Last Updated on 2025-11-27 by Anze

The U.S. automotive interior market is one of the most advanced and competitive in the world. From high-end sedans to luxury SUVs and performance vehicles, American consumers increasingly expect premium seating materials—especially ventilated leather seats. Ventilation requires extremely precise perforation, and manufacturers need a reliable leather perforating machine capable of producing accurate, uniform, and visually flawless hole patterns at high speed.

As demand continues to grow, American automotive seat suppliers are turning to advanced global equipment manufacturers to support their production needs. This is where Anze, a professional leather perforation equipment company with 20 years of experience, enters the picture.

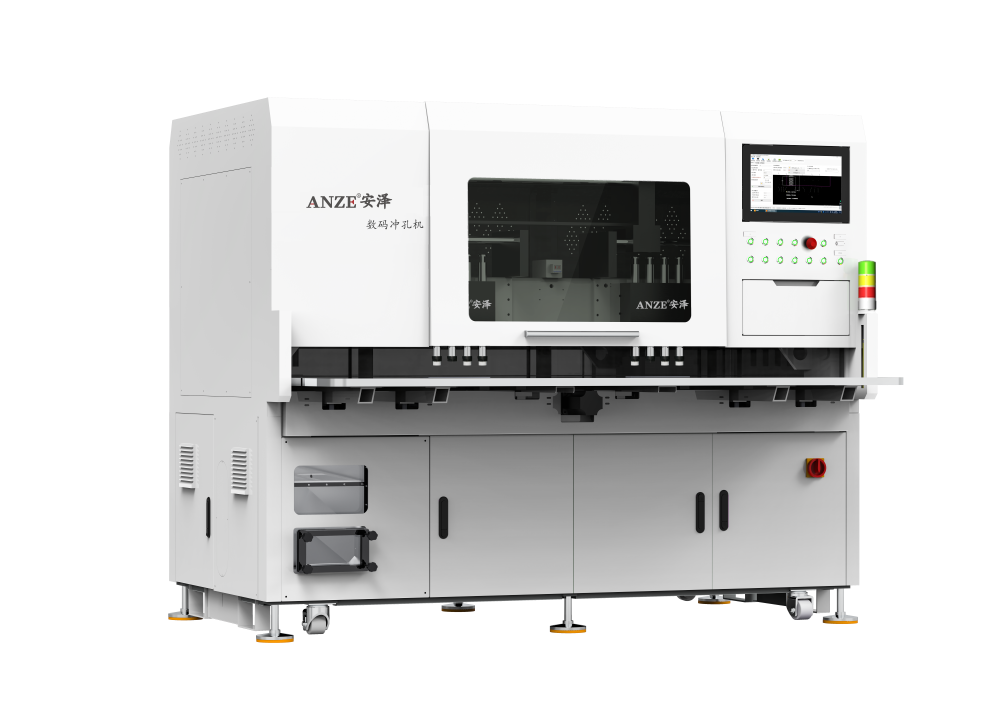

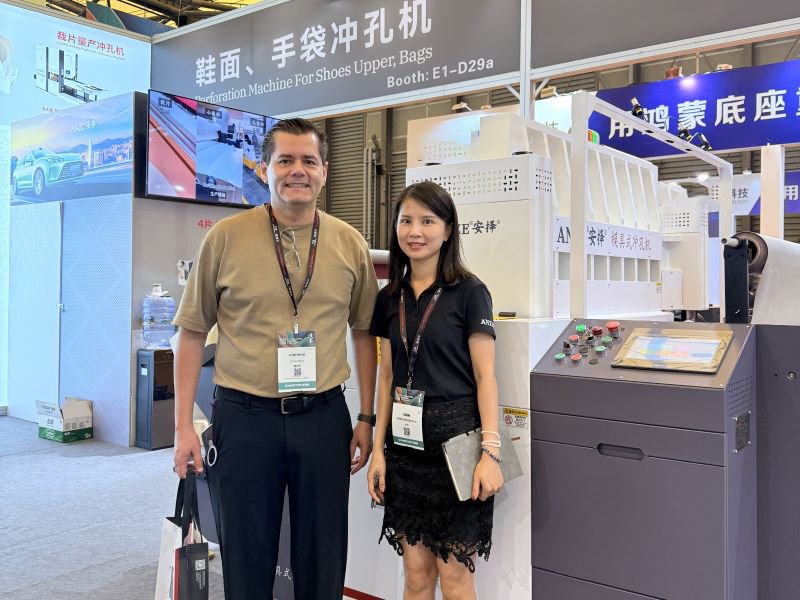

Recently, a well-established U.S. automotive seat manufacturer discovered our technology through our YouTube demonstration videos. After seeing the performance of our specialized leather perforating machine for car seat covers, they contacted our U.S. regional manager by email—leading to a highly successful technical communication, factory visit, and confirmed order for our newest high-speed model.

This blog shares the complete story, explores why the customer chose Anze, and explains why our leather perforating machine is becoming the preferred choice for automotive seating factories across the United States.

1. How the Customer Found Us: YouTube Demonstrations That Showcase Real Performance

In the digital age, customers no longer rely only on trade shows or catalogs. They want real operation videos, high-quality demonstrations, and authentic machine performance they can evaluate remotely.

Over the past years, our team has continuously published operational videos of our leather perforating machine on YouTube, including:

Automotive seat leather perforation

Ventilated seat cover perforation

High-speed continuous perforation demonstrations

Precision hole alignment tests

Multi-pattern and custom pattern demonstrations

Leather edge integrity tests

The American customer was impressed by several aspects:

1.1 High perforation speed

They noticed how our leather perforating machine was able to run smooth, continuous perforation with stable motion control. Many machines on the market slow down when processing thick automotive leather, but Anze machines maintain consistent speed.

1.2 Precise hole spacing and alignment

Ventilated automotive seats require hole spacing accuracy often within ±0.1 mm. Our videos demonstrated:

consistent hole alignment

uniform pattern density

no material drifting

