Last Updated on 2025-11-03 by Anze

In the modern fashion and leather goods industry, perforation has evolved from a decorative technique into a precision engineering process that determines both product aesthetics and functional performance. Whether it is a luxury handbag, a high-end backpack, or a custom leather accessory, leather perforation allows manufacturers to achieve design distinction, lightweight construction, and enhanced breathability — all while maintaining the natural beauty of genuine leather.At the heart of this craftsmanship lies the perforating machine — a precision-engineered system that enables consistent, accurate, and high-speed perforation on leather surfaces. For bag manufacturers, the quality of perforation can influence tactile feel, strength, durability, and even brand perception.

Anze, a professional perforating machine manufacturer, has more than 20 years of design and manufacturing experience. The company has developed over 20 bestselling machine models used across multiple industries, including automotive interiors, footwear, furniture, and luxury leather goods. For bag production, Anze’s perforating machines deliver customizable patterns, exact tolerances, and stable operation suited for natural and synthetic leather materials.

1. Principles of Leather Perforation

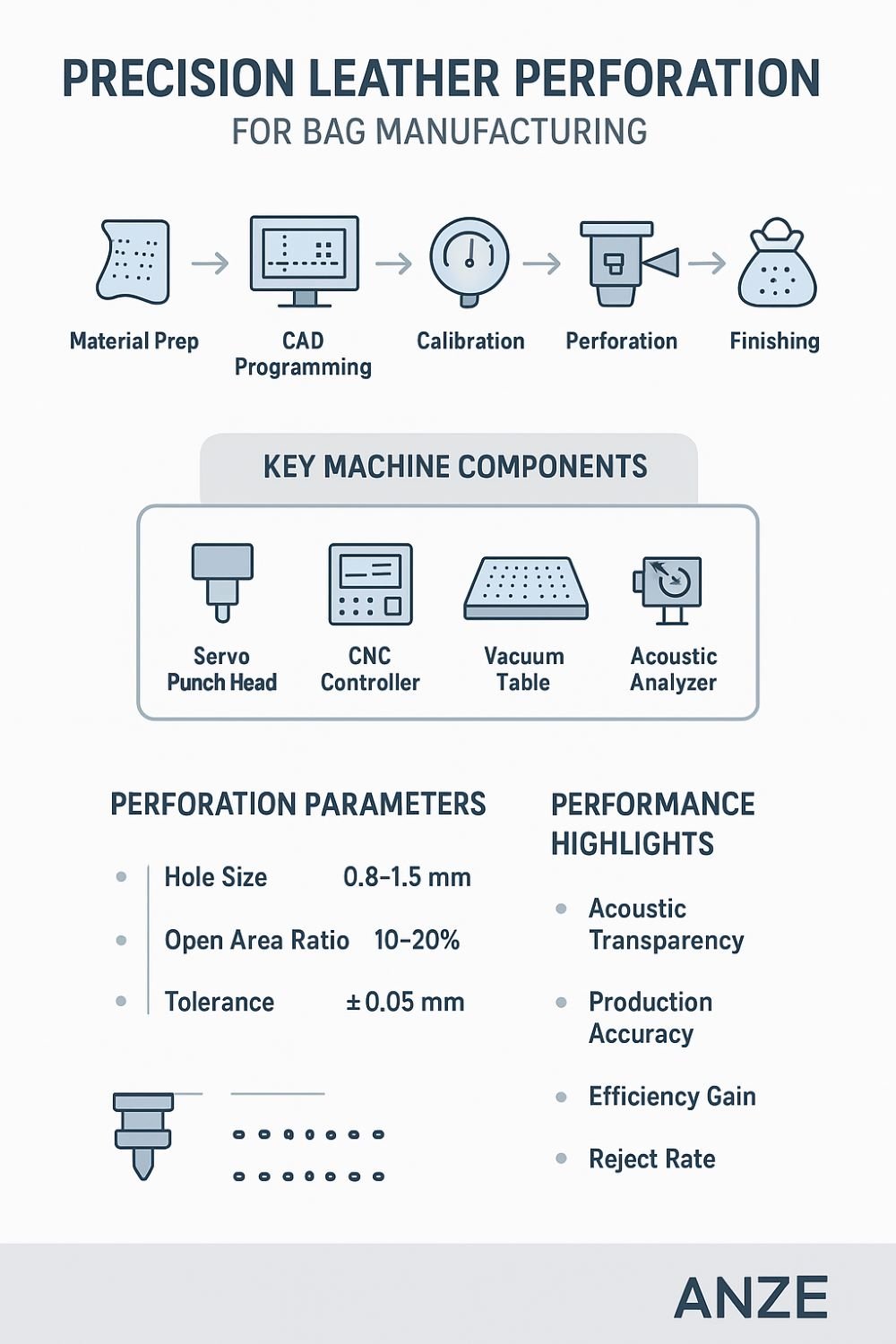

Leather perforation involves creating precise holes or micro-patterns on leather surfaces without damaging material integrity. The process requires a balance between mechanical force, tool geometry, and material response.

1.1 Material Considerations

Leather is an anisotropic material — its fibers have direction-dependent strength. When perforating:

Natural leather fibers can stretch and tear if punch speed or pressure is inconsistent.

Synthetic or coated leather may melt or discolor under excessive heat or pressure.

Therefore, each leather type demands specific perforation parameters determined by machine calibration.

1.2 Geometry of Perforation

The hole shape and pattern significantly influence visual and functional outcomes.

Common geometries include:

Circular holes (classic aesthetic, high airflow)

Diamond-shaped holes (decorative, fashion-oriented)

Hexagonal or grid patterns (modern, lightweight design)

A high-quality perforating machine must maintain ±0.05 mm tolerance in hole size and spacing to ensure visual uniformity and mechanical stability.

2. Structure of a Perforating Machine

A perforating machine combines mechanical precision with intelligent control. Below are its core components:

| Component | Function | Key Features |

|---|---|---|

| Punching Unit | Creates perforation patterns using mechanical pins or laser modules. | Servo-driven for accuracy; replaceable dies for pattern variation. |

