Last Updated on 2025-10-27 by Anze

In the global manufacturing industry, perforating machines have become indispensable tools that combine precision, creativity, and productivity. Whether it’s producing breathable leather for automotive seats or decorative patterns for luxury handbags, the perforating machine enables manufacturers to achieve high-quality results efficiently.

At its core, a perforating machine is designed to create small, consistent holes or patterns in various materials — leather, plastic, paper, or fabric. These perforations serve both functional and aesthetic purposes, improving airflow, flexibility, design appeal, and product performance.

For over 20 years, Anze has been a professional perforating machine manufacturer, specializing in leather perforation equipment. The company has developed more than 20 machine models, used across industries such as automotive interiors, footwear, luggage, and furniture. This combination of experience, innovation, and craftsmanship positions Anze among the world’s leading names in the perforating machine industry.

1. What Is a Perforating Machine? Understanding the Technology

A perforating machine is a specialized piece of equipment that uses mechanical, pneumatic, or CNC-controlled systems to punch or laser-cut holes in materials. The goal is to create uniform patterns, textures, or ventilation features.

1.1 Basic Components of a Perforating Machine

Feeding Mechanism: Automatically moves the material through the machine with precision.

Punching or Laser Head: Performs the actual perforation, using tools, needles, or beams.

Die Set or Tooling: Determines the size and pattern of the holes.

Control System: A CNC or PLC-based unit for accurate pattern control and repeatability.

Collection and Suction System: Removes waste and ensures a clean working environment.

1.2 Working Principle of a Perforating Machine

The perforating machine operates by applying force or energy to the material to form holes in pre-set positions. The process can be:

Mechanical Punching: Using physical dies and punches.

Laser Perforation: Using focused laser beams for ultra-fine results.

Rotary Perforation: Employing rotating drums for continuous sheet materials.

CNC-Controlled Perforation: Offering digital precision for custom patterns.

Each method serves different industries — for example, mechanical perforation is ideal for leather and textiles, while laser perforation suits plastics and metals.

