Last Updated on 2025-10-22 by Anze

In today’s fast-paced industrial world, perforating machine manufacturer is playing an essential role in the evolution of modern production systems. From luxury leather handbags to high-performance automotive interiors, the demand for accurate and efficient perforation continues to expand across industries.

A perforating machine is not just a mechanical device — it is a bridge between design and function, enabling manufacturers to add precision holes and patterns that enhance both aesthetics and usability. Whether it’s breathable car seats, elegant shoe uppers, or stylish furniture coverings, these perforations define modern craftsmanship.

As manufacturing technology continues to advance, choosing the right perforating machine manufacturer becomes a strategic decision that affects product quality, production efficiency, and market competitiveness.

1. Understanding Perforating Machines: The Technology Behind Precision

A perforating machine is designed to create holes, slots, or micro-patterns on materials through controlled punching, drilling, or laser processes. Depending on the material type — leather, metal, plastic, paper, or textile — manufacturers use different perforation methods such as mechanical punching, die-cutting, or CNC-based control systems.

Key Components of a Modern Perforating Machine

Feeding System: Automatically guides material into the working area.

Perforation Head: Equipped with punching tools, dies, or laser modules.

Control System: Uses computer numerical control (CNC) for accuracy and repeatability.

Vacuum & Collection System: Removes waste material to ensure a clean working surface.

User Interface: Touchscreen or PC-based interface for easy parameter adjustment.

Modern perforating machine manufacturer incorporate AI, automation, and precision servo systems to achieve higher speeds, tighter tolerances, and reduced material waste — all while maintaining superior surface quality.

3. Applications of Perforating Machines Across Industries

The power of a perforating machine manufacturer lies in its ability to adapt technology to a wide range of industries.

Automotive Industry

Perforation enhances airflow, acoustic control, and luxury appearance in car interiors. Automotive leather seat covers are often precision-perforated to balance comfort and design.

Footwear Manufacturing

Shoes require micro-perforations for both aesthetic design and ventilation. Anze’s perforating machines have been used by global footwear brands for consistent, high-speed production.

Leather Goods and Bags

For handbags, wallets, and fashion accessories, decorative perforations allow brands to stand out with unique patterns and custom branding effects.

Furniture and Upholstery

Perforated leather and fabrics are popular in modern furniture, improving air circulation and ergonomic comfort while maintaining a sophisticated appearance.

Packaging and Paper

In industries like packaging and printing, perforating machines are used for tear lines, micro holes, and artistic patterns, increasing usability and visual appeal.

4. The Global Market for Perforating Machine Manufacturer

The global perforating machine manufacturer market is projected to grow steadily as automation, digitalization, and sustainability transform the manufacturing landscape.

Market Growth Drivers

Rising demand for customized products with detailed surface designs.

Expansion of automotive, fashion, and leather industries in Asia and Europe.

Increased adoption of CNC and AI-driven perforation technology.

Demand for energy-efficient and environmentally friendly machines.

Industry analysis forecasts a 6–7% CAGR from 2024 to 2030 for perforation machinery, with Asia-Pacific leading in manufacturing volume, followed by Europe and North America.

5. Leading Global Perforating Machine Manufacturers

The perforation equipment industry includes both specialized niche producers and large industrial groups offering multi-purpose systems. Below are several global leaders recognized for their technology and reliability.

Trumpf (Germany)

A global innovator in industrial automation, Trumpf manufactures advanced punching and laser systems that can be configured for perforation processes. Their machines are known for precision, software integration, and durability.

Amada (Japan)

Amada produces high-speed perforating and punching machines designed for the metalworking sector. Their systems combine strength with intelligent CNC control.

Bystronic (Switzerland)

A leader in automation and digital manufacturing, Bystronic offers smart systems for sheet metal perforation, integrating robotics and data-driven production management.

Prima Power (Italy/Finland)

Prima Power specializes in laser cutting and perforation technology, known for energy efficiency and hybrid machine configurations.

Bobst (Switzerland)

Bobst is recognized for packaging and paper perforation solutions, especially for folding cartons and flexible materials, where precision cuts are essential.

Finn-Power (Finland)

As part of the Prima Power Group, Finn-Power pioneered servo-electric punching and eco-efficient perforation systems for industrial production.