| Material Feeding System | Moves leather sheet accurately under the punching head. | Servo motor control ensures consistent feed rate and alignment. |

| Vacuum Suction Platform | Stabilizes leather to prevent slippage or deformation. | Multi-zone suction with adjustable pressure. |

| CNC Controller | Manages tool movement, pattern geometry, and synchronization. | Compatible with CAD/CAM software for digital design import. |

| Vision Correction System | Detects and adjusts for leather texture or shape irregularities. | Optical sensors ensure repeatable precision. |

Anze’s next-generation machines feature CNC synchronization, AI-driven pattern alignment, and intelligent pressure feedback, ensuring consistent perforation across natural and synthetic leathers.

3. Leather Perforation Techniques for Bags

3.1 Mechanical Punching Perforation

The most traditional and widely used method for bag manufacturing. It involves steel dies with sharp pins that mechanically punch holes in the leather.

Advantages:

Ideal for thick natural leathers

High throughput and low maintenance

Excellent edge definition

Limitations:

Limited flexibility for intricate patterns

Requires die replacement for each design

3.2 CNC Perforation

In CNC perforating machines, servo-driven punches follow digitally programmed paths.

Advantages:

Supports variable-density patterns

High accuracy (±0.03 mm)

Perfect for premium or limited-edition leather bags

3.3 Laser Perforation

Laser-based perforating machines utilize focused energy beams to burn microholes.

Advantages:

Suitable for synthetic or coated leathers

No mechanical stress

Enables creative patterns and micro-details

Limitations:

Requires thermal control to prevent discoloration

Higher energy consumption

3.4 Rotary Die Perforation

Used for continuous perforation on roll-fed materials.

Advantages:

High-speed production for large volumes

Uniform holes with excellent repeatability

Applications:

Leather rolls for large-scale bag manufacturing lines.

4. Process Parameters and Optimization

4.1 Key Parameters

| Parameter | Typical Range | Effect on Leather |

|---|---|---|

| Punching Pressure | 1.5 – 3.0 kN | Affects edge sharpness and hole clarity |

| Feed Speed | 50 – 200 mm/s | Impacts throughput and tearing risk |

| Hole Diameter | 0.8 – 2.5 mm | Controls texture and breathability |

| Spacing Pitch | 2 – 5 mm | Affects pattern density and strength |

| Vacuum Pressure | 0.2 – 0.5 bar | Stabilizes thin leathers |

4.2 Optimization Tips

Calibrate machine before each batch.

Use pre-conditioned leather (controlled humidity 40–60%).

Monitor punch wear to maintain edge sharpness.

For laser systems, adjust pulse width to <10 ms to avoid burn marks.

