Last Updated on 2025-11-07 by Anze

1. The Precision Art of Leather Perforation in Footwear

Leather perforation has long been a vital process in the footwear industry, merging aesthetic appeal with functional performance. From breathable sports sneakers to luxury dress shoes, the art of creating precise holes in leather directly impacts comfort, flexibility, and visual identity.

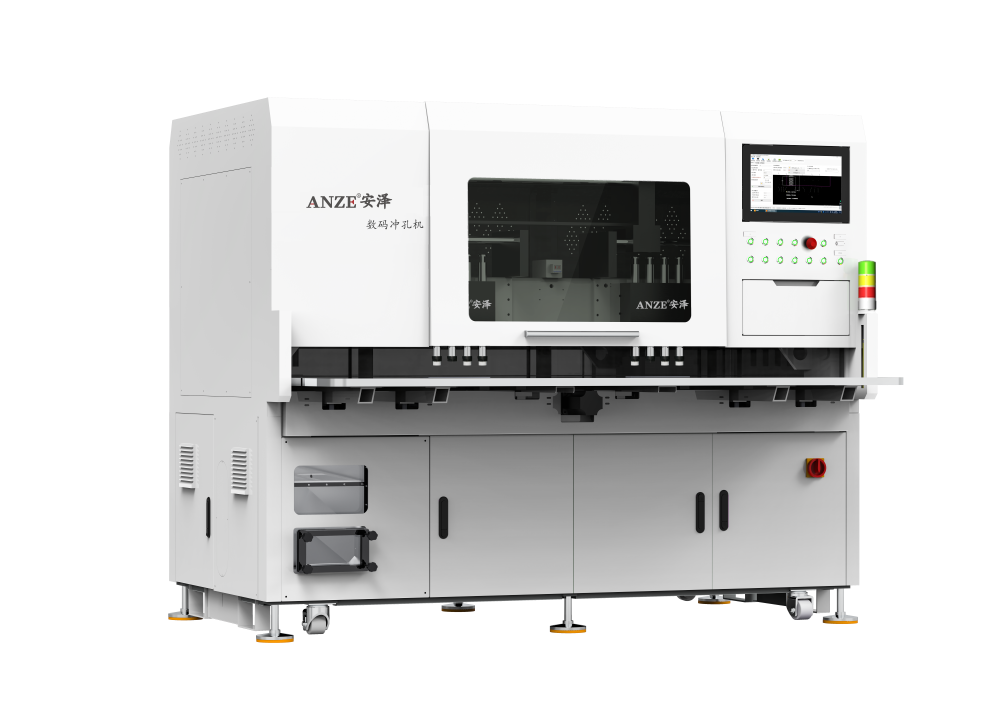

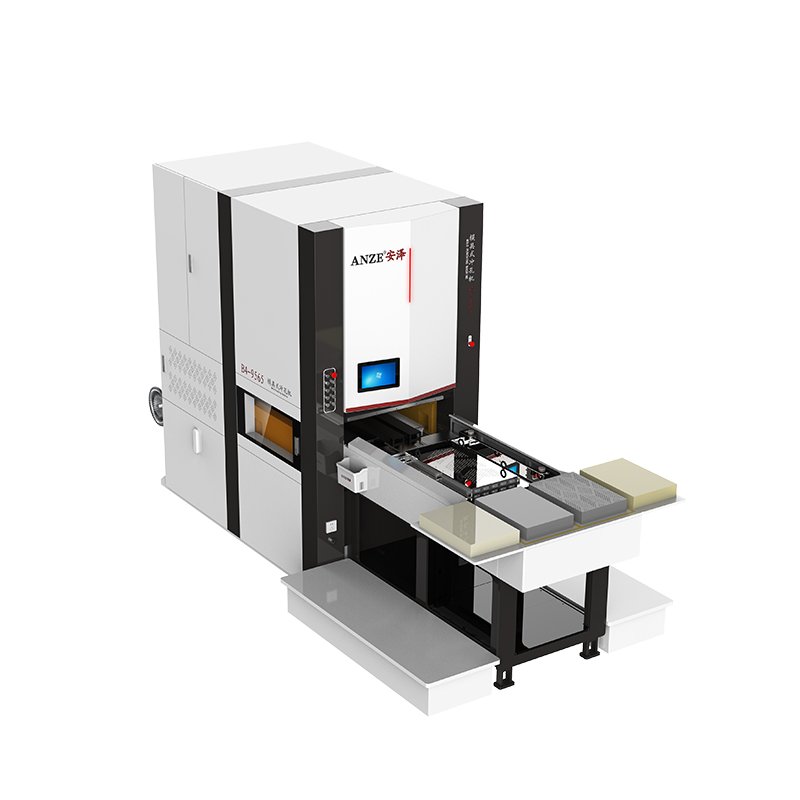

At the heart of this process lies the shoes leather perforation machine — an advanced piece of equipment engineered to ensure accuracy, repeatability, and high throughput. It combines precision mechanics with CNC and servo control systems to achieve uniform perforation patterns across various types of leather — from soft cowhide to synthetic polyurethane.

