Last Updated on 2025-08-28 by Anze

In the dynamic world of automotive manufacturing, precision, efficiency, and innovation stand as the cornerstones of success. As a premier manufacturer specializing in leather perforating machine, we have consistently pushed the boundaries of technology to meet and exceed the evolving demands of the automotive industry. Recently, our dedication to excellence caught the attention of a renowned German car seat manufacturer, leading to a fruitful interaction that underscores the global appeal and superiority of our products.

The Genesis of a Partnership

It all began when a leading German car seat manufacturer stumbled upon our website during their quest for cutting-edge leather perforating solutions. Our specialized leather perforating machine, designed explicitly for automotive seat covers, immediately piqued their interest. What set our offering apart was not just its speed and precision but also the comprehensive demonstration videos we had posted, showcasing the machine’s capabilities in real-world scenarios.

The German client, impressed by the technological prowess displayed on our website, reached out via email to our German market manager. Their inquiry was detailed, focusing on the technical intricacies of our leather perforating machine. We responded promptly, providing in-depth answers that highlighted not only the machine’s specifications but also our commitment to innovation and customer satisfaction.

The Leather Perforating Machine: A Marvel of Engineering

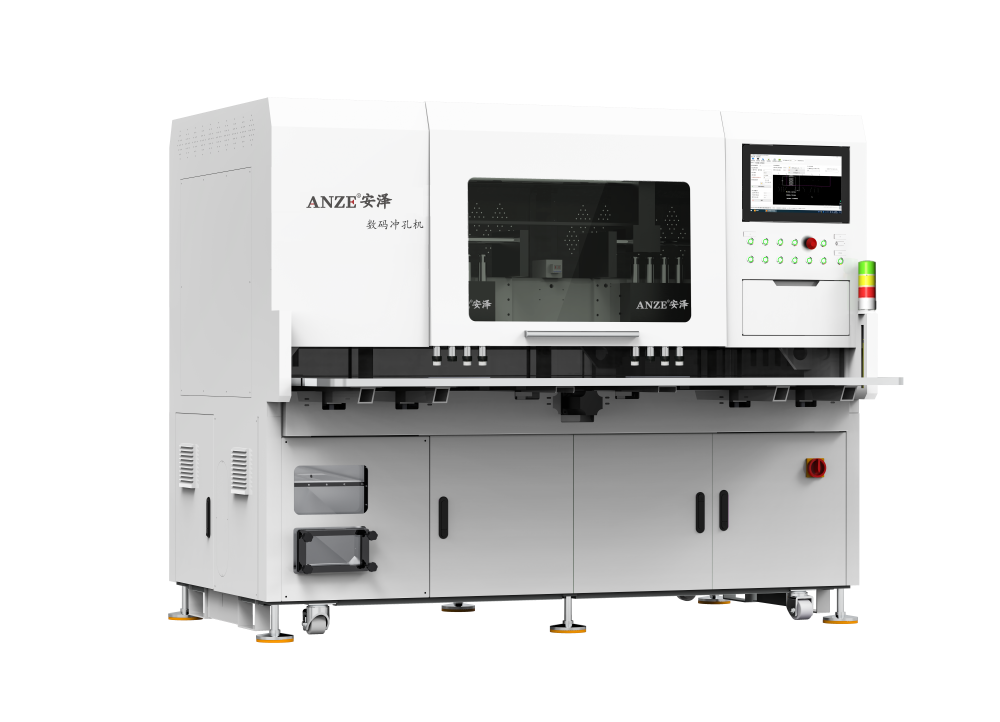

At the heart of our product lineup lies the leather perforating machine, a testament to our engineering excellence and understanding of the automotive interior industry’s unique needs. This machine is not just a tool; it’s a solution crafted to revolutionize the way leather is perforated for car seats, offering unparalleled speed, accuracy, and versatility.

Speed and Efficiency

One of the standout features of our leather perforating machine is its remarkable speed. In an industry where time is money, our machine ensures that production lines keep moving smoothly without compromising on quality. It achieves this through a combination of advanced CNC (Computer Numerical Control) technology and optimized mechanical design, allowing for rapid yet precise perforation of leather materials.

Precision Perforation

Accuracy is non-negotiable when it comes to automotive interiors. Every hole must be perfectly placed to ensure a seamless fit and aesthetic appeal. Our leather perforating machine excels in this regard, employing state-of-the-art sensors and control systems that guarantee hole placement accuracy down to the micrometer. This level of precision not only enhances the final product’s quality but also reduces waste and rework, saving manufacturers significant costs in the long run.

