Last Updated on 2025-10-20 by Anze

In the age of precision engineering, the CNC perforation machine has become a cornerstone technology for manufacturers seeking accuracy, efficiency, and customization. These machines integrate computer numerical control (CNC) with specialized perforation systems to create patterns of holes or cuts on various materials — from metal and plastic to leather, fabric, and composites.

Whether used in automotive interiors, footwear production, luxury leather goods, or furniture manufacturing, the CNC perforation machine provides unmatched control over pattern design and production quality. The result is a perfect balance between speed, accuracy, and aesthetic appeal.

As industries demand more flexibility and sustainability, the CNC perforation machine stands as an essential innovation for modern manufacturing lines.

1. How a CNC Perforation Machine Works: Technical Overview

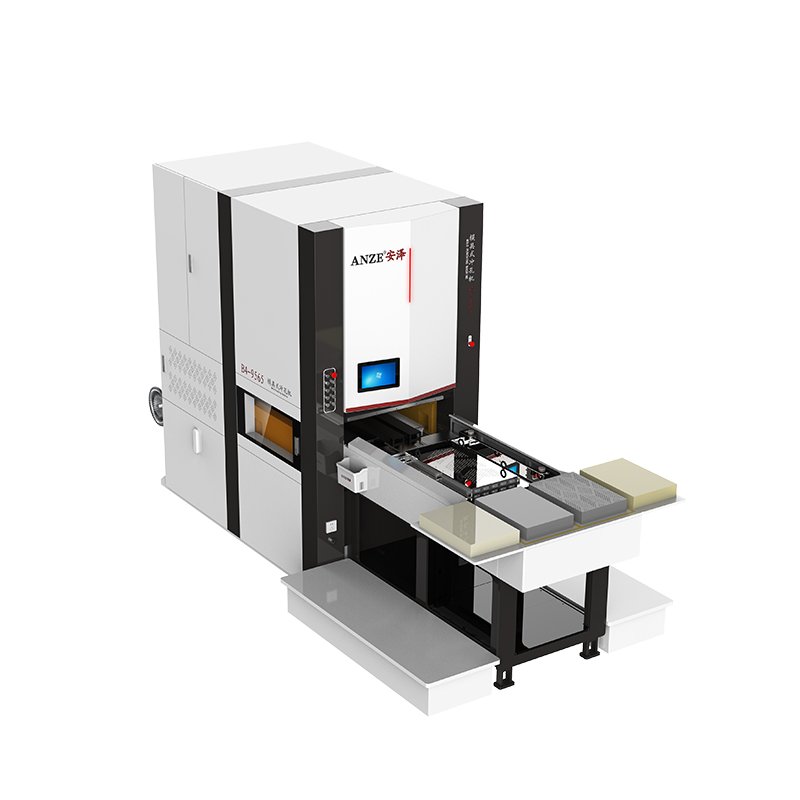

A CNC perforation machine operates by combining mechanical perforation tools with digitally controlled motion systems. The entire process is programmed through a CNC interface, allowing precise control of perforation patterns, spacing, and depth.

Core Components

Control System: The “brain” of the machine, responsible for executing programmed instructions with micron-level precision.

Perforation Head or Tool: Equipped with high-speed punches, laser heads, or rotary dies for different material types.

Material Feed System: Automatically positions and secures materials for continuous processing.

Servo Motors and Drive Units: Enable accurate, repeatable movement in multiple axes.

Software Interface: Allows operators to design custom patterns and import CAD/CAM files directly.

Working Process

The operator inputs a digital pattern via CAD software.

The CNC system translates the design into a toolpath.

The perforation head punches or cuts holes according to the programmed pattern.

Sensors and feedback systems ensure consistency and adjust for material variations.

This level of automation eliminates human error and enables mass customization, which is increasingly valuable in markets such as leather goods manufacturing.

2. CNC Perforation Machine Applications in Modern Manufacturing

The versatility of the CNC perforation machine allows it to serve multiple sectors, from industrial to artisanal. Its ability to perform precise, repeatable perforations gives manufacturers the freedom to innovate while maintaining efficiency.

