Last Updated on 2025-10-30 by Anze

In modern automotive design, leather perforation has become a defining element of luxury, comfort, and functionality. Whether in high-end sedans or sports cars, perforated leather seats provide better ventilation, acoustic comfort, and visual refinement. Behind this precision lies a crucial technology — the perforating machine.

A perforating machine is not simply a punching device. It is a sophisticated system engineered for precision, repeatability, and customization. It enables manufacturers to produce thousands of microscopic holes in leather or synthetic materials with exact spacing, consistent depth, and aesthetically pleasing patterns.

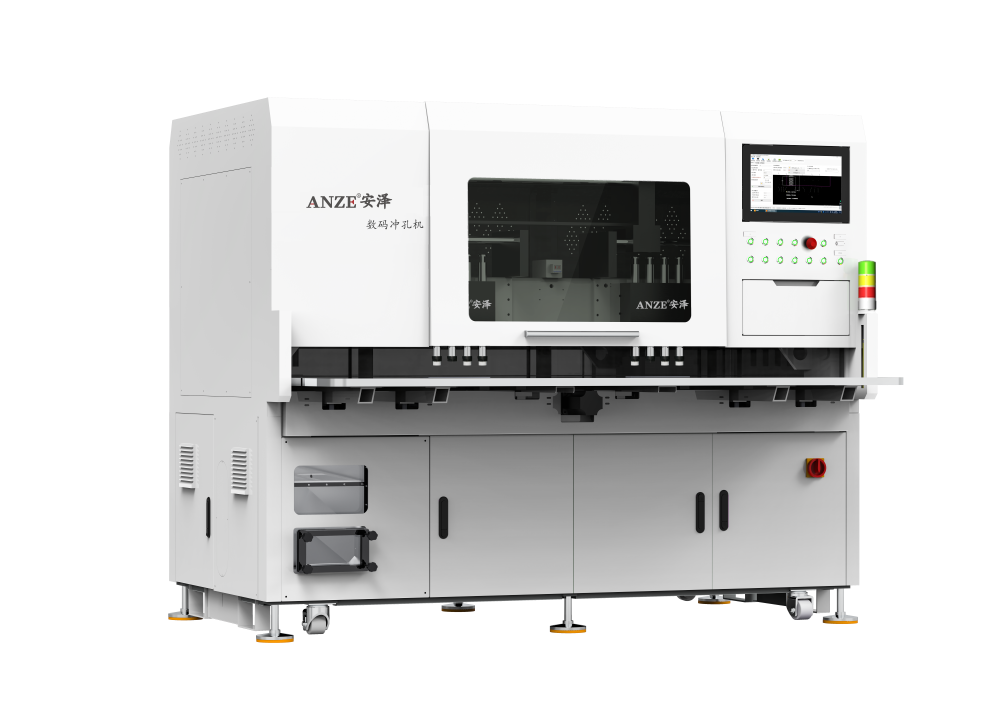

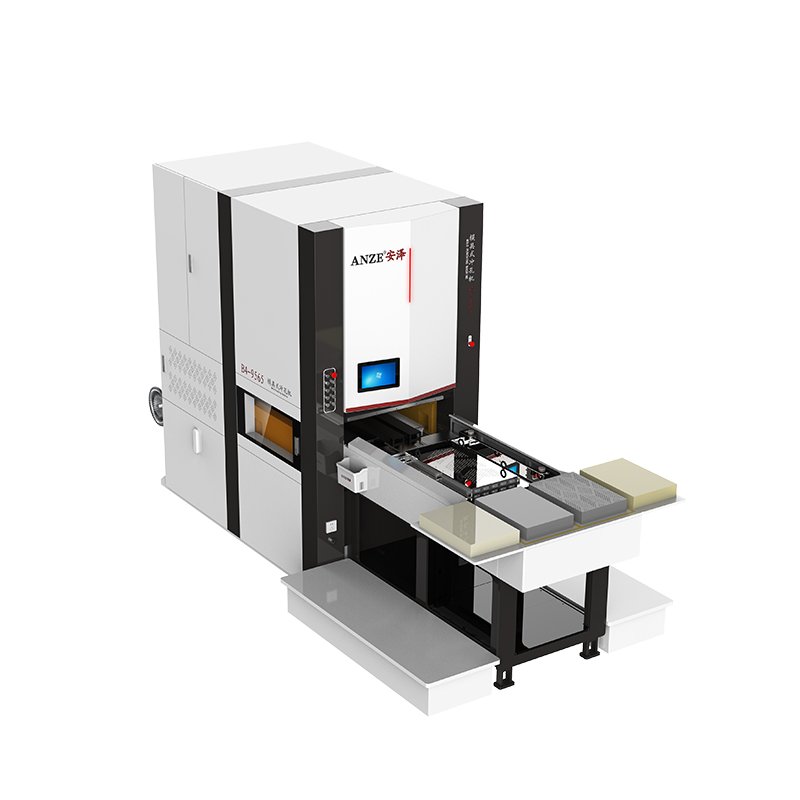

For over 20 years, Anze has been a professional manufacturer specializing in leather perforating machines. With over 20 best-selling models serving the automotive, footwear, luggage, and furniture industries, Anze has earned a reputation for excellence in both design and engineering. This article explores how perforating machines revolutionize automotive seat leather production — from technology and techniques to optimization and sustainability.

1. What Is a Perforating Machine?

A perforating machine is a mechanical or computer-controlled system designed to create holes or micro-patterns on various materials, such as leather, textiles, or synthetic leather used in car interiors.

In automotive applications, the perforating machine is responsible for creating the tiny, evenly spaced holes that make car seats breathable, stylish, and comfortable.

1.1 Core Components

A modern perforating machine typically includes:

Material feeding system – guides leather sheets into the machine precisely.

Punching or laser head – creates perforations through mechanical or laser action.

Die set and tooling – determines hole size, spacing, and pattern shape.

Control system (CNC or PLC) – programs pattern layouts for consistency.

Vacuum waste removal system – keeps the workspace clean during production.

Pattern management software – allows customization for different car seat designs.

Anze’s latest CNC perforating machines integrate servo-driven control and intelligent automation, providing unrivaled accuracy and speed.