Anze, a professional leather perforating machine manufacturer with over 20 years of experience, has developed more than 20 bestselling machine models. Our systems are widely used in industries including automotive interiors, furniture, and especially footwear manufacturing, providing custom perforation solutions for shoe uppers, linings, and decorative leather panels.

2. The Role of Leather Perforation in Shoe Design

Leather perforation for shoes is both functional and decorative.

2.1 Functional Benefits

Ventilation: Perforations increase airflow, enhancing breathability for the wearer.

Weight Reduction: Fine perforation patterns reduce overall material weight without compromising strength.

Flexibility: Micro holes help leather panels flex more naturally during movement.

2.2 Aesthetic Purposes

Designers often use intricate perforation patterns — geometric, floral, or logo-based — to distinguish their footwear lines. This requires extremely precise hole placement and consistent sizing, achievable only with a modern shoes leather perforation machine.

3. Understanding the Shoes Leather Perforation Machine

A shoes leather perforation machine is a precision device combining mechanical punching and CNC control for exact hole placement.

3.1 Core Components

| Component | Function | Description |

|---|---|---|

| Punching Head | Creates perforations | High-speed servo or pneumatic punches with replaceable dies. |

| Feeding Platform | Moves leather under the punch | Controlled by servo motors for smooth movement and accuracy. |

| Vacuum Table | Holds leather flat | Prevents wrinkling or shifting during perforation. |

| CNC Controller | Digital pattern control | Loads CAD patterns for variable perforation designs. |

| Vision Alignment System | Pattern correction | Uses cameras to ensure holes align with pre-marked leather contours. |

Anze’s latest series of CNC shoes leather perforation machines are designed with AI-driven feedback, pressure sensors, and smart calibration modules to maintain consistent quality even across textured or uneven leather surfaces.

4. Techniques for Shoe Leather Perforation

Different shoe types and materials require specific perforation techniques.

4.1 Mechanical Punching

Traditional yet highly reliable, mechanical punching uses hardened steel pins or dies to perforate leather sheets.

Advantages:

Ideal for thick, natural leathers.

Consistent hole edges.

Low maintenance costs.

Applications:

Men’s leather dress shoes, classic brogue patterns.

4.2 CNC Controlled Perforation

CNC perforation combines mechanical punching with digital control, allowing pattern flexibility and precision.

Advantages:

High accuracy (±0.03 mm).

Complex pattern capability.

Fast setup using digital CAD files.

Applications:

Luxury footwear, designer brands, custom-made shoes.

4.3 Laser Perforation

Laser-based perforation systems use focused energy beams to create holes without physical contact.

Advantages:

Ideal for synthetic and coated leathers.

Allows micro-perforations with unique decorative shapes.

No mechanical tool wear.

Challenges:

Requires strict heat control to prevent charring.

Not suitable for thick natural leathers.

4.4 Rotary Die Perforation

Used primarily in high-volume production, rotary dies apply continuous perforation to roll-fed materials.

Advantages:

Excellent for uniform repetitive patterns.

High throughput.

Consistent alignment for shoe lining materials.

5. Process Parameters and Control

Achieving perfect perforation requires fine control over multiple process parameters.

| Parameter | Recommended Range | Impact |

|---|---|---|

| Hole Diameter | 0.8 – 2.0 mm | Smaller holes for ventilation, larger for decorative purposes. |

| Pitch (Spacing) | 2 – 5 mm | Determines density and structural integrity. |

| Punch Pressure | 1.8 – 3.5 kN | Affects edge sharpness and tear resistance. |

| Feed Speed | 50 – 150 mm/s | Influences throughput and pattern accuracy. |

| Vacuum Pressure | 0.3 – 0.5 bar | Prevents movement of soft leathers. |

5.1 Leather Type Optimization

Soft leather (goat, calf): Use lower pressure and slower speed.

Thick leather (cowhide): Increase punch force and use sharper dies.

Synthetic leather: Consider laser perforation with controlled pulse width (<10 ms).

6. Best Practices for Leather Perforation in Footwear

6.1 Preparation

Condition leather in 40–60% humidity to ensure flexibility.

Avoid surface coatings that may crack during punching.

6.2 Perforation Execution

Always perform test runs to verify hole alignment.

Use vacuum hold-down tables to minimize slippage.

Ensure tool temperature stability for consistent quality.

6.3 Post-Processing

Remove debris and dust with compressed air or vacuum cleaning.

Inspect for burrs or uneven hole edges.

Apply soft finishing to restore surface sheen.