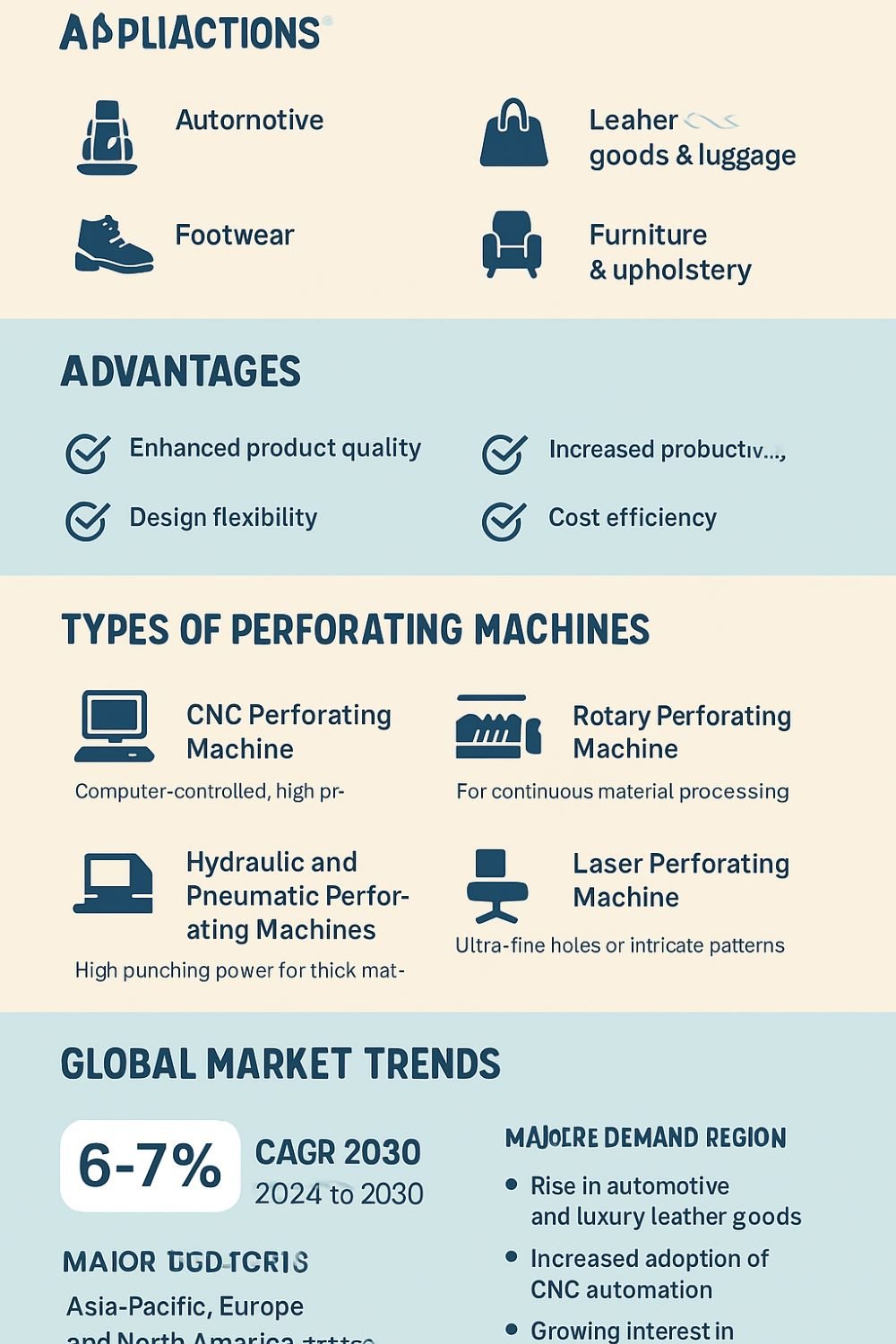

2. Applications of the Perforating Machine Across Industries

The perforating machine plays a vital role in diverse industrial applications. Below are the main sectors that rely on this technology.

2.1 Automotive Industry

Modern vehicles use perforated leather for seat covers, dashboards, and door panels. These perforations improve ventilation, enhance aesthetics, and reduce weight.

Anze’s leather perforating machines are widely used by automotive interior suppliers to achieve precise hole spacing and consistent depth across large surfaces.

2.2 Footwear Manufacturing

In the footwear industry, perforating machines help improve airflow and style. Shoe uppers, insoles, and decorative panels are often perforated for comfort and design variety.

2.3 Leather Goods and Luggage

High-end handbags, belts, and travel cases often feature perforated designs for texture and luxury appeal. Anze’s machines allow brands to customize patterns and hole sizes to match brand aesthetics.

2.4 Furniture and Upholstery

Perforated upholstery materials enhance comfort and breathability, particularly in modern sofas, chairs, and office furniture. Precision perforation ensures even spacing and durability.

2.5 Packaging and Paper

Beyond leather, perforating machines are used in packaging to create tear lines and ventilation holes, ensuring easy use and improved performance.

3. The Advantages of Using a Perforating Machine

3.1 Enhanced Product Quality

Consistent, evenly spaced holes give products a professional finish.

Anze’s CNC-controlled perforating machines ensure accuracy within microns.

3.2 Increased Productivity

Modern perforating machines can handle large batches with minimal downtime, significantly improving output.

3.3 Design Flexibility

Manufacturers can switch between custom patterns easily using Anze’s digital pattern control software.

3.4 Cost Efficiency

Automation reduces labor costs and material waste, making perforating machines an ideal investment for scalable production.

4. Types of Perforating Machines

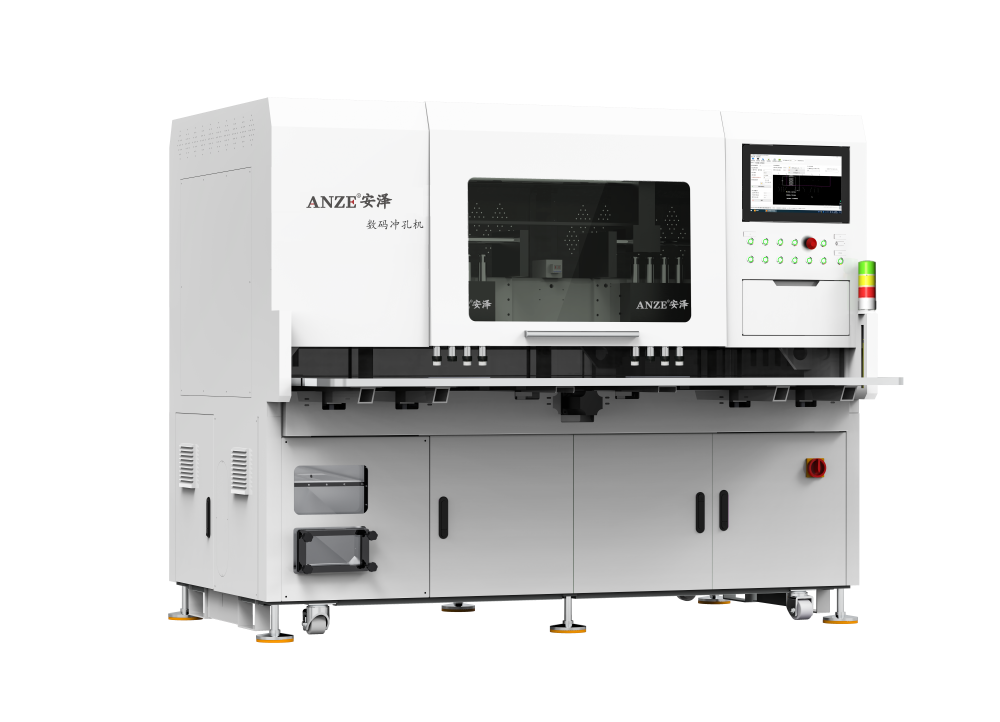

4.1 CNC Perforating Machine

The CNC perforating machine uses digital programming to manage pattern design and hole positioning. It’s ideal for high-precision industries like automotive interiors.