stable servo-driven control

1.3 Clean perforation without burning or tearing

Some perforation solutions—especially laser-only systems—can cause:

burnt edges

melted leather backing

discoloration

fuzzy or irregular edges

Our mechanical perforation technology produces a clean, sharp, premium finish ideal for visible automotive interiors.

These video results convinced the customer that Anze’s leather perforating machine had the reliability and precision required for U.S. automotive standards.

2. First Contact: Technical Consultation With Our U.S. Market Manager

After studying our online content, the customer reached out through email. Their initial questions were highly technical, indicating they were already experienced with perforation processes:

How does your machine maintain hole spacing accuracy?

Can your leather perforating machine handle soft Napa leather and thick coated leather?

What tooling options are available for different hole diameters?

How is material feeding stabilized?

What is the maximum perforation area?

Can the machine integrate with their internal pattern design software?

What is the typical maintenance schedule?

What is your track record in the U.S. market?

Our U.S. market manager provided detailed answers, including:

CAD integration workflow

Servo motor control structure

Vacuum table stabilization

Punch die durability and replacement cycles

Machine energy consumption

Real processing time per square meter

After-sales support in the United States

The customer quickly recognized our professional engineering background and long experience in developing leather perforation equipment.

They expressed satisfaction with the clarity, precision, and professionalism of our communication—leading them to request a factory visit immediately.

3. Factory Visit: Demonstrating the Power of a True Leather Perforating Machine Manufacturer

When the U.S. automotive manufacturer arrived at our factory, they were able to witness:

3.1 Full-scale production demonstration

We ran live perforation tests using:

automotive-grade coated leather

synthetic leather

perforated ventilation patterns

micro-hole patterns

decorative geometric patterns

The customer observed the speed, accuracy, and material stability firsthand.

3.2 Machine structure, components, and quality control

Our engineers gave detailed explanations of:

CNC motion architecture

servo motor drive system

imported bearings and guide rails

precision punching dies

vacuum suction table

waste removal system

long-run temperature stability

noise control engineering

Seeing the inside of the machine reinforced their confidence in our engineering capability.

