Last Updated on 2025-11-20 by Anze

In recent years, global demand for precision-engineered leather products—including automotive interiors, luxury fashion accessories, footwear, and high-end furniture—has grown rapidly. OEMs and factories must now meet higher standards for aesthetics, ventilation, comfort, acoustic performance, and design customization. As a result, traditional punching machines can no longer satisfy industry needs for consistency, processing speed, pattern flexibility, and material protection.This is where the CNC leather perforation machine becomes an indispensable part of modern leather manufacturing.

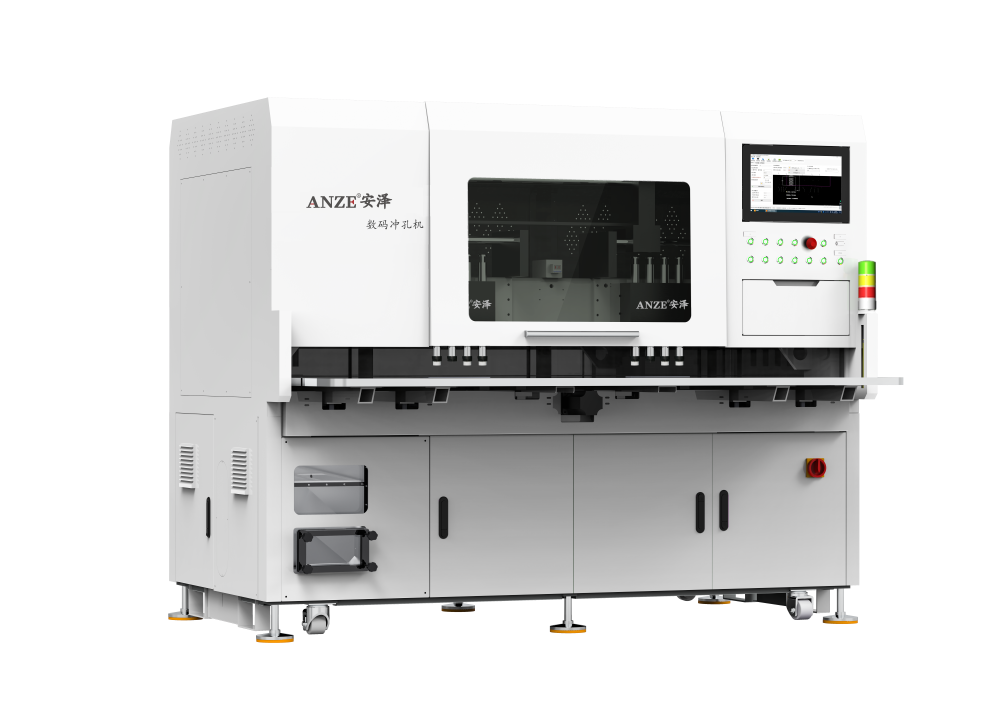

For 20 years, Anze has specialized exclusively in the R&D and manufacturing of leather perforation machinery. With over 20 best-selling machine models used worldwide, Anze’s solutions support industries including automotive seats, door panels, steering wheels, furniture upholstery, footwear, luxury handbags, sports equipment, and acoustic leather applications.

This technical whitepaper examines the core advantages of the modern CNC leather perforation machine, the engineering disciplines behind the technology, and why production facilities increasingly rely on digitalized perforation systems to stay competitive.

This document also addresses:

Machine-level engineering innovations

Perforation process optimization

Material-specific considerations

Industry application scenarios

Quality-control frameworks

Total manufacturing ROI and productivity analysis

1. Understanding the Role of the Leather Perforation Machine in Modern Manufacturing

A leather perforation machine is designed to create controlled hole patterns on natural leather, synthetic leather, microfiber, PU, PVC, or composite materials. These perforations may serve functional or aesthetic purposes:

Functional Purposes

Ventilation (breathability for seats, shoes, or gloves)

Sound absorption (acoustic leather panels)

Weight reduction

Laser-light transparency (smart interior designs)

Aesthetic Purposes

Geometric patterns for handbags

Fashion-driven decorative uniform holes

Signature brand patterns

Industrial buyers expect perforations to be:

Dimensional accurate

Clean-cut

Free of char, distortion, or cracking

Consistent across batches

Precisely aligned

This requires far more than a simple punching mechanism—it requires a full-scale CNC leather perforation machine engineered with:

Servo positioning

CNC pattern programming

High-speed mechanical or laser perforating heads

Vacuum stabilization systems

Multi-axis synchronized movement

Digital tension control

Error compensation algorithms

The combination of these elements enables manufacturers to execute designs previously impossible with manual or semi-automatic equipment.