Automotive Industry

In car interiors, especially leather seat covers, precision perforation ensures both functionality and aesthetics. Perforations enhance breathability, acoustic properties, and visual design.

Footwear and Leather Goods

High-end brands rely on CNC perforation machines to produce intricate patterns on shoes, handbags, and accessories. Anze’s machines, for example, are widely adopted for leather punching in these industries due to their reliability and speed.

Furniture Manufacturing

Perforated leather and fabric are trending in modern furniture design. The CNC process guarantees even hole spacing and smooth edges, crucial for premium upholstery.

Industrial Applications

Beyond leather, CNC perforation systems are also used for metal sheets, filters, and aerospace components, where structural integrity and airflow control are critical.

3. Global Market Overview of CNC Perforation Machines

The global CNC perforation machine market has experienced consistent growth due to rising automation and design customization demands. Between 2023 and 2030, analysts project a compound annual growth rate (CAGR) exceeding 6%.

Key drivers include:

Expansion of automotive interior manufacturing in Asia.

Growth in sustainable leather processing and eco-friendly materials.

Rising demand for energy-efficient CNC systems.

Integration of AI and IoT technologies in CNC machinery.

As production shifts toward Southeast Asia, companies like Anze have gained prominence by delivering customized CNC perforation machines optimized for leather and soft materials — a niche often underserved by larger industrial machine producers.

4. Leading CNC Perforation Machine Manufacturers Worldwide

The CNC perforation machine industry includes a mix of global giants and specialized manufacturers. Below are some of the most recognized companies shaping this field.

Trumpf (Germany)

A global leader in laser technology and metal fabrication, Trumpf offers advanced CNC systems designed for sheet metal perforation and high-speed precision applications.

Amada (Japan)

Renowned for its innovation in punching and forming technologies, Amada integrates CNC automation with flexible tooling systems to deliver superior perforation performance.

Bystronic (Switzerland)

Bystronic focuses on automation, smart manufacturing, and digital integration, with CNC solutions that cater to the metal processing and high-tech fabrication industries.

Prima Power (Italy/Finland)

Known for eco-friendly and highly automated production systems, Prima Power delivers multifunctional CNC perforation machines combining punching, shearing, and laser cutting capabilities.

Finn-Power (Finland)

Now part of the Prima Power Group, Finn-Power pioneered servo-electric punching and automation systems, emphasizing precision and energy efficiency.

