Last Updated on 2025-11-13 by Anze

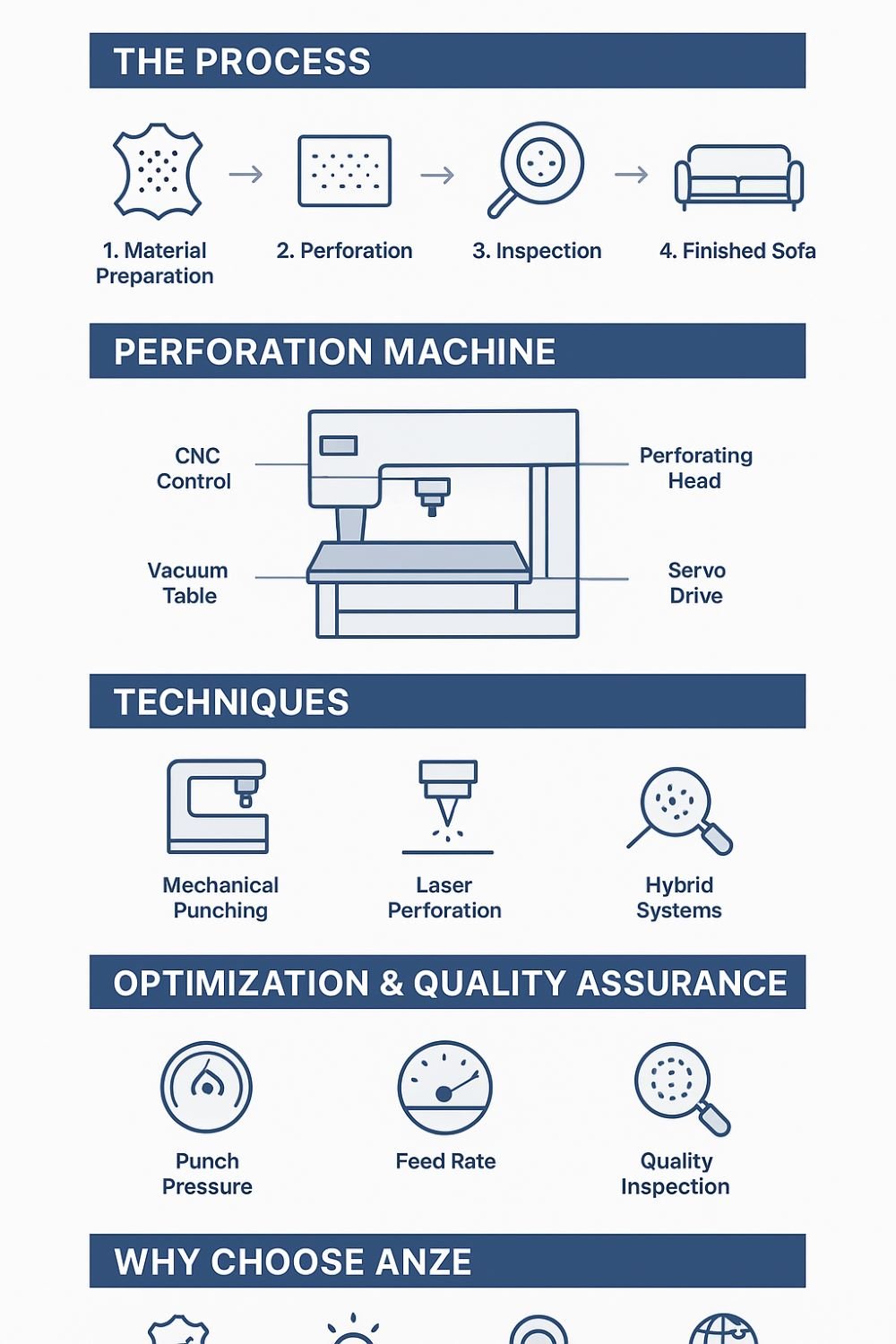

1. The Art and Engineering Behind Sofa Leather Perforation

In modern sofa design, leather perforation is not merely a decorative process—it’s an essential engineering step that enhances comfort, breathability, and style. The tactile appeal and ventilation performance of a sofa depend heavily on how precisely each perforation is made.At Anze, a professional sofa leather perforation machine manufacturer with over 20 years of experience, we’ve developed over 20 high-performance models designed specifically for leather perforation in furniture manufacturing. Our machines are used globally by upholstery and sofa makers to achieve superior craftsmanship through automated precision.