2. The Importance of Leather Perforation in Automotive Seats

Why do nearly all premium cars feature perforated leather seats? Because perforation enhances comfort, luxury, and practicality.

2.1 Comfort and Breathability

Perforated leather improves air circulation, reducing heat and moisture buildup — essential for ventilated seat systems.

2.2 Aesthetic Design

Through customized patterns, perforating machine create unique textures and visual appeal. Luxury car brands use distinct perforation layouts as part of their design identity.

2.3 Acoustic Performance

Perforation helps absorb sound within the car cabin, enhancing the sense of quiet and comfort.

2.4 Material Efficiency

Precision perforation maintains leather integrity while optimizing airflow, minimizing material waste through intelligent pattern layout.

3. Types of Perforating Machines Used in Automotive Leather Production

3.1 CNC Perforating Machine

The CNC perforating machine uses computer numerical control to manage pattern design, punching precision, and synchronization. It is ideal for car seats where high precision and repeatability are critical.

Anze’s CNC perforating systems deliver accuracy within ±0.1 mm, ensuring consistent hole patterns even in large-scale production.

3.2 Rotary Perforating Machine

This type of perforating machine uses rotating drums to create holes continuously on long rolls of leather or synthetic fabric. It’s efficient for mass production of uniform materials.

3.3 Hydraulic or Pneumatic Perforating Machine

These systems apply strong mechanical force through dies or needles, suitable for thicker or multi-layer materials.

3.4 Laser Perforating Machine

A high-precision, contactless option for extremely fine perforations. The laser perforating machine ensures clean edges and can work on synthetic leather, vinyl, or delicate materials used in modern car interiors.

4. Common Perforation Techniques for Automotive Leather

Each perforating machine offers unique methods depending on the design requirements and leather type.

4.1 Micro-Perforation

Creates very small holes for improved breathability without affecting the leather’s strength or appearance.