3.3 Customization options for automotive seat manufacturers

We introduced various options:

custom punching die sets

custom leather feeding methods

custom working table dimensions

enhanced ventilation patterns

multi-zone perforation

branding patterns or stitching line calibration

integration into seat-cover production lines

The customer confirmed that our customization capability exceeded their expectation.

3.4 Reviewing machines already shipped to American clients

We showed examples of machines recently built for other U.S. manufacturers and explained:

typical production capacity

long-term durability

case studies from existing clients

maintenance records

improvements made based on U.S. user feedback

This demonstrated our extensive presence and experience in the U.S. automotive interiors market.

4. Why the Customer Chose Anze: Key Advantages of Our Leather Perforating Machine

After a full-day inspection, the American customer confirmed that our leather perforating machine was superior in several important areas.

4.1 Precision Beyond Industry Standards

Our machine achieves:

±0.1 mm hole spacing accuracy

extremely stable punching force

excellent edge sharpness

no drift during long perforation paths

This is critical for ventilated automotive seats, luxury interiors, and high-end leather products.

4.2 Faster Output, Higher Productivity

Thanks to our optimized CNC system and servo drive:

perforation speed is significantly higher

feeding and punching movements are synchronized

entire seat-cover panels can be processed rapidly

The customer noted that our productivity was 30–50% higher than other systems they had tested.

4.3 Specialized for Automotive Leather

Unlike general-purpose perforators, our machines are designed for:

ventilated seating

seating side panels

decorative interior leather

headrest leather

center console leather

The versatility of our leather perforating machine allows factories to run multiple product lines using one system.

4.4 Long-Term Durability for Heavy Production Volumes

Automotive factories run machines:

10–16 hours/day

6–7 days/week

Our heavy-duty build ensures long-term stability under high workload.

4.5 Excellent U.S. Market Support

The customer appreciated that:

we have shipped many machines to the U.S.

we offer remote engineering support

consumable parts are readily available

our after-sales response is fast

This reduced their operational risk and increased purchasing confidence.

5. The Final Decision: Immediate Purchase of Our Latest Leather Perforating Machine Model

On the same day as their factory visit, the customer confirmed the purchase of our newest high-speed leather perforating machine designed specifically for automotive seat covers.

They commended:

our engineering expertise

the high-quality machine demonstration

fast and clear technical communication

our 20 years of experience in leather perforation

the professionalism of our international support team

This order also marks another expansion of our presence in the U.S. automotive interior industry.

6. Why More U.S. Manufacturers Are Choosing Anze Leather Perforating Machines

The U.S. market values:

high accuracy

fast production

consistent quality

reliable service

advanced industrial engineering

Anze excels in all of these categories.

Our leather perforating machine line continues to grow in popularity among:

automotive seat manufacturers

interior component suppliers

luxury leather goods manufacturers

seating foam & leather integrators

aviation interior suppliers

marine upholstery producers

With increasing demand for ventilated leather seats in the U.S., more factories are upgrading their perforation capabilities—and Anze is becoming the preferred partner.

7. The Future: Smarter, Faster, and More Automated Leather Perforation

We continue to innovate by developing:

AI-optimized punching paths

CNC pattern generation

ultra-high-speed multi-head perforation

improved noise reduction

intelligent leather detection systems

advanced servo precision technology

Our next generation of leather perforating machine models will provide:

20% higher throughput

improved energy efficiency

full digital production line integration

This ensures that our customers stay ahead in a rapidly evolving global automotive interior market.

A Success Story That Represents the Future of U.S.–China Manufacturing Cooperation

This collaboration with the American automotive seat manufacturer demonstrates the growing global recognition of Anze’s technological strength. By providing high-precision, durable, and high-speed leather perforating machines, we support U.S. manufacturers in meeting rising consumer demand for premium ventilated leather seating.

Our commitment remains unchanged:

20 years of professional experience

over 20 best-selling machine models

thousands of successful installations worldwide

complete solutions for automotive leather perforation

As more U.S. companies search for reliable, high-performance perforation solutions, Anze will continue to lead the industry with engineering excellence and innovative technology.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.