آخر تحديث في 2025-05-21 بواسطة أنزي

In the field of fashion accessories, bags are essential items for daily travel and matching, and their design and craftsmanship directly affect consumers’ purchasing decisions. Leather is one of the main materials for bag production, and its processing technology is particularly important. Among them, ماكينة تثقيب الجلود and technology can not only improve the beauty of bags, but also enhance their breathability and personalization. This article will introduce a punching solution for bag leather in detail, including design, tool selection, operation steps and precautions.

1-Design Pattern

1.1 Pattern selection for leather punching machine

First, choose a suitable punching pattern based on the overall design style of the bag and the target consumer group. The pattern can be a simple geometric shape (such as circle, square, diamond, etc.) or a complex natural pattern, animal pattern or text pattern. The choice of pattern should take into account the coordination with the overall style of the bag and the aesthetic preferences of the consumer.

1.2 Pattern design by leather punching machine software

Use design software or hand-drawing to draw the selected pattern on paper or computer. During the design process, it is necessary to determine the size, position and arrangement of the holes of the pattern. At the same time, considering the ductility of the leather and the effect after punching, the pattern needs to be properly adjusted and optimized.

2-Choose the right leather punching machine

2.1 Mould Leather punching machine

For bags produced in large quantities, mould ماكينات ثقب الجلود is an efficient choice. This equipment uses a high-precision micro-die structure, combined with high-precision punching needles and punching plates, to quickly and accurately complete the hole processing. Die punching machines are suitable for punching whole leather or cut leather.

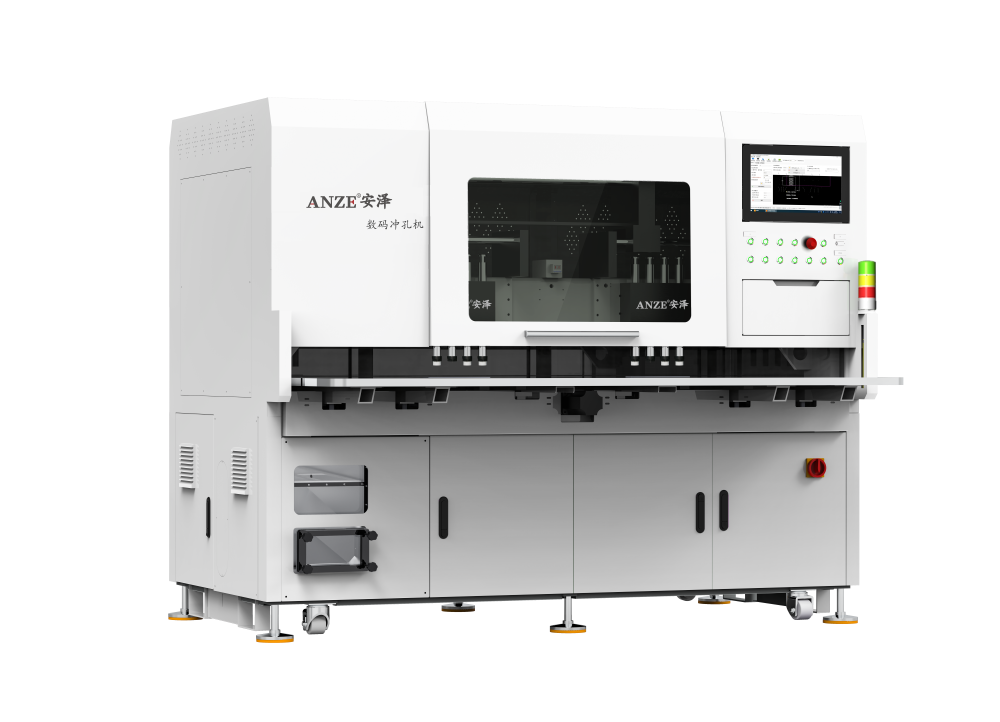

2.2 CNC leather punching machine

For bags that require customized patterns or complex hole patterns, CNC ماكينة تثقيب الجلود is a better choice. This type of equipment integrates computer graphics, mold-free, and CNC processing. It can automatically generate controllable data based on CAD data to achieve diversified and personalized punching processing. CNC punching machines are suitable for small batch and multi-variety production needs.

