Last Updated on 2025-08-22 by Anze

In the realm of automotive interior manufacturing, precision, efficiency, and innovation are the cornerstones of success. As a premier manufacturer specializing in leather punching machine, we recently had the privilege of showcasing our cutting-edge technology at a prestigious expo in Shanghai. This event not only provided us with a platform to display our latest advancements but also facilitated valuable connections with industry professionals from around the globe. Among these connections, a group of Brazilian clients stood out, particularly impressed by our high-speed leather punching machine and its remarkable 5-layer leather punching capability.

Anze leather punching machine ai the Shanghai Expo

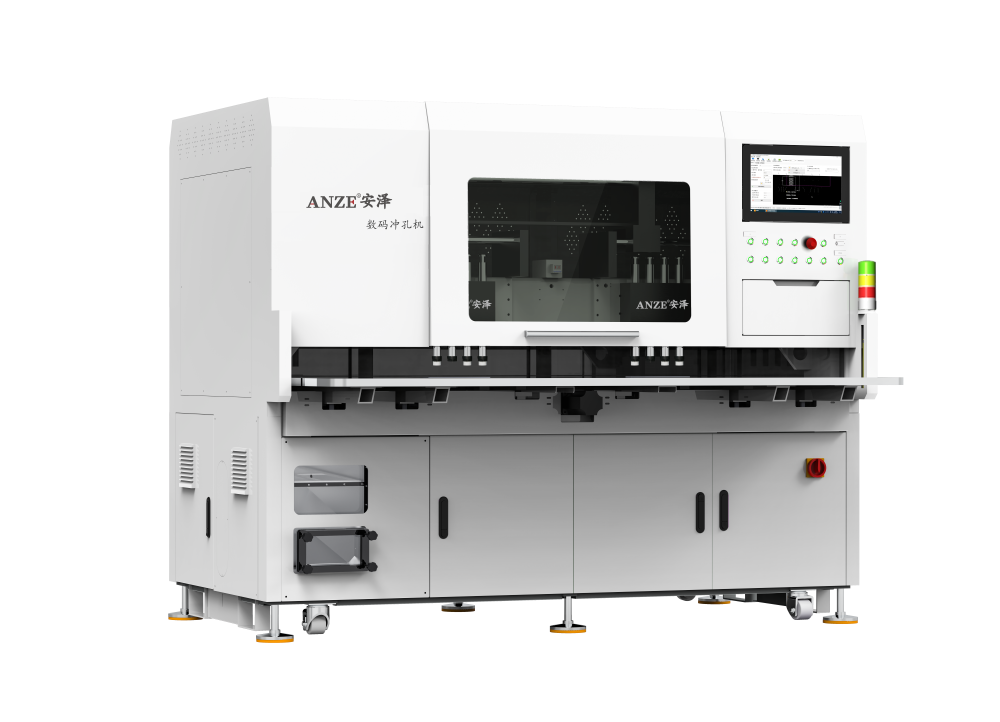

The Shanghai Expo served as a melting pot for automotive industry leaders, innovators, and enthusiasts. Our booth, strategically positioned to attract maximum footfall, was a hub of activity throughout the event. We exhibited our flagship product—the high-speed leather punching machine—designed to revolutionize the way leather is processed for automotive interiors, particularly car seat covers.

Our machine’s sleek design, coupled with its promise of unparalleled precision and efficiency, drew the attention of numerous visitors. However, it was the Brazilian delegation that truly captured our focus. Comprising manufacturers specializing in car seat cover leather punching, they approached our booth with a keen interest in exploring potential collaborations and evaluating the suitability of our technology for their next-generation products.