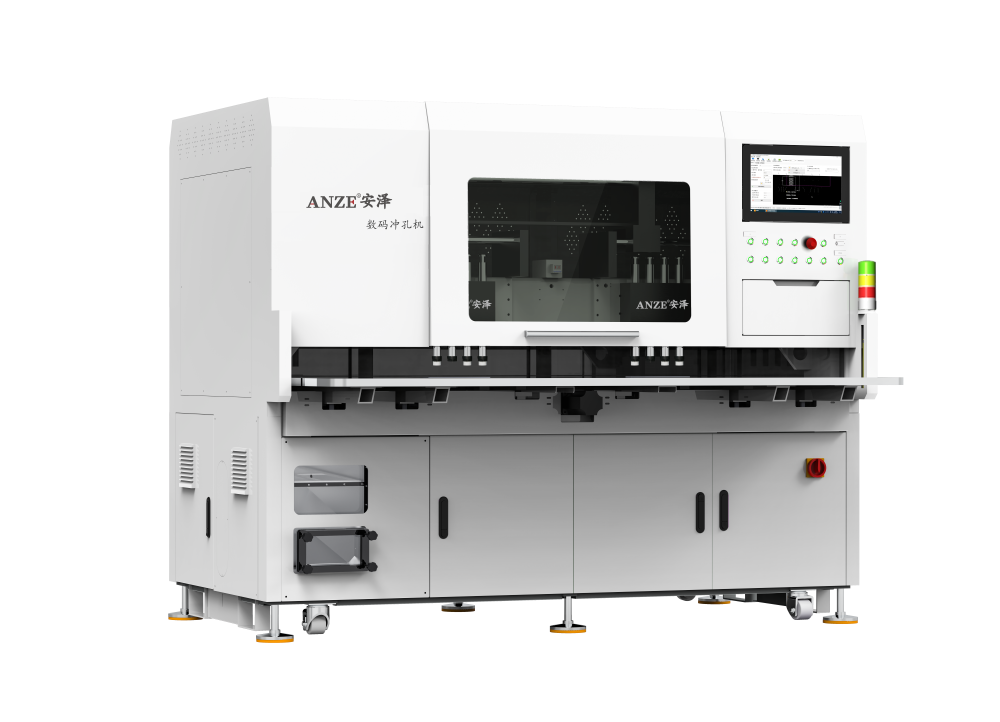

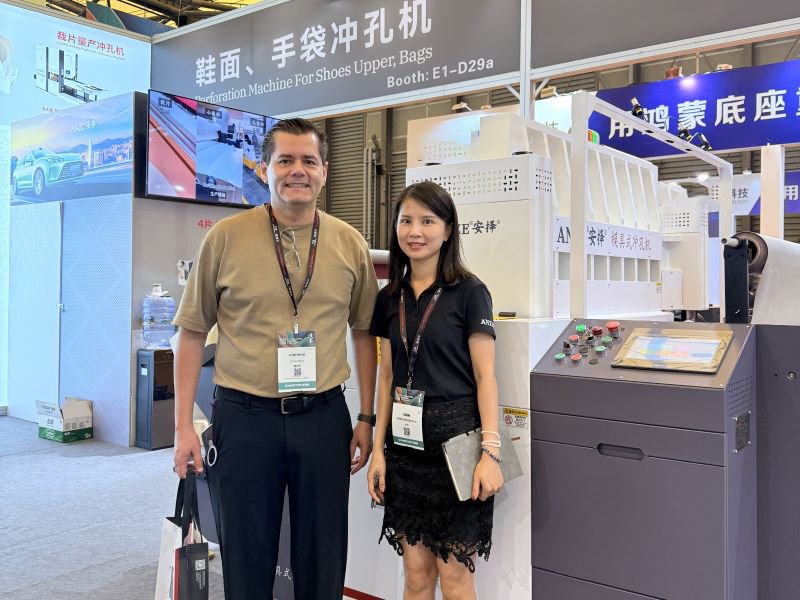

Anze (China)

For over 20 years, Anze has been a trusted perforating machine manufacturer focusing on leather perforation technology. With more than twenty best-selling models, Anze’s machines serve industries including automotive seats, footwear, luggage, and furniture.

Anze’s machines are designed for soft materials, providing stable performance, precise pattern definition, and long-term durability. With a combination of engineering expertise, customization capability, and global service, Anze has become one of the most reliable perforating machine manufacturers in Asia and beyond.

