about Anze

More than 20 years of

Leather Punch Machine experience

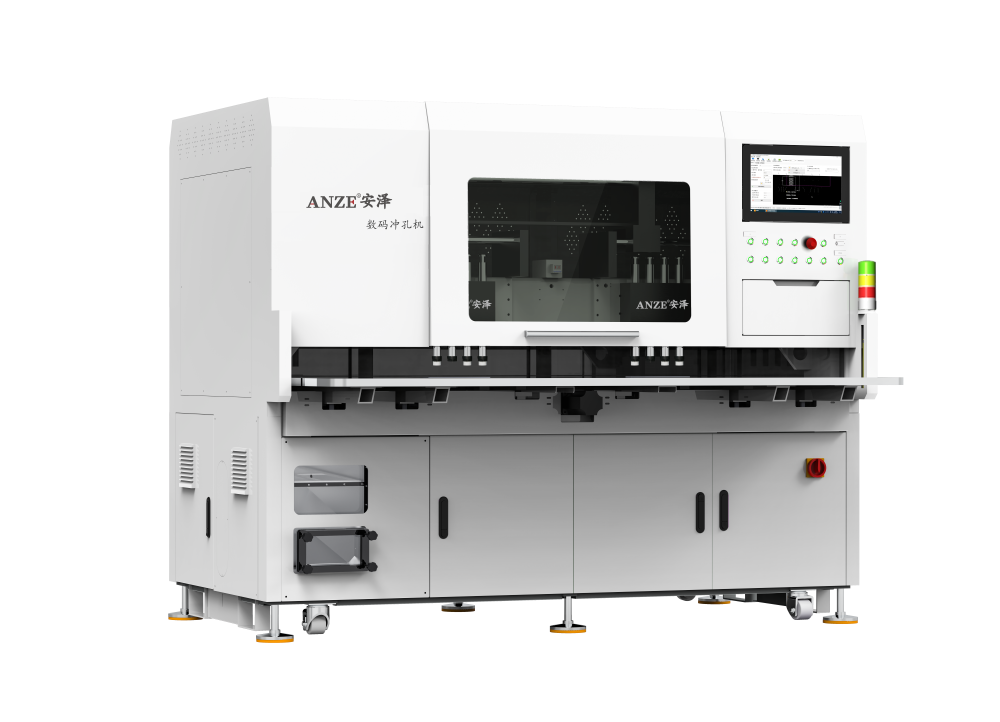

The intelligent flexible leather punch machine provided by Anze Company can improve production efficiency and reduce production costs for seat cover factories, leather factories with the advantages of scalability of mechanical structure, iterative software functions and intelligent punching technology.

At the same time, it can also provide flexible and diverse production equipment options according to customer needs to meet production needs at different stages. Anze Company can provide corresponding punching equipment from proofing, small batch production, mass production and other stages.

CEO: Mr. Xu

Production process standardization

Safety grating technique

The safety grating equipped with the leather punch machine can ensure the personal safety of the operator and improve the safety in the production process.

Low noise punching technology

The noise during the punching process is less than 75 dB, which meets environmental requirements and also provides a better working environment for employees.