2. Core Technologies Behind a Modern CNC Leather Perforation Machine

A state-of-the-art leather perforation machine integrates several key engineering and software systems that differentiate it from ordinary punching equipment.

2.1 High-Precision CNC Control Architecture

CNC (Computer Numerical Control) technology allows:

Full digital control of the perforation head

Accurate X-Y positioning

Real-time path planning for complex patterns

Automated compensation for leather stretching

Consistent output regardless of operator skill

Modern CNC controllers execute multi-axis interpolation, meaning the perforation machine can adjust the path dynamically, achieving:

Sub-0.1 mm hole spacing accuracy

Perfect pattern alignment

Smooth transitions between design areas

This transforms the leather perforation machine into a design-driven production system, not merely a punching device.

2.2 Servo Motor Drive Systems

Servo motors provide:

High torque

Instant feedback

Zero-lag positioning

Smooth motion curves

In leather perforation:

Hole spacing accuracy depends heavily on servo stability

Servo drives prevent over-travel and maintain perfect spacing

The machine can operate at extremely high punching speeds without losing alignment

Anze’s leather perforation machines use industrial-grade servo drives, providing:

Higher duty cycle

Longer lifespan

Stable 24/7 operation

2.3 Interchangeable Mechanical and Laser Perforation Heads

Mechanical Perforation Head

Benefits:

Clean mechanical edges

High durability

Ideal for natural leather

No burnt smell or discoloration

Applications: automotive seating, furniture, footwear.

Laser Perforation Head

Benefits:

Ultra-fine micro-holes

Zero tool wear

Suitable for synthetic leather and films

Enables artistic patterns

Applications: luxury bags, design branding, lightweight sports gear.

Hybrid Systems

Some models combine both technologies, enabling:

Mechanical punching for high-volume areas

Laser micro-perforation for design zones

This significantly expands the capability of the leather perforation machine.

2.4 Vacuum Stabilization Platform

A critical engineering requirement:

Leather is a soft, deformable material

Slight movement leads to hole misalignment

Vacuum tables ensure:

Full-surface leather stabilization

Zero slipping, warping, or shifting

Consistent punching across the entire sheet

Premium machines employ zoned vacuum chambers, activating only under the active working area—optimizing energy usage and stability.

2.5 Tooling and Punch Die Systems

An advanced leather perforation machine requires:

Hardened steel dies

Anti-burr punching structures

Multi-diameter die sets

Quick-change tool modules

Die engineering determines:

Edge finish

Tool life

Hole consistency

Anze machines support micron-level die alignment, ensuring flawless hole quality even in delicate Nappa leather.

3. Technical Advantages of CNC Leather Perforation Machines

Below are the engineering-driven reasons manufacturers upgrade from traditional punching equipment to a CNC leather perforation machine.

3.1 Ultra-High Accuracy and Repeatability

CNC and servo control systems achieve:

Hole spacing accuracy within ±0.1 mm

Pattern repeatability >99.9%

Zero misalignment over long production runs

Such precision is critical for:

Automotive OEMs requiring symmetrical seat patterns

Luxury bag brands using signature perforation motifs

Footwear brands needing identical hole distribution

3.2 Superior Production Efficiency

Compared to manual perforation:

| Feature | Manual | CNC Leather Perforation Machine |

|---|---|---|

| Productivity | Low | Extremely high |

| Accuracy | Variable | Precise, repeatable |

| Patterns | Limited | Unlimited CNC files |

| Labor cost | High | Minimal |

| Consistency | Unreliable | Perfect batch alignment |

Modern CNC systems increase production rates by 300–600%, with much lower defect rates.