This whitepaper explores how sofa leather perforation machines work, technical considerations, key process parameters, and best practices for producing consistent, high-quality results.

2. Understanding Leather Perforation machine in Sofa Manufacturing

Leather perforation involves creating precise holes in upholstery material—typically genuine leather or synthetic substitutes—to improve airflow, reduce stiffness, and enhance aesthetic appeal.

2.1 Functional Benefits

Ventilation – Reduces heat buildup, improving user comfort.

Weight Reduction – Especially useful for modular sofa systems.

Acoustic Improvement – Enhances sound absorption for cinema seating or luxury interiors.

Aesthetic Enhancement – Enables patterned designs and branding.

2.2 Common Sofa Perforation Patterns

Uniform Micro-Perforation – Small, evenly distributed holes.

Decorative Geometric Patterns – Circles, diamonds, or waves.

Custom Logo Perforation – Branding for high-end furniture lines.

3. Overview of the Sofa Leather Perforation Machine

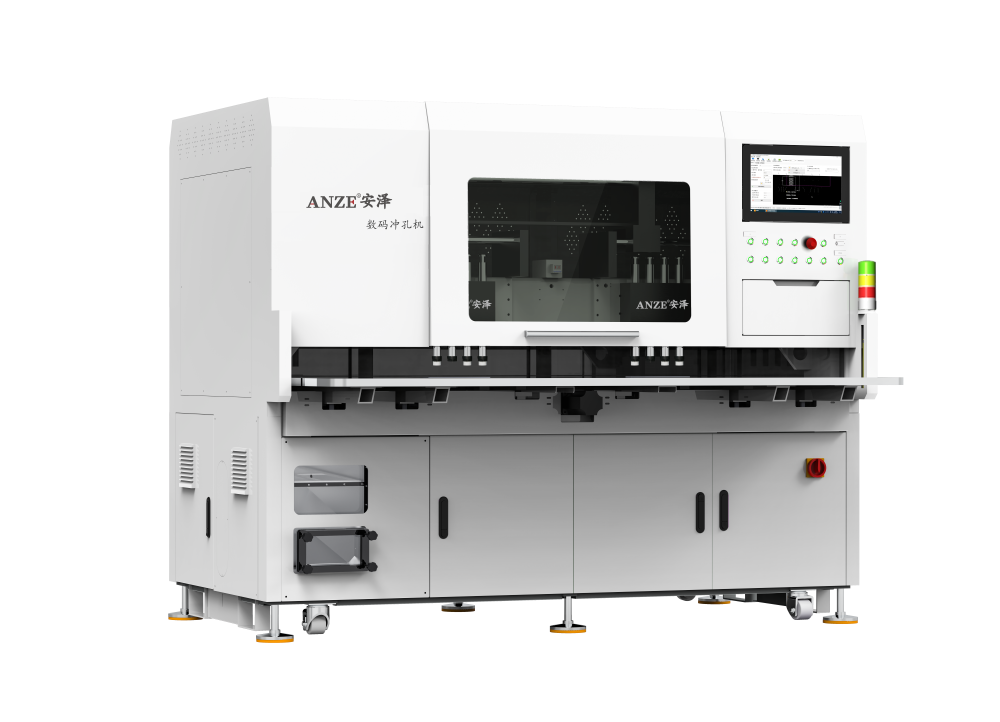

A sofa leather perforation machine is a specialized CNC-controlled system designed for soft material punching. Anze’s latest models integrate servo precision drive systems, vacuum hold-down beds, and programmable perforation templates.

3.1 Core Components

CNC Control System – For automatic pattern design and positioning.

Servo Motor Drive – Ensures repeatable punching accuracy.

Perforating Head – Equipped with replaceable dies and punches for various diameters.

Vacuum Table – Prevents material movement during high-speed punching.

Safety System – Infrared or laser-based protection to ensure operator safety.

3.2 Technical Specifications (Typical Anze Model)

| Parameter | Specification |

|---|---|

| Max Working Area | 1600 mm × 800 mm |

| Perforation Speed | 200–600 holes/sec |

| Hole Diameter | 0.8 – 3.0 mm |

| Drive System | Dual Servo Motor |

| Control Accuracy | ±0.05 mm |

| Supported Materials | Natural leather, PU, PVC, microfiber |

| Air Pressure | 0.5–0.8 MPa |

4. Perforation Techniques for Sofa Leather

4.1 Mechanical Punching

This is the most common method. Using mechanical punches and dies, holes are created at high speed. Suitable for thicker or natural leathers.