6. Why Choose Anze as Your Perforating Machine Manufacturer

As a professional perforating machine manufacturer, Anze stands out for its specialization, quality, and technical innovation.

a. 20 Years of Industry Experience

Anze has dedicated two decades to designing and producing perforating equipment, focusing exclusively on leather perforation applications.

b. Proven Model Lineup

With over 20 unique machine models, Anze offers solutions for different materials, hole sizes, and design needs — from compact workshop systems to fully automated production lines.

c. Customization Capability

Every manufacturer has unique requirements. Anze provides customized perforation solutions, including pattern design, tooling, and workflow integration.

d. Superior Quality Control

Each Anze machine undergoes rigorous testing and calibration to ensure consistent performance and minimal downtime.

e. Global Service Network

Anze’s international service team offers technical training, remote assistance, and spare parts support for clients in over 30 countries.

7. Technological Advances in Perforating Machine Manufacturing

Modern perforating machine manufacturers integrate advanced technologies to meet growing industry demands.

Smart Automation

Automation reduces manual intervention and increases production stability. Multi-axis control and servo feedback improve positional accuracy.

AI-Based Pattern Optimization

Artificial intelligence now enables pattern recognition, adaptive hole spacing, and defect detection in real time.

Energy-Efficient Engineering

Servo-electric drives consume less energy and offer precise motion control compared to traditional hydraulic systems.

Digital Integration

Industry 4.0-compatible machines collect and share operational data for predictive maintenance and performance optimization.

Anze continues to innovate in these areas, ensuring its perforating machines remain future-ready.

8. Comparing Perforating Machine Manufacturers: Key Evaluation Criteria

When choosing a perforating machine manufacturer, consider the following aspects:

Material Specialization: Some manufacturers focus on metal, others on leather or textiles.

Technology Base: Look for CNC or servo-driven systems for high precision.

Software Integration: Check CAD/CAM compatibility for easy design import.

Speed & Accuracy: Evaluate production rate vs. hole quality.

Service & Support: A strong after-sales network is vital for long-term ROI.

Anze provides all these features — with the added advantage of deep domain expertise in leather perforation systems.

9. Sustainability and Green Manufacturing in Perforating Machine Production

Leading perforating machine manufacturers are now committed to sustainability. Energy-efficient motors, recyclable materials, and low-waste perforation systems are standard in next-generation designs.

Anze’s approach includes:

Reducing material waste through smart nesting algorithms.

Optimizing energy use via servo-controlled motion systems.

Promoting the use of eco-leathers and synthetic materials in production.

10. The Future of the Perforating Machine Manufacturer Industry

The global perforation industry is evolving rapidly. As demand for customized designs, flexible production, and digital manufacturing grows, perforating machine manufacturers are shifting toward:

AI-driven automation for intelligent pattern recognition.

Cloud-based control systems for remote monitoring.

Modular machine architectures for easy upgrades.

Integration with robotic arms for continuous production.

Anze’s R&D team is actively developing next-generation CNC perforating machines that combine intelligent control with advanced precision — setting new benchmarks for quality and reliability.

11. How to Select the Best Perforating Machine Manufacturer for Your Business

Here’s a simple checklist to help you identify the right perforating machine manufacturer:

| Criteria | Importance | Anze’s Solution |

|---|---|---|

| Years of Experience | High | 20+ years dedicated to leather perforation |

| Product Range | High | 20+ models covering different materials |

| Technical Support | Essential | Global after-sales network |

| Custom Design | High | Fully customizable tooling & software |

| Energy Efficiency | Moderate | Servo-driven design |

| Reliability | Critical | 100% factory-tested |

Anze – Your Trusted Global Perforating Machine Manufacturer

For over two decades, Anze has been a name synonymous with precision, innovation, and reliability in the perforation industry. As a leading perforating machine manufacturer, Anze continues to push technological boundaries, delivering machines that redefine quality standards in automotive, footwear, luggage, and furniture manufacturing.

By combining deep engineering expertise with a customer-first philosophy, Anze empowers global manufacturers to achieve better efficiency, higher precision, and greater creative freedom.

If you’re searching for a perforating machine manufacturer that truly understands your production needs, Anze is your partner in precision.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.