Versatility and Customization

The automotive industry is characterized by its diversity, with each car model requiring unique seat designs and perforation patterns. Recognizing this, we have designed our leather perforating machine to be highly customizable. Whether it’s a complex pattern for a luxury sedan or a simple, functional design for an economy car, our machine can adapt to meet the specific requirements of any project. This versatility is further enhanced by our extensive library of pre-programmed patterns and the ability to create custom designs using our intuitive software interface.

A Global Reach and Trusted Partnerships

Our journey over the past nearly two decades has been marked by a relentless pursuit of excellence and a commitment to building lasting relationships with our clients. With over 600 strategic partnerships with leather product manufacturers worldwide, including exports to 36 countries, we have established ourselves as a trusted name in the industry.

Client Satisfaction and Positive Feedback

The positive feedback from our clients is a testament to our machine’s performance and the quality of our after-sales service. We take pride in the fact that many well-known brands have chosen our leather perforating solutions, relying on us to deliver consistent, high-quality results. Our clients appreciate not just the technological superiority of our machines but also the efficient service and sustainable technology that underpin our projects.

Sustainable Technology for a Greener Future

In today’s environmentally conscious world, sustainability is no longer an option but a necessity. We recognize this and have integrated sustainable practices into our manufacturing processes. Our leather perforating machine is designed to minimize energy consumption and waste generation, contributing to a greener, more sustainable future for the automotive industry.

The Factory Visit: A Testament to leather perforating machine

The German client’s decision to visit our factory was a significant milestone in our burgeoning partnership. It provided them with a firsthand look at our manufacturing facilities, research and development labs, and the people behind our innovative products.

A Warm Welcome and Comprehensive Tour

Upon their arrival, our German market manager extended a warm welcome, setting the tone for a productive and enlightening visit. The tour began with an overview of our company’s history, mission, and values, followed by a detailed presentation on our leather perforating machine’s technical aspects.

Hands-On Demonstration

The highlight of the visit was undoubtedly the hands-on demonstration of our leather perforating machine in action. Watching the machine perform with such speed and precision left a lasting impression on the German delegation. They were particularly impressed by the ease with which the machine could switch between different patterns and the quality of the perforated leather samples produced.

In-Depth Discussions and Future Prospects

The visit also provided an opportunity for in-depth discussions on potential collaborations and future projects. We explored various customization options to cater to the German client’s specific needs and discussed how our machine could be integrated into their existing production lines. The exchange of ideas was fruitful, paving the way for a mutually beneficial partnership.

leather perforating machine Innovations and Expansions

As we look to the future, our focus remains on continuous innovation and expansion. We are constantly researching and developing new technologies to further enhance the performance and capabilities of our leather perforating machine. Our goal is to stay ahead of the curve, anticipating and meeting the evolving needs of the automotive industry.

Expanding Our Product Line

In addition to our existing range of leather perforating machines, we are working on introducing new models that cater to niche markets and specialized applications. These include machines designed for high-volume production, as well as compact, portable units for smaller workshops and prototyping.

Strengthening Global Partnerships

We also recognize the importance of strengthening our global partnerships. By collaborating closely with our clients, we can gain valuable insights into their specific needs and challenges, allowing us to tailor our solutions accordingly. This collaborative approach not only enhances customer satisfaction but also drives innovation and growth.

Embracing Digital Transformation

In the era of digital transformation, we are embracing new technologies to streamline our operations and enhance customer experience. This includes the use of AI and machine learning algorithms to optimize machine performance, as well as the development of a user-friendly digital platform for remote monitoring and support.

The leader of leather perorating machine

The interaction with the German car seat manufacturer is a shining example of our commitment to excellence and innovation in the field of leather perforating machine. Our machine’s speed, precision, and versatility, combined with our unwavering dedication to customer satisfaction, have positioned us as a leader in the industry.

As we continue on our journey, we remain focused on pushing the boundaries of what’s possible, delivering cutting-edge solutions that empower our clients to achieve new heights of success. Whether it’s through continuous innovation, expanding our product line, or strengthening global partnerships, we are committed to shaping the future of automotive seating, one perforation at a time.

In the ever-evolving landscape of automotive manufacturing, our leather perforating machine stands as a beacon of precision, efficiency, and innovation. Join us on this exciting journey as we redefine the standards of excellence in the industry.

Contact May Whatsapp +86 180 0298 0031

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us!

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.