Last Updated on 2025-09-15 by Anze

The International Furniture Fair (CIFF), held from September 9th to 12th, 2025, was a dazzling spectacle of innovation, design, and craftsmanship in the furniture industry. As a professional manufacturer specializing in leather perforation machine, our participation in this prestigious event was a strategic move to showcase our latest technological marvel tailored specifically for furniture leather applications. Over the four vibrant days, our booth became a beacon of creativity and efficiency, drawing in a diverse array of clients eager to explore the customization possibilities offered by our cutting-edge leather perforation machine.

CIFF 2025 - Anze leather perforation machine

CIFF has long been recognized as a global platform where furniture manufacturers, designers, and suppliers converge to exchange ideas, showcase their latest products, and forge new business relationships. This year’s edition was no exception, with exhibitors from around the world displaying an impressive array of furniture styles, materials, and technologies. Amidst this bustling environment, our booth stood out, not just for its sleek design but for the revolutionary leather perforation machine that took center stage.

The Star of the Show: Our Advanced Leather Perforation Machine

At the heart of our exhibition was our latest leather perforation machine, a device engineered to meet the specific demands of the furniture industry. This machine is not just a tool; it’s a game-changer, offering unparalleled precision, versatility, and customization capabilities for furniture leather applications. From intricate patterns on sofa upholstery to unique textures on office chair leather, our machine demonstrated its ability to transform ordinary leather into a canvas of creativity.

Customization at Its Finest

One of the most striking features of our leather perforation machine is its ability to create custom perforation patterns tailored to the specific needs of furniture manufacturers. Whether it’s a delicate floral motif for a luxury sofa or a geometric design for a modern office chair, our machine can execute it with flawless precision. This level of customization opens up a world of possibilities for designers, allowing them to push the boundaries of traditional furniture aesthetics and create truly unique pieces.

During the exhibition, we showcased a range of samples featuring different perforation patterns, each meticulously crafted to highlight the machine’s capabilities. Clients were amazed by the level of detail and consistency achieved, with many expressing their desire to incorporate such customization into their own product lines.

Efficiency and Productivity

In addition to its customization capabilities, our leather perforation machine is designed for maximum efficiency and productivity. With its high-speed operation and automated features, it can significantly reduce production times while maintaining consistent quality. This is particularly important in the furniture industry, where meeting tight deadlines and maintaining high standards are crucial for success.

Clients who visited our booth were impressed by the machine’s ability to handle large volumes of leather without compromising on precision or quality. Many saw it as a solution to their production bottlenecks, enabling them to streamline their processes and increase output without sacrificing the craftsmanship that defines their brand.

User-Friendly Interface and Ease of Operation

Another aspect that won over clients was the machine’s user-friendly interface and ease of operation. Despite its advanced technology, our leather perforation machine is designed with the operator in mind. The intuitive control panel and straightforward programming make it accessible to users of all skill levels, reducing the need for extensive training and minimizing the risk of errors.

During live demonstrations, our team guided clients through the process of setting up a custom perforation pattern, highlighting how easy it was to adjust parameters, preview the design, and initiate the perforation process. This hands-on experience left a lasting impression, with many clients commenting on how user-friendly and efficient the machine was compared to traditional methods.