7. Common Issues and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Tearing at hole edges | Excessive punch force | Reduce pressure or use sharper tools. |

| Uneven hole spacing | Feed slippage | Check servo calibration or suction stability. |

| Burn marks | Laser power too high | Decrease power or increase pulse interval. |

| Pattern misalignment | Incorrect pattern import | Use vision correction system for alignment. |

| Wrinkling | Inadequate vacuum | Increase suction or use better clamping. |

Anze’s perforating machines integrate intelligent feedback systems that automatically detect these defects and adjust parameters in real time, ensuring consistent quality across production runs.

8. Quality Control and Performance Testing

Quality control ensures every perforated shoe leather meets visual and functional standards.

8.1 Inspection Parameters

Hole Uniformity: ±0.05 mm tolerance.

Pattern Alignment: <0.1 mm deviation.

Edge Smoothness: No visible fraying or cracking.

8.2 Testing Methods

| Test | Standard | Description |

|---|---|---|

| Tensile Strength | ASTM D4705 | Ensures leather retains durability post-perforation. |

| Flex Test | ISO 5402 | Simulates repetitive bending in shoe uppers. |

| Air Permeability | ISO 9237 | Measures ventilation efficiency. |

| Visual Defect Detection | Automated Camera | AI-based pattern recognition to flag deviations. |

Anze’s QC system uses high-speed optical sensors integrated directly into the machine workflow, minimizing post-production rejection rates.

9. Maintenance and Safety

9.1 Routine Maintenance

| Frequency | Task |

|---|---|

| Daily | Clean vacuum table and remove leather dust. |

| Weekly | Check punch alignment and lubrication. |

| Monthly | Inspect servo motor accuracy and replace worn dies. |

| Quarterly | Run full recalibration test. |

9.2 Safety Measures

Always disconnect power during die change.

Use protective eyewear during laser operation.

Ensure proper fume extraction when processing synthetic materials.

Anze machines are equipped with emergency stop systems, overload detection, and automatic shutdown in case of irregular vibration or overheating.

10. Case Study: Anze Shoes Leather Perforation Machine in Action

10.1 Client Overview

A Southeast Asian sports shoe manufacturer needed precise ventilation holes in synthetic leather uppers, with production capacity exceeding 8,000 pairs per week.

10.2 Challenges

Inconsistent hole sizes due to material stretch.

Pattern deviation under high-speed operation.

Excess scrap waste.

10.3 Solution

Anze provided the AZ-SP800 CNC Shoes Leather Perforation Machine, equipped with:

Dual servo punching heads for high throughput.

Vision correction and AI pattern alignment.

Smart vacuum system with adjustable zone control.

10.4 Results

| Metric | Before | After Using Anze Machine |

|---|---|---|

| Hole Uniformity | ±0.12 mm | ±0.04 mm |

| Scrap Rate | 6.8% | 1.2% |

| Production Speed | 90 pcs/hr | 140 pcs/hr |

| Downtime | 15% | <3% |

The client achieved 55% higher efficiency and significant improvement in finish quality, leading to a new export contract with a global sports brand.

11. Advanced Technology in Anze’s Shoes Leather Perforation Machines

Anze integrates next-generation innovations for superior performance:

CNC Digital Control: Real-time hole pattern adjustment.

AI Pattern Recognition: Detects defects and compensates instantly.

Intelligent Pressure Feedback: Ensures uniform force distribution.

Modular Tooling Design: Quick pattern changeover.

IoT Connectivity: Allows remote diagnostics and performance tracking.

12. Future Trends in Footwear Perforation Technology

12.1 Smart Manufacturing

Future shoes leather perforation machines will leverage AI and big data analytics to predict tool wear, auto-adjust force, and optimize cycle time.

12.2 Sustainable Operations

Anze’s R&D focuses on energy-efficient drives and eco-friendly vacuum systems, reducing power consumption by up to 20%.

12.3 Multi-Functional Perforation

Combining perforation with embossing or laser marking to create hybrid textures and design elements.

13. Why Choose Anze for Shoe Leather Perforation Solutions

With two decades of innovation and global service experience, Anze stands as a reliable partner for footwear manufacturers worldwide.

Key Advantages:

20+ years of experience in leather perforation systems.

More than 20 machine models for diverse applications.

Customizable solutions for shoe uppers, linings, and decorative leather.

Integrated R&D, production, and after-sales service.

Exported to over 40 countries across Asia, Europe, and the Americas.

Whether you produce luxury fashion footwear or high-performance sports shoes, Anze’s shoes leather perforation machines deliver precision, efficiency, and consistency.

a shoes leather perforation machine ensures the perfect balance

The evolution of footwear design increasingly depends on material engineering precision. Leather perforation not only enhances comfort and ventilation but also defines brand aesthetics.

A well-calibrated shoes leather perforation machine ensures the perfect balance between artistry and technology — every hole placed with accuracy, every pattern flawlessly replicated.

With 20 years of expertise and a commitment to innovation, Anze empowers footwear manufacturers to lead in both style and performance.

Our mission is simple:

“To transform raw leather into functional beauty — one perforation at a time.”

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.