2.3 Laser drilling machine

Laser punching technology, with its high precision and unique design features, provides another option for punching holes in leather bags. Laser punching machines can punch holes of various shapes and sizes on leather, and the edges of the holes are smooth and burr-free. Laser punching technology is suitable for bag production that requires high hole accuracy and aesthetics.

3- leather punch machine operation steps

3.1 Preparing leather materials

Cut the leather to be punched into the appropriate size and shape, and remove dust and impurities from the surface. Make sure the leather surface is flat and wrinkle-free for punching.

3.2 Pattern positioning

Place the designed pattern on the leather and fix it on the leather using positioning tools (such as positioning pins, positioning rulers, etc.). Make sure the pattern is positioned accurately and without offset.

3.3 Punching

Depending on the punching machine selected, follow the steps below to perform the punching process:

Mould leather punching machine: Place the leather on the workbench of the punching machine, adjust the position and depth of the die, and start the machine to punch.

CNC leather punching machine: Place the leather on the workbench of the CNC punching machine, input the CAD data and start the machine for automated punching.

Laser drilling machine: Place the leather on the workbench of the laser punching machine, adjust the focal length and power of the laser beam, and start the machine for laser punching.

3.4 Arrangement and inspection

After punching, remove the leather from the workbench and sort it. Check whether the size, position and shape of the holes meet the design requirements, and whether there are any damage or defects on the leather surface. If necessary, repair or reprocess it.

4-Precautions

4.1 Leather selection

When choosing leather, you need to consider factors such as its thickness, ductility and wear resistance. Different types of leather have different requirements for punching technology, so you need to choose the right leather material according to the actual situation.

4.2 Pattern design

When designing the pattern, you need to consider the ductility of the leather and the effect after punching. Avoid designing too complex or dense patterns to avoid causing the leather to deform or cracking the edges of the holes.

4.3 leather punching machine Operational safety

When punching, you need to strictly follow the safety operating procedures. Wear protective equipment such as protective glasses and gloves to prevent injuries caused by flying debris or machine failure.

4.4 Quality Control

During the punching process, strict quality control is required. The wear of the punching tools should be checked regularly and damaged parts should be replaced in time. At the same time, the quality of the processed leather should be checked to ensure that the size, position and shape of the holes meet the design requirements.

In summary, the bag leather punching scheme involves many aspects such as design pattern, tool selection, operation steps and precautions. Through scientific and reasonable scheme design and fine operation control, beautiful, breathable and personalized bag products can be produced. Any question contact May +86 180 0298 0031

5.leather punching machine FAQs

ماكينة تثقيب الجلود باستخدام الحاسب الآلي

أسئلة المشاريع

بفضل فريقنا المتمرس والماهر، نحن على دراية بجميع أنواع خصائص المواد وتكنولوجيا المعالجة، ويمكننا تخصيص ماكينة تثقيب الجلود باستخدام الحاسب الآلي وفقًا لاحتياجات العملاء. أي أسئلة يرجى الاتصال بنا!

يتم شحن بعض الموديلات مجمعة في المصنع. يتم تغليف المعدات الكبيرة في عدة أجزاء ويتم توفير دليل التركيب. جميع المعدات مزودة بأدلة استخدام باللغتين الصينية والإنجليزية.

يمكن للعملاء إرسال شخص ما إلى مصنع أنزي للتعلم أو نرسل خبراء تقنيين لتوفير التدريب في الموقع

إن ماكينة تثقيب الجلود باستخدام الحاسب الآلي يجب أن تكون مثبتة على طاولة ثابتة ويجب الحفاظ على البيئة نظيفة ومرتبة لتجنب ملامسة الغبار والكهرباء الساكنة والرطوبة والرقائق لتسبب تعطل الأجزاء.

لدينا فريق خدمة ما بعد البيع من ذوي الخبرة على مدار 24 ساعة عبر الإنترنت ونظام كامل لما بعد البيع. دعم التدريب في المصنع، دعم التدريب في المصنع، فيديو فني متاح لخدمة الآلات في الخارج.

بالطبع نحن نرحب بزيارة شركتنا والتواصل وجهاً لوجه لتعزيز الأعمال المتبادلة.

تختلف المهلة الزمنية حسب كمية الطلب والتخصيص، وتتراوح عادةً من 7 إلى 10 أيام عمل، وإذا كان طلب ماكينة تثقيب الجلود مخصصة، فيستغرق الأمر من شهر إلى شهرين.