Advantages:

High precision

Uniform hole size

Long tooling life

Applications: Automotive and high-end sofas requiring large-area perforations.

4.2 Laser Perforation

Laser-based perforating machines use focused beams to melt and vaporize holes. This is ideal for thin synthetic leathers and custom decorative designs.

Advantages:

No physical tool wear

High flexibility for complex patterns

Clean edges and minimal deformation

Limitations: Not suitable for genuine leather due to heat sensitivity.

4.3 Hybrid Systems

Some advanced sofa leather perforation machine integrate both mechanical and laser systems, giving manufacturers flexibility depending on the material type.

5. Process Optimization Techniques

Achieving the perfect sofa leather perforation requires fine-tuning machine settings and environmental factors.

5.1 Key Parameters to Monitor

| Parameter | Impact | Recommended Value |

|---|---|---|

| Punch Pressure | Determines hole clarity | 0.5–0.8 MPa |

| Feed Rate | Affects spacing uniformity | 200–500 mm/s |

| Tool Temperature | Prevents leather burn | < 60°C |

| Die Clearance | Impacts edge smoothness | 0.1–0.2 mm |

5.2 Material Preparation Tips

Use flat, moisture-balanced leather to avoid warping.

Apply temporary adhesive backing film for stability.

Conduct pre-test perforation on sample strips.

6. Common Challenges and Technical Solutions

| Challenge | Cause | Solution |

|---|---|---|

| Uneven Holes | Inconsistent feed rate | Recalibrate servo motor |

| Leather Burn Marks | Overheating | Optimize air cooling or reduce laser power |

| Tool Wear | Hard leather | Replace dies regularly |

| Misalignment | Improper clamping | Use vacuum bed or magnetic fixture |

Anze’s smart CNC control system automatically compensates for minor misalignments, ensuring each hole is placed with perfect precision.

7. Advanced Features in Modern Sofa Leather Perforation Machine

7.1 Digital Pattern Design

Operators can upload CAD files directly to the control software, generating complex layouts automatically.

7.2 Vision Alignment System

Integrated cameras detect material boundaries and align perforation grids accordingly.

7.3 Smart Data Feedback

Real-time sensors provide operational data such as punch count, wear level, and pressure metrics.

7.4 Multi-Zone Vacuum System

Prevents slippage even on oversized leather sheets, enhancing productivity.

8. Quality Inspection and Testing

8.1 Visual Inspection

Use magnification tools to check for burrs or burn marks.

8.2 Dimensional Accuracy

Measure hole diameter and spacing using optical measuring systems.

8.3 Air Permeability Test

Ensures that perforation meets comfort and airflow requirements.

9. Case Study: Anze’s Sofa Leather Perforation Success Story

A premium furniture manufacturer in Italy faced issues with inconsistent hole patterns on natural leather. After installing Anze’s Model AZ-P1600 sofa leather perforation machine, their production efficiency increased by 42% and rejection rate dropped by 35%.

“Anze’s precision system helped us achieve uniform perforation even on thick leather upholstery. It’s a true game-changer for our luxury sofa line.”

— Production Manager, Italian Furniture OEM

10. Safety and Maintenance Tips

Always clean the punch dies after each batch.

Check air pressure levels weekly.

Calibrate servo systems monthly.

Use Anze’s original spare parts for long-term performance.

Preventive maintenance extends machine life by 25–30%.

11. Future Trends: Smart Automation and Eco-Leather Perforation

The next generation of sofa leather perforation machine will feature:

AI-driven defect detection

Automatic pattern switching

Energy-efficient pneumatic systems

Compatibility with vegan and recycled leather

Anze is actively integrating these innovations into its upcoming Smart Perforation Series.

12. Why Choose Anze leather perforation machine

With over two decades of continuous innovation, Anze stands as a leading sofa leather perforation machine manufacturer, offering complete solutions—from mechanical systems to fully automated CNC models.

Our Advantages:

20 years of R&D excellence

Over 20 machine models serving global markets

Custom perforation solutions for sofas, automotive, and fashion

Comprehensive after-sales support and training

Anze – Precision in Every Perforation.

Leather perforation machine in furniture is both an art and a science

Leather perforation in furniture is both an art and a science. The right sofa leather perforation machine can transform plain upholstery into breathable, elegant, and durable furniture. With Anze’s high-precision CNC systems, manufacturers can achieve unmatched consistency, speed, and design flexibility.

Whether you are producing modern minimalist sofas or luxurious leather recliners, Anze’s perforation technology ensures superior comfort and craftsmanship.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.