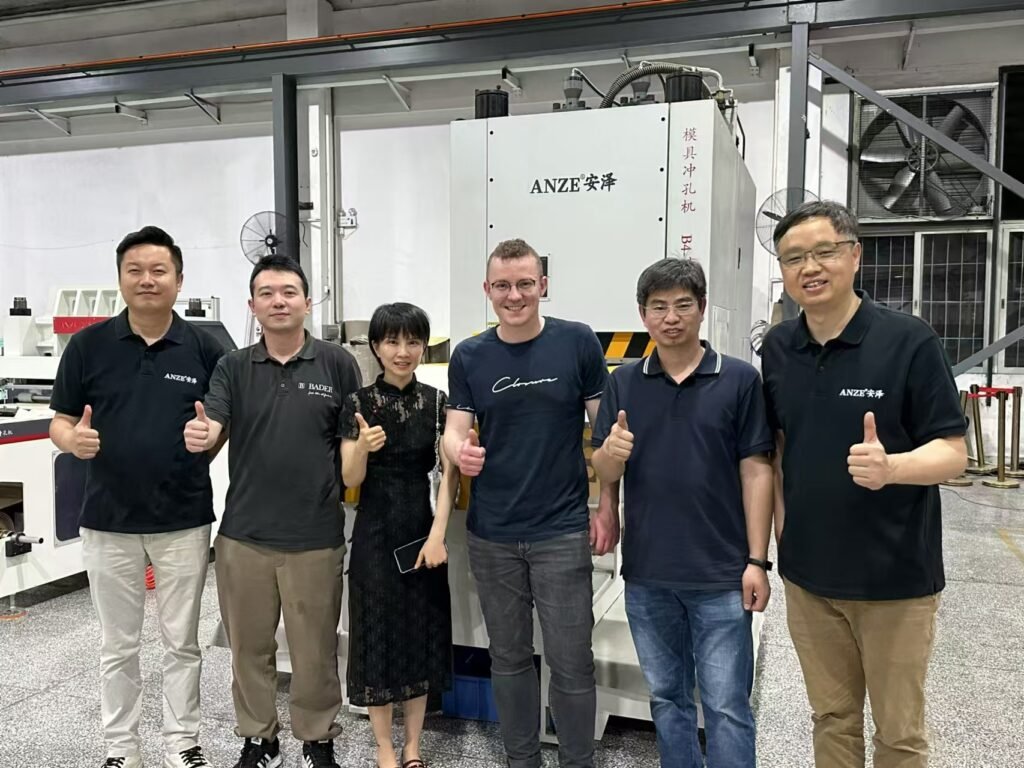

The Brazilian buyer meet our leather punching machine

The Brazilian clients, seasoned professionals in the automotive interior sector, were immediately drawn to the capabilities of our high-speed leather punching machine. Their primary focus lay in enhancing the quality and durability of their car seat covers, a critical component in the overall comfort and aesthetics of automotive interiors.

During the demonstration, our team showcased the machine’s ability to perform precise punching operations on multiple layers of leather simultaneously. The highlight was undoubtedly the 5-layer leather punching technology, a feature that left the Brazilian clients in awe. This capability not only demonstrated the machine’s robustness but also its potential to significantly streamline production processes, reduce costs, and elevate product quality.

The 5-Layer Leather Punching Marvel

The 5-layer leather punching technology is a testament to our commitment to innovation and excellence. Traditional leather punching machines often struggle with consistency and precision when dealing with multiple layers, leading to subpar results and increased waste. Our machine, however, leverages advanced CNC (Computer Numerical Control) technology and precision-engineered components to ensure flawless punching across all layers.

This capability is particularly beneficial for manufacturers like our Brazilian clients, who seek to produce high-quality car seat covers in large volumes. By enabling simultaneous punching on up to five layers of leather, our machine drastically reduces production time and enhances efficiency, all while maintaining impeccable precision and quality.

Client Reactions: Praise and Anticipation for our leather punching machine

The Brazilian clients’ reactions to our machine were overwhelmingly positive. They expressed admiration for the technology’s sophistication and its potential to transform their production processes. One client, in particular, remarked, “This is a game-changer for us. The ability to punch through five layers of leather with such precision is incredible. It could significantly reduce our production costs and improve the quality of our products.”

Another client highlighted the machine’s versatility, noting its potential applications beyond car seat covers. “While our primary focus is on automotive interiors, the versatility of this machine opens up possibilities for us to explore other markets as well,” he said.

The clients were equally impressed by the machine’s user-friendly interface and intuitive controls, which they believed would facilitate a smooth transition for their operators. “The ease of use is remarkable. Our operators will be able to quickly adapt to this machine, minimizing downtime and maximizing productivity,” one of the clients observed.

A Factory Visit Scheduled: Deepening the Partnership

Eager to learn more about our machine and assess its suitability for their next-generation products, the Brazilian clients scheduled a visit to our factory. This visit, they believed, would provide them with a firsthand look at our manufacturing processes, quality control measures, and after-sales support.

Preparing for the Factory Visit

In anticipation of the factory visit, our team meticulously planned every aspect to ensure a seamless and informative experience for our clients. We prepared detailed presentations on the machine’s technical specifications, operational procedures, and maintenance requirements. Additionally, we arranged live demonstrations to showcase the machine’s capabilities in a real-world setting.