3.3 Unlimited Pattern Customization

The machine imports DXF, AI, PLT, and custom pattern files, enabling manufacturers to create:

Geometric patterns

Gradient patterns

Laser-signature brand holes

Micro-perforations

EU/US automotive seat standards

Hexagon, diamond, or honeycomb designs

Manufacturers can refresh product styles quickly without new tooling investment.

3.4 Reduced Material Waste

Leather is expensive. Every millimeter saved matters.

The leather perforation machine optimizes:

Nesting layouts

Edge alignment

Path planning

Intelligent compensation for leather stretch

These features reduce waste by 8%–15%, a major cost advantage.

3.5 Enhanced Leather Protection

Advanced machines prevent:

Tearing

Burn marks

Over-punching

Edge deformation

Through controlled punching pressure and optimized laser settings.

This is essential for premium Nappa, full-grain leather, microfiber, and other high-value materials.

3.6 Intelligent Monitoring and Quality Traceability

High-end machines integrate:

Camera alignment systems

Hole quality sensors

Production logging

Batch traceability reporting

Quality control becomes digital, eliminating manual inspection.

4. Material-Specific Engineering Considerations

4.1 Natural Leather

Challenges: uneven thickness, stretching

Solutions: vacuum stabilization, dynamic pressure control

4.2 Synthetic Leather (PU/PVC)

Challenges: melting, burning

Solutions: optimized laser frequency, cooling systems

4.3 Microfiber Leather

Challenges: fiber distortion

Solutions: high-sharpness mechanical dies

4.4 Composite Automotive Leather

Challenges: multi-layer delamination

Solutions: servo-stage punching control

5. Application Scenarios for the Leather Perforation Machine

The CNC leather perforation machine is widely used in:

Automotive Interiors

Seat leather

Door panel leather

Steering wheel leather

Acoustic leather covers

Footwear

Breathable sports shoes

Leather uppers

Fashion footwear patterns

Luxury Bags & Accessories

Brand-specific perforation patterns

Designer micro-perforation

Furniture & Upholstery

Sofas

Lounge chairs

Acoustic panels

Technical Leather

Motorcycle gear

Sports gloves

Military protective leather

This versatility is why the CNC leather perforation machine is a standard tool across numerous industries.

6. Process Optimization Techniques in Leather Perforation

6.1 Punch Pressure Calibration

Different materials require different punch pressure curves.

6.2 Feed Rate Adjustments

Faster → lower quality

Slower → higher precision

CNC systems automate this.

6.3 Multi-Pass Perforation Strategies

Used to prevent leather cracking.

6.4 Pattern Zone Compensation

Edges may distort; CNC algorithms compensate automatically.

6.5 Real-Time Laser Frequency Tuning

For synthetic leather stability.

7. Quality Control Framework for Leather Perforation

Professional production lines use:

Visual hole inspection

Dimensional accuracy testing

Density/spacing validation

Material tensile checks

Burn-mark and edge inspection for laser jobs

Batch traceability reports

CNC equipment simplifies all of these steps.

8. ROI Analysis: Why Manufacturers Upgrade to CNC Perforation

Cost Savings

Less waste

Less labor

Lower defect rate

Revenue Increase

Ability to accept high-value custom work

Expand product design flexibility

Improve product branding

Typical ROI period: 6–12 months

9. Why Choose Anze as Your Leather Perforation Machine Partner

For 20 years, Anze has specialized exclusively in leather perforation technology.

Our Advantages

Over 20 best-selling perforation machine models

Mechanical, laser, and hybrid systems

Servo-driven CNC precision

Long-life steel die systems

Customized pattern development

Global technical support

Experience across all major leather industries

We do not build general machines—we focus only on leather perforation, making us one of the industry’s most specialized manufacturers.

The Future of Leather Manufacturing Is Intelligent Perforation

The CNC leather perforation machine represents the future of leather processing: faster, more accurate, more flexible, and more cost-effective. Brands and factories that adopt advanced perforation systems will enjoy the competitive benefits of:

Stronger product identity

Higher quality control

Faster production lead times

Lower material costs

Expanded design possibilities

For manufacturers in automotive interiors, footwear, luggage, furniture, and high-end fashion, upgrading to a precision-engineered leather perforation machine is not only a technological improvement—it is a strategic business decision.

To learn more, request a sample test, or inquire about customizing a machine for your production line, contact Anze anytime.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.