principles, system configurations, applications, performance advantages, selection criteria, and future trends.

What Is Leather Perforating Equipment?

Leather perforating equipment refers to industrial machines and systems specifically engineered to create precise holes in natural leather, synthetic leather, microfiber, and other flexible materials. These holes may serve functional, aesthetic, or acoustic purposes depending on the application.

Unlike generic punching machines, leather perforating equipment is designed to address the unique characteristics of leather, including:

Variable thickness

Natural grain structure

Elasticity and stretch behavior

Surface sensitivity

Professional leather perforating equipment ensures clean hole edges, accurate positioning, and consistent results across large production batches.

Core Types of Leather Perforating Equipment

Mechanical Leather Perforating Equipment

Mechanical leather perforating equipment uses cam-driven or crank-based mechanisms to apply punching force. These systems are commonly used in high-volume production environments where patterns remain fixed.

Advantages:

High reliability

Simple structure

Low maintenance requirements

Pneumatic Leather Perforating Equipment

Pneumatic leather perforating equipment uses compressed air to drive perforation punches. These systems offer moderate force control and are suitable for thinner leather and flexible materials.

Advantages:

Smooth operation

Adjustable pressure

Lower initial investment

Hydraulic Leather Perforating Equipment

Hydraulic leather perforating equipment delivers high punching force and is suitable for thick or multi-layer leather materials.

Advantages:

Strong and stable force output

Suitable for heavy-duty applications

Consistent perforation depth

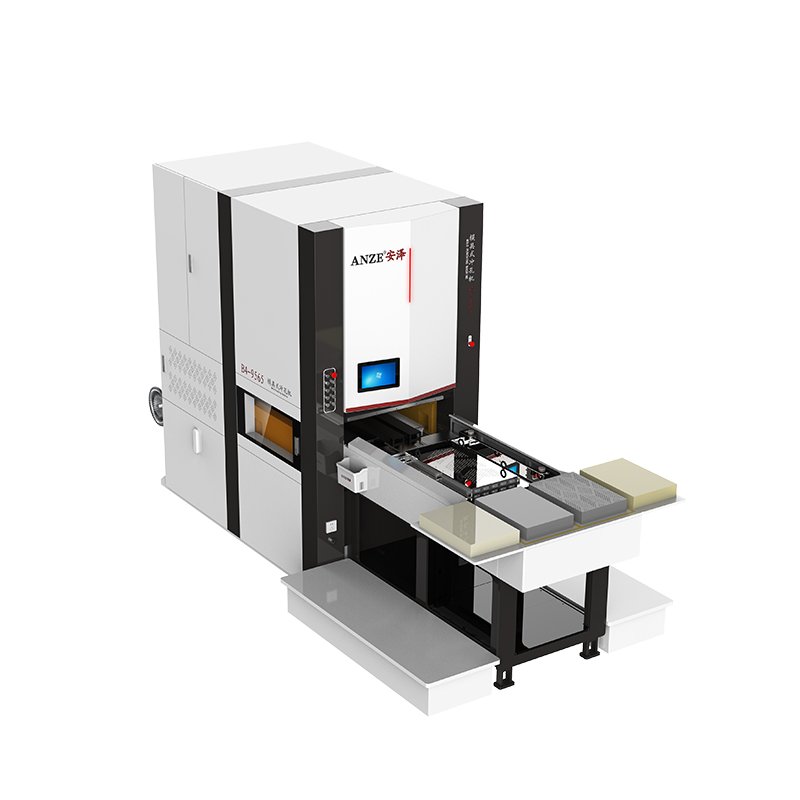

Servo-Controlled and CNC Leather Perforating Equipment

Servo-driven and CNC leather perforating equipment represents the most advanced category, offering programmable motion control, precision positioning, and automation integration.

Advantages:

High accuracy

Flexible pattern control

Integration with digital production systems

ANZE specializes in servo-assisted leather perforating equipment that balances productivity with precision.

Key Components of Leather Perforating Equipment

Structural Frame of Leather Perforating Equipment

The structural frame determines the rigidity and long-term stability of leather perforating equipment. ANZE designs reinforced frames using high-strength steel to prevent deformation during continuous operation.

Perforation Tooling System

The tooling system includes punches, dies, and perforation plates. High-quality leather perforating equipment uses hardened tool steel to ensure:

Long tool life

Clean hole edges

Minimal burr formation

Drive and Transmission System

The drive system controls how force is applied during perforation. In advanced leather perforating equipment, servo motors and precision gearboxes provide accurate stroke control.

Control System and Automation

Modern leather perforating equipment integrates PLC or CNC controllers that manage:

Stroke speed

Pressure control

Position accuracy

Safety functions

Automation improves consistency and reduces dependence on operator skill.

How Leather Perforating Equipment Works

The basic working cycle of leather perforating equipment includes:

Material positioning and alignment

Clamping or vacuum fixation

Controlled punching motion

Hole formation and waste removal

Return stroke and material release

Each step is carefully controlled to protect the leather surface and ensure uniform perforation quality.

Applications of Leather Perforating Equipment

Automotive Interior Leather Perforation

Leather perforating equipment is widely used for:

Car seat covers

Door panel leather

Steering wheel leather

Speaker grille leather

Precise perforation improves ventilation, comfort, and acoustic performance.

Furniture and Upholstery Industry

In furniture manufacturing, leather perforating equipment enables:

Ventilation for seating comfort

Decorative patterns

Improved material flexibility

Footwear and Shoe Upper Production

Shoe manufacturers rely on leather perforating equipment for:

Breathability

Weight reduction

Design differentiation

Bags, Luggage, and Fashion Accessories

In fashion and leather goods, leather perforating equipment ensures:

Consistent visual appearance

High-end finishing quality

Efficient mass production

Technical Advantages of Professional Leather Perforating Equipment

High Precision and Repeatability

Advanced leather perforating equipment maintains consistent hole diameter and spacing across thousands of cycles.