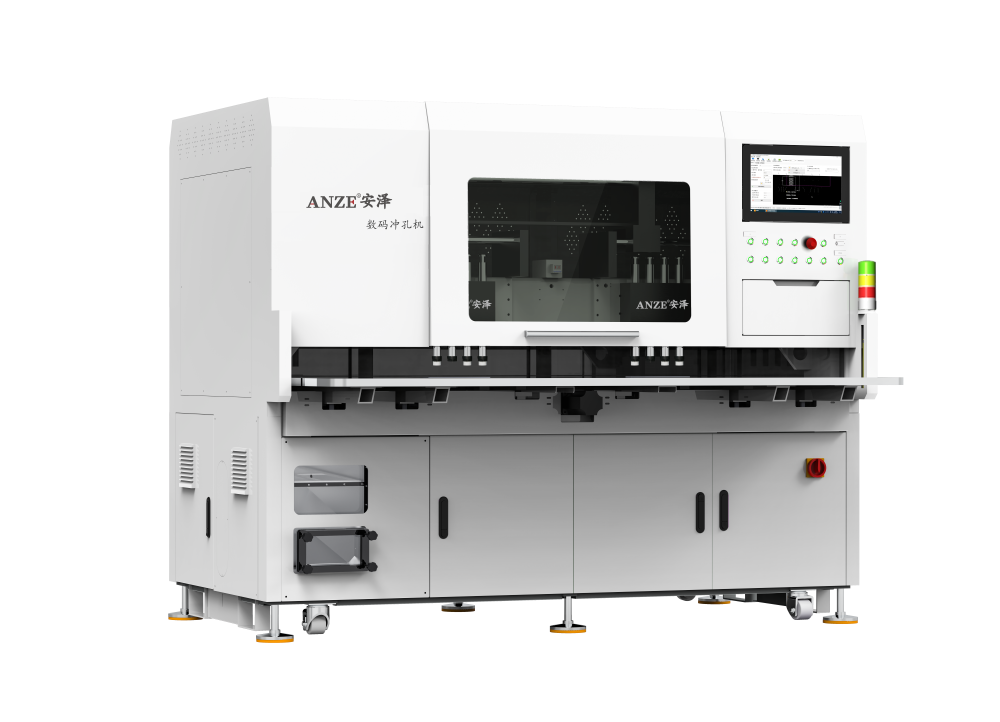

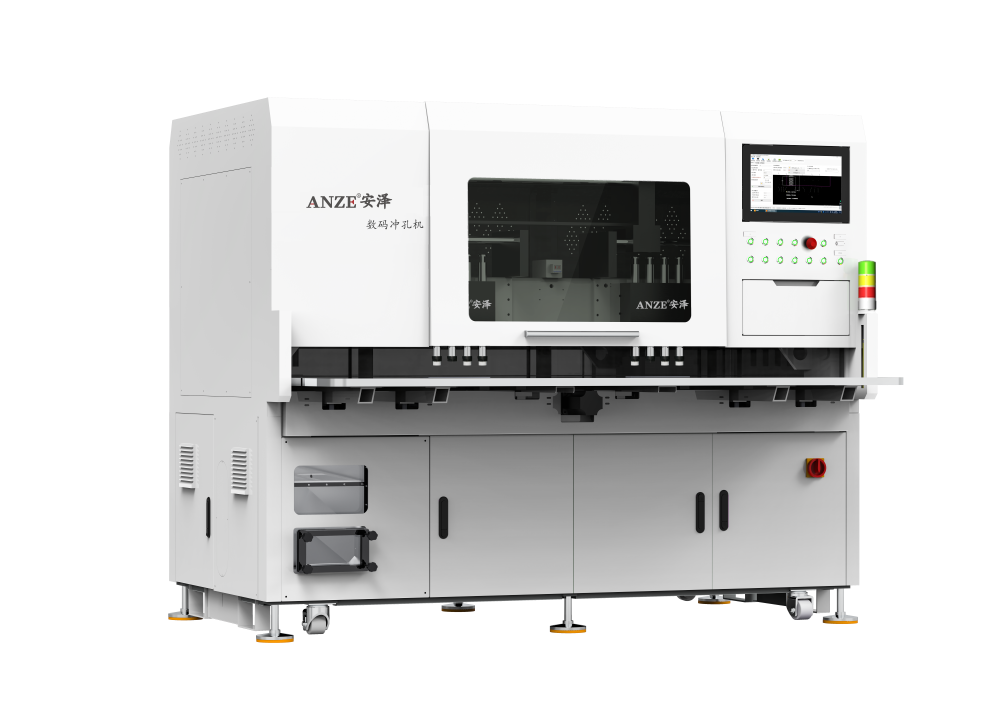

Anze (China) — 20 Years of Expertise in Leather CNC Perforation Machines

Founded over 20 years ago, Anze specializes in the design and manufacture of CNC perforation machines for leather applications. With more than twenty bestselling models, Anze machines are used worldwide for automotive seat leather, footwear, luggage, and furniture.

Unlike general-purpose CNC machines, Anze’s solutions are engineered specifically for soft material processing, offering superior pattern accuracy and edge quality. Anze combines robust engineering with user-friendly interfaces, making their machines ideal for both mass production and custom design applications.

5. Why Anze’s CNC Perforation Machines Lead in Precision Leather Processing

Anze’s core strength lies in its focus and specialization. While other manufacturers target metal and composite materials, Anze’s CNC perforation machines are uniquely optimized for leather and flexible materials.

Key Advantages

Dedicated Leather Algorithms: Software fine-tuned for perforation behavior on natural and synthetic leathers.

Stable Mechanical Design: Ensures uniform hole quality even at high production speeds.