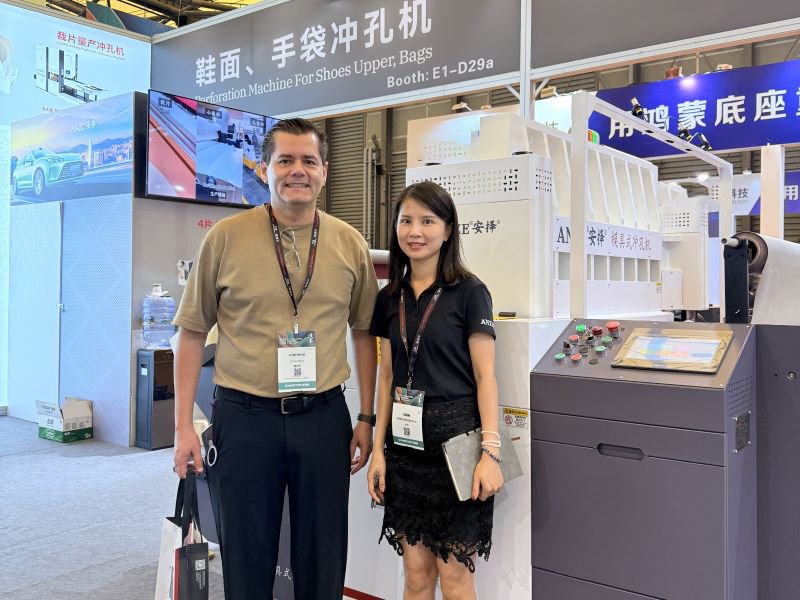

A Landmark Deal: French Modern Furniture Manufacturer Places Order

The excitement at our booth reached a fever pitch when a representative from a renowned French modern furniture manufacturer approached us. After witnessing a live demonstration of our leather perforation machine and discussing its potential applications in their product line, they were convinced of its value and placed a significant order on the spot.

What made this deal even more special was the client’s enthusiasm for customization. They shared their vision for incorporating unique perforation patterns into their latest collection of sofas and office chairs, aiming to create a distinct aesthetic that would set them apart in the competitive French furniture market. Our machine’s ability to deliver on this vision was the deciding factor, and they eagerly agreed to visit our factory after the exhibition to finalize the details and witness the machine in action on a larger scale.

Beyond the Booth: Building Relationships and Exploring Opportunities

While the French order was undoubtedly a highlight of our CIFF experience, it was just one of many positive interactions we had with clients from around the world. Throughout the exhibition, we engaged in meaningful conversations with furniture manufacturers, designers, and suppliers, all of whom shared a common interest in leveraging technology to enhance their products and processes.

These conversations provided valuable insights into the evolving needs and trends of the furniture industry. We learned about the growing demand for sustainable materials, the importance of ergonomic design in office furniture, and the desire for greater customization in both residential and commercial settings. Armed with this knowledge, we are better positioned to refine our leather perforation machine and develop new solutions that address these emerging needs.

Innovation and Sustainability in Leather Perforation machine

As we reflect on our successful participation in CIFF 2025, we are filled with a sense of optimism and anticipation for the future. The positive response to our leather perforation machine has reinforced our belief in the power of innovation to transform industries. Moving forward, we are committed to pushing the boundaries of what’s possible in leather perforation technology.

Sustainability as a Core Focus

One area where we see significant potential for growth is in sustainable leather perforation solutions. As the global furniture industry becomes increasingly conscious of its environmental impact, there is a growing demand for eco-friendly materials and processes. We are actively researching ways to reduce the energy consumption of our machines, minimize waste, and promote the use of recycled or biodegradable materials. Our goal is to provide our clients with leather perforation solutions that not only enhance their products but also contribute to a more sustainable future.

Digital Integration and Smart Manufacturing

Another exciting frontier is the integration of digital technologies into our leather perforation machines. By incorporating features such as real-time monitoring, predictive maintenance, and remote diagnostics, we aim to provide our clients with greater control and visibility over their production processes. This digital transformation will not only improve efficiency but also enable data-driven decision-making, helping our clients stay ahead in a competitive market.

Expanding Applications Beyond Furniture

While our focus at CIFF 2025 was on furniture leather applications, we recognize the potential for our leather perforation machine in other industries as well. From automotive interiors to fashion accessories, the demand for custom leather perforation is on the rise. We are exploring ways to adapt our technology to meet the specific needs of these industries, opening up new markets and opportunities for growth.

Our Leather Perforation Machine Steals The Spotlight At CIFF

CIFF 2025 was a resounding success for our company, showcasing the capabilities of our advanced leather perforation machine and generating significant interest from clients around the world. The landmark deal with the French modern furniture manufacturer was a testament to the machine’s potential to transform the furniture industry, while the numerous positive interactions with other clients provided valuable insights into emerging trends and needs.

As we look to the future, we are excited about the new opportunities and challenges that lie ahead. Our focus remains on delivering innovative, sustainable, and customized leather perforation solutions that meet the evolving needs of our clients. Whether it’s through advancements in sustainability, digital integration, or expanding applications, we are dedicated to helping our clients achieve their production goals and drive their businesses forward.

We extend our heartfelt gratitude to all the clients who visited our booth at CIFF 2025, experienced our leather perforation machine, and expressed their interest in partnering with us. Your support and trust are the driving forces behind our success. We look forward to continuing this journey together, exploring new frontiers, and achieving even greater heights in the world of leather perforation.

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatspp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.