5. Tips and Techniques for Perfect Leather Perforation

5.1 Preventing Material Deformation

Maintain proper suction and even clamping pressure.

Use leather with uniform thickness (< ±0.1 mm variation).

5.2 Achieving Uniform Hole Edges

Replace dies regularly.

Keep punching tools clean from fiber buildup.

Use self-lubricating tool coatings (e.g., TiN or DLC).

5.3 Reducing Waste

Optimize layout using CAD nesting software.

Run pilot tests before large production batches.

Automate pattern correction via AI modules.

6. Quality Control and Testing

A high-end leather bag requires not only aesthetic precision but also structural integrity.

Quality assurance involves both visual and mechanical testing.

| Test Type | Purpose | Standard / Method |

|---|---|---|

| Visual Inspection | Detect pattern deviation or discoloration. | Manual or AI camera-based. |

| Dimensional Tolerance Test | Ensure hole diameter and spacing uniformity. | ±0.05 mm tolerance. |

| Tear Resistance Test | Check material strength post-perforation. | ASTM D4705. |

| Color Stability | Ensure no edge darkening or discoloration. | ISO 11644. |

| Flexibility Test | Simulate long-term use for bag bending zones. | ISO 5402. |

Anze integrates inline vision inspection and automated defect rejection in its perforating machines, minimizing human error.

7. Maintenance and Safety Guidelines

Regular maintenance extends the lifespan and accuracy of every perforating machine.

7.1 Maintenance Schedule

| Frequency | Task |

|---|---|

| Daily | Clean vacuum platform and inspect suction. |

| Weekly | Lubricate servo and guide rails. |

| Monthly | Check tool wear and recalibrate axis alignment. |

| Quarterly | Replace filters and inspect sensors. |

7.2 Safety Practices

Always disconnect power during die replacement.

Use protective gloves when handling laser systems.

Keep the work area free of dust and leather debris.

8. Case Study: Anze’s Perforating Machine for Premium Handbag Production

8.1 Client Background

A European luxury handbag brand required precision perforation for its 2024 limited-edition collection. Key requirements were:

1.2 mm holes in complex floral patterns

Uniform edge finish

Production capacity: 5,000 pieces/month

8.2 Solution

Anze provided the AZ-PL600 CNC Perforating Machine, equipped with:

Dual-head servo punch unit

Vision alignment system

Intelligent pressure feedback module

Real-time pattern correction

8.3 Outcome

| Metric | Before | After Using Anze Machine |

|---|---|---|

| Hole Uniformity | ±0.1 mm | ±0.03 mm |

| Reject Rate | 5.8% | 0.7% |

| Production Speed | 80 pcs/hr | 120 pcs/hr |

| Edge Quality | Average | Excellent |

The client reported 35% higher efficiency and consistent visual quality, later standardizing Anze’s system across its facilities.

9. Future Trends in Leather Perforation for Bags

9.1 Digital Pattern Modulation

Next-generation perforating machines use AI to dynamically adjust hole density based on pattern curvature — achieving perfect alignment even on curved or contoured bag panels.

9.2 Eco-Friendly Operation

Anze is integrating energy-saving servo drives and low-noise vacuum systems, reducing power use by up to 18%.

9.3 Smart Process Monitoring

IoT-based systems allow operators to monitor pressure, feed rate, and tool wear remotely via dashboard analytics.

10. Why Choose Anze as Your Perforating Machine Partner

With over two decades of innovation, Anze has become a trusted global name in leather perforation technology.

Core Strengths:

20+ years of engineering experience

Over 20 machine models for different leather applications

Global clients across automotive, footwear, furniture, and fashion

Integrated R&D, production, and after-sales support

Customizable patterns and acoustic, decorative, or functional designs

Anze machines are built for precision, durability, and flexibility, empowering manufacturers to achieve excellence in every leather product.

Leather perforation is both an art and a science

Leather perforation is both an art and a science. For high-end bags, it defines the tactile experience, the brand aesthetic, and the perceived value of craftsmanship. A reliable, precision-engineered perforating machine is the cornerstone of this process.

Through its continuous innovation and 20 years of expertise, Anze provides complete, turnkey leather perforation solutions — enabling bag manufacturers to achieve uniformity, creativity, and productivity at scale.

From fashion studios to global OEMs, Anze’s machines help transform leather into elegance — one perforation at a time.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.