Customizable Tooling Options: Adaptable to diverse leather thicknesses and textures.

Comprehensive After-Sales Support: Global technical service and spare parts availability.

Proven Reliability: Thousands of Anze CNC perforation machines operating in over 30 countries.

By combining tradition with technology, Anze enables manufacturers to achieve higher yield, lower waste, and outstanding pattern fidelity.

6. Technological Innovations in CNC Perforation Machine Design

Modern CNC perforation machines integrate a range of innovations that enhance performance, accuracy, and connectivity.

Automation and Integration

Today’s CNC perforation systems feature automatic material feeding, pattern switching, and tool calibration — reducing downtime and human error.

Digital Pattern Management

Through advanced CAD/CAM integration, users can design, simulate, and modify perforation layouts before production. Anze’s proprietary software supports rapid file conversion and batch management.

Energy Efficiency

Servo-driven systems and smart energy recovery technologies reduce power consumption by up to 30%, aligning with green manufacturing standards.

AI and Predictive Maintenance

AI algorithms now monitor vibration, tool wear, and processing temperature in real-time, predicting maintenance needs before downtime occurs.

7. The Role of CNC Perforation Machines in the Automotive, Footwear, and Furniture Industries

The CNC perforation machine has redefined quality standards in consumer goods manufacturing.

Automotive: Enables breathable leather seats and noise-reducing cabin panels.

Footwear: Ensures symmetry and consistency in decorative perforation.

Furniture: Provides comfort, design flexibility, and enhanced air circulation.

Luxury Goods: Adds intricate, repeatable perforation patterns that elevate product branding.

By automating precision perforation, manufacturers reduce manual labor costs while achieving consistent aesthetic excellence.

8. Sustainability and Efficiency in CNC Perforation Machine Manufacturing

Sustainability is no longer optional — it’s an expectation. CNC perforation machines play a key role in supporting eco-friendly production by:

Reducing Material Waste: Precise perforation ensures minimal scrap.

Optimizing Energy Use: Smart drives and power management systems lower energy consumption.

Supporting Recyclable Materials: Machines are compatible with eco-leathers and synthetic alternatives.

Anze has also introduced environmentally friendly production processes in its own facilities, ensuring a smaller carbon footprint from design to delivery.

9. How to Choose the Right CNC Perforation Machine for Your Business

Selecting the best CNC perforation machine depends on your material, production scale, and customization needs. Consider the following:

Material Compatibility: Choose machines optimized for your primary material (metal, leather, fabric, etc.).

Production Volume: High-speed models suit mass production; compact units fit small workshops.

Precision Requirements: Look for servo systems and digital calibration features.

Software Flexibility: Ensure the system supports CAD/CAM integration and easy design import.

After-Sales Service: A reliable support network ensures long-term performance.

Anze’s technical team provides tailored consultations to match the ideal CNC perforation machine to your production goals.

10. The Future of CNC Perforation Machines: Automation, AI, and Customization

As Industry 4.0 accelerates, the next generation of CNC perforation machines will integrate deeper automation, real-time analytics, and machine learning.

Smart Factories: Connected machines sharing production data for full-process optimization.

Adaptive Perforation: AI-driven systems that automatically adjust patterns based on material characteristics.

Cloud-Based Pattern Libraries: Remote access and sharing of perforation templates across facilities.

Human-Machine Collaboration: Operators focusing on creative design while machines handle repetitive tasks.

Anze is actively investing in these technologies, ensuring that its CNC perforation machines remain at the forefront of intelligent manufacturing.

Anze’s Commitment to Advancing CNC Perforation Machine Technology

For over two decades, Anze has stood as a trusted name in CNC perforation machine manufacturing, combining craftsmanship with advanced automation. With more than twenty proven models and a global customer base, Anze continues to drive innovation in leather perforation technology.

The company’s mission is clear: to provide manufacturers worldwide with high-precision, energy-efficient, and customizable CNC perforation machines that meet the highest standards of quality and design.

As the global market evolves, Anze remains committed to pioneering the next era of intelligent perforation technology — where precision meets creativity, and automation meets artistry.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.