4.2 Rotary Perforating Machine

This type uses rotating cylinders or drums for continuous material processing, perfect for rolls of leather or fabric.

4.3 Hydraulic and Pneumatic Perforating Machines

These machines deliver high punching power, suitable for thicker materials.

4.4 Laser Perforating Machine

A modern choice for industries needing ultra-small holes or intricate patterns. Laser systems work without physical contact, minimizing wear and tear.

5. Global Market Trends for Perforating Machines

The global perforating machine market has seen steady growth due to automation, customization, and sustainability trends.

Market Growth Rate: Expected CAGR of 6–7% (2024–2030).

Major Demand Regions: Asia-Pacific, Europe, and North America.

Key Drivers:

Rise in automotive and luxury leather goods.

Increased adoption of CNC automation.

Growing interest in eco-friendly materials.

Manufacturers like Anze have contributed to this growth by offering advanced, energy-efficient perforation systems.

6. Leading Global Manufacturers of Perforating Machines

Trumpf (Germany)

A leader in laser and punching technology, offering machines capable of high-speed precision perforation.

Amada (Japan)

Specializes in metal processing machines with integrated CNC control systems for automated perforation.

Bystronic (Switzerland)

Known for laser perforation systems optimized for sheet metals and composites.

Prima Power (Italy/Finland)

Offers hybrid punching and laser perforating solutions for industrial-scale production.

Bobst (Switzerland)

A major name in paper and packaging perforation technology.

Finn-Power (Finland)

Pioneered servo-electric punching systems, improving energy efficiency.

Anze (China)

A globally recognized leather perforating machine specialist with two decades of innovation.

Anze’s machines are known for:

High-speed automatic operation

Consistent hole accuracy

Low maintenance

Customizable patterns and software

Anze’s focus on leather perforation technology makes it one of the few manufacturers dedicated to serving automotive, footwear, and furniture industries specifically.

7. Why Choose Anze’s Perforating Machines

Anze’s perforating machines are engineered to deliver precision, durability, and customization.

7.1 Custom Design Capability

Every manufacturer’s needs differ — Anze provides tailor-made tooling and pattern software.

7.2 Advanced CNC Control

Achieve perfect alignment and pattern reproduction for complex designs.

7.3 Stable Performance

Built with high-grade components for long-term reliability.

7.4 Strong After-Sales Support

Anze offers global training, remote diagnostics, and spare part supply.

8. Innovation and Technology in Modern Perforating Machines

Modern perforating machine incorporate advanced features such as:

AI-based pattern optimization

Servo-driven systems for energy efficiency

Industry 4.0 compatibility for data tracking

Touchscreen operation for easy use

Noise reduction engineering for quieter operation

Anze’s R&D team is continually upgrading its machines to meet new challenges in digital manufacturing.

9. Sustainability in Perforating Machine Design

Environmental responsibility is a growing priority in the manufacturing world.

Anze’s eco-friendly perforating machines are designed to:

Minimize energy consumption

Reduce waste through smart material nesting

Extend machine lifespan through robust engineering

By promoting green production, Anze supports global efforts toward sustainable manufacturing.

10. Choosing the Right Perforating Machine for Your Business

When selecting a perforating machine, consider the following factors:

| Criterion | Importance | Anze’s Advantage |

|---|---|---|

| Material Type | High | Specialized in leather & soft materials |

| Production Volume | High | Machines for both small and mass production |

| Hole Accuracy | Critical | CNC precision ±0.1mm |

| Energy Use | Medium | Servo-driven efficiency |

| Customization | Essential | Software-based pattern control |

| Maintenance | High | Long lifespan, low downtime |

Anze’s versatile solutions cover both entry-level and high-end production requirements.

11. The Future of Perforating Machines

The future of the perforating machine industry lies in:

Automation & Robotics

AI pattern learning systems

Multi-material compatibility

Remote monitoring & predictive maintenance

Anze is at the forefront of this transformation, ensuring its clients stay ahead in performance and efficiency.

Anze — Your Global Partner in Perforating Machine Technology

For over 20 years, Anze has redefined precision in the field of perforating machine. With over 20 models and a presence in multiple countries, the company continues to serve as a benchmark for quality and innovation.

Whether your business focuses on automotive leather, fashion footwear, or premium upholstery, Anze provides customized perforating machine solutions that enhance productivity, creativity, and long-term profitability.

If you’re looking for a trusted global partner, Anze’s team is ready to help you transform your production with the next generation of perforating machines.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.