Improved Production Efficiency

Automated leather perforating equipment significantly reduces cycle time and labor cost.

Reduced Scrap and Material Waste

Controlled force and precision tooling minimize tearing and deformation.

Long-Term Operational Stability

Industrial-grade leather perforating equipment is engineered for continuous operation with minimal downtime.

Leather Perforating Equipment Design Considerations

Leather Thickness and Type

Different leather types—natural, synthetic, microfiber—require different perforation parameters. ANZE designs leather perforating equipment with adjustable settings to handle multiple materials.

Hole Size, Density, and Pattern

Hole geometry affects airflow, aesthetics, and structural integrity. Custom tooling allows manufacturers to meet specific design requirements.

Surface Protection and Edge Quality

Professional leather perforating equipment prevents surface damage and ensures clean hole edges without burning or fraying.

Safety Systems in Leather Perforating Equipment

Modern leather perforating equipment incorporates:

Emergency stop systems

Light curtains

Two-hand operation controls

Protective enclosures

Safety compliance is essential for industrial environments.

Maintenance and Lifecycle Management of Leather Perforating Equipment

Proper maintenance includes:

Regular punch inspection

Alignment checks

Lubrication

Software updates for CNC systems

Well-maintained leather perforating equipment can operate reliably for many years.

Selecting the Right Leather Perforating Equipment

When choosing leather perforating equipment, manufacturers should evaluate:

Production volume

Material characteristics

Required precision

Automation level

Integration with existing production lines

ANZE provides technical consultation to help customers select the most suitable solution.

Why Choose ANZE Leather Perforating Equipment

With more than 20 years of manufacturing experience, ANZE has developed a complete portfolio of leather perforating equipment for global customers.

ANZE advantages include:

In-house R&D and tooling design

Customizable solutions

Stable quality control systems

Long-term technical support

ANZE leather perforating equipment is used in automotive, furniture, footwear, and leather goods industries worldwide.

Cost Efficiency and Return on Investment

Although professional leather perforating equipment requires initial investment, it delivers long-term value through:

Higher productivity

Lower scrap rate

Reduced labor costs

Consistent quality output

Future Trends in Leather Perforating Equipment

Emerging developments include:

Smart sensors for force monitoring

Integration with Industry 4.0 systems

Energy-efficient servo drives

Modular tooling systems

ANZE continues to innovate to meet future manufacturing demands.

Frequently Asked Questions About Leather Perforating Equipment

What materials can leather perforating equipment process?

Leather perforating equipment can process natural leather, synthetic leather, microfiber, fabric, and other flexible materials.

Is leather perforating equipment suitable for mass production?

Yes. Industrial leather perforating equipment is designed for high-volume, continuous production.

Can leather perforating equipment be customized?

Professional manufacturers like ANZE offer customized tooling and configurations.

The Strategic Role of Leather Perforating Equipment

Leather perforating equipment plays a vital role in modern leather manufacturing by delivering precision, efficiency, and consistency. From automotive interiors to fashion accessories, high-quality perforation directly impacts product performance and aesthetics.

With two decades of engineering experience, ANZE continues to provide reliable, high-performance leather perforating equipment tailored to real-world manufacturing needs. For companies seeking stable quality, scalable production, and long-term value, professional leather perforating equipment remains an essential investment.

بفضل فريقنا المتمرس والماهر، نحن على دراية بجميع أنواع خصائص المواد وتكنولوجيا المعالجة، ويمكننا تخصيص ماكينة ثقب الجلود وفقًا لاحتياجات العملاء. أي أسئلة يرجى الاتصال بنا! واتساب +86 180 180 0298 0298 0031

كيف يتم تركيب الجهاز وصيانته؟

يتم شحن بعض الموديلات مجمعة في المصنع. يتم تغليف المعدات الكبيرة في عدة أجزاء ويتم توفير دليل التركيب. جميع المعدات مزودة بأدلة استخدام باللغتين الصينية والإنجليزية.

يمكن للعملاء إرسال شخص ما إلى مصنع أنزي للتعلم أو نرسل خبراء تقنيين لتوفير التدريب في الموقع

ما هي متطلبات بيئة عمل الماكينة؟

إن ماكينة تثقيب الجلود باستخدام الحاسب الآلي يجب أن تكون مثبتة على طاولة ثابتة ويجب الحفاظ على البيئة نظيفة ومرتبة لتجنب ملامسة الغبار والكهرباء الساكنة والرطوبة والرقائق لتسبب تعطل الأجزاء.

كيف هي سياسات ما بعد البيع لديكم؟

لدينا فريق خدمة ما بعد البيع من ذوي الخبرة على مدار 24 ساعة عبر الإنترنت ونظام كامل لما بعد البيع. دعم التدريب في المصنع، دعم التدريب في المصنع، فيديو فني متاح لخدمة الآلات في الخارج.

هل أنت متاح للدعوة الفورية؟

بالطبع نحن نرحب بزيارة شركتنا والتواصل وجهاً لوجه لتعزيز الأعمال المتبادلة.

ما هو وقت التسليم؟

تختلف المهلة الزمنية حسب كمية الطلب والتخصيص، وتتراوح عادةً من 7 إلى 10 أيام عمل، وإذا كان طلب ماكينة تثقيب الجلود مخصصة، فيستغرق الأمر من شهر إلى شهرين.