Our factory, sprawling over 5,000 square meters, is equipped with state-of-the-art facilities and adheres to stringent quality control standards. We wanted our clients to witness firsthand the dedication and precision that go into every machine we manufacture.

The Factory Tour: A Glimpse into Excellence

During the factory tour, our clients were guided through various departments, including R&D, production, assembly, and quality control. They had the opportunity to interact with our engineers, technicians, and operators, gaining insights into the intricate processes involved in manufacturing our high-speed leather punching machines.

The highlight of the tour was undoubtedly the live demonstration of the 5-layer leather punching machine. Our clients watched in awe as the machine effortlessly punched through multiple layers of leather, producing consistent and precise results. The demonstration reinforced their confidence in the machine’s capabilities and solidified their interest in incorporating it into their production lines.

Assessing Suitability for Next-Generation Products

The Brazilian clients’ primary objective for the factory visit was to assess the suitability of our machine for their next-generation car seat cover products. They aimed to leverage our technology to enhance the quality, durability, and aesthetics of their offerings, thereby gaining a competitive edge in the market.

Collaborative Discussions: Tailoring Solutions

Throughout the visit, we engaged in in-depth discussions with our clients, exploring ways to tailor our machine to their specific requirements. We discussed customization options, such as adjusting punching patterns, optimizing machine settings for different leather types, and integrating additional features to enhance functionality.

Our clients appreciated the collaborative approach, noting that it demonstrated our commitment to customer satisfaction and our willingness to go the extra mile to meet their needs. “The level of customization and support you’re offering is impressive. It gives us confidence that this machine will be a perfect fit for our production requirements,” one of the clients remarked.

Evaluating Long-Term Benefits

In addition to assessing the machine’s immediate suitability, our clients also evaluated its long-term benefits. They recognized that investing in our high-speed leather punching machine would not only improve their current production processes but also position them for future growth and innovation.

The machine’s scalability, coupled with our ongoing support and upgrades, would enable them to adapt to changing market demands and technological advancements. This forward-looking approach resonated with our clients, who viewed our machine as a strategic investment in their company’s future.

Building Trust and Fostering Long-Term Relationships

The success of our interaction with the Brazilian clients at the Shanghai Expo and the subsequent factory visit underscores the importance of building trust and fostering long-term relationships in the business world. By demonstrating our expertise, commitment to quality, and willingness to collaborate, we have laid the foundation for a fruitful partnership with our Brazilian clients.

Client Testimonials: A Seal of Approval

The positive feedback from our Brazilian clients serves as a testament to our machine’s capabilities and our company’s dedication to customer satisfaction. One client stated, “Working with this manufacturer has been a pleasure. Their professionalism, expertise, and commitment to quality are evident in every aspect of their operation. We’re excited about the potential of this partnership.”

Another client highlighted the value of our after-sales support, noting, “The level of support and guidance they’ve provided us, even before we’ve made a purchase, is remarkable. It gives us confidence that they’ll be there for us every step of the way, ensuring the smooth integration and operation of the machine.”

Buy leather punching machine

As we look ahead, we are optimistic about the future of our partnership with the Brazilian clients. We believe that our high-speed leather punching machine, coupled with our unwavering commitment to innovation and customer satisfaction, will enable them to achieve their production goals and elevate the quality of their car seat cover products.

Furthermore, we are excited about the potential for expanding our collaboration beyond car seat covers. The versatility of our machine opens up possibilities for exploring other markets and applications, thereby diversifying our clients’ product offerings and enhancing their competitiveness.

A Testament to Innovation and Collaboration

Our encounter with the Brazilian clients at the Shanghai Expo and the subsequent factory visit serve as a testament to the power of innovation and collaboration in driving business success. By showcasing our cutting-edge technology and engaging in meaningful discussions, we have not only impressed our clients but also laid the groundwork for a mutually beneficial partnership.

As we continue to push the boundaries of leather punching technology, we remain committed to providing our clients with the best possible solutions to meet their evolving needs. Our high-speed leather punching machine, with its remarkable 5-layer leather punching capability, is just the beginning. We look forward to exploring new horizons, fostering long-term relationships, and contributing to the success of our clients in the automotive interior sector and beyond.

In the ever-evolving landscape of automotive manufacturing, innovation and collaboration are the keys to staying ahead. We are proud to be at the forefront of this revolution, driving change, and shaping the future of leather punching technology. Join us on this exciting journey, and together, let’s redefine the possibilities of automotive interiors.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.