4.2 Decorative Perforation

Used for luxury seat patterns — diamond, wave, or honeycomb — adding brand distinction.

4.3 Functional Perforation

Designed for airflow in ventilated or heated seat systems, ensuring maximum comfort.

4.4 Acoustic Perforation

Specially arranged patterns for reducing sound reflection inside the cabin.

4.5 Stitch Alignment Perforation

Ensures holes align perfectly with stitching paths for seamless integration into seat design.

Anze’s CNC perforating machines combine these methods through customizable digital templates, enabling designers to switch from one pattern to another instantly.

5. The Leather Perforation Process: Step-by-Step

Producing high-quality perforated automotive leather involves multiple precise stages, all controlled by a perforating machine.

Material Preparation – Inspect and pre-treat leather for uniform thickness and elasticity.

Pattern Design – Define the desired perforation layout using CAD or Anze’s proprietary pattern software.

Machine Setup – Calibrate tool head, die set, and pressure settings.

Trial Perforation – Test a small sample to ensure hole alignment and visual consistency.

Full Production Run – Continuous feeding and automated perforation.

Inspection and Quality Control – Use optical sensors or manual inspection to detect irregularities.

Finishing – Clean and condition the perforated leather for installation.

The result: smooth, perfectly aligned perforations with uniform appearance — a hallmark of quality.

6. Key Performance Metrics of a High-End Perforating Machine

| Performance Factor | Importance in Automotive Seats | Anze Solution |

|---|---|---|

| Hole Accuracy | Ensures consistent airflow and aesthetics | ±0.1 mm precision CNC control |

| Speed | Impacts production output | 300–600 strokes/min (adjustable) |

| Pattern Flexibility | Allows design customization | Built-in digital pattern library |

| Energy Efficiency | Reduces operating costs | Servo-driven low-energy systems |

| Maintenance | Affects long-term reliability | Self-cleaning and low-wear tooling |

Every perforating machine from Anze is built for precision, efficiency, and reliability — qualities essential in the automotive supply chain.

7. Optimization Techniques: Getting the Most from Your Perforating Machine

Even the best perforating machine requires optimized workflow for maximum performance.

7.1 Material Conditioning

Keep leather at stable humidity and temperature to maintain hole consistency.

7.2 Tooling Maintenance

Regularly clean punches and dies to prevent edge burrs or uneven perforations.

7.3 Pattern Optimization

Use software to minimize material waste — Anze’s smart nesting algorithm can reduce waste by up to 12%.

7.4 Alignment Control

Use laser alignment systems for consistent spacing on large seat panels.

7.5 Continuous Quality Feedback

AI-powered inspection can detect misalignments in real time and auto-correct deviations.

8. Why Choose Anze as Your Leather Perforation Partner

8.1 Two Decades of Expertise

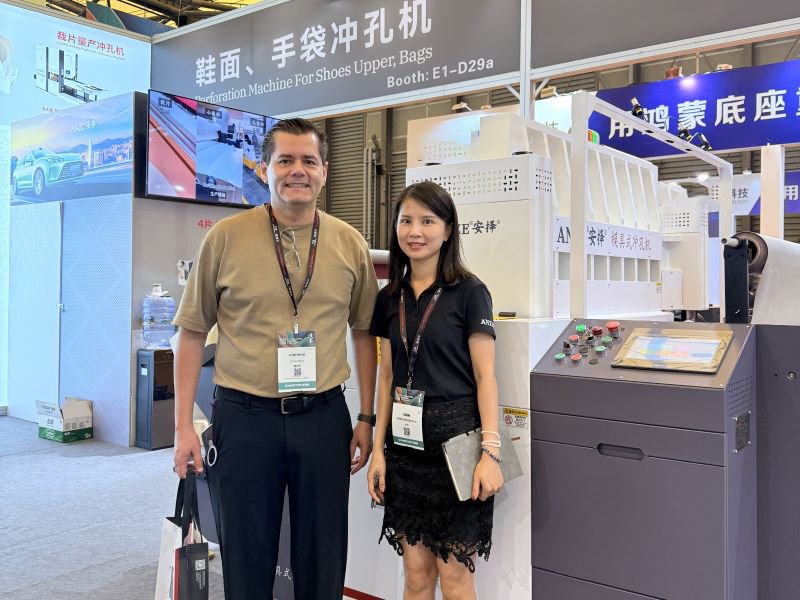

With 20 years of design and manufacturing experience, Anze has become a trusted perforating machine manufacturer for global automotive brands.