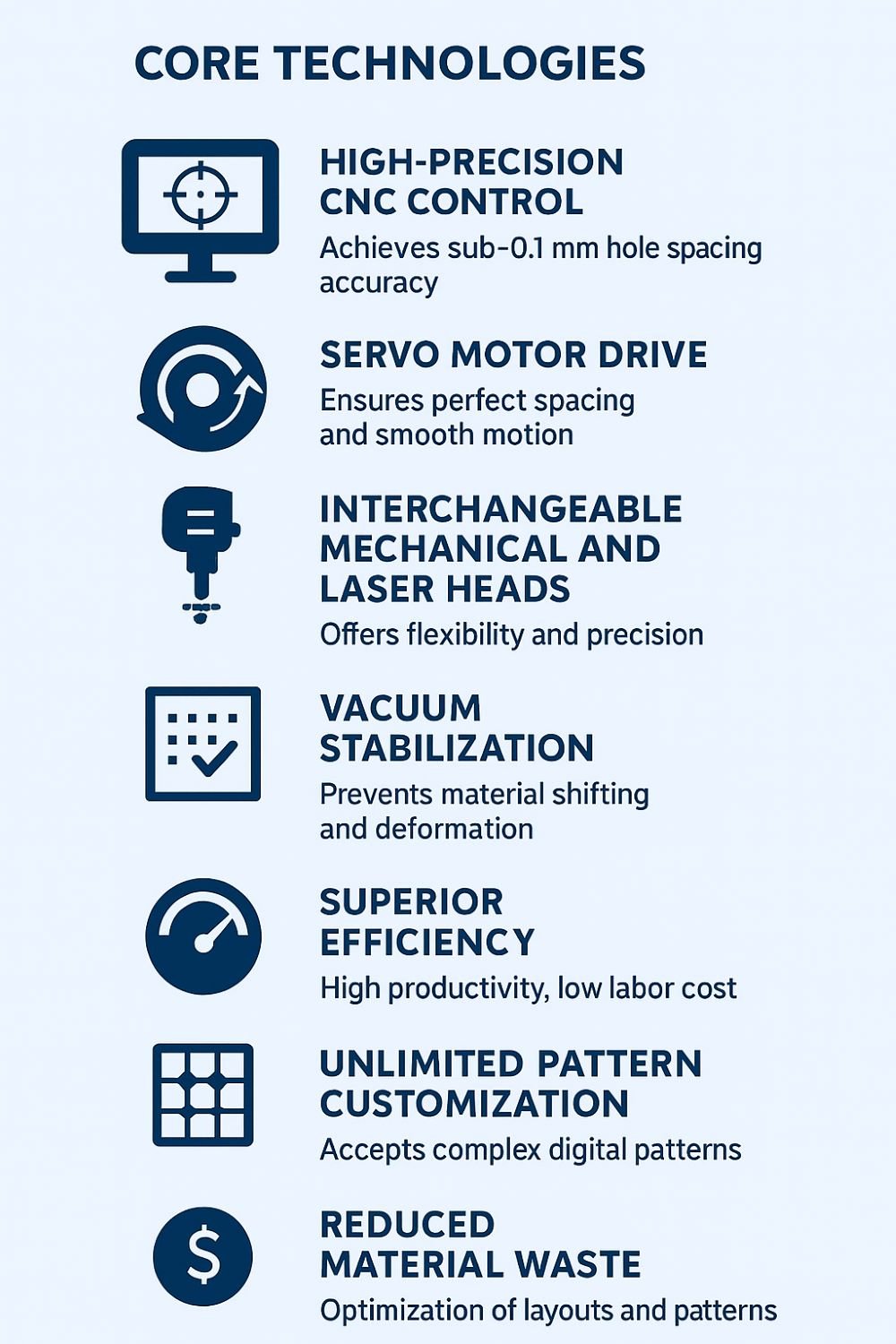

High-end CNC machining technology

The high standard of parts production is ensured, and the precision of punching is further improved.

Intelligent pattern composition

Automatic tool selection technology

Support 1 to 6 different sizes of aperture in the same cut, whether it is a single layer leather or multi-layer composite material can easily cope.

Punching path optimization technology

The self-developed CNC system has the function of optimizing the punching path, reducing the empty stroke of the leather punching machine in the processing process, and improving the processing efficiency.

Automation of punching process

Intelligent conveying technology

The special conveying platform is responsible for the entry and exit of leather materials, which realizes the automation of the conveying process, reduces manual operation, and can effectively prevent industrial accidents.

Automatic height adjustment technology

The automatic height adjustment technology of the punching die greatly extends the service life of the die and reduces the maintenance cost of the die.

Automated waste collection technology

Through the automatic control system and self-developed dust collection system to achieve automatic collection of waste, without stopping the collection of waste, reduce the downtime, that is, improve the efficiency of the machine.

Production scheduling is flexible

Intelligent mode shifting technology

The intelligent die shifting typesetting technology realizes personalized mass customization, meets the diversified needs of customers, and saves the cost of mold manufacturing.

Multi-layer punching technology

It can handle fluffy materials up to 20 mm and solid multi-layer materials up to 6 mm, which broadens the application range of the device and allows punching of all seat cover materials.

Anze develops more technology

Software application digitization

Self-developed software data format conversion technology:

it is compatible with most of the software formats on the market, ensuring that the data is no difference and no deformation in the conversion process, reducing the customer's data conversion cost

Numerical control acceleration computing technology

Anze leather punch machine speed is more than 50% faster than that of similar models, and the production efficiency is significantly improved

The production operation is convenient

Integrated structure technology

Through the integration of structural equipment upgrade and ergonomic design, the operation process is more convenient and smooth, and the work efficiency and comfort of employees are improved.

saving production cost

Steady operation technique

Through excellent structural design, the average time to failure (MTBF) of the product has reached 2000 hours, reducing equipment failures and downtime, thus saving production costs and time.

find the perfect representation in leather punching cases

Get The Lastest News

Leather Punching Machine

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.