8.2 Over 20 Best-Selling Models

Anze’s wide range of perforating machines accommodates different materials, hole sizes, and production scales.

8.3 Tailor-Made Solutions

Every car brand and seat supplier has unique requirements. Anze provides customized perforation patterns, machine settings, and software support.

8.4 Proven Quality Control

Each perforating machine is tested under simulated production environments to ensure stability and longevity.

8.5 Global Technical Support

Anze’s professional team provides on-site installation, training, and remote diagnostics, ensuring uninterrupted productivity.

9. Comparing Global Industry Leaders

The perforation machinery market includes several renowned brands known for their advanced engineering.

However, each focuses on different materials and industries:

| Manufacturer | Primary Specialization | Application Area |

|---|---|---|

| Trumpf (Germany) | Laser and punching systems | Metal and composites |

| Amada (Japan) | CNC punching & forming | Sheet metal fabrication |

| Bystronic (Switzerland) | Automation & robotics | Laser manufacturing |

| Prima Power (Italy/Finland) | Hybrid punching & laser cutting | Industrial sheet metal |

| Bobst (Switzerland) | Paper and packaging perforation | Packaging industry |

| Anze (China) | Leather perforating machines | Automotive, footwear, furniture |

While most global manufacturers focus on metals or paper, Anze specializes exclusively in leather perforating machines — giving it a unique edge in industries requiring softness, flexibility, and surface precision.

10. Sustainability and Environmental Efficiency

Anze’s perforating machines are designed with sustainability in mind:

Servo-driven motors reduce energy consumption.

Smart material optimization reduces waste.

Noise-reduction engineering ensures quieter operation.

Eco-leather compatibility supports sustainable production trends.

By improving efficiency and reducing waste, Anze helps car manufacturers meet environmental standards while maintaining luxury quality.

11. The Future of Automotive Leather Perforation

As the automotive industry evolves toward smart manufacturing, perforating machines are integrating new technologies:

11.1 AI and Automation

AI-driven pattern analysis can automatically detect defects and adjust parameters.

11.2 Smart Factory Integration

Machines connected through IoT platforms enable real-time data sharing, predictive maintenance, and quality tracking.

11.3 Multi-Material Processing

Future perforating machines will handle hybrid materials such as vegan leather, composite fabrics, and nanocoatings.

11.4 Design Customization

Digital pattern libraries will allow car brands to offer fully customized perforation designs for every customer.

Anze’s R&D division is already developing next-generation intelligent perforating machines equipped with these features.

12. How to Select the Right Perforating Machine for Automotive Seats

When choosing a perforating machine for automotive leather, consider:

Material type: Genuine, synthetic, or composite leather.

Production volume: Small batch or mass production.

Precision needs: Micro or decorative perforations.

Automation level: Manual, semi-automatic, or CNC-controlled.

Budget and lifecycle cost: Balance between performance and ROI.

Anze’s engineering team assists clients in selecting and customizing the ideal perforating machine for their needs.

Partnering with Anze for Precision and Performance

In the world of automotive leather interiors, precision defines perfection. The ability to create flawless, breathable, and beautifully patterned leather depends on one key factor — a reliable perforating machine.

For over two decades, Anze has been a pioneer in developing advanced leather perforation solutions, combining engineering expertise, cutting-edge technology, and customer-focused innovation. From car seats to steering wheels and headliners, Anze’s perforating machines deliver performance, reliability, and quality that redefine the art of automotive leather production.

If you’re looking for a trusted partner to elevate your manufacturing capability, Anze’s perforating machines are your gateway to the future of smart, sustainable, and luxurious